Beruflich Dokumente

Kultur Dokumente

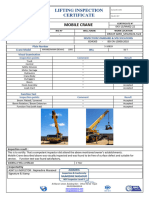

Hoist Load Test Report

Hochgeladen von

Soedarjoto S100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

448 Ansichten2 SeitenReport for hoist load test

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenReport for hoist load test

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

448 Ansichten2 SeitenHoist Load Test Report

Hochgeladen von

Soedarjoto SReport for hoist load test

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

HOIST LOAD TEST REPORT

MANUFACTURER: _______________________________ SN. ____________

BLDG. # EQUIPMENT # ________________ CAPACITY: ____________

Notes:

1. Load test prior to initial use, at 125% of rated capacity, all new hoists or hoists in which load-sustaining

parts have been modified, repaired, or replaced. Test weights must be accurate to within 5%, +0% of

stipulated values. Load test at 100% of rated capacity hoists with overload devices. Test the function of the

overload device.

2. Qualified inspector must verify all steps as listed below.

---------------------------------------------------------------------------------------------------------------------

_____ 1. Perform the periodic inspection. Check unit for proper operation.

______2. HAND-CHAIN-OPERATED HOISTS ONLY. Check brake mechanism for work glazed, or

contaminated disks, worn pawls, cams, or ratchets. Check for broken, corroded, or stretched

pawl springs. Repair as needed.

______3. ELECTRIC-AND AIR-POWERED HOISTS. Check:

a. All functional operating mechanisms for maladjustment interfering with proper operation

b. Limit switches or devices for proper operation

c. External evidence of damage or excessive wear of load sprockets, idler sprockets, and drums or

sheaves

d. External evidence of wear on motor or load brake

e. Electrical apparatus for signs of pitting or any deterioration of visible controller contacts

f. All anchorage or hoist suspensions.

_____ 4. Set hoist up for load test and inspection. Where applicable, ensure that the load chart is legible.

_____ 5. Perform load test using the required test weights (See Note 1) and appropriate slings.

_____ 6.Measure a length of the load chain under tension; measure a length of 15 links. If wire rope is

used, then measure the diameter.

IF HOIST IS EQUIPPED WITH A TROLLEY:

______1. Mount hoist on a monorail.

______2. Rig test weight to load hook

_______3. Perform load test raise and hold load for 10 minutes check brakes during hoisting and lowering,

moving weight along monorail. Observe hoist and trolley. Observe performance of all load-

bearing components.

_______4. Lower test weight to floor. Note performance of hoist during lowering operation. Remove

rigging.

6.1/12911e041.pdf 1 (12/2007)

At the completion of the load test, inspect the following items:

1. Visually inspect and remeasure the load chain and/or hoist rope after the load test. Check for deformed or

broken links, stretch, etc. No more than a 10% permanent stretch in load chain is acceptable, and a wire

rope decrease of 1/64 up to 5/16, 1/32 up to 1/2 , 3/64 up to 3/4 1/16 up to 1 1/8 and 3/32 up to 1 .

2. Inspect load hook and suspension hook for bending or twisting.

LOAD HOOK: PREVIOUS PRESENT

Qualified Inspector Verify _______ Throat Opening ___________ _____ ____

Qualified Inspector Verify _______ Hook Twist _______________ ____________

SUSPENSION HOOK:

Qualified Inspector Verify _______ Throat Opening ____________ ____________

Qualified Inspector Verify _______ Hook Twist ________________ ____________

Qualified inspector must perform nondestructive tests on hook by visual examination, liquid penetrant

examination, or magnetic particle examination.

Acceptance: No cracks, linear indications, laps, or seams.

Hooks with any distortion causing an increase in the throat opening of 5% not to exceed of

original throat opening, hooks with any visible bend or twist from the original plane of the hook,

and hooks having any wear exceeding 10% of original must be replaced.

Lubricate hook bearing and latch pin, as applicable.

Establish three marks, A, B, and C, with a center punch. For ease in measuring, set distances on a whole

number of inches. A to B measurement should equal B to C measurement.

BEFORE LOAD TEST

Length AB _________ in

Length BC _________ in

AFTER LOAD TEST

Length AB _________ in

Length BC _________ in

Check for:

1. Wear and deformation

2. Cracks

3. Signs of opening between Point A and Point B.

(use the B to C marks as a reference)

Qualified Inspector: ________________ Equipment Operator: __________________

Actual Load Test: __________________ Percentage of Rated Capacity: __________

Load Test Inspection Date: ____________ BNL Inspection Tag # __________________

Remarks:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

6.1/12911e041.pdf 2 (12/2007)

Das könnte Ihnen auch gefallen

- Mobile Crane Load TestDokument4 SeitenMobile Crane Load TestMeritorious KhanNoch keine Bewertungen

- Solo Run For MotorsDokument8 SeitenSolo Run For MotorsMohamed Haleem100% (1)

- Fire Extingusiher Inspection, Maintenance, and Testing ProceduresDokument5 SeitenFire Extingusiher Inspection, Maintenance, and Testing ProceduresSumathi Sundaram SundaramNoch keine Bewertungen

- EIAC Requirements TrainingDokument52 SeitenEIAC Requirements TrainingFarrukh AhmedNoch keine Bewertungen

- HT Panel QapDokument2 SeitenHT Panel QapAlla Naveen KumarNoch keine Bewertungen

- E-Plant Earthing Layout-R2 27.09.2022Dokument1 SeiteE-Plant Earthing Layout-R2 27.09.2022Electrical RadicalNoch keine Bewertungen

- Crane Inspection ChecklistDokument2 SeitenCrane Inspection ChecklistRahul DhaneNoch keine Bewertungen

- 1-03-036!04!0 Inspection of Repaired MotorDokument19 Seiten1-03-036!04!0 Inspection of Repaired MotorAhmed AshourNoch keine Bewertungen

- Crane Load Test ProcedureDokument3 SeitenCrane Load Test ProcedureBadeng LawotNoch keine Bewertungen

- Overhead Crane SadDokument30 SeitenOverhead Crane SadVicky GautamNoch keine Bewertungen

- Elect-Ttip-05 - Inspection and Test Plan For Ring Main Unit (Rmu) - R1Dokument1 SeiteElect-Ttip-05 - Inspection and Test Plan For Ring Main Unit (Rmu) - R1Muhammad IrfanNoch keine Bewertungen

- Inspection Checklist Overhead Crane PDFDokument2 SeitenInspection Checklist Overhead Crane PDFMOST PASONNoch keine Bewertungen

- Visual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsDokument2 SeitenVisual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsrajuajiNoch keine Bewertungen

- EotDokument16 SeitenEotMayuresh GoregaonkarNoch keine Bewertungen

- HV TestDokument4 SeitenHV TestNaveedNoch keine Bewertungen

- Portacabin Inspection ChecklistDokument2 SeitenPortacabin Inspection ChecklistApm FoumilNoch keine Bewertungen

- Motors Solo Run TestDokument2 SeitenMotors Solo Run TestSureshYarlagaddaNoch keine Bewertungen

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADokument2 SeitenSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDokument3 SeitenFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005Noch keine Bewertungen

- Inspection and Test Plan For Switchgear: Before ManufacturingDokument5 SeitenInspection and Test Plan For Switchgear: Before ManufacturingELE FutureWillNoch keine Bewertungen

- Method Statement - Polarity TestDokument5 SeitenMethod Statement - Polarity TestKhaled Badawy100% (1)

- Overhead Crane - FunctionTestProcedureDokument15 SeitenOverhead Crane - FunctionTestProcedurepetazNoch keine Bewertungen

- Introduction To Switch Gear and ProtectionDokument12 SeitenIntroduction To Switch Gear and ProtectionKrishna PrasadNoch keine Bewertungen

- SOP - Electrical EarthingDokument10 SeitenSOP - Electrical EarthingJitendra kumarNoch keine Bewertungen

- Mobile Cranes Check ListDokument6 SeitenMobile Cranes Check ListBanesco TemplarisNoch keine Bewertungen

- DC - Traction Motor 752RS1A-Final Test ReportDokument5 SeitenDC - Traction Motor 752RS1A-Final Test ReportGaurav ChaudharyNoch keine Bewertungen

- Deck Cranes PDFDokument7 SeitenDeck Cranes PDFIndra Ranu KusumaNoch keine Bewertungen

- Mobile Crane Test Procedure.Dokument4 SeitenMobile Crane Test Procedure.Deepak GehlotNoch keine Bewertungen

- Crane DEMAG Cert 03-08-2022Dokument1 SeiteCrane DEMAG Cert 03-08-2022Omar ZarrougNoch keine Bewertungen

- Inspection and Test Plan For Induction MotorDokument5 SeitenInspection and Test Plan For Induction MotorDino PedutoNoch keine Bewertungen

- KS1-Power Boiler First Inspection Guide ListDokument14 SeitenKS1-Power Boiler First Inspection Guide ListArul Kumaran KothandapaniNoch keine Bewertungen

- Overhead Crane Inspection ProcedureDokument2 SeitenOverhead Crane Inspection ProcedureEphraim John Tangelon AquinoNoch keine Bewertungen

- Electrical Insulation and Thermal Measurements For Motors and Drives AnDokument4 SeitenElectrical Insulation and Thermal Measurements For Motors and Drives Anmu_ignoreNoch keine Bewertungen

- Overhead Crane Pre Shift InspectionDokument1 SeiteOverhead Crane Pre Shift InspectionRafflesia GroupNoch keine Bewertungen

- Operating and MaintenanceDokument3 SeitenOperating and Maintenancesoni90kumarNoch keine Bewertungen

- Inspection and Test Plan For Power Transformer PDFDokument6 SeitenInspection and Test Plan For Power Transformer PDFSiva Kumar100% (1)

- Ractical Training Seminar: Balveer Singh 132 KV G.S.S. Ultratech Cement LTDDokument14 SeitenRactical Training Seminar: Balveer Singh 132 KV G.S.S. Ultratech Cement LTDAnupriya PandeyNoch keine Bewertungen

- Inspection and Testing Plan of Electrical Equipment Procedure May 2013 PDFDokument19 SeitenInspection and Testing Plan of Electrical Equipment Procedure May 2013 PDFUjang Sonjaya100% (1)

- LEEA Correspondence Courses: Assignment 1.3Dokument3 SeitenLEEA Correspondence Courses: Assignment 1.3alexedamalaNoch keine Bewertungen

- Crawler Crane ChecklistDokument2 SeitenCrawler Crane ChecklistAnuraj100% (1)

- Test Procedure TXDokument4 SeitenTest Procedure TXVasu100% (1)

- JSA For MPIDokument3 SeitenJSA For MPIMohammed MinhajNoch keine Bewertungen

- Ametek Land User Guide 4500 MKIIIDokument128 SeitenAmetek Land User Guide 4500 MKIIIwarawutNoch keine Bewertungen

- Inspection and Maintenance of Drillpipe Ebook PDFDokument39 SeitenInspection and Maintenance of Drillpipe Ebook PDFAntónio OliveiraNoch keine Bewertungen

- Overhead CraneDokument18 SeitenOverhead Craneemail2yogeshshindeNoch keine Bewertungen

- LV Dielectric TestingDokument2 SeitenLV Dielectric TestingwaseemsamsodienNoch keine Bewertungen

- How To Use A Megger Insulation TesterDokument2 SeitenHow To Use A Megger Insulation TesterRakesh Babu0% (1)

- Hose Test MethodsDokument5 SeitenHose Test MethodstriagusmanNoch keine Bewertungen

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistDokument1 SeiteHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioNoch keine Bewertungen

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDokument2 SeitenThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNoch keine Bewertungen

- T&C ManualDokument65 SeitenT&C ManualKarthikeyan S100% (1)

- CT Secondary InjectionDokument2 SeitenCT Secondary InjectionHumayun AhsanNoch keine Bewertungen

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDokument9 SeitenCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNoch keine Bewertungen

- LE Inspection Procedure-02Dokument156 SeitenLE Inspection Procedure-02Moetaz MohamedNoch keine Bewertungen

- Itp UpsDokument4 SeitenItp UpsAshraf MohammedNoch keine Bewertungen

- Load Test Inspection FormDokument3 SeitenLoad Test Inspection FormIziyon Harrison OsalobohNoch keine Bewertungen

- Mobile Crane Load Test Report FormDokument4 SeitenMobile Crane Load Test Report FormBayuo2k100% (3)

- Overhead Crane Load Test ProceduresDokument6 SeitenOverhead Crane Load Test ProceduresMeritorious Khan100% (5)

- Mobile CranesDokument7 SeitenMobile CranesEr Faiyaz Ahmed100% (1)

- Crane OperationDokument67 SeitenCrane OperationErc Nunez V100% (2)

- Scaffold User in Construction: ©2010 Grainger Safety Services, IncDokument34 SeitenScaffold User in Construction: ©2010 Grainger Safety Services, Inckanakarao1100% (1)

- Tech Brief 3 PDFDokument14 SeitenTech Brief 3 PDFSoedarjoto SNoch keine Bewertungen

- Iso 45000Dokument25 SeitenIso 45000Sharaf Ageed75% (8)

- Komparasi Iso 9001 Vs Iso 14001 Vs 45001Dokument2 SeitenKomparasi Iso 9001 Vs Iso 14001 Vs 45001Soedarjoto S100% (2)

- Energized Electrical SafetyDokument22 SeitenEnergized Electrical SafetySoedarjoto SNoch keine Bewertungen

- 5-ISO 45001 - Vs 14001 Vs 9001 PDFDokument16 Seiten5-ISO 45001 - Vs 14001 Vs 9001 PDFSoedarjoto SNoch keine Bewertungen

- Hse-Saf-55 Petronas 10 Zero Tolerance RulesDokument18 SeitenHse-Saf-55 Petronas 10 Zero Tolerance RulesSoedarjoto S80% (5)

- Hoist Inspection ManualDokument71 SeitenHoist Inspection ManualErc Nunez V100% (3)

- Lever Operated Chain HoistDokument64 SeitenLever Operated Chain HoistSoedarjoto SNoch keine Bewertungen

- Hand Chain BlockDokument12 SeitenHand Chain BlockSoedarjoto SNoch keine Bewertungen

- Hoist Safety Inspection CGv2Dokument1 SeiteHoist Safety Inspection CGv2Soedarjoto SNoch keine Bewertungen

- Bamboo ScaffoldingDokument2 SeitenBamboo ScaffoldingSoedarjoto SNoch keine Bewertungen

- Guidelines On The Design and Construction of Bamboo ScaffoldsDokument24 SeitenGuidelines On The Design and Construction of Bamboo ScaffoldsRizwan MirzaNoch keine Bewertungen

- Bamboo Scaffolding Guidance NotesDokument9 SeitenBamboo Scaffolding Guidance NotesSoedarjoto SNoch keine Bewertungen

- A Guide To Selecting Appropriate Tools To Improve HSE CultureDokument24 SeitenA Guide To Selecting Appropriate Tools To Improve HSE CultureSAYED100% (3)

- Bamboo ScaffoldingDokument2 SeitenBamboo ScaffoldingSoedarjoto SNoch keine Bewertungen

- Lesson 23 Career PathwaysDokument34 SeitenLesson 23 Career PathwaysAlfredo ModestoNoch keine Bewertungen

- 5000-5020 en PDFDokument10 Seiten5000-5020 en PDFRodrigo SandovalNoch keine Bewertungen

- Patricio Gerpe ResumeDokument2 SeitenPatricio Gerpe ResumeAnonymous 3ID4TBNoch keine Bewertungen

- Context in TranslationDokument23 SeitenContext in TranslationRaluca FloreaNoch keine Bewertungen

- Geopolymer Book Chapter1 PDFDokument37 SeitenGeopolymer Book Chapter1 PDFDick ManNoch keine Bewertungen

- Assignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Dokument8 SeitenAssignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Ren ZkNoch keine Bewertungen

- Case Study in Architectural Structures: A-7E Avionics System - ADokument36 SeitenCase Study in Architectural Structures: A-7E Avionics System - Ajckz8Noch keine Bewertungen

- CP3 - June2019 2Dokument5 SeitenCP3 - June2019 2Sifei ZhangNoch keine Bewertungen

- PRINCIPLES OF TEACHING NotesDokument24 SeitenPRINCIPLES OF TEACHING NotesHOLLY MARIE PALANGAN100% (2)

- Agency Procurement Request: Ipil Heights Elementary SchoolDokument1 SeiteAgency Procurement Request: Ipil Heights Elementary SchoolShar Nur JeanNoch keine Bewertungen

- Ibragimova Lesson 4Dokument3 SeitenIbragimova Lesson 4Dilnaz IbragimovaNoch keine Bewertungen

- SAP HCM Case StudyDokument17 SeitenSAP HCM Case StudyRafidaFatimatuzzahraNoch keine Bewertungen

- History of Old English GrammarDokument9 SeitenHistory of Old English GrammarAla CzerwinskaNoch keine Bewertungen

- 2 Calculation ProblemsDokument4 Seiten2 Calculation ProblemsFathia IbrahimNoch keine Bewertungen

- Synchronous Machines-1Dokument41 SeitenSynchronous Machines-1Rouxcel abutoNoch keine Bewertungen

- IFSSO Newsletter Jul-Sep 2010Dokument2 SeitenIFSSO Newsletter Jul-Sep 2010rjotaduranNoch keine Bewertungen

- Distillation ColumnDokument22 SeitenDistillation Columndiyar cheNoch keine Bewertungen

- Chemistry II EM Basic Learning MaterialDokument40 SeitenChemistry II EM Basic Learning MaterialMAHINDRA BALLANoch keine Bewertungen

- Reflective Memo 1-PracticumDokument5 SeitenReflective Memo 1-Practicumapi-400515862Noch keine Bewertungen

- RADMASTE CAPS Grade 11 Chemistry Learner GuideDokument66 SeitenRADMASTE CAPS Grade 11 Chemistry Learner Guideamajobe34Noch keine Bewertungen

- PUPiApplyVoucher2017 0006 3024Dokument2 SeitenPUPiApplyVoucher2017 0006 3024MätthëwPïńëdäNoch keine Bewertungen

- Categories of Cargo and Types of ShipsDokument14 SeitenCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Operator'S Manual PM20X-X-X-BXX: 2" Diaphragm PumpDokument12 SeitenOperator'S Manual PM20X-X-X-BXX: 2" Diaphragm PumpOmar TadeoNoch keine Bewertungen

- Studies - Number and Algebra P1Dokument45 SeitenStudies - Number and Algebra P1nathan.kimNoch keine Bewertungen

- Bugatti Type 57SCDokument10 SeitenBugatti Type 57SCjorge Angel Lope100% (1)

- MSDS Formic AcidDokument3 SeitenMSDS Formic AcidChirag DobariyaNoch keine Bewertungen

- Certificate of Attendance: Yosapat NashulahDokument2 SeitenCertificate of Attendance: Yosapat NashulahStrata WebNoch keine Bewertungen

- AWS Compete CustomerDokument33 SeitenAWS Compete CustomerSergeyNoch keine Bewertungen

- دور أخلاقيات الأعمال في تحسين أداء المنظماتDokument14 Seitenدور أخلاقيات الأعمال في تحسين أداء المنظماتChaima LaifaNoch keine Bewertungen

- Matrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014Dokument19 SeitenMatrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014navigareeNoch keine Bewertungen