Beruflich Dokumente

Kultur Dokumente

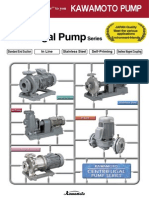

Centrifugal Pumps: Range of Performance Guarantee 2 Years Construction Characteristics

Hochgeladen von

Rik StevenOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Centrifugal Pumps: Range of Performance Guarantee 2 Years Construction Characteristics

Hochgeladen von

Rik StevenCopyright:

Verfügbare Formate

28

EN 60034-1

IEC 34-1

CEI 2-3

CONSTRUCTION AND SAFETY STANDARDS

RANGE OF PERFORMANCE

Flow rate up to 160 l/min (9.6 m

3

/h)

Head up to 58 m

LIMITS OF USE

Manometric suction lift up to 7 m

Liquid temperature up to + 90C

Liquid temperature up to + 40C in the CPX version

(with technopolymer impeller)

Environment temperature up to + 40C

centrifugal pumps

INSTALLATION AND USE

They are recommended for pumping clean water and liquids that are

chemically non aggressive to the materials from which the pump is made.

RELIABLE AND MAINTENANCE FREE THEY ARE WIDELY USED

IN THE DOMESTIC AND CIVIL SECTOR, IN PARTICULAR FOR

WATEER DISTRIBUTION IN COMBINATION WITH SMALL OR

MEDIUM PRESSURE SETS, FOR TRANSFER IN GENERAL, FOR

IRRIGATING GARDENS.

The pumps must be installed in enclosed places, or at least protected

against inclement weather.

GUARANTEE 2 YEARS subject to our general terms of sale.

CONSTRUCTION CHARACTERISTICS

PUMP BODY: cast iron, with threaded ports ISO 228/1.

BODY BACK-PLATE: stainless steel AISI 304 or cast iron on

higher powered models.

BRASS IMPELLER:

CP 100-CP 132-CP 152-CP 150-CP 170-CP 190-CP 200

STAINLESS STEEL IMPELLER:

CP 130-CP 158

MOTOR SHAFT: stainless steel EN 10088-3 - 1.4104.

MECHANICAL SEAL: ceramic - graphite - NBR.

ELECTRIC MOTOR: the pumps are close-coupled to a carefully

matched PEDROLLO electric motor, quiet running, totally enclosed

fan cooled (TEFC), suitable for continuous duty.

CPm: single-phase 230 V - 50 Hz with capacitor and thermal

overload protector built into the winding.

CP: three-phase230/400 V - 50 Hz.

INSULATION: class F. PROTECTION: IP 44.

REGISTERED MODEL n 72753.

OPTIONS ON REQUEST

impeller in technopolymer (CPm...X - CP...X)

special mechanical seal

other voltages or frequency 60 Hz

29

CP158

CP152

CP130

CP100

CP200

CP190

CP170

CP170M

CP150

CP132A

CP132B

CPm 100 CP 100 0.25 0.33

CPm 130 CP 130 0.37 0.50

CPm 132B CP 132B 0.45 0.60

CPm 132A CP 132A 0.60 0.85

CPm 152 CP 152 0.55 0.75

CPm 150 CP 150 0.75 1

CPm 158 CP 158 0.75 1

CPm 170 CP 170 1.1 1.5

CPm 170M CP 170M 1.1 1.5

CPm 190 CP 190 1.5 2

CP 200 2.2 3

0 0.6 1.2 1.8 2.4 3.0 3.6 4.2 4.8 5.4 6.0 6.6 7.2 7.8 8.4 9.0 9.6

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

16 15 14 12.5 11 9 7

23 22 21 20 19 18 17 15.5 14

20 18 17 16 15 13.5 12 10.5 9 7

23 22 21.5 21 20 19 18 17 16 14 12 9

33 32 31 29.5 28.5 27 25 23 19

29.5 29 28.5 28 27.5 26.5 26 24.5 23 21 18 15

36 34 33.5 33 32.5 31.5 30 28.5 27 25

41 38 37 36 35 33.5 32 30 27.5 25 22

36 35 34.5 33.5 33 32 31 30 29 28 26.5 25 23 21 19

50 46 44.5 43 41.5 40 38 36 34.5 32.5 30.5 28 26

58 55 54.5 53.5 52 51 49.5 48 46 44.5 42.5 40.5 38.5 36

Q

H

DN1 DN2 a f h h1 h2 n n1 w s 1~ 3~

CPm 100 CP 100 1" 1" 34 247 187 77 110 148 118 45 10 6.8 6.9

CPm 130 CP 130 1" 1" 42 259 205 82 123 165 135 41 10 7.8 7.6

CPm 132B CP 132B 1" 1" 42 259 205 82 123 165 135 41 10 8.0 7.5

CPm 132A CP 132A 1" 1" 42 266/259 205 82 123 165 135 41 10 8.4 8.1

CPm 152 CP 152 1" 1" 42 285 240 92 148 190 160 38 10 11.5 11.5

CPm 150 CP 150 1" 1" 42 285 240 92 148 190 160 38 10 12.5 11.3

CPm 158 CP 158 1" 1" 42 285 240 92 148 190 160 38 10 12.1 11.6

CPm 170-170M CP 170-170M 11/4" 1" 51 367 260 110 150 206 165 44.5 11 19.2 18.5

CPm 190 CP 190 11/4" 1" 51 338 290 115 175 242 206 32.5 11 25.0 24.2

CP 200 11/4" 1" 51.5 338 290 115 175 242 206 32.5 11 - 25.5

1" 1"

11/4" 1"

42

285 240 92 148 190 160 38

10

259

205 82 123 165 135 41

290 115 175

242 206 32.5 364

f

a

DN2

w

D

N

1

n

h

h

1

h

2

n1

s

DIMENSIONS AND WEIGHTS

CURVES AND PERFORMANCE DATA AT n= 2900 1/min

Flow rate Q

H

e

a

d

H

(

m

e

t

r

e

s

)

TYPE POWER

m

3

/h

Single-phase Three-phase kW HP l/min

Q = Flow rate H = Total manometric head Tolerance of the performance curves according to EN ISO 9906 App. A.

metres

TYPE PORTS DIMENSIONS mm kg

Single-phase Three-phase

Das könnte Ihnen auch gefallen

- MEM18002B Use Power Tools Hand Held Operations - Learner GuideDokument9 SeitenMEM18002B Use Power Tools Hand Held Operations - Learner Guidequestionbank.com.au0% (1)

- Chilled Water Pump Head CalculationDokument18 SeitenChilled Water Pump Head CalculationMohammed Ahmed Khan88% (8)

- Fagor 2lf-013sxDokument10 SeitenFagor 2lf-013sxSalome Cuerda100% (1)

- Faulhaber DatasheetDokument5 SeitenFaulhaber DatasheetMuhammad SharifNoch keine Bewertungen

- Midea 2005 Split Service ManualDokument359 SeitenMidea 2005 Split Service ManualSotiris Ioannou60% (5)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- F1267Dokument6 SeitenF1267pratishgnairNoch keine Bewertungen

- Kemira, Leonard Dan Bethel Acid FormicDokument22 SeitenKemira, Leonard Dan Bethel Acid FormicBen Yudha SatriaNoch keine Bewertungen

- Ferrography PosterDokument1 SeiteFerrography PosterDAnielNoch keine Bewertungen

- Centrifugal Pumps: Installation and Use Performance RangeDokument4 SeitenCentrifugal Pumps: Installation and Use Performance RangeRik StevenNoch keine Bewertungen

- CPDokument4 SeitenCPingearroyoNoch keine Bewertungen

- Catalogo Bombas PedrolloDokument80 SeitenCatalogo Bombas PedrolloChesster EscobarNoch keine Bewertungen

- Goulds Pumps: Dimensions and Weights 15SV Series 3500 RPMDokument2 SeitenGoulds Pumps: Dimensions and Weights 15SV Series 3500 RPMOscar CruzNoch keine Bewertungen

- Technical Data 37 FlaredDokument13 SeitenTechnical Data 37 FlaredhernychtNoch keine Bewertungen

- Electrical Panel Load Calculation (22.8.12)Dokument28 SeitenElectrical Panel Load Calculation (22.8.12)Erfan AhmedNoch keine Bewertungen

- Ferraz Shawmut High Voltage Fuses CatalogueDokument93 SeitenFerraz Shawmut High Voltage Fuses CataloguerocketvtNoch keine Bewertungen

- Fuel Oil PumpDokument8 SeitenFuel Oil PumprezashahalamNoch keine Bewertungen

- Stock Saer Al 10 12 19Dokument36 SeitenStock Saer Al 10 12 19Manuel Dos SantosNoch keine Bewertungen

- Vitomax 200HSDokument14 SeitenVitomax 200HSDamir ĆavarNoch keine Bewertungen

- Tour and Andersson MD60 SpecificationsDokument14 SeitenTour and Andersson MD60 SpecificationsblindjaxxNoch keine Bewertungen

- Catalog Profile Cu Pereti SubtiriDokument52 SeitenCatalog Profile Cu Pereti Subtirinelutu12345100% (1)

- Water Chillers R407C - R22: Air Cooled Water Chillers With Scroll Compressors and Axial FansDokument4 SeitenWater Chillers R407C - R22: Air Cooled Water Chillers With Scroll Compressors and Axial FansgoodtiNoch keine Bewertungen

- Uniworld: Series Pneumatic ValvesDokument2 SeitenUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- Series 919 Specification SheetDokument4 SeitenSeries 919 Specification SheetWattsNoch keine Bewertungen

- Gate Globe Check Valves FlowDokument6 SeitenGate Globe Check Valves FlowIPSITNoch keine Bewertungen

- Catalogo Regulador Watts Mod 152-ADokument2 SeitenCatalogo Regulador Watts Mod 152-AGuatemalan1979Noch keine Bewertungen

- ZXSpectrum128+2 ServiceManualDokument12 SeitenZXSpectrum128+2 ServiceManualrisxcNoch keine Bewertungen

- C&D Front Acces PDFDokument0 SeitenC&D Front Acces PDFPaul RasmussenNoch keine Bewertungen

- Ebara Pumps Catalog DVS CatalogueDokument30 SeitenEbara Pumps Catalog DVS CataloguePutry Tria ChristyNoch keine Bewertungen

- Exhaust Gas Brochure - Issue K PDFDokument12 SeitenExhaust Gas Brochure - Issue K PDFFrancisco Mosquera LopezNoch keine Bewertungen

- GFM Marking - Smcj33a TvsDokument4 SeitenGFM Marking - Smcj33a TvscraponzelNoch keine Bewertungen

- PNEUMATEX TervezesiSegedlet PlanningDokument24 SeitenPNEUMATEX TervezesiSegedlet Planningatisz333Noch keine Bewertungen

- Valve CalculationDokument2 SeitenValve Calculationjay_rajeshirkeNoch keine Bewertungen

- Series 909 Specification SheetDokument4 SeitenSeries 909 Specification SheetWattsNoch keine Bewertungen

- Someflu FP ECO-N ENDokument2 SeitenSomeflu FP ECO-N ENAnonymous r3MoX2ZMTNoch keine Bewertungen

- MDFO UK LowDokument17 SeitenMDFO UK Lowmsn86Noch keine Bewertungen

- Series 909RPDA Specification SheetDokument4 SeitenSeries 909RPDA Specification SheetWattsNoch keine Bewertungen

- Almig Belt GB WebDokument8 SeitenAlmig Belt GB WebIPV_UANoch keine Bewertungen

- Analog and Digital Circuits Laboratory: Analog Experiment: Common Source AmplifierDokument11 SeitenAnalog and Digital Circuits Laboratory: Analog Experiment: Common Source AmplifierSanjai SenthilNoch keine Bewertungen

- TS Apollo 50Dokument8 SeitenTS Apollo 50Carlos GonzalezNoch keine Bewertungen

- Pumps With Peripheral Impeller: Performance Range Installation and UseDokument4 SeitenPumps With Peripheral Impeller: Performance Range Installation and UseRik StevenNoch keine Bewertungen

- Whirlpool Aw G 372 WPDokument12 SeitenWhirlpool Aw G 372 WPsandorio1964Noch keine Bewertungen

- Flow MeterDokument6 SeitenFlow MeterYvoSteentjes100% (1)

- Ickola PDFDokument92 SeitenIckola PDFMiloš MarkovićNoch keine Bewertungen

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Dokument5 SeitenVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNoch keine Bewertungen

- BoqDokument18 SeitenBoqPradeep Yallanki100% (1)

- ECTI ProductCatalogueDokument16 SeitenECTI ProductCatalogueCorazón GrandeNoch keine Bewertungen

- G93 123keDokument3 SeitenG93 123kejclevox100% (1)

- 100 SeriesDokument5 Seiten100 Seriesfathur2107Noch keine Bewertungen

- Techanicaldiary 490 MW PDFDokument13 SeitenTechanicaldiary 490 MW PDFsauravyadav33Noch keine Bewertungen

- OPGW - Sag - Tension - TCGY To MBRSDokument4 SeitenOPGW - Sag - Tension - TCGY To MBRSJayabalan R KNoch keine Bewertungen

- Flow Cal. Intervalve BVDokument3 SeitenFlow Cal. Intervalve BVf_riseNoch keine Bewertungen

- Reduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesDokument2 SeitenReduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesWattsNoch keine Bewertungen

- SDM 102 eDokument24 SeitenSDM 102 eseaqu3stNoch keine Bewertungen

- Centrifugal PumpDokument32 SeitenCentrifugal PumpAhmadMoaazNoch keine Bewertungen

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsVon EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsBewertung: 5 von 5 Sternen5/5 (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Group 15. Mechanics of Fluids: Vocabulary of Mechanics in Five Languages: English/German/French/Polish/Russian, Vol. 2Von EverandGroup 15. Mechanics of Fluids: Vocabulary of Mechanics in Five Languages: English/German/French/Polish/Russian, Vol. 2Bewertung: 1.5 von 5 Sternen1.5/5 (3)

- Sni KersDokument1 SeiteSni KersRik StevenNoch keine Bewertungen

- Ac DCDokument4 SeitenAc DCRik StevenNoch keine Bewertungen

- Piles KoDokument3 SeitenPiles KoRik StevenNoch keine Bewertungen

- 1 ADokument1 Seite1 ARik StevenNoch keine Bewertungen

- D Sacra 00008434Dokument4 SeitenD Sacra 00008434Rik StevenNoch keine Bewertungen

- BonsaDokument3 SeitenBonsaRik StevenNoch keine Bewertungen

- Sampan JDokument1 SeiteSampan JRik StevenNoch keine Bewertungen

- KatalogBC525 Data SheetnnnDokument0 SeitenKatalogBC525 Data SheetnnnRik StevenNoch keine Bewertungen

- Thomson ICC4Dokument5 SeitenThomson ICC4Rik StevenNoch keine Bewertungen

- Nov Vic1Dokument1 SeiteNov Vic1Rik StevenNoch keine Bewertungen

- CP 2Dokument12 SeitenCP 2Rik StevenNoch keine Bewertungen

- Salati 1Dokument1 SeiteSalati 1Rik StevenNoch keine Bewertungen

- Design Note 1 ADokument9 SeitenDesign Note 1 ARik StevenNoch keine Bewertungen

- Standardised "EN 733" Centrifugal Pumps: Installation and Use Performance RangeDokument28 SeitenStandardised "EN 733" Centrifugal Pumps: Installation and Use Performance RangeRik StevenNoch keine Bewertungen

- Pumps With Peripheral Impeller: Performance Range Installation and UseDokument4 SeitenPumps With Peripheral Impeller: Performance Range Installation and UseRik StevenNoch keine Bewertungen

- 7471371917224HF Medium Flow Rates - enDokument5 Seiten7471371917224HF Medium Flow Rates - enRik StevenNoch keine Bewertungen

- Plymouth UsaDokument32 SeitenPlymouth UsaRik StevenNoch keine Bewertungen

- Pumps With Peripheral Impeller: Performance Range Installation and UseDokument4 SeitenPumps With Peripheral Impeller: Performance Range Installation and UseRik StevenNoch keine Bewertungen

- KatalogBC525 Data SheetnnnDokument0 SeitenKatalogBC525 Data SheetnnnRik StevenNoch keine Bewertungen

- Plymouth UsaDokument32 SeitenPlymouth UsaRik StevenNoch keine Bewertungen

- Pumps With Peripheral Impeller: Performance Range Installation and UseDokument4 SeitenPumps With Peripheral Impeller: Performance Range Installation and UseRik StevenNoch keine Bewertungen

- BC337Dokument3 SeitenBC337Emanuele100% (2)

- BC 635Dokument4 SeitenBC 635Floricica Victor VasileNoch keine Bewertungen

- BC 635Dokument4 SeitenBC 635Floricica Victor VasileNoch keine Bewertungen

- BC337Dokument3 SeitenBC337Emanuele100% (2)

- BC337Dokument3 SeitenBC337Emanuele100% (2)

- BC337Dokument3 SeitenBC337Emanuele100% (2)

- BC 635Dokument4 SeitenBC 635Floricica Victor VasileNoch keine Bewertungen

- Copper Technology and CompetitivenessDokument267 SeitenCopper Technology and CompetitivenessleniucvasileNoch keine Bewertungen

- Water Jet MachiningDokument20 SeitenWater Jet MachiningRazvan MargineanNoch keine Bewertungen

- Cold RolledDokument18 SeitenCold RolledkhurshedlakhoNoch keine Bewertungen

- TS en 10120 - 2010Dokument12 SeitenTS en 10120 - 2010Çağlar EbeperiNoch keine Bewertungen

- Material With Specific Magnetic PropertiesDokument23 SeitenMaterial With Specific Magnetic PropertiesFiki FirdausNoch keine Bewertungen

- Title: Minimum Requirements On Welding From Supplier and Sub-SupplierDokument10 SeitenTitle: Minimum Requirements On Welding From Supplier and Sub-SupplierDeepak DasNoch keine Bewertungen

- European Steel Scrap Specification: General Conditions Applicable To All GradesDokument5 SeitenEuropean Steel Scrap Specification: General Conditions Applicable To All GradesdzizicNoch keine Bewertungen

- Abs Approved Steel Mills PDFDokument129 SeitenAbs Approved Steel Mills PDFravmansion100% (1)

- 130508-100817-EVertical Multistage Centrifugal Electric Pumps Available in Various Versions: Cast Iron (EVMG), AISI 304 Stainless Steel (EVM), AISI 316 Stainless Steel (EVML) .VM - EngDokument35 Seiten130508-100817-EVertical Multistage Centrifugal Electric Pumps Available in Various Versions: Cast Iron (EVMG), AISI 304 Stainless Steel (EVM), AISI 316 Stainless Steel (EVML) .VM - Engaco1970Noch keine Bewertungen

- API 510 Openbook QuestionDokument25 SeitenAPI 510 Openbook QuestionMastram Hathesh100% (6)

- Weld Filler Metal SelectionDokument7 SeitenWeld Filler Metal SelectionsusanwebNoch keine Bewertungen

- Tubular Bell Wind Chime Design and Build Compendium by Lee HiteDokument51 SeitenTubular Bell Wind Chime Design and Build Compendium by Lee HiteNoircheval100% (2)

- 6KramerFurnaceMaintenance PDFDokument3 Seiten6KramerFurnaceMaintenance PDFcarrialdiNoch keine Bewertungen

- Balancing Chemical Equations From Names - Answers - Page 1 of 5Dokument5 SeitenBalancing Chemical Equations From Names - Answers - Page 1 of 5Raja WajahatNoch keine Bewertungen

- ASME IX Interpretations No. 14Dokument10 SeitenASME IX Interpretations No. 14Justin MorseNoch keine Bewertungen

- Hybrid Electrochemical ProcessesDokument19 SeitenHybrid Electrochemical ProcessesYahya Abdelhameed AamerNoch keine Bewertungen

- Boran Family PDFDokument6 SeitenBoran Family PDFggk2013Noch keine Bewertungen

- Ansi C 119.4Dokument28 SeitenAnsi C 119.4Cristóbal de la RosaNoch keine Bewertungen

- Market Survey - Manganese OreDokument235 SeitenMarket Survey - Manganese Oremujib uddin siddiqui100% (1)

- 27 AprvdSawDokument19 Seiten27 AprvdSawMarleneLopesNoch keine Bewertungen

- Fasteners-Technical Data and ChartsDokument15 SeitenFasteners-Technical Data and ChartsChrill DsilvaNoch keine Bewertungen

- TCE 5107 Course OutlineDokument4 SeitenTCE 5107 Course OutlinekudaNoch keine Bewertungen

- SIE SA PanelboardsP1-P5Dokument84 SeitenSIE SA PanelboardsP1-P5asim saeedNoch keine Bewertungen

- Single Phase Pad Mounted Transformer Specifications For Constumers and Electrical ContractorsDokument37 SeitenSingle Phase Pad Mounted Transformer Specifications For Constumers and Electrical ContractorsJuan Juan100% (1)

- C75C - Ck75 Steel DataDokument2 SeitenC75C - Ck75 Steel DatavinibeNoch keine Bewertungen

- Complete Piping Training Course PresentationDokument446 SeitenComplete Piping Training Course Presentationrammech85100% (1)