Beruflich Dokumente

Kultur Dokumente

Mechanical MPSC Syllabus

Hochgeladen von

more_sandeep0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten6 SeitenMaharashtra engineering services syllabus

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenMaharashtra engineering services syllabus

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten6 SeitenMechanical MPSC Syllabus

Hochgeladen von

more_sandeepMaharashtra engineering services syllabus

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

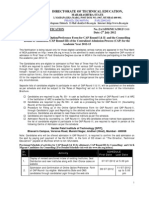

P a g e | 1

MPSC Main - Mechanical Engineering

Paper I

Standard: Degree in Mechanical Engineering

Total Marks: 200

Nature of Paper: Conventional Type

Duration: 3 Hours

Note:

1)Answers to this paper must be written in English only

2)This paper will test the candidate's ability to comprehend, to analyze, to interpret, to criticize and to

appraise subject matterrelated to the topics/sub- topics mentioned below.

3) For judging candidates' conceptual understanding, appropriate number of numerical problems will be

asked.

4)It is expected from candidates to study the latest and recent developments and happenings pertaining

to the topics/sub- topics mentioned below.

Section A (Marks: 50)

Materials and Their Behavior

1) Fundamentals : Force, moment, couple, resultant of forces, Equilibrium offorces, friction and friction

angle, coulomb friction, rolling friction andbelt friction, frictional torque in pivot and Collar bearings, MI,

Work andenergy

2) Strength of Materials : Normal and Shearstresses, Stress-strain diagram, thermal stresses, shear force

and bendingmoment diagrams, bending stresses in solid, hollow and built up sections,deflection

ofbeams, shear stress distribution, strain energy, torsion ofbars, shafts and helical springs, Deflection

ofbeam under differentconditions,impact load

3) Theory of Machines : Kinematic link,pair, chain, Mechanism and structure, degrees of freedom,Cams,

Gear trains,fluctuation of speed and energy in flywheel, Gyroscope, Balancing of rigidrotor, Single and

multi-cylinder engines and V-engines, belts and chaindrives, Hydrodynamic bearing

4) Engineering Materials : Crystallinestructure of metals and alloys, defects in crystalline materials, Iron-

Carbonequilibrium diagram, plain carbon steel, alloy steel, cast iron and types,Brass and Bronze,

Aluminum, lead, Tin, Zinc- their properties andapplications, Plastic deformation, bearing materials,

plastics, ceramics,composite materials, Heat treatment of steels

P a g e | 2

Section - B( Marks : 50 )

Machine Design

5) Design of Elements: Theories of failure,factor of safety, combined stressesPressure vessels, struts and

columnsDesign of Screw and bolt, power screw, Design of Shafts andsprings,keys, couplings

6) Design of Gears : (Spur, helical, bevel and worm), Designof clutches and brakes, fatigue consideration

in design

7) System Design : Design of mechanicalsystems, specification of components, Design of system

including material handlingsystems, power plants, refrigeration and air conditioning systems,

pneumaticand hydraulic systems, etc

8) Dynamics of machines : Inertia forceanalysis, law of gearing, interference and minimum number of

teeth,Longitudinal - transverse and Torsional vibration, free-forced vibration,critical and whirling speed

of shaft, vibration isolation

Section C( Marks : 50 )

Manufacturing Science and Processes

9) Manufacturing Science : Theory of metal cutting, Merchant'sforce analysis, Tool materials,

Taylor'stool life equation, Machinabilityeconomics, cutting fluids, Chip removal, Calculation of cutting

force onsingle point cutting tools, twist drills, milling cutter, broaches, reamers,Jigs and fixtures Recent

machiningmethods - EDM, ECM, PAM, Ultrasonic and Laser, etc

10) Manufacturing Processes : Casting, moulding-Types, equipments and defects, hot and cold working

of metals - blanking,shearing, punching, piercing, coining, embossing, drawing, spinning andforging,

Metal joining processes- welding, soldering, brazing, High energyrate forming, electroplating, surface

finishing processes

11) Manufacturing Management : Production planningand control, forecasting - Moving average,

moving range, exponential smoothening, scheduling, assembly line balancing, Inventory Control

ABCanalysis, EOQ models, Statistical quality control and TQM, TPM Elements of cost, job costing,

processcosting, estimation of machining time

12) Operation Research: Linear programming -Graphical and simplex methods, transportation and

assignment models, gametheory, queuing models, CPM and PERT, Replacement models, value analysis

P a g e | 3

Section - D( Marks : 50 )

CAD / CAM

13) CAD : Overview and benefits of CAD,primitives, 2D / 3D animation, Bazier curves and splines, Wire-

framemodeling, surface and solid modeling, kinematic analysis of open and closedloop mechanisms,

stiffness matrix, finite element analysis , optimum design,constrained optimization - Penalty function

method, computer aided optimumdesign of gears, bearing sand shafts

14) Product Development : Design materials, human factors indesign, applied ergonomics, product

development processes, customer needs,product specifications, concept generation and selection,

productarchitecture, product design methods - function analysis, objective trees,QFD, morphological

chart method, weighted objective method, value engineeringmethod Design for manufacturing , legal

issues in product design, economics

15)Machine Tool Design : Kinematics ofmachine Tools, structural and ray diagrams for speed, stepped

and step lessregulation of speed, static and dynamic rigidity of machine tools, Vibrationof machine tools,

chatter, Slide ways and guide ways

16) CAM: Types of automation, Steps in NCmanufacturing, manual and NC part programming, APT,

Machining centers, FMS,Computer Aided Process Planning, CMM, CIMS & its components, Robotics

P a g e | 4

Paper II

Standard: Degree in Mechanical Engineering

Total Marks: 200

Nature of Paper:Conventional Type

Duration: 3 Hours

Note:

1) Answers to this paper must be written in English only

2) This paper will test the candidate's ability to comprehend, to analyze, to interpret, to criticize and to

appraise subject matter related to the topics/sub- topics mentioned below.

3) For judging candidates' conceptual understanding, appropriate number of numerical problems will be

asked.

4) It is expected from candidates to study the latest and recent developments and happenings

pertaining to the topics/sub- topics mentioned below.

Section A(Marks: 50)

Thermodynamics, Heat and Mass Transfer

1) Thermodynamics:

01) Fundamentals- Work, Heat, Zeroth law,First law- application to thermodynamic system components,

efficiency, Secondlaw (theoretical treatment only)- quality of energy, increase of entropy,availability and

irreversibility, applications, Third law

02) Ideal gas, real gases, compressibilityfactor, Joule - Thomson Coefficient Gas power cycles- Air

standard workoutput and efficiency, mean effective pressure, indicated power, brake power

03) Vapour Power Cycles- Carnot and Rankine,Reheating and regenerative feed heating, Binary vapour

cycle, Thermalefficiency and work ratio

2) Heat and mass transfer:

01)Various modes of heat transfer,Fourier's, Newton's and Stefan Boltzmannslaw, combined modes,

overall heattransfer coefficient Conduction-Thermal conductivity, factors influencing,measurement,

general differential equation, steady state, linear heat flowthrough a plain and composite wall, tube and

sphere, conduction with heatsources, heat transfer from rods, fins of uniform cross section

02)Convection- Forced and Natural, HeatExchangers-Types, performance, analysis restricted to parallel

and counterflow exchangers Thermal Radiation-Black and non black bodies, Kirchhoffs law, grey body

radiationexchange,Mass transfer- mass and mole concentration

P a g e | 5

Section B (Marks: 50)

Fluid Mechanics and Machinery, Pneumatics and Hydraulics, Power Plant Engineering, Energy

Engineering

3)Fluid Mechanics : Fluid andflow-definition and types, properties of ideal and real fluids,

Continuumconcept, Lagrangian and Eulerian approach Fluid statics, Kinematics andDynamics of fluid,

flow in pipes, Laminar flow of viscous fluids, Turbulentflow, Dimensional analysis , Compressible fluid

flow

4) Fluid Machinery: Introduction- Classification, energytransfer between fluid and rotor, flow through

machines, ideal and actualslip Hydraulic turbines, pumps, compressors and blowers

5) Pneumatics and Hydraulics:Productionofcompressed air, Pneumatic control- Components and

Systems, electro Pneumaticlogic circuits, Pneumatic counters, typical applications, Circuits, Sensors

6) Power Plant Engineering : Sources of energy,variable load problem, power planteconomics and

selection Steam powerplant- boilers, general layout, different systems, turbine auxiliary systems,heat

balance and efficiency Gas turbine power plant - regeneration, reheating,cogeneration, auxiliary

systems, operation, Nuclear Power Plants basiccomponents, power stations Hydroelectric power plant

- site selection, arrangement, operation Electrical systems and instrumentation

7) Energy Engineering : Energy conservationmethods, audit Solar energy -collectors, area calculations,

Solar Systems - power plants, driers, cookers,refrigerationsystems Wind energy -rotors, system design,

site selectionBiogas plants - Types, plant performance, Cogeneration Plants, GeothermalPlants Direct

Energy Conversion - Fuel Cells, Thermoelectric, Thermionic andMHD systems, Govt. policies and

programmes for energy and environmentconservation

Section C(Marks: 50)

IC Engines, Automobile Engineering, Refrigeration and Air Conditioning

8) IC Engines:

01) Fuel air cycles, real cycles, volumetricefficiency and thermal efficiency, SI Engines - carburetion,

combustion,combustion chambers, CI Engines - fuel injection, combustion,

combustionchambers Detonation - Knock rating offuels, parameters Emission Control Systems

Supercharging - effect of altitudeon power output, types of superchargers

02)Cooling, lubrication and ignitionsystems, testing of IC enginesCompressors - centrifugal and axial,

performance Gas turbines Idealcycles, intercooling, regeneration, reheatingJet propulsion

P a g e | 6

9) Automobile Engineering: Testing ofautomobiles, resistances to motion, power requirement for

propulsion, Automobile engines, frames, transmissionsystems, drive line and rear axle, wheels and tyres,

steering systems,suspension systems, brakes, starter motors, emission norms

10)Refrigerationand Air Conditioning :

Refrigeration and heating systems,vapour compression and vapor absorption refrigeration systems,

refrigerationequipments, psychrometrics, solar radiation, estimating requirements, ductingsystems,

automotive air conditioning

Section D(Marks: 50)

Measurement and Metrology, Numerical Analysis and ComputerProgramming, Numerical Control of

Machine Tools, Automatic Control

11) Mechanical Measurement:

01)Measuring instruments, generalized measuring systems, static and dynamic performance

characteristics of devices,calibration, error - sources and analysisSensors and Transducers,

Measurement of - displacement, angularvelocity, pressure, strain, force and torque, temperature, flow,

vibrationand noise Data acquisition systems

02) Metrology: Standards of linear measurement, Limitsand Fits, Limit gauges, Measurement of

geometric forms, Interferometry, Comparators,Measurement of screw threads and gears, surface

texture

12) Numerical Analysis and Computer Programming :

Approximations and round of errors,truncation errors and Taylor series, determination of roots of

polynomialsand transcendental equations, Programming using C and C++ languages for- Solutions of

linear simultaneousalgebraic equations, curve fitting, Backward, forward and Central

Differencerelations, Numerical solution of ordinary differential equations

13) Numerical Control of Machine Tools :

Components, open andclosed loop control, actuation and feedback systems, Point to Point, linearand

contouring systems, Tooling for NC systems, Computer numerical control,Direct and distributed

numerical control, adaptive control

14) Automatic Control : Components ofautomation - actuators, sensors, vision systems, controllers,

Logic controland PLCs, Factory communication, Mathematical models, transfer function,Block diagrams,

proportional controls, derivative and integral control, steadystate and transient response analysis,

different inputs, root locus,frequency response methods, speed control systems

Das könnte Ihnen auch gefallen

- MarathiDokument5 SeitenMarathiPinak VadherNoch keine Bewertungen

- C:/Users/pc2011-5/Downloads/SSM 14 NOTIFICATION - Doc/ - 1Dokument3 SeitenC:/Users/pc2011-5/Downloads/SSM 14 NOTIFICATION - Doc/ - 1more_sandeepNoch keine Bewertungen

- 14-Mechanical Engineering PDFDokument5 Seiten14-Mechanical Engineering PDFmore_sandeepNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- IBPS Clerk Official Notification 2017Dokument47 SeitenIBPS Clerk Official Notification 2017Kabya Srivastava100% (4)

- GATE 2018 Information Brochure - v2 PDFDokument39 SeitenGATE 2018 Information Brochure - v2 PDFmaheshfbNoch keine Bewertungen

- GATE 2018 Information Brochure - v2 PDFDokument39 SeitenGATE 2018 Information Brochure - v2 PDFmaheshfbNoch keine Bewertungen

- Ex ServiceDokument1 SeiteEx Servicemore_sandeepNoch keine Bewertungen

- INTFile 730Dokument7 SeitenINTFile 730more_sandeepNoch keine Bewertungen

- Engineer Design 10-4-2011Dokument2 SeitenEngineer Design 10-4-2011more_sandeepNoch keine Bewertungen

- District Project Officer Selection ListDokument5 SeitenDistrict Project Officer Selection Listmore_sandeepNoch keine Bewertungen

- Proforma UndertakingDokument1 SeiteProforma Undertakingmore_sandeepNoch keine Bewertungen

- Reliving & Experience LetterDokument3 SeitenReliving & Experience LetterAlok KhuntiaNoch keine Bewertungen

- Advertisement 31 March 2017Dokument1 SeiteAdvertisement 31 March 2017more_sandeepNoch keine Bewertungen

- MPSC Interview ScheduleDokument3 SeitenMPSC Interview Schedulemore_sandeepNoch keine Bewertungen

- MPSC Pre SyllabusDokument1 SeiteMPSC Pre Syllabusmore_sandeepNoch keine Bewertungen

- FM Question Paper Mid Term 2Dokument1 SeiteFM Question Paper Mid Term 2more_sandeepNoch keine Bewertungen

- AssessmentDokument2 SeitenAssessmentmore_sandeepNoch keine Bewertungen

- 17412-Theory of MachinesDokument9 Seiten17412-Theory of Machinesmore_sandeepNoch keine Bewertungen

- Thermal EngineeringDokument6 SeitenThermal Engineeringmore_sandeepNoch keine Bewertungen

- Letter 3Dokument6 SeitenLetter 3more_sandeepNoch keine Bewertungen

- Revised State Service Prelim SyllabusDokument1 SeiteRevised State Service Prelim SyllabusmpscmitraNoch keine Bewertungen

- Approved Annual Programme 2015Dokument1 SeiteApproved Annual Programme 2015Sharath HegdeNoch keine Bewertungen

- File 3 - Syllabus - Jr. Engr. & Sub Engr.Dokument2 SeitenFile 3 - Syllabus - Jr. Engr. & Sub Engr.more_sandeepNoch keine Bewertungen

- Maharashtra Engineering Services: Mechanical MPSC SyllabusDokument6 SeitenMaharashtra Engineering Services: Mechanical MPSC Syllabusmore_sandeepNoch keine Bewertungen

- Collection 9Dokument3 SeitenCollection 9more_sandeepNoch keine Bewertungen

- Mca CetDokument2 SeitenMca CetAbhilash RuhelaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Sri KelanitissaDokument12 SeitenSri KelanitissaAsanka MaheshNoch keine Bewertungen

- We Move You. With Passion.: YachtDokument27 SeitenWe Move You. With Passion.: YachthatelNoch keine Bewertungen

- Series 1163 TB73-TB93LDokument72 SeitenSeries 1163 TB73-TB93LDimas SaputroNoch keine Bewertungen

- Shell Turbo S5 DR 46Dokument2 SeitenShell Turbo S5 DR 46Muhammad SaputraNoch keine Bewertungen

- Poster-SGT-800-ENG-230127-pdf_Original%20fileDokument2 SeitenPoster-SGT-800-ENG-230127-pdf_Original%20fileSBNoch keine Bewertungen

- Final-Report8 0Dokument78 SeitenFinal-Report8 0vinuth nNoch keine Bewertungen

- Gas turbine engine architecture with geared turbofanDokument26 SeitenGas turbine engine architecture with geared turbofanFouad0% (1)

- Marine Propulsion SystemsDokument5 SeitenMarine Propulsion SystemsIbrahim SameirNoch keine Bewertungen

- Ijet10 02 06 18 PDFDokument3 SeitenIjet10 02 06 18 PDFmikeNoch keine Bewertungen

- GT - Turbine Inlet CoolingDokument12 SeitenGT - Turbine Inlet CoolingSharon Lambert100% (1)

- Ansh VermaDokument2 SeitenAnsh VermaanshvermaNoch keine Bewertungen

- Thermal and Nuclear Power Plant Assignment QuestionsDokument3 SeitenThermal and Nuclear Power Plant Assignment QuestionsAshok KumarNoch keine Bewertungen

- A Gas Turbine Operating On The Steam-Injected CycleDokument7 SeitenA Gas Turbine Operating On The Steam-Injected Cyclegedyon fikadeNoch keine Bewertungen

- GT & JP QuestionsDokument7 SeitenGT & JP QuestionsNaveen gupiNoch keine Bewertungen

- Module Exam Application Form PDFDokument10 SeitenModule Exam Application Form PDFBazli UmarNoch keine Bewertungen

- BSEL-RD-16-05-05 Gas Turbine Engine R&DDokument4 SeitenBSEL-RD-16-05-05 Gas Turbine Engine R&DShai WeissNoch keine Bewertungen

- WG's Process Engineers' Codes StandardsDokument18 SeitenWG's Process Engineers' Codes StandardskurtbkNoch keine Bewertungen

- M.E. - Heat Power RGPV Syllabus 2011Dokument5 SeitenM.E. - Heat Power RGPV Syllabus 2011Arun MalviyaNoch keine Bewertungen

- 1 - 5071382346712744122 Mech NotesDokument22 Seiten1 - 5071382346712744122 Mech NoteskadarNoch keine Bewertungen

- B.E. (IT) Parallel Computing Semester AssignmentsDokument102 SeitenB.E. (IT) Parallel Computing Semester AssignmentsAnanya SwaminathanNoch keine Bewertungen

- Tauras 60 SolarDokument83 SeitenTauras 60 SolarAbid Lakhani100% (1)

- Business Plan Perpetual Power Solution Co., LTD: 15 July 2016Dokument49 SeitenBusiness Plan Perpetual Power Solution Co., LTD: 15 July 2016Ko Aung KoNoch keine Bewertungen

- South America and Mexico Sourcing ListDokument204 SeitenSouth America and Mexico Sourcing Listcristianoclem50% (2)

- Thermal Analysis of a Steam Turbine BladeDokument82 SeitenThermal Analysis of a Steam Turbine BladeVamsi SakhamuriNoch keine Bewertungen

- Thermal Engineering - I (Diploma - L Scheme) PDFDokument7 SeitenThermal Engineering - I (Diploma - L Scheme) PDFnjaiguru89% (9)

- SGT5-4000F Brochure 2008Dokument10 SeitenSGT5-4000F Brochure 2008mkcsekarNoch keine Bewertungen

- 3.design and Analysis of Gas Turbine Rotor BladeDokument22 Seiten3.design and Analysis of Gas Turbine Rotor BladeBalaji BeliveNoch keine Bewertungen

- TFE 731 Chap 75Dokument18 SeitenTFE 731 Chap 75Egor85Noch keine Bewertungen

- Commissioning Manual (Rev 4, 10-6-06) Tp60Dokument321 SeitenCommissioning Manual (Rev 4, 10-6-06) Tp60Ismar Adrian100% (4)

- Superalloystable - castcomp-IN 738-2Dokument11 SeitenSuperalloystable - castcomp-IN 738-2leoNoch keine Bewertungen