Beruflich Dokumente

Kultur Dokumente

26 - Helical Gears

Hochgeladen von

Ibraheem KhressCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

26 - Helical Gears

Hochgeladen von

Ibraheem KhressCopyright:

Verfügbare Formate

CHAPTER 26

Helical Gears

Chapter Objectives

1. Descri be the vari ous parameters of a hel i cal gear.

2. Desi gn a hel i cal gear after taki ng i nto account the

vi rtual number of teeth, the tooth l oad and the

di fferent strengths.

26-1 INTRODUCTION

Moti on through hel i cal gears can be transmi tted between paral l el

shafts, non-paral l el shafts, and noni ntersecti ng shafts. A pai r of

paral l el hel i cal gears i s used on paral l el shaft and crossed hel i cal

gears are used on non-paral l el shafts. For the generati on of a spur-

gear tooth, a pl ane rol l s on a base ci rcl e, and the edge of the pl ane i s

a strai ght l i ne paral l el to the axi s of the cyl i nder, when thi s pl ane

rol l s or unwraps from the cyl i nder edge and a poi nt on edge traces

an i nvol ute. In the case of hel i cal gear, the edge of the pl ane i s

i ncl i ned to the axi s of the base cyl i nder. As the generati ng pl ane

unwraps and becomes taut, the hori zontal pl ane edge becomes a

strai ght l i ne, curved surface bounded i s an i nvol ute hel i coi d, and

i t forms the surface of the tooth of a hel i cal gear (See Fi g. 26-1).

When a pai r of paral l el hel i cal gears mesh, the fol l owi ng

condi ti ons must be sati sfi ed for proper meshi ng and runni ng of the

set:

1. Gears must have hel i x angl es of equal val ue.

2. Gear teeth of each member, that i s, pi ni on and gear,

must have the same modul e.

3. Gear teeth of each member must have opposi te hel i ces; If

one gear has ri ght-handed hel i cal teeth, then other gear

must have l eft-handed hel i cal teeth.

Fi gure 26-1 Surface of the tooth of a hel i cal gear

In a hel i cal gear, i ni ti al contact i s a poi nt whi ch gradual l y

changes i nto a l i ne as engagement proceeds. This line of contact is a

diagonal across the face and flank of the tooth.

Fi gure 26-2 shows a hel i cal gear wi th hel i x angl e . Hel i x angl e

i s the angl e whi ch the tooth trace of a hel i cal gear i n the pi tch

pl ane makes wi th the gear axi s. Thi s i ncl i nati on to the gear axi s

vari es al ong wi th the i nvol ute, as i t ori gi nates from the base

cyl i nder and devel ops outwards. In general , hel i x angl e refers onl y

to the hel i x angl e at the pi tch cyl i nder.

PREV

25 - Gears

NEXT

27 - Straight Bevel G

Machine Design

Recent

Topics

Highlights

Settings

Keyboard Shortcuts

Feedback

Sign Out

Settings

days left in your trial. Subscribe.

Feedback

Sign Out

Fi gure 26-2 Hel i cal angl e

Spur gears make noi se duri ng operati on due to sudden contact

between gear teeth at the ti me of engagement, but hel i cal gears

devel ops gradual contact between gear teeth extendi ng from one

edge of the tooth to the other edge, on the opposi te si de of face wi dth.

Thi s gradual engagement provi des smooth and noiseless operation

wi th hi gher effi ci ency than spur gears.

Hel i cal gears offer consi derabl e advantage for hi gh-speed and

heavy-duty gear dri ves.

A meshi ng hel i cal gear pai r has greater contact rati o than a

correspondi ng spur-gear pai r. Fri cti onal forces, whi ch are

generated due to mutual sl i di ng of teeth surfaces before and after

the pi tch poi nt, are consi derabl y reduced. Due to greater contact

ratio, l esser fri cti onal forces are devel oped. The deteri mental effects

are comparati vel y smal l er i n case of reversi bl e dri ve and i mpact-

type servi ce condi ti ons. The basi c rack for spur and hel i cal gears i s

the same. For normal appl i cati ons, hel i x angl e l i es between 8 to

20 degrees.

Hel i x angl e shoul d not cross 20 to avoi d a l arge resul tant axi al

thrust. On the l ower si de, shoul d not be l ess then 8 as otherwi se

the advantages offered by hel i cal gears become margi nal .

26-2 PARAMETERS OF AHELICAL GEAR

Fi gure 26-3 shows a hel i cal gear wi th hel i x angl e , transverse

pi tch, AB = .

Secti on al ong transverse pl ane TT shows transverse pressure angl e,

.

Transverse pi tch = P

Secti on al ong normal pl ane (normal to tooth surface) shows:

In the tri angl e ABC, AB = transverse pi tch

AC = normal pi tch,

= cos

n

n

Fi gure 26-3 Secti on at TT

Normal modul e, m = mcos, where m i s transverse modul e.

In tri angl e ABD:

There are two pressure angl es, transverse pressure angl e and

normal pressure angl e, .

Normal pressure angl e i s usual l y 20.

Centre di stance between pi ni on and gear:

Speed rati o between hel i cal gears i s gi ven by:

For smooth operati on of hel i cal gears, l eadi ng edge of the tooth

shoul d be advanced ahead of the trai l i ng edge by a di stance greater

than the ci rcul ar pi tch or the transverse pi tch. In Fi g. 26-3:

For tooth i n hel i cal gear, di mensi ons are:

n

n

Addendum ci rcl e di ameter:

Dedendum ci rcl e di ameter:

Normal modul es are sel ected from standards. The fi rst

preference val ues of normal modul e are 1 mm, 1.25, 1.5, 2, 2.5, 3, 4,

5, 6, 8 and 10 mm.

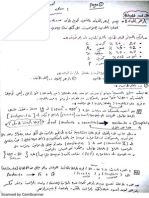

SOLVED EXAMPLES

Exampl e 26-1 A pai r of hel i cal gears consi sts of a pi ni on of 20

teeth and gear of 50 teeth. Hel i x angl e for gears i s 15 and normal

pressure angl e i s 20. If the normal modul e of gear teeth i s 4 mm,

cal cul ate: (a) transverse modul e, (b) transverse pressure angl e, (c)

addendum and dedendum ci rcl e di ameters of both pi ni on and gear,

and (d) mi ni mum wi dths of gears for smooth operati on.

Sol uti on:

Number of teeth on pi ni on, Z = 20

Number of teeth as gear, Z = 50

Pressure angl e = 20

Hel i x angl e = 15

Normal modul e, m = 4 mm

1. Transverse modul es, m =

2. Transverse pressure angl e, :

3. Pi tch ci rcl e di ameter of pi ni on:

d = Z m

= 20 4.14 = 82.8mm

Pi tch ci rcl e di ameter of gear, d = Z m

= 50 4.14 = 207 mm

Normal modul e m = 4 mm

Addendum, h = 4 mm

Dedendum, h = 1.25m = 1.25 4 = 5 mm

Pi ni on

Addendum ci rcl e di ameter = 82.8 + 2 m

= 82.8 + 8 = 90.8mm

Dedendum ci rcl e di ameter = 82.8 2.5m

= 82.8 10 = 72.8

Gear

Addendum ci rcl e di ameter = 207 + 2m = 207 + 8 = 215 mm

Dedendum ci rcl e di ameter = 207 2.5m = 197mm

Mi ni mum wi dth of gear:

26-3 VIRTUAL NUMBER OF TEETH ONHELICAL GEARS

Fi gure 26-4 shows a hel i cal gear of pi tch ci rcl e di ameter, d, and

axi al breadth, b. Hel i x angl e i s . A hel i cal tooth at O i s al so shown.

A pl ane, NN, cuts the gear al ong a di recti on normal to the tooth.

p

g

n

n

p p

g g

n

a

d n

n

n

n

n

Enjoy Safari Flow? Subscribe Today

You have 10 days left in

your trial,

Ibraheem_khress.

Safari Flow is your trusted guide for building a

remarkable career. We hope you've been

enjoying your trialready to join?

Support(http://msupport.safaribooksonline.com/?prod=flow) /

Contact Us(http://www.safaribooksonline.com/contact) /

Blog(http://blog.safaribooksonline.com)

2014 Safari Books Online.

(http://www.safaribooksonline.com)

Terms of Service / Privacy Policy

Subscribe Today

Projected vi ew of the pl ane i s an el l i pse of mi nor di ameter, b = d/2,

and major di ameter, a = (d/2) (1/cos) where i s hel i x angl e.

Compl ete the rectangl e OABC, wi th di mensi ons a b. Joi n

di agonal CA. To obtai n centre of equi val ent spur gear, draw a

perpendi cul ar from B to di agonal CA and extend thi s to meet CO at

O', where O' gi ves the centre of equi val ent formati ve spur gear wi th

radi us of the gear R = O'C. From si mi l ar tri angl es, CBO' and CAB, we

get:

Fi gure 26-4Hel i cal gear

Radi us of equi val ent spur gear:

Therefore,

Or,

But,

Vi rtual number of teeth:

26-4 FORCE COMPONENTS ONATOOTH OF HELICAL GEAR

A hel i cal gear i n mesh wi th another gear exerts pressure on the

tooth of the other gear when i n operati on. General l y, pi ni on (a gear

wi th l esser number of teeth) i s the dri vi ng gear exerti ng dri vi ng

force on the tooth of the dri ven gear. Fi gure 26-5 shows the tooth

l oad P on the gear tooth i n a hel i cal gear. Hel i x angl e of teeth are

and normal pressure angl e of tooth i s P i s the resul tant tooth

l oad wi th components i n axi al , tangenti al , and radi al di recti ons,

P , P , and P , respecti vel y.

From the di agram of forces on tooth.

Fi gure 26-5 Tooth l oad on the gear tooth of a hel i cal gear

where, tan = costan

= transverse pressure angl e

= normal pressure angl e

The onl y di sadvantage i n a pai r of hel i cal gear operati on i.e.,

devel opment of axi al thrust due to hel i x angl e and axi s of shaft

carryi ng hel i cal gear i s subjected to axi al thrust whi ch

necessi tates the provi si on of thrust beari ngs at the ends of the

shaft. The si de thrust can be el i mi nated by usi ng the hel i cal gears

i n pai rsone wi th the ri ght hel i x and the other wi th the l eft hel i x.

These gears are mounted on the shaft si de by si de, and end thrust

produced by one gear i s cancel l ed by the other. If both the gears are

formed on one bl ank, as shown i n Fi g. 26-6, the resul ti ng gear i s

cal l ed Herri ngbone gear.

Fi gure 26-6 Doubl e hel i cal Herri ngbone gear

Mi ni mum face wi dth of Herri ngbone gear:

where, b = Ci rcul ar pi tch

Si nce there i s no end thrust, hel i x angl e can be taken as hi gh as

45.

SOLVED EXAMPLES

Exampl e 26-2 A pai r of hel i cal gears transmi ts 5 kW. The

fol l owi ng are i ts detai l s:

Teeth on pi ni on, Z = 25

Teeth on gear, Z = 50

Normal modul e, m = 4 mm

Hel i x angl e, = 20

Normal pressure angl e, = 20

n

a t r

n

n

p

g

n

n

Determi ne P , P , and P components of tooth l oad i f rpm of pi ni on

are 1,200.

Sol uti on:

Number of teeth on pi ni on, Z = 25

Normal modul e, m = 4 mm

Hel i x angl e, = 20

Transverse modul e, m=

= 4.2567 mm

Pi tch ci rcl e di ameter of pi ni on, d = m Z = 4.2567 25

= 106.42 mm

Pi tch l i ne vel oci ty,

Tangenti al tooth l oad

Axi al l oad,

Radi al l oad,

26-5 DIFFERENT STRENGTHS OF HELICAL GEAR TOOTH

In previ ous arti cl es we have di scussed equi val ent spur gear of a

hel i cal gear, where we have determi ned that for equi val ent spur

gear, the number of teeth on gear i s equal to Z / cos , and di ameter

i s equal to d/ cos . We know about the vari ous strengths, such as

beam strength, wear strength and dynami c l oad, due to Spotts's

equati on of spur gear. The same can be appl i ed for an equi val ent

spur gear.

Beam strength normal to the tooth as shown i n Fi g. 26-7.

Fi gure 26-7 Beam Strength normal to tooth

(S ) = b'm Y

where, b' = face wi dth of equi val ent spur gear

where, = hel i xangl e

m = normal modul eof gear

= , al l owabl ebendi ng stress

where, = ul ti mate tensi l e strength

Z' = , vi rtual number of teeth or teeth on an equi val ent spur gear

Y = Lewi s form factor dependi ng on Z', vi rtual number of teeth

Si mi l arl y, wear strength of hel i cal gear tooth can be obtai ned.

b' = face wi dth of equi val ent spur gear

d' = pi tch ci rcl e di ameter of pi ni on for equi val ent spur gear

Fi gure 26-8 Wear strength of hel i cal gear tooth

t a r

p

n

p p

b n n b

n

b

ut

p

3

2

For 20 normal pressure angl e and both pi ni on and gear made of

steel .

So, (S ) = wear strength i n normal di recti on

Say, the power transmi tted by gears i s P kW, then:

P = N, tangenti al tooth l oad

v = pi tch l i ne vel oci ty of gears i n m/s

C = servi ce factor

C = vel oci ty factor to account for dynami c l oad

P = effecti ve tooth l oad =

To desi gn the tooth for normal modul e:

S = FOS P

or, S = FOS P , dependi ng upon the requi rement

26-5-1Dynamic Load as per Spotts's Equation

As per Spotts's equati on:

For equi val ent spur gear, thi s dynami c l oad i s assumed to be

i ncl i ned at an angl e to the tangent pl ane.

Tangenti al component of the dynami c l oad i s P cos cos.

r , r , are pi tch-ci rcl e radi i of pi ni on and gears

Error, e = e + e = error i n pi ni on + error i n gear (i n mi crons).

Errors i n pi ni on and gear are cal cul ated based on the grade of

machi ni ng accuracy.

SOLVED EXAMPLES

Exampl e 26-3 A pai r of hel i cal gears consi sts of 24 teeth pi ni on

meshi ng wi th 72 teeth gear. Normal pressure angl e i s 20, and

hel i x angl e i s 24. The pi ni on rotates at 720 rpm. Normal modul e of

gear i s 5 mm and face wi dth i s 50 mm. Both, pi ni on and gear are

made of steel wi th = 600 Mpa. Gears are heat treated to a surface

hardness of 360 BHN.

What power can be transmi tted by gears i f servi ce factor i s 1.4 and

factor of safety i s 2? Assume that vel oci ty factor accounts for the

dynami c l oad.

Sol uti on:

Normal modul e, m = 5 mm

Face wi dth, b = 50 mm

Hel i x ampl e, = 24, cos = 0.9135

Beam strength, S = bm Y

Al l owabl e bendi ng stress,

Vi rtual number of teeth on pi ni on:

w n

t

S

v

eff

b eff

w eff

n

d n

1 2

p g

ut

n

b n b

b

Fi gure 26-9

(i n transverse di recti on)

(i n transverse di recti on)

Power transmi ssi on wi l l depend upon beam strength, S .

Servi ce factor C = 1.5

Factor of safety, FOS = 2

Vel oci ty factor, C =

Power = P vNm

= 4,324.6 4.95W

= 21406.7 = 21.406 kW

Exampl e 26-4 A pai r of hel i cal gears wi th pi ni ons 26 teeth and

gear 100 teeth suppl i es power 5 kW at 2,000 rpm of pi ni on. Normal

pressure angl e i s 20 and hel i x angl e of teeth i s 15. Both the gears

are made of hardened steel wi th = 660 N / mm . Gears are

fi ni shed to the accuracy of grade 8. Assumi ng servi ce factor = 1.5,

factor of safety 1.8, and pi tch l i ne vel oci ty of gears as 10 m/s,

determi ne normal modul e of gear teeth as per beam strength.

Speci fy the hardness of the surface of gears i f S = S b = 12 m

where b = face wi dth. Check the safety of desi gn as per Spotts's

equati on for accuracy of grade 8. Gi ven:

Error, e (mi crons) = 16.00 + 1.25, where = m + 0.25 .

Sol uti on:

Z = 25

Z = 100

Hel i x angl e, = 15

Vi rtual number of teeth,

Lewi s form factor, Y = 0.348 + 0.74 0.004

= 0.351

Beam strength, S = bm Y

Transverse modul e,

d for pi ni on = 25 m = 25 x 1.035m

= 25.88m

RPM of pi ni on = 2,000

Pi tch l i ne vel oci ty,

Tangenti al tooth l oad,

Vel oci ty factor, (assumi ng v = 10m/s)

Servi ce factor, C = 1.5

Effecti ve tooth l oad,

b

s

v

t

ut

w b n

n

p

g

b n b

p n

n

s

2

Beam strength, S = (FOS) x P

or, m = 8.41

m = 2.032 mm

Normal modul e can be safel y taken as 2.5 mm.

Wi th m = 2.5:

v = 2.71 m = 2.71 2.5 = 8.775 m/s < 10 m/s (assumed)

Surface hardness

where, b = 12m = 12 2.5 = 30 mm

Therefore, 926.64m = 12m 25.88m 1.6 K

Spotts's equati on:

Taki ng m = 2.5 mm

d = 25.88 2.5 = 64.7 mm

d = 4 64.7 = 258.8mm

Grade 8 accuracy e = 16 + 1.25

= m + 0.25

Pi ni on

Gear

Dynami c l oad,

Total l oad = Stati c + dynami c l oads

Tangenti al component

whereas, S = beam strength

= 926.64m = 926.64 2.5

= 5,791.5 N

Desi gn i s safer agai nst Spotts's theory al so.

PRACTICAL APPLICATIONS

For noi sel ess operati ons and hi gh effi ci ency, hel i cal

gears are commonl y used i n gear boxes of

automobi l es.

Hel i cal gears are used as operati onal gears i n

machi nes, such as l athe, mi l l i ng machi nes, and

earth movi ng machi nes.

POINTS TO REMEMBER

1. Moti on through hel i cal gears can be transmi tted

between paral l el shafts, non-paral l el shafts and

noni ntersecti ng shafts.

2. An i nvol ute hel i coi d surface forms the surface of the

tooth of a hel i cal gear.

3. In hel i cal gear, the l i ne of contact i s a di agonal across

the face and the fl ank of the tooth.

4. In hel i cal gears, gradual engagement between the

meshi ng teeth provi des smooth and noi sel ess operati on

wi th hi gher effi ci ency than spur gears.

5. There i s greater contact rati o i n hel i cal gears than i n

b eff

n

n

n

n

n n n

n

p

g

n

b

3

2

2

n

2

spur gears, l esser fri cti onal forces are devel oped.

6. The hel i x angl e l i es between 820, for normal

appl i cati ons.

7. For smooth operati on of hel i cal gears, l eadi ng edge of

the tooth shoul d be advanced ahead of the trai l i ng edge

by a di stance greater than the ci rcul ar or transverse

pi tch.

8. For the anal ysi s of stresses i n hel i cal gears, an

equi val ent spur gear i s consi dered for whi ch vi rtual

number of teeth and di ameter of equi val ent spur gear

are cal cul ated. In expressi on for beam strength, Lewi s

form factor corresponds to vi rtual number of teeth.

9. There are 3 components of a tooth l oad i n hel i cal gear, i n

radi al , axi al and tangenti al di recti ons.

10. The onl y di sadvantage of hel i cal gears i s the

devel opment of axi al thrust whi ch necessi tates the use

of thrust beari ngs at the ends of a shaft.

11. Herri ngbone gears i s a pai r of hel i cal gears wi th hel i x

angl es i n opposi te di recti ons. The axi al thrust i s

cancel l ed out.

12. Dynami c l oad i n hel i cal gears as per Spotts's equati on i s

determi ned on the basi s of equi val ent spur gear.

REVIEW QUESTIONS

1. What i s a hel i cal gear? In what respects a hel i cal gear i s

di fferent than a spur gear?

2. What are meri ts and demeri ts of hel i cal gears over spur

gears?

3. Make a si mpl e sketch of a hel i cal gear tooth and show

the fol l owi ng:

1. Transverse pi tch

2. Normal pi tch

3. Axi al pi tch

4. Deri ve expressi on for vi rtual number of teeth i n a

hel i cal gear.

5. Make a neat sketch of forces acti ng on a hel i cal gear

tooth. What are the rel ati onshi ps, between tangenti al

l oad, axi al l oad and radi al l oad?

6. Deri ve expressi on for S = beam strength of hel i cal gear

tooth.

7. What i s l oad stress factor, and how i t i s reduced to for

20 pressure angl e steel gears?

PRACTICE PROBLEMS

1. A pai r of hel i cal gears on paral l el shafts consi sts of a

pi ni on of 25 teeth and gear of 60 teeth. Normal modul e

of gears i s 3 mm. Determi ne the fol l owi ng, i f hel i x angl e

i s 22.

1. Transverse modul e

2. Ci rcul ar pi tch

3. Addendum and dedendum

4. Mi ni mum wi dth of gears

5. Transverse pressure angl e i f normal pressure

angl e i s 20

6. Centre di stance between shafts

2. A pai r of hel i cal gears wi th Z = 20, Z = 60, hel i x

angl e 25, = normal pressure angl e 20 transmi ts 7.5

kW when pi ni on rotates at 800 rpm. If pi tch ci rcl e

di ameter of pi ni on i s 80 mm, determi ne 3 components of

tooth l oad.

3. A pai r of hel i cal gears wi th Z = 20, speed rati o 2.6 i s to

be desi gned. Fol l owi ng data i s gi ven:

Speed of pi ni on = 520 rpm.

Power to be transmi tted = 8 kW

Hel i x angl e i s 25

Face wi dth = 10 mm

Gear surfaces are heat treated to 400 BHN

Servi ce factor = 1.5

Factor of safety = 2

of materi al = 600 MPa

Determi ne normal modul e of gears i f normal pressure

angl e i s 20.

Dynami c l oad i s accounted by vel oci ty factor.

4. Fol l owi ng data i s gi ven for a pai r of paral l el hel i cal

gears 24 teeth on pi ni on and 60 teeth on gear.

Speed of pi ni on = 750 rpm

Centre di stance between gears = 217 to 218 mm

Normal modul e = 5 mm

Normal pressure angl e = 20

Ul ti mate tensi l e strength of gear materi al = 600 MPa

Surface hardness of gears = 320 BHN

Grade of machi ni ng accuracy = 8

Factor of safety = 1.8

Servi ce factor = 1.3

Face wi dth = 10 mm

Determi ne how much power can be transmi tter by the

gears. Determi ne beam strength, wear strength and

dynami c l oad as per Spotts's equati on.

INTERACTIVE LEARNING

A wi de range of mul ti pl e choi ce questi ons i s avai l abl e at

www.pearsoned.co.i n/ucji ndal (http://www.pearsoned.co.i n/ucji ndal ).

b

p g

n

p

ut

Log on to test yoursel f, check your scores and get the ri ght answers.

Recommended / Queue / Recent / Topics / Settings / Blog(http://blog.safaribooksonline.com) /

Support(http://msupport.safaribooksonline.com/?prod=flow) / Feedback / Sign Out

2014 Safari Books Online(http://www.safaribooksonline.com/).

Terms of Service / Privacy Policy

PREV

25 - Gears

NEXT

27 - Straight Bevel G

Das könnte Ihnen auch gefallen

- 111Dokument1 Seite111Ibraheem KhressNoch keine Bewertungen

- Post Info - LatheDokument2 SeitenPost Info - LatheIbraheem KhressNoch keine Bewertungen

- 2014 SOLIDWORKS Help - Equation Driven CurvesDokument2 Seiten2014 SOLIDWORKS Help - Equation Driven CurvesIbraheem KhressNoch keine Bewertungen

- Fuse Blows Power Lost Motor(s) OverheatDokument2 SeitenFuse Blows Power Lost Motor(s) OverheatIbraheem KhressNoch keine Bewertungen

- 3 1 Eight Forms CorrosionDokument20 Seiten3 1 Eight Forms CorrosionIbraheem KhressNoch keine Bewertungen

- Work OrderDokument2 SeitenWork OrderIbraheem KhressNoch keine Bewertungen

- Running On Windows 64 BitDokument8 SeitenRunning On Windows 64 BitIbraheem KhressNoch keine Bewertungen

- General Mech EnglishDokument19 SeitenGeneral Mech EnglishIbraheem KhressNoch keine Bewertungen

- ReportDokument6 SeitenReportIbraheem KhressNoch keine Bewertungen

- Work Package 2: DR Jüri RiivesDokument34 SeitenWork Package 2: DR Jüri RiivesIbraheem KhressNoch keine Bewertungen

- معادن سكندDokument15 Seitenمعادن سكندIbraheem KhressNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Analysis of Heat and Mass Transfer On Cooling Tower FillDokument8 SeitenAnalysis of Heat and Mass Transfer On Cooling Tower FillabdulazizrohmanhakimNoch keine Bewertungen

- Vonellenrieder - Open Water Tow Tan.2010.SYMPDokument8 SeitenVonellenrieder - Open Water Tow Tan.2010.SYMPldigasNoch keine Bewertungen

- Strength of MaterialsDokument833 SeitenStrength of MaterialsSuvendu ParidaNoch keine Bewertungen

- Boundary LayerDokument16 SeitenBoundary LayerSatyanand ErankiNoch keine Bewertungen

- En 10025Dokument16 SeitenEn 10025Sorin Radu100% (1)

- StrengthDokument5 SeitenStrengthJean DigosmanNoch keine Bewertungen

- Centrifugal ForceDokument5 SeitenCentrifugal Forceasd3e23Noch keine Bewertungen

- VectorsDokument34 SeitenVectorsaryamamanNoch keine Bewertungen

- Hydrodynamics of Two-Phase Loop ThermosyphonDokument7 SeitenHydrodynamics of Two-Phase Loop ThermosyphonVlad MartianNoch keine Bewertungen

- CBSE Class 8 Mathematics Worksheet - Direct and Inverse Variations PDFDokument6 SeitenCBSE Class 8 Mathematics Worksheet - Direct and Inverse Variations PDFRitesh SethiaNoch keine Bewertungen

- Ebook Vector Mechanics For Engineers Dynamics PDF Full Chapter PDFDokument67 SeitenEbook Vector Mechanics For Engineers Dynamics PDF Full Chapter PDFelsie.mcintyre883100% (29)

- F23 HW5 v231015Dokument3 SeitenF23 HW5 v231015Sun Li BattenNoch keine Bewertungen

- Special RelativityDokument236 SeitenSpecial RelativityAndrei Avadani100% (3)

- A21VGDokument32 SeitenA21VGcunvip163.comNoch keine Bewertungen

- Experimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilDokument6 SeitenExperimental Evaluation of Aerodynamics Characteristics of A Baseline AirfoilAJER JOURNALNoch keine Bewertungen

- Strength of MaterialsDokument264 SeitenStrength of MaterialsDenisa TodoracheNoch keine Bewertungen

- 01 - Class Test (TAPS) - EngDokument3 Seiten01 - Class Test (TAPS) - EngUtkarsh AgrawalNoch keine Bewertungen

- Syllabus Solid MechanicsDokument2 SeitenSyllabus Solid MechanicsrajuNoch keine Bewertungen

- CRT Set - 4 Adv P-1 PDFDokument24 SeitenCRT Set - 4 Adv P-1 PDFPawan KNoch keine Bewertungen

- @StudyTime - Channel 12 - Sound (Ex) PDFDokument10 Seiten@StudyTime - Channel 12 - Sound (Ex) PDFSipra PaulNoch keine Bewertungen

- Composite Materials and StructuresDokument35 SeitenComposite Materials and StructuresGundoju SreenivasNoch keine Bewertungen

- Aieee 2005Dokument41 SeitenAieee 2005Vicky JeetNoch keine Bewertungen

- Assignment On Complex Variable Techniques in Linear Elastic Fracture MechanicsDokument1 SeiteAssignment On Complex Variable Techniques in Linear Elastic Fracture MechanicsSilent KnightNoch keine Bewertungen

- Soil Mehanics II ManualDokument56 SeitenSoil Mehanics II ManualPasi C4Siele100% (1)

- Exp 3 PhysDokument13 SeitenExp 3 PhysAli Issa OthmanNoch keine Bewertungen

- 6.1.1 Eigenvalue Analysis of A Piezoelectric Transducer: Abaqus Example Problems ManualDokument7 Seiten6.1.1 Eigenvalue Analysis of A Piezoelectric Transducer: Abaqus Example Problems Manualzebra00Noch keine Bewertungen

- Fluent HeatTransfer L04 NaturalConvectionDokument51 SeitenFluent HeatTransfer L04 NaturalConvectionsingourNoch keine Bewertungen

- Vibration AnalysisDokument17 SeitenVibration AnalysispmagrawalNoch keine Bewertungen

- Classical MechanicsDokument364 SeitenClassical MechanicsalmarpaNoch keine Bewertungen

- Filtration: Batch Filtration (Small Scale)Dokument6 SeitenFiltration: Batch Filtration (Small Scale)Anonymous ZAr1RKNoch keine Bewertungen