Beruflich Dokumente

Kultur Dokumente

Tertiary Recovery Methods

Hochgeladen von

Ding J. LimOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tertiary Recovery Methods

Hochgeladen von

Ding J. LimCopyright:

Verfügbare Formate

1

Tertiary recovery

So our well has been drilled and production has started.

We have produced using the wells natural momentum, pressure and

temperature.

Our reservoir drives have helped produce via dissolved gas, gas cap and water

drive.

We then use our primary methods.

We will artificially help our reservoir via pumps and gas lift.

We then used our secondary methods.

We will inject our wells with gas and water.

Once reservoir drives, primary and secondary methods have been exhausted,

we have our final option which will be our tertiary methods.

These methods do not have to be used last or even when all other methods

have finished therefore, they will be called enhanced oil recovery (EOR).

EOR methods can increase productivity up to 75% of the oil in place, so can

take about 5-20% itself.

But this extra % comes with a much higher price tag then the previous methods

that we have looked at.

2

3

These methods unlike our previous do not just try and push the hydrocarbons

through the well but they try to alter the oil properties.

So they do not only provide pressure but also try to increase flow.

4

Tertiary recovery types

There are three main types of enhanced oil recovery including:

Chemical

Miscible Displacement

Thermal

As already said, these methods are quite expensive so a lot of research has to

go in to this to ensure money is not wasted

Chemical recovery

Chemical recovery is in form of chemical injection or chemical flooding

Chemical injection

In this method, chemicals are injected into the reservoir to reduce capillary

pressure to allow oil to flow more easily.

In fluids, capillary pressure is the pressure difference between

two immiscible fluids

Pcapillary = Pnon-wetting phase Pwetting phase

In an oil-water reservoir, water is the wet phase and in gas-oil reservoirs, oil is

the wet phase.

5

In chemical injection method, chemicals (surfactants) are pumped in to othe

reservoir to lower surface tension to allow the reservoir to be more free flowing.

Polymers can also be injected to increase the water flooding/water injection. In

this case the injection process will be as below:

Reservoir fluid is pumped in

Then the surfactant which has caused the oil to form droplets in the water is

injected

Finally, polymers are injected.

Chemical injection works best in sandstone as clay and limestone can absorb

the surfactants, so injection wells must be drilled in the correct location and in

the ideal beds

Chemical injection can increase recovery by up to 40%.

6

Miscible displacement

Miscible displacement is pumping liquid petroleum, gas, CO2 or Nitrogen to

push against the reservoir fluid into the wellbore.

The gas is expanded and pushed through the reservoir or mixed/dissolved in

the oil to decrease viscosity and allow better flow.

7

CO2 is either pumped in from a CO2 well, bought in liquefied or in storage

containers in a gas state.

Some of this gas can then be re-injected into the well once separated from the

oil.

Air cannot be used instead of CO2.

CO2 injection is the most common injection method as CO2 is a by product from

the industry and it is very cheap.

Nearly 50% of EOR in the USA is CO2 injection.

8

Thermal recovery

Thermal recovery is a method of injecting heat into reservoir.

The heat allows the oil to flow more freely by reducing viscosity.

Thermal recovery is very widely used especially on very viscous oil.

Thermal recovery can be split in to three main groups:

Hot injections including steam flood and cycle steam injection

Hot water flooding

Combustion

9

Hot fluid injection

Steam injection to reduce viscosity or a cycle which starts off by injecting steam

into the reservoir, then shutting the well for a few days to allow the steam to

spread out evenly and then produce the oil out,

This process can be done over and over again.

10

Combustion

In this method, gas and air are injected into the reservoir and then a device is

lowered in to ignite a fire.

Heat is generated by the heavy oil burning and vaporization of the lighter oil,

gas and reservoir water forming steam and hot water.

The fire moves and the burning front pushes the gases, steam and hot water

which will then reduce oil viscosity and displace oil toward production wells.

Hot water flooding

Also known as hot water injection, this works in the same way as steam

injection in that it reduces the viscosity of the oil, however, it is not as successful

as steam because it is not as hot

Thermal recovery can recover between 25-70% of oil in place.

11

Microbial recovery

In this method, biology is used to break down the hydrocarbon to make it easier

to recover or enhance the micro-organisms already down there.

Microbial technology can cause a chain of reactions which release gas and

therefore increase pressure.

This method breaks down the heavy oil into lighter oil i.e. reduces viscosity

It also produces natural surfactants

This type of recovery is not used too much as it is still a new and expensive

technology and prices are very high

12

Das könnte Ihnen auch gefallen

- EorDokument13 SeitenEorAnuragNoch keine Bewertungen

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen

- Enhanced Oil Recovery: Prepared by Yasir AlbeatiyDokument6 SeitenEnhanced Oil Recovery: Prepared by Yasir AlbeatiyMahatab HasanNoch keine Bewertungen

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyVon EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNoch keine Bewertungen

- Enhanced Oil Recovery Techniques: Jntu Iv Year B.Tech Petroleum EngineeringDokument54 SeitenEnhanced Oil Recovery Techniques: Jntu Iv Year B.Tech Petroleum EngineeringNadeemSKNoch keine Bewertungen

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Enhanced Oil Recovery TechniquesDokument18 SeitenEnhanced Oil Recovery Techniquesavula43Noch keine Bewertungen

- Enhanced Oil RecoveryDokument3 SeitenEnhanced Oil RecoveryHyacintha Dian TatiwiNoch keine Bewertungen

- EOR Enhanced Oil RecoveryDokument37 SeitenEOR Enhanced Oil RecoveryMarko CetrovivcNoch keine Bewertungen

- Enhanced Oil Recovery NewDokument12 SeitenEnhanced Oil Recovery NewArvind SinghNoch keine Bewertungen

- Enhanced Oil RecoveryDokument17 SeitenEnhanced Oil Recoveryurooj jawwad100% (1)

- Enhanced Oil RecoveryDokument10 SeitenEnhanced Oil RecoveryhanifmfathurrahmanNoch keine Bewertungen

- Enhanced Oil Recovery MethodsDokument4 SeitenEnhanced Oil Recovery MethodsAkash RanjanNoch keine Bewertungen

- Thermal Recoveries Methods.Dokument11 SeitenThermal Recoveries Methods.Florian Ananias ByarugabaNoch keine Bewertungen

- Thermal Recovery: Steam FloodingDokument5 SeitenThermal Recovery: Steam FloodingprimesamNoch keine Bewertungen

- Eor MethodsDokument32 SeitenEor MethodsSuleiman BaruniNoch keine Bewertungen

- Reservoir Drive MechanismsDokument36 SeitenReservoir Drive MechanismsUsman HasanNoch keine Bewertungen

- Thermal Recovery MethodDokument25 SeitenThermal Recovery Methodmahmud masudNoch keine Bewertungen

- Heavy OilDokument9 SeitenHeavy OilMeyda AstriaNoch keine Bewertungen

- Enhanced Oil Recovery PDFDokument8 SeitenEnhanced Oil Recovery PDFعمر العبيدىNoch keine Bewertungen

- Evaluation of Polymeric Materials For ChemEORDokument45 SeitenEvaluation of Polymeric Materials For ChemEORIhsan ArifNoch keine Bewertungen

- Chapter 3Dokument28 SeitenChapter 3peter.pucciNoch keine Bewertungen

- Eor SecreeningDokument59 SeitenEor SecreeningGilang MuhammadNoch keine Bewertungen

- Eor - Enhance Oil RecoveryDokument14 SeitenEor - Enhance Oil RecoveryVivek bhajipaleNoch keine Bewertungen

- Introduction To Eor Processes Introduction To Eor Processes: Dr. Shivanjali SharmaDokument19 SeitenIntroduction To Eor Processes Introduction To Eor Processes: Dr. Shivanjali SharmaRavi ShankarNoch keine Bewertungen

- Enhanced Oil Recovery TechnologyDokument4 SeitenEnhanced Oil Recovery Technologykhalifa abdulsalamNoch keine Bewertungen

- Various Methods of Oil Recovery: By:-Geikaran Patel ROLL NO:-U10CH025Dokument26 SeitenVarious Methods of Oil Recovery: By:-Geikaran Patel ROLL NO:-U10CH025duyvkNoch keine Bewertungen

- Report REDokument13 SeitenReport REElite MusicNoch keine Bewertungen

- Eor Course 2012 Lecture#2 Eor MethodsDokument40 SeitenEor Course 2012 Lecture#2 Eor Methodsabdulrahman mohamed100% (2)

- Enhanced Oil Recovery Using CO2 InjectionDokument2 SeitenEnhanced Oil Recovery Using CO2 InjectionRiko Susetia YudaNoch keine Bewertungen

- Gemsa Company Exam From AONG WebsiteDokument12 SeitenGemsa Company Exam From AONG WebsiteezioNoch keine Bewertungen

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Dokument6 SeitenPE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelNoch keine Bewertungen

- Spe113464 PDFDokument10 SeitenSpe113464 PDFعبدالغفار بيزانNoch keine Bewertungen

- Chemical FloodingDokument18 SeitenChemical FloodingAli AbukhzamNoch keine Bewertungen

- Water Injection/water FloodingDokument3 SeitenWater Injection/water FloodingArvind SinghNoch keine Bewertungen

- Enhanced Oil Recovery - DocxsDokument4 SeitenEnhanced Oil Recovery - Docxsbu7amudNoch keine Bewertungen

- EOR TeknicaDokument345 SeitenEOR TeknicaMauricio Sanchez BernalNoch keine Bewertungen

- Enhanced Oil Recovery (EOR)Dokument2 SeitenEnhanced Oil Recovery (EOR)Ranjan PhukanNoch keine Bewertungen

- Steam Injection For Enhanced Oil RecoveryDokument5 SeitenSteam Injection For Enhanced Oil Recoverytarek senigraNoch keine Bewertungen

- 1.3 NotedDokument2 Seiten1.3 NotedAlbus SeverusNoch keine Bewertungen

- Reservoir Drive MechanismsDokument7 SeitenReservoir Drive MechanismsgorkemerkanliNoch keine Bewertungen

- IntroductionDokument7 SeitenIntroductionMohamed ElabbasyNoch keine Bewertungen

- Eor Course 2012 Lecture#2 Eor MethodsDokument40 SeitenEor Course 2012 Lecture#2 Eor Methodsmiss1whateverNoch keine Bewertungen

- Enhanced Oil Recovery Using PolymerDokument12 SeitenEnhanced Oil Recovery Using Polymerkalpak jadhavNoch keine Bewertungen

- Misible Rec PDFDokument2 SeitenMisible Rec PDFDianaNoch keine Bewertungen

- SPE-182190-MS Optimization of Steamflooding Heavy Oil Reservoirs Under UncertaintyDokument24 SeitenSPE-182190-MS Optimization of Steamflooding Heavy Oil Reservoirs Under Uncertaintyoppai.gaijinNoch keine Bewertungen

- How Does Gas Injection WorkDokument3 SeitenHow Does Gas Injection WorkrajasekharboNoch keine Bewertungen

- Textos para Traducir en Clase N.º 1. Todas Las CarrerasDokument5 SeitenTextos para Traducir en Clase N.º 1. Todas Las CarrerasMatias Alfredo VillagraNoch keine Bewertungen

- Geology of Natural Resources1Dokument81 SeitenGeology of Natural Resources1Abhinav ThakurNoch keine Bewertungen

- BWMRDokument2 SeitenBWMRAbd Elrahman HamdyNoch keine Bewertungen

- Erle C. Donaldson, Yen and George V. ChilingarianDokument10 SeitenErle C. Donaldson, Yen and George V. ChilingarianEmanuela NogueiraNoch keine Bewertungen

- Enhanced Oil Recovery (Abbreviated EOR), Also Called Tertiary Recovery, Is The Extraction ofDokument9 SeitenEnhanced Oil Recovery (Abbreviated EOR), Also Called Tertiary Recovery, Is The Extraction ofAnonymous QM0NLqZO100% (1)

- Toe To Heal Air Injection - THAIDokument5 SeitenToe To Heal Air Injection - THAIAnthon100% (2)

- Thermal Recovery ProcessesDokument19 SeitenThermal Recovery Processesحسين رامي كريم A 12Noch keine Bewertungen

- Enhanced Oil RecoveryDokument43 SeitenEnhanced Oil RecoveryDigvijay DasNoch keine Bewertungen

- Thermal Recovery Processes: ReferenceDokument10 SeitenThermal Recovery Processes: Referenceحسين رامي كريم A 12Noch keine Bewertungen

- Heavy Oil Production Pumping SystemDokument26 SeitenHeavy Oil Production Pumping SystemrahulNoch keine Bewertungen

- 1 Dec2008Dokument9 Seiten1 Dec2008el_sharkawy2011Noch keine Bewertungen

- KANTHAL HANDBOOK. Resistance Heating Alloys and Systems For Industrial FurnacesDokument28 SeitenKANTHAL HANDBOOK. Resistance Heating Alloys and Systems For Industrial Furnacesugui81Noch keine Bewertungen

- Supply of Aluminium Sulphate Final For Use in Water TreatmentDokument19 SeitenSupply of Aluminium Sulphate Final For Use in Water TreatmentWeida KuchingNoch keine Bewertungen

- Cabot Carbon BlackDokument16 SeitenCabot Carbon Blackmust_readyNoch keine Bewertungen

- Lab2determination of The Ka Value of Weak AcidDokument3 SeitenLab2determination of The Ka Value of Weak AcidshaniamatthewNoch keine Bewertungen

- Karakteristik Fisik, Mekanik Dan Sensoris Edible Film Dari Pati Ubi Talas Pada Berbagai Konsentrasi Asam PalmitatDokument7 SeitenKarakteristik Fisik, Mekanik Dan Sensoris Edible Film Dari Pati Ubi Talas Pada Berbagai Konsentrasi Asam PalmitatsamsirNoch keine Bewertungen

- MDSReport 1257675056Dokument4 SeitenMDSReport 1257675056s.aydinNoch keine Bewertungen

- IMO55 2021 T1 Solutions EngDokument11 SeitenIMO55 2021 T1 Solutions EngLazar SavicNoch keine Bewertungen

- Research PaperDokument6 SeitenResearch PaperDhawalSoniNoch keine Bewertungen

- CHAPTER 2 - Last LastDokument14 SeitenCHAPTER 2 - Last LastSyiera MujibNoch keine Bewertungen

- Biotechnologya Todos Los HODokument27 SeitenBiotechnologya Todos Los HOHanan AmarkiNoch keine Bewertungen

- Bauer1960 PDFDokument2 SeitenBauer1960 PDFmilagrosNoch keine Bewertungen

- Weiland Aama 2605 05 Kynar 500Dokument10 SeitenWeiland Aama 2605 05 Kynar 500Øwięs MØhãmmedNoch keine Bewertungen

- Aldehyde and KetoneDokument19 SeitenAldehyde and KetoneEra MelaniaNoch keine Bewertungen

- AL 6XN SourceBookDokument56 SeitenAL 6XN SourceBookdrbeyerNoch keine Bewertungen

- Emitterline Lime en LeachingDokument2 SeitenEmitterline Lime en LeachingvictorNoch keine Bewertungen

- Ceramic Membranes 1Dokument12 SeitenCeramic Membranes 1Cristian PaulNoch keine Bewertungen

- Metals (Part 3 Stoichiometry Part I)Dokument8 SeitenMetals (Part 3 Stoichiometry Part I)(4C20) Chun Ting (Michael) LiNoch keine Bewertungen

- Ullmann's Enc. of Industrial ChemistryDokument72 SeitenUllmann's Enc. of Industrial ChemistrySlim Toumi50% (2)

- Chemical Ammonia Report PDFDokument72 SeitenChemical Ammonia Report PDFAli J. Hojeij100% (1)

- Saes A 007 - 1 PDFDokument1 SeiteSaes A 007 - 1 PDFmuhammad bilalNoch keine Bewertungen

- H-AC-0016 Translucent Car Wax With PearlsDokument1 SeiteH-AC-0016 Translucent Car Wax With PearlsNeli AriasNoch keine Bewertungen

- Silco Af 889 PDFDokument1 SeiteSilco Af 889 PDFmarcela walterosNoch keine Bewertungen

- Astm 4590Dokument3 SeitenAstm 4590Gyna SH67% (3)

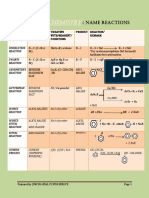

- Organic Chemistry - Name Reactions of All Organic ChaptersDokument5 SeitenOrganic Chemistry - Name Reactions of All Organic ChaptersRanit Mukherjee67% (3)

- EnzimDokument21 SeitenEnzimribiNoch keine Bewertungen

- Submitted By: CARL JORICH P. DURIA Submitted To: MS. MARIEL S. REDONDO Date Submitted: September 26, 2019Dokument2 SeitenSubmitted By: CARL JORICH P. DURIA Submitted To: MS. MARIEL S. REDONDO Date Submitted: September 26, 2019anon_435077119Noch keine Bewertungen

- Chemical Nomenclature: Experiment #3Dokument27 SeitenChemical Nomenclature: Experiment #3Ayi PunsalanNoch keine Bewertungen

- Project ReportDokument14 SeitenProject ReportJoel Gray50% (4)