Beruflich Dokumente

Kultur Dokumente

DMCR Protection Relay For Oil Transformer

Hochgeladen von

JayadevDamodaranOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DMCR Protection Relay For Oil Transformer

Hochgeladen von

JayadevDamodaranCopyright:

Verfügbare Formate

electrical-engineering-portal.com http://electrical-engineering-portal.

com/dmcr-protection-relay-for-oil-transformer

Edvard

D.M.C.R. Protection Relay for Oil Transformer

DMCR - Detection, Measurement and Control Relay for Hermetically Sealed Oil Transformer

Content

Introduction to D.M.C.R.

Faults detected on live transformer unit:

Standards

Possibilities of D.M.C.R.:

1. Oil level control and gas detection

2. Pressure control

3. Temperature control

Introduction to D.M.C.R.

The DMCR is a protection relay designed for the hermetically sealed oil immersed transformers without gas

cushion. This device enables complete control of the tanks internal parameters, i.e. pressure, temperature, oil

level and gas detection.

Fitted directly to the transformer cover, this relay ensures protection against internal faults, prolonged

overvoltages and fire risks associated with the use of inflammable dielectric fluids.

The accessory continuously monitors:

1. Dielectric fluid level,

2. Tank internal pressure,

3. Dielectric fluid temperature at two different thresholds.

To operate properly, the protection relay mustbe fully filled with fluid (level higher than the float visible in the

transparent section of the unit). If this is not the case, check the instructions which appear inside each casing.

To ensure optimum protection, the following action and adjustments are recommended:

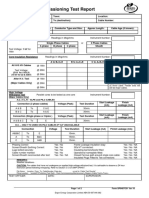

Finding Recommended adjustment Fault detected Action to be taken

Gas emitted or drop in level Large float at the top Serious fault De-energize unit

Pressure switch 0.20 bar Serious fault De-energize unit

Thermostat threshold 1 90C Overvoltages Activate alarm

Thermostat threshold 2 100C Overvoltages De-energize unit

There are two types of transformers:

1. The air-cooled transformer, also called dry transformer

2. The oil immersed transformer. The transformer is immersed in an oil-filled tank.

The DMCR is a protection relay designed for the hermetically sealed oil immersed transformers without gas

cushion. This device enables complete control of the tanks internal parameters, i.e. pressure, temperature, oil

level and gas detection.

Go to Content

Faults detected on live transformer unit

1. Dielectric fluid level is detected as low

The protection relay is empty and the large float is at the bottom.

May be due to:

1.1 Air entering

There must be a dielectric fluid leak and thus oily stains should be visible on the ground. Accurately localise the

fault, carry out repair, then recheck the level with the body of fluid at a temperature of 20C, before switching the

unit live again.

1.2 Internal gas emission

Gas should be sampled using a syringe and then analysed.

Whilst awaiting results, under no circumstances should the transformer be switched live again because a risk of

total destruction exists.

Go to Content

2. Overheating is detected

This may be due to:

1. Improper cooling of the transformer (insufficient air flow around unit or plan-troom ventilation),

2. Continuous overvoltage.

Go to Content

3. Excess pressure is detected

This may be due to:

1. Overheating

2. Internal gas emission

3. Topping up of dielectric fluid with the body of fluid below 20C; drain the over-flow with the transformer de-

energised and the dielectric fluid at 20C.

Go to Content

Standards

This protection relay has been designed according to the European standard EN 50216-3, specification which

came into action on the 5th of June 2002.

This standard applies to protection relays for hermetically sealed oil immersed transformers, (in accordance with

the EN 60076 standard) and induction coils (in accordance with the EN 60289 standard) without gas cushion for

an indoor or outdoor use.

The DMCR relay is an IDEF Systemes design, made in France. It has two French and one European patents.

DMCR relay dimensions

Go to Content

Possibilities of D.M.C.R.

1. Oil level control and gas detection

The DMCR enables to control both the oil level and the presence of gas inside the transformers tank. The DMCR

body is a small see-through tank fitted ontothe transformers tank.

Should gas form inside the transformer, it will then accumulate inside the DMCR and cause the oil level to

drop.

Visual information

The level drop is first visible through the lowering of the small red float inside the upper part of the DMCR,

followed by the lowering of the main red float.

The 360 degree visibility is a specifically designed and patented system.

Electrical information

A circular magnet is fitted in the main float and it acts upon a magnetic changeover contact (REED switch)

sitting inside the brass tube that runs through the float. The lowering of the float triggers the activation of an

electrical contact, through the magnets motion.

A bleeding system facilitates gas collection inside the relay so that one can analyze it and understand the reason

for its presence. The bleeding system has a male G1/8 thread, accordingto the standard.

For the oil level and gas detection control, the contacts have been chosen in order to use the REED switchs

working contact when the float is in a high position. This means that, in such a position, i.e. with a normal oil level

and therefore normal conditions of use, the contact has already switched.

This is a positive safety system. With this method, any potential damage to the switch is immediately spotted.

The DMCR below is filled in with oil: the main float and the secondary float are both in high position.

The DMCR - Oil level control and gas detection

Go to Content

2. Pressure control

Pressure inside a transformers tank can increase significantly when:

1. There is a temperature rise due to the transformer charge: oil expands and pressure increases

2. An internal short-circuit occurs and provokes an oil temperature rise.

An adjustable pressure captor detects overpressure in the transformers tank. It features a changeover

contact actuated by a soft membrane which deforms under pressure.

Go to Content

The DMCRs pressure captor is accessible from above, once the top removed

3. Temperature control

Visual check:

A needle thermometer indicates the

temperature inside the transformer.

Electrical check

Two identical adjustable thermostats detect

potential over-heating inside the transformer.

The thermostats feature a changeover

contact actuated bya diaphragm linked by a capillary tube to a temperature probe sitting deep inside the central

brass tube, which is immersed in the transformers tank. The capillary tube and probe are filled in with a liquid

which expands proportionally to the temperature surrounding the probe.

The ALARM thermostat detects a primary temperature threshold.

The TRIPPING thermostat detects a secondary temperature threshold, superior to the first.

DMCR - Tripping and alarm treshold settings

Go to Content

Resources:

MINERA Transformer Installation guide Schneider Electric

DMCR relay IDEF Systems

Edvard - Electrical engineer, programmer and founder of EEP. Highly specialized for design of

LV high power busbar trunking (<6300A) in power substations, buildings and industry fascilities.

Designing of LV/MV switchgears. Professional in AutoCAD programming and web-design.

Present on Google+.

Das könnte Ihnen auch gefallen

- Earth MatDokument6 SeitenEarth MatSmitha PatelNoch keine Bewertungen

- Earthing DesignDokument35 SeitenEarthing DesignDony SaputraNoch keine Bewertungen

- Vector Group Test Procedure for TransformersDokument4 SeitenVector Group Test Procedure for TransformersHamayoun Murtaza100% (2)

- PDS OperatorStationDokument7 SeitenPDS OperatorStationMisael Castillo CamachoNoch keine Bewertungen

- Mitsubishi diesel forklifts 1.5-3.5 tonnesDokument2 SeitenMitsubishi diesel forklifts 1.5-3.5 tonnesJoniNoch keine Bewertungen

- Earthing Distribution SubstationDokument10 SeitenEarthing Distribution SubstationJayadevDamodaranNoch keine Bewertungen

- Curacao CNG-LNG Terminal Feasibility StudyDokument262 SeitenCuracao CNG-LNG Terminal Feasibility StudyjamesbekNoch keine Bewertungen

- Technical Comparison of AIS Vs - Gis Substation OptDokument19 SeitenTechnical Comparison of AIS Vs - Gis Substation OptJayadevDamodaran100% (1)

- AutoCAD Mechanical 2015 Overview Brochure - A4Dokument4 SeitenAutoCAD Mechanical 2015 Overview Brochure - A4Raul ReynosoNoch keine Bewertungen

- Itp For Commissioning Procedure For LV Switchgear SystemDokument4 SeitenItp For Commissioning Procedure For LV Switchgear SystemSulimanNoch keine Bewertungen

- Inspection AND Test Procedures 7.6.4 Circuit Breakers, SFDokument7 SeitenInspection AND Test Procedures 7.6.4 Circuit Breakers, SFCarlos AguiarNoch keine Bewertungen

- Meggering Insulation Resistance TestingDokument3 SeitenMeggering Insulation Resistance TestingSugeng SumarnoNoch keine Bewertungen

- Design of Earthing SystemDokument5 SeitenDesign of Earthing SystemNishant SinhaNoch keine Bewertungen

- SOIL CHARACTERISTICSDokument10 SeitenSOIL CHARACTERISTICSRamesh AnanthanarayananNoch keine Bewertungen

- SP0407C01 HV Cable Commissioning Test ReportDokument2 SeitenSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNoch keine Bewertungen

- Ikan Di Kepualauan Indo-AustraliaDokument480 SeitenIkan Di Kepualauan Indo-AustraliaDediNoch keine Bewertungen

- Sip TrainingDokument96 SeitenSip Trainingronics123Noch keine Bewertungen

- Oil IndiaDokument445 SeitenOil IndiaJayadevDamodaranNoch keine Bewertungen

- Working principle and construction of a transformerDokument67 SeitenWorking principle and construction of a transformermartinez_josel100% (1)

- Substation EarthingDokument6 SeitenSubstation Earthingjpsridhar100% (1)

- Substation EarthingDokument6 SeitenSubstation Earthingjpsridhar100% (1)

- Starting a gas turbineDokument12 SeitenStarting a gas turbineHeri CovirgoNoch keine Bewertungen

- GPMC Profile SummaryDokument51 SeitenGPMC Profile SummaryJayadevDamodaranNoch keine Bewertungen

- Dry TR TestDokument9 SeitenDry TR Testamjaad100% (1)

- Pre-Commissioning Tests AC Equipment ListDokument5 SeitenPre-Commissioning Tests AC Equipment ListnagarajanNoch keine Bewertungen

- Disolved Gas in OltcDokument4 SeitenDisolved Gas in Oltcaljuhanim4260Noch keine Bewertungen

- Regulador de Voltage KVGC 202Dokument168 SeitenRegulador de Voltage KVGC 202mimiii36Noch keine Bewertungen

- VLF Test Unit HVA60Dokument2 SeitenVLF Test Unit HVA60Anonymous 1AAjd0Noch keine Bewertungen

- Dynamic Modeling of GE 1.5 andDokument31 SeitenDynamic Modeling of GE 1.5 andErtuğrul ÇamNoch keine Bewertungen

- Earthing Commissioning ProcedureDokument5 SeitenEarthing Commissioning Proceduresteve_osullivanNoch keine Bewertungen

- Erection Procedure For Control Battery - LatestDokument12 SeitenErection Procedure For Control Battery - LatestAnmohieyNoch keine Bewertungen

- DMCR Protection Relay For Oil TransformerDokument9 SeitenDMCR Protection Relay For Oil TransformerDawn HernandezNoch keine Bewertungen

- Solomons Organic Chemistry Solution Manual - Chapter 3Dokument12 SeitenSolomons Organic Chemistry Solution Manual - Chapter 3Imanghh25% (4)

- HT Breaker ChecklistDokument1 SeiteHT Breaker ChecklistElectrial DeptNoch keine Bewertungen

- Power Factor Regulator PDFDokument19 SeitenPower Factor Regulator PDFammha_tasmah100% (2)

- PRD - 3407 - Archivo - Preventive Om Checklist Inverter StationDokument7 SeitenPRD - 3407 - Archivo - Preventive Om Checklist Inverter StationRichie RimbaniNoch keine Bewertungen

- AEG Protect-8 INV ENDokument4 SeitenAEG Protect-8 INV ENibs434Noch keine Bewertungen

- Manual-4RY8812 Version 2.0Dokument36 SeitenManual-4RY8812 Version 2.0Katty MenaNoch keine Bewertungen

- OG Akım Gerilim TRF AK VK SerisiDokument19 SeitenOG Akım Gerilim TRF AK VK SerisiGeorge Asuncion100% (1)

- VCB ServiceDokument1 SeiteVCB ServiceimranNoch keine Bewertungen

- 3 038R R301 SF6 Multi AnalyserDokument3 Seiten3 038R R301 SF6 Multi AnalyserBen WeeNoch keine Bewertungen

- Self Dehydrating BreatherDokument12 SeitenSelf Dehydrating BreatherJOSE DANIEL PEREZNoch keine Bewertungen

- Akm Manual TD34 Ec10001Dokument12 SeitenAkm Manual TD34 Ec10001JOSE DANIEL PEREZNoch keine Bewertungen

- Buku PUIL 2011 Edisi 2014Dokument3 SeitenBuku PUIL 2011 Edisi 2014slamet_rNoch keine Bewertungen

- Cpr-3 - Catalouge Rele RubberDokument2 SeitenCpr-3 - Catalouge Rele Rubbermanuel100% (1)

- ABB REL5xx RIOConverterDokument10 SeitenABB REL5xx RIOConverterzinab90100% (1)

- 1030365248421-Mvap en 0899Dokument4 Seiten1030365248421-Mvap en 0899Stone123456789Noch keine Bewertungen

- Fundamental, Technology and Manufacturing in Indonesia: HV Power TransformerDokument82 SeitenFundamental, Technology and Manufacturing in Indonesia: HV Power TransformerAriNoch keine Bewertungen

- Kyn28-12安装使用说明书 Kyn28-12 Installation InstructionsDokument23 SeitenKyn28-12安装使用说明书 Kyn28-12 Installation Instructionshendrias_budiNoch keine Bewertungen

- Baur PGK25 Cable Test Set User ManualDokument1 SeiteBaur PGK25 Cable Test Set User ManualKuyan LesmanaNoch keine Bewertungen

- LT Panel Pre-Commissioning TestsDokument42 SeitenLT Panel Pre-Commissioning TestsDhivagar Namakkal100% (1)

- 1.6 Kva Transformer Testing ReportDokument5 Seiten1.6 Kva Transformer Testing ReportVikrant DeshmukhNoch keine Bewertungen

- IMS FORM Inspection and Test PlanDokument8 SeitenIMS FORM Inspection and Test PlanKrisnandha RahardianNoch keine Bewertungen

- Sfere Dts1946-t Energy MeterDokument5 SeitenSfere Dts1946-t Energy Metersujingthet50% (2)

- E110 - Motor Installation Checklist Rev 00 11.11Dokument2 SeitenE110 - Motor Installation Checklist Rev 00 11.11nayumNoch keine Bewertungen

- LV Switchgear Dielectric TestsDokument2 SeitenLV Switchgear Dielectric TestswaseemsamsodienNoch keine Bewertungen

- Direct-Coupled Damper Actuators for Modulating and Floating ControlDokument8 SeitenDirect-Coupled Damper Actuators for Modulating and Floating ControlLindEtjulietcapulet KplesetmontagueNoch keine Bewertungen

- Explanation of RoutineTests For FATs On Current Transformers According To IEC 60044Dokument6 SeitenExplanation of RoutineTests For FATs On Current Transformers According To IEC 60044Hung VuNoch keine Bewertungen

- 1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECDokument61 Seiten1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECRobert RocafuerteNoch keine Bewertungen

- Management and Safe Handling Procedures For (Sf6) GasDokument21 SeitenManagement and Safe Handling Procedures For (Sf6) GasKhaled KhaledNoch keine Bewertungen

- Erection Procedure For 6.6 KV Bus DuctDokument7 SeitenErection Procedure For 6.6 KV Bus DuctAnmohieyNoch keine Bewertungen

- 8BK88PLUSDokument8 Seiten8BK88PLUSSwapnil PatilNoch keine Bewertungen

- Series ZYD Operation ManualDokument11 SeitenSeries ZYD Operation ManualDaniel SubelzaNoch keine Bewertungen

- Test Report: Measurement of Turns RatioDokument2 SeitenTest Report: Measurement of Turns RatioJRC TestingNoch keine Bewertungen

- 7sr1206 Relay ModelDokument1 Seite7sr1206 Relay ModelSudipto MajumderNoch keine Bewertungen

- Testing Procedure For Earth Leakage RelayDokument1 SeiteTesting Procedure For Earth Leakage RelaySujintharan Nair100% (2)

- Dgt801b Gen - Unit ADokument30 SeitenDgt801b Gen - Unit ASamraddh TiwariNoch keine Bewertungen

- Old LT Panel 400 AmpDokument5 SeitenOld LT Panel 400 AmpAbhinav TewariNoch keine Bewertungen

- Turret CT &tan Delta ReportDokument4 SeitenTurret CT &tan Delta ReportSantosh BagadeNoch keine Bewertungen

- WI-NG-6460-002-085 Work Instruction For Relay & Control Panel Scheme and Function Test Rev00Dokument15 SeitenWI-NG-6460-002-085 Work Instruction For Relay & Control Panel Scheme and Function Test Rev00Mohamed NasrNoch keine Bewertungen

- Technical Data Fluokit m24 LengkapDokument20 SeitenTechnical Data Fluokit m24 LengkapAbdulhakk Agai100% (1)

- DMCR Protection Relay Monitors Oil TransformerDokument8 SeitenDMCR Protection Relay Monitors Oil Transformerabhi_akNoch keine Bewertungen

- Oil Transformer Protection RelayDokument7 SeitenOil Transformer Protection RelayAhmedNoch keine Bewertungen

- D.M.C.R. Protection Relay For Oil Transformer: ContentDokument8 SeitenD.M.C.R. Protection Relay For Oil Transformer: Contenttamer gamalNoch keine Bewertungen

- DGPT RelayDokument12 SeitenDGPT RelayfaizNoch keine Bewertungen

- DMCR Protection Relay For Oil TransformerDokument8 SeitenDMCR Protection Relay For Oil Transformerraul_bsuNoch keine Bewertungen

- DMCR Detection Measurement Control RelayDokument5 SeitenDMCR Detection Measurement Control RelayMuhammad AbuzarNoch keine Bewertungen

- DMCR Protection Reloy For Oil TransformersDokument9 SeitenDMCR Protection Reloy For Oil TransformersSugeng SumarnoNoch keine Bewertungen

- T&D UK Hazardous Area Electrical Equipment DistributorDokument8 SeitenT&D UK Hazardous Area Electrical Equipment DistributorJayadevDamodaranNoch keine Bewertungen

- Is 3043 EarthingDokument86 SeitenIs 3043 EarthingMohammed Areef SNoch keine Bewertungen

- Good Grounding PracticesDokument24 SeitenGood Grounding PracticesJayadevDamodaranNoch keine Bewertungen

- Ie Rules-1956Dokument191 SeitenIe Rules-1956Murali MohanNoch keine Bewertungen

- RefineryDokument5 SeitenRefineryJayadevDamodaranNoch keine Bewertungen

- Kds Tutorial GIS SubstationDokument357 SeitenKds Tutorial GIS SubstationmkbpgcilNoch keine Bewertungen

- Sub Stations 140318113806 Phpapp01Dokument51 SeitenSub Stations 140318113806 Phpapp01JayadevDamodaranNoch keine Bewertungen

- Electrical Substation General EquipmentsDokument22 SeitenElectrical Substation General EquipmentsAnoop DikshitNoch keine Bewertungen

- Solid Copper Earth Plate PDFDokument1 SeiteSolid Copper Earth Plate PDFJayadevDamodaranNoch keine Bewertungen

- Earthing PDFDokument40 SeitenEarthing PDFJayadevDamodaranNoch keine Bewertungen

- Design of Earthing System For HV Ac SubstationDokument9 SeitenDesign of Earthing System For HV Ac Substationwas00266Noch keine Bewertungen

- Solutions For Liquid and Gas Pipeline ManagementDokument4 SeitenSolutions For Liquid and Gas Pipeline ManagementJayadevDamodaranNoch keine Bewertungen

- Substation Grounding Study Specification: Name of Station Name of Location Number of Lines Number of CircuitsDokument7 SeitenSubstation Grounding Study Specification: Name of Station Name of Location Number of Lines Number of CircuitsDony SaputraNoch keine Bewertungen

- Earthing Calculation - Open ElectricalDokument12 SeitenEarthing Calculation - Open ElectricalsupermannonNoch keine Bewertungen

- The Power of TechnologyDokument24 SeitenThe Power of Technologycuongnv_19Noch keine Bewertungen

- Fuel Oil PDFDokument5 SeitenFuel Oil PDFJayadevDamodaranNoch keine Bewertungen

- Station Intermediate Class USDokument28 SeitenStation Intermediate Class USJayadevDamodaranNoch keine Bewertungen

- Troubleshooting Induction MotorsDokument14 SeitenTroubleshooting Induction MotorsImelda LadrilloNoch keine Bewertungen

- Makalah LED PDFDokument4 SeitenMakalah LED PDFMelissa WigginsNoch keine Bewertungen

- Example 3 - S-Beam CrashDokument13 SeitenExample 3 - S-Beam CrashSanthosh LingappaNoch keine Bewertungen

- Tutorial CorelDRAW-X8Dokument10 SeitenTutorial CorelDRAW-X8Ajay BhargavaNoch keine Bewertungen

- Windows Mbox Viewer User Manual 1.0.3.4Dokument33 SeitenWindows Mbox Viewer User Manual 1.0.3.4Billy NoelNoch keine Bewertungen

- Excel Dynamic Arrays: Department Item Quantity Price Total $Dokument5 SeitenExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousNoch keine Bewertungen

- VRV A 12 PDFDokument1 SeiteVRV A 12 PDFMoe Thiri ZunNoch keine Bewertungen

- QAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023Dokument1 SeiteQAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023LeroyNoch keine Bewertungen

- Unit 3: Databases & SQL: Developed By: Ms. Nita Arora Kulachi Hansraj Model School Ashok ViharDokument18 SeitenUnit 3: Databases & SQL: Developed By: Ms. Nita Arora Kulachi Hansraj Model School Ashok ViharAthira SomanNoch keine Bewertungen

- Sem 2Dokument128 SeitenSem 2Agustin A.Noch keine Bewertungen

- Is A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsDokument6 SeitenIs A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsGustavo CastroNoch keine Bewertungen

- MleplustutorialDokument13 SeitenMleplustutorialvorge daoNoch keine Bewertungen

- Shares Dan Yang Belum Diterbitkan Disebut Unissued SharesDokument5 SeitenShares Dan Yang Belum Diterbitkan Disebut Unissued Sharesstefanus budiNoch keine Bewertungen

- Product - 20V4000G24F 3B FODokument32 SeitenProduct - 20V4000G24F 3B FOmohammed khadrNoch keine Bewertungen

- Login Form: User Name Password Remember MeDokument8 SeitenLogin Form: User Name Password Remember MeBridget Anne BenitezNoch keine Bewertungen

- Lesson 1Dokument24 SeitenLesson 1Jayzelle100% (1)

- HFM Currency CubeDokument2 SeitenHFM Currency CubeSudhakar kNoch keine Bewertungen

- Unit-I-2-Marks-With-Ans3 Hydrology1 - BY Civildatas - Blogspot.in PDFDokument4 SeitenUnit-I-2-Marks-With-Ans3 Hydrology1 - BY Civildatas - Blogspot.in PDFHimanshu sharmaNoch keine Bewertungen

- Unit 10Dokument18 SeitenUnit 10ChaithraMalluNoch keine Bewertungen

- 171 - New CAN-filter For Cran Com. SCS4 and MidrangeDokument4 Seiten171 - New CAN-filter For Cran Com. SCS4 and MidrangeMohamed ElnagdyNoch keine Bewertungen

- Hot Rolled Sheet Pile SHZ Catalogue PDFDokument2 SeitenHot Rolled Sheet Pile SHZ Catalogue PDFkiet eelNoch keine Bewertungen

- OracleDokument23 SeitenOracleriza arifNoch keine Bewertungen

- VCTDS 00543 enDokument62 SeitenVCTDS 00543 enguido algaranazNoch keine Bewertungen

- Records of Intervention On The Findings of Test Results and Other Forms of AssessmentDokument10 SeitenRecords of Intervention On The Findings of Test Results and Other Forms of AssessmentLea May MagnoNoch keine Bewertungen

- Craig Vaughan CHPTR 07Dokument44 SeitenCraig Vaughan CHPTR 07Jorge CananeaNoch keine Bewertungen