Beruflich Dokumente

Kultur Dokumente

Risk Asses 65-Piping Fabricated and Assembly - H03

Hochgeladen von

Rochdi BahiriOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Risk Asses 65-Piping Fabricated and Assembly - H03

Hochgeladen von

Rochdi BahiriCopyright:

Verfügbare Formate

Location: TERGA Date of Assessment:

Assessor(s): A.FRIDI System/Activity:

INTRODUCTION

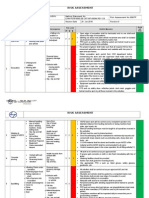

The table below provides a simplified representation of the methodology used and the processes

Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage proje

IDENTIFICATION - Pre planning, Method

statement , Job safety analysis.

ASSESSMENT

Mitigation measure, Residual risk

Identify activities , Identify hazards Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligible 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5

days)

High Priority (2-3 days) Immediate

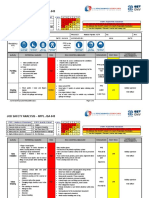

RISK ASSESSMENT FORM

Date of Assessment: 11-04-2010 Assessment No:

System/Activity: Piping fabrication and Erection on the pipe rack

The table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification &

Management) to be undertaken by OCIA and all Subcontractors in order to initiate, act on, review and effectively manage proje ct-related risks

ASSESSMENT Impact, Risk factor,

Mitigation measure, Residual risk

IMPLEMENTATION &

COMMUNICATION

REVIEW & UP DATE

Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

Communication & Training Audit, Inspection & Up dating of Log.

Page 2 of 12

65

Erection on the pipe rack (H03) for Unit 1-2-3

involved in this Hazard Identification & Risk Analysis Procedure (Risk

related risks throughout the Construction Phase.

REVIEW & UP DATE

Audit, Inspection & Up dating of Log.

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Transfer of

equipment

Transfer device collide

with other things;

Oil leakage

4

Locate the crane Hitting injury 4

Transport Traffic risk

Collision with person

Collision device

3

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

3 12 Chose a qualified driver before

work

Check the calibration of all

tools

Make sure the transport device

in good condition

2

3 12 Solid the ground

Reinforce the pads beneath the

outriggers

Check the around circumstance

before working

2

3 9 The trucks must respect:

The limited speed in the site

The circulation signs

The circulation plan (updated)

2

Page 3 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

1 2

1 2

3 6

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Movement of

traffic

Slip/trip/all

3

Lifting Fall from height and

hurt workers

Component fall down

Component collide

with other things

surrounded

Collision with person

Falling materials

Poor visibility for the

driver

Crane tilt

4

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

3 9

All hose/ropes/cables in use

shall be secured to the side of

walkways and handrails

All unnecessary materials and

equipment to be immediately

removed from site

All exits and walkways to be

kept clear for use of personnel

High standard of housekeeping

to be maintained at all times

2

4 16

Lifting crane, wires should be

regularly calibrated, safe

working loads are announced

max speed at site is respected

for all vehicle

It is not allowed to work under

loads

Handling by qualified riggers

worn the related PPE and under

supervision

Qualified crane operator and

qualified rigger to operate

lifting work

Crane in calibrated period

Barricade the lifting area

2

Page 4 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 4

3 6

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Lifting

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be

Implemented

Probability

1 - 5

Proper lifting tools

Make sure lifting wok operated

in good weather

Mark the area of operations of

the crane

Officer commanding the ship

maneuver through regulatory

actions to avoid accidents

Control of the safety catch hook

the slings

Ensure the crane on his

dashboard that the load weight

does not exceed the maximum

allowed

Ban the person be under a

suspended load

Defining the radius of the rotary

crane

Prohibit the movement of

people around the handling

Stop the lifting operation in

strong winds exceed the 50km

/h and heavy rain

Not lifting at night

Page 5 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

Tasks

Hazards Identified (include

the exposed groups)

Probability

1 - 5

Grinding operation

Projection of particles

Emanation of dust

High noise

Glare

Injury to the hands in

contact with reinforcing

bar

Dust irritating

3

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

3 9 Regular tool box talks to be

conducted during operations

Working party awareness in

adjacent areas

Warning signs

Daily housekeeping

Identify emergency stop of

machines

A respiratory dust mask covering

nose and mouth

Specific PPE mandatory

2

Page 6 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 4

Tasks

Hazards Identified (include

the exposed groups)

Probability

1 - 5

Cutting operation Cut - severing by using

incorrectly the tools

Projection of abrasives

particles

Shear incision

Glare

Dust irritating

Burn

Gas and fumes

Fire and/or Explosion

the gas cylinder

3

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

3 9 Inspection prior to use cutting

equipment

The cutting machine must be

used by qualified personnel

Specific PPE mandatory

A respiratory dust mask covering

nose and mouth

Toolbox talks prior to starting the

activity.

Dilution of gas and smoke with

ventilation

Cleanliness of welding at risk of

abrasive particles

check valve and Pressure of gas

cylinder

Leak Detection Gas cylinders and

hoses

2

Page 7 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 4

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Erection

Work at height

(Pipe rack and Man

basket)

Falls from height

Falling objects

material and tools

falling down

Pipe rack fall down

4

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

4 16 Prohibition to work at heights of

night

Prohibit work at height if the

weather affected the safety of

persons

Protection of persons with safety

harnesses

The pipe rack should be based on

graded soil with good foundation

Protect a guard with a height of

1.15 m

Protect with an end-board 10 to

15 cm high

All gaps in pipe rack structure

shall be highlighted by tiger tape

Pipe rack boards shall be well

secured

Use of scafftag

Removal of garnet from boards to

avoid stress on pipe rack

Tools put into the tools pocket

their capacity.

2

Page 8 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

3 6

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Work at height

(Pipe rack and Man

basket)

Welding Burn

Sting

Glare

Gas and smock

Fire and/or Explosion

the gas cylinder

4

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

Erection in accordance with the

requirement

It is forbidden to exceed the

prescribed load on the Man

basket

All man baskets will be load

tested and certified.

All man baskets will not be

overloaded and will be used

inside

4 16 Port PPE: Face shield or goggles,

gloves, aprons and leggings

Respiratory protection

Aeration of the workspace

Dilution of gas and smoke with

ventilation

Cleanliness of welding at risk of

abrasive particles

check valve and Pressure of gas

cylinder

Leak Detection Gas cylinders and

hoses

2

Page 9 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

3 6

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Electricity

Electrocution

3

Fire Explosion

Abrasive particles

Gas cylinder

3

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

4 12

Protect electrical equipment from

ingress of water

Identify equipment risk

Warning notices

Verification of electric cables

before the start of work by an

electrician

2

3 9

Check the cleanness of the

workplace

Site emergency plan to be

followed in event fire or

explosion.

All personnel to be inducted and

aware of emergency procedures.

Leak detection cylinder gas and

hoses

Installation of fire extinguishers

visible and accessible

No smoking or naked lights

2

Page 10 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

3 6

3 6

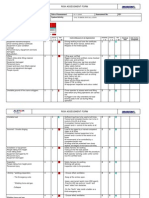

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Chemical risk

Projection of chemical

products

4

Communication

miscommunication

between riggers and

crane operators

3

Waste control

Environmental impact

from used chemicals

Waste of cut

33

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

4 16

Materials to be clearly and

correctly labelled

Protection of personnel under the

guidance of MSDS for each

chemical product used

2

3 9

Only the designated riggers who

are allowed to communicate with

the crane operators.

Operators and riggers will use

hand held radios at all times and

will be sure that they use the

same frequency prior to lifting.

2

4 12 Empty drums to be collected

and disposed off regularly to

avoid waste accumulation and

disposal according waste

management procedures

To finish the work site clean

2

Page 11 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

3 6

2 4

3 6

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Environmental

Pollution the air:

Exhaust gas, The dust

Leaking oil or diesel

machines on soil

3

Assessor Print :

RISK ASSESSMENT FORM

Probability Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

3 9

Checking the condition of

equipments before beginning

the work

ventilation Workstation

2

Sign: Date:

Page 12 of 12

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 4

Das könnte Ihnen auch gefallen

- Ehs Risk AssessmentDokument2 SeitenEhs Risk AssessmentRohit Singh100% (1)

- Generic Risk AssessmentDokument8 SeitenGeneric Risk Assessmentmorgojoyo100% (3)

- Project:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONDokument20 SeitenProject:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONghaleb alhourani100% (1)

- 20) Pumping of WaterDokument7 Seiten20) Pumping of WaterMobin Thomas Abraham75% (12)

- Risk Assesment 16 - Pre - Assembly and Erection ofDokument7 SeitenRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNoch keine Bewertungen

- Risk Assesment 16 - Pre - Assembly and Erection ofDokument7 SeitenRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNoch keine Bewertungen

- (SWMS-01) Loading, Unloading and ShiftingDokument5 Seiten(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- 3-REV.1 - Hot Work - Risk Assessment JHADokument16 Seiten3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- RISK ASSE 110 - Fire Fighting System - F03Dokument8 SeitenRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNoch keine Bewertungen

- 009 Installation of Pumps Risk AssessmentDokument2 Seiten009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Water Tank Base Construction Hazard Identification and Risk ControlDokument5 SeitenWater Tank Base Construction Hazard Identification and Risk Controlramod100% (2)

- HIRA (Pipeline Construction Work)Dokument28 SeitenHIRA (Pipeline Construction Work)sheerazali90% (10)

- Risk Assessment For Earthing Work-R1Dokument3 SeitenRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- Electric Hand Drill Risk AssessmentDokument4 SeitenElectric Hand Drill Risk AssessmentTariq AkhtarNoch keine Bewertungen

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDokument7 SeitenHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Installing Cladding Risk AssessmentDokument3 SeitenInstalling Cladding Risk AssessmentAhmed Tarek67% (3)

- Assignment Nos. 3 - Scaffolding Risk AssessmentDokument11 SeitenAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- Cyclopedia of Architecture Carpentry & Building Vol VIIIDokument422 SeitenCyclopedia of Architecture Carpentry & Building Vol VIIIbootsola100% (2)

- Risk Assessment - Concrete CastingDokument3 SeitenRisk Assessment - Concrete Castingdnmule50% (2)

- Excavation Risk Assessment KTPS - 8 PAGESDokument7 SeitenExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- Welding, Cutting and GrindingDokument6 SeitenWelding, Cutting and GrindingMohammed MinhajNoch keine Bewertungen

- 7 Hand Held Power ToolsDokument4 Seiten7 Hand Held Power ToolsGilmar MonteiroNoch keine Bewertungen

- 009 Installation of Pumps Risk AssessmentDokument2 Seiten009 Installation of Pumps Risk AssessmentRadhaKrishnan RNoch keine Bewertungen

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDokument12 SeitenRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Job Safety Analysis - Pipeline Bending (38 charactersDokument6 SeitenJob Safety Analysis - Pipeline Bending (38 charactersMoaatazz NouisriNoch keine Bewertungen

- Risk Assessment & Control Register - Grease Trap CleaningDokument7 SeitenRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanNoch keine Bewertungen

- Column Lifting & Erection JSADokument7 SeitenColumn Lifting & Erection JSAAli Mohsin100% (3)

- Primavera Project Planner p3Dokument300 SeitenPrimavera Project Planner p3MARIANO100% (19)

- JSA-049 Valves & Support Installation and DismantlingDokument4 SeitenJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Excavation Risk AssessmentDokument3 SeitenExcavation Risk Assessmentrashid zaman57% (7)

- Use of Hand ToolsDokument2 SeitenUse of Hand Toolsvictor100% (1)

- Risk Assessment - Lifting OperationsDokument3 SeitenRisk Assessment - Lifting Operationsdnmule100% (1)

- Risk Assessment of Scaffolding Works - Rev. 1Dokument20 SeitenRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Risk Assessment LoaderDokument3 SeitenRisk Assessment Loadermohamed ghalyNoch keine Bewertungen

- RISK ASSES-105-Erection of Steel Structure BuildinDokument4 SeitenRISK ASSES-105-Erection of Steel Structure BuildinRochdi Bahiri75% (8)

- Risk Assessment For Sand Blasting PDFDokument8 SeitenRisk Assessment For Sand Blasting PDFOvais FarooqNoch keine Bewertungen

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Dokument4 SeitenHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNoch keine Bewertungen

- SWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftDokument7 SeitenSWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftBodakunta Ajay VarmaNoch keine Bewertungen

- Hydrotest & Pneumatic Test - TRADokument6 SeitenHydrotest & Pneumatic Test - TRAOws Anish100% (2)

- Hazard Task Risk Control MeasuresDokument5 SeitenHazard Task Risk Control MeasuresIshan DankharaNoch keine Bewertungen

- RISK ASSES-106-Erection of Steel Structure BuildinDokument4 SeitenRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- P6 Reference ManualDokument550 SeitenP6 Reference Manualsaluthomas100% (22)

- DewateringDokument1 SeiteDewateringChandruNoch keine Bewertungen

- Risk Assessment For Sand BlastingDokument8 SeitenRisk Assessment For Sand BlastingRochdi Bahiri69% (16)

- Grinding Equipment Risk AssessmentDokument3 SeitenGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Power Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe ChenDokument68 SeitenPower Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe Chennelber_xNoch keine Bewertungen

- Forklift Risk AssessmentDokument5 SeitenForklift Risk AssessmentNii Ashiii100% (1)

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDokument3 SeitenRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNoch keine Bewertungen

- Demolition Risk AssessmentDokument41 SeitenDemolition Risk AssessmentVenkadesh Periathambi100% (3)

- Risk Assessment for Lifting OperationsDokument2 SeitenRisk Assessment for Lifting OperationsPrem Shiva100% (1)

- Audit of Power Purchase AgreementsDokument6 SeitenAudit of Power Purchase AgreementsRochdi BahiriNoch keine Bewertungen

- 007 - Risk Ass. - CE-0994-MEP WorksDokument9 Seiten007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Risk Asses23 - Generator RotorDokument3 SeitenRisk Asses23 - Generator RotorRochdi BahiriNoch keine Bewertungen

- Risk Asses23 - Generator RotorDokument3 SeitenRisk Asses23 - Generator RotorRochdi BahiriNoch keine Bewertungen

- TSA Appendices State - 16 09 2014 - WPDokument24.221 SeitenTSA Appendices State - 16 09 2014 - WPRochdi BahiriNoch keine Bewertungen

- TRA of Lifting of EquipmentsDokument3 SeitenTRA of Lifting of EquipmentsandreNoch keine Bewertungen

- JSA Template 5 - Plumbing and Wastewater System InspectionsDokument13 SeitenJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Risk Asses 53-GPR Fitting AssemblyDokument6 SeitenRisk Asses 53-GPR Fitting AssemblyRochdi BahiriNoch keine Bewertungen

- Fencing Installation Risk AssessmentDokument6 SeitenFencing Installation Risk AssessmentVictorNoch keine Bewertungen

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Dokument3 Seiten(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNoch keine Bewertungen

- Risk Asses 116 - Boiler Hydro Test LP3Dokument5 SeitenRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriNoch keine Bewertungen

- Risk Assessment FormDokument8 SeitenRisk Assessment FormRochdi BahiriNoch keine Bewertungen

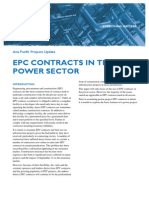

- Epc Contracts in The Power SectorDokument30 SeitenEpc Contracts in The Power SectorIwan Anggara100% (2)

- Pump Efficiency For Single Stage Centrifugal PumpsDokument8 SeitenPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- JSA GC-5 Mobile ScaffoldingDokument6 SeitenJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Evaluate economic feasibility of power plant projectsDokument7 SeitenEvaluate economic feasibility of power plant projectsfundu123Noch keine Bewertungen

- Risk Assess Plastering 2006 Tcm17 26368Dokument2 SeitenRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNoch keine Bewertungen

- Cisco CCIE CCNP RS Study Flashcards Ver 49Dokument102 SeitenCisco CCIE CCNP RS Study Flashcards Ver 49niboozNoch keine Bewertungen

- Civil Works Construction Confined Space JSADokument5 SeitenCivil Works Construction Confined Space JSAkosoko100% (1)

- Ansaldo Thomassen - Flexible Service Agreements (2014)Dokument4 SeitenAnsaldo Thomassen - Flexible Service Agreements (2014)guerrezNoch keine Bewertungen

- Risk Assessment Form Gaz Turbine InstallationDokument6 SeitenRisk Assessment Form Gaz Turbine InstallationRochdi Bahiri100% (1)

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDokument38 SeitenA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- Chiller Selection Made Easier With myPLV™Dokument12 SeitenChiller Selection Made Easier With myPLV™Omair FarooqNoch keine Bewertungen

- (Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerDokument332 Seiten(Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerFuadAshadLNoch keine Bewertungen

- Risk Assessment For Hot WorksDokument4 SeitenRisk Assessment For Hot Workseldho100% (1)

- Job Hazard AssessmentDokument26 SeitenJob Hazard AssessmentGeherson AbustanNoch keine Bewertungen

- Environmental, Health and Safety Risks AnalysisDokument3 SeitenEnvironmental, Health and Safety Risks AnalysisKrishna PatilNoch keine Bewertungen

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDokument6 Seitenjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNoch keine Bewertungen

- Financing and Performance Contracting For EE Projects OutlineDokument1 SeiteFinancing and Performance Contracting For EE Projects OutlineRochdi BahiriNoch keine Bewertungen

- Project Finance and Merchant PowerDokument76 SeitenProject Finance and Merchant Powersimplyanks_5100% (2)

- Financial Analysis of Projects I - OutlineDokument2 SeitenFinancial Analysis of Projects I - OutlineRochdi BahiriNoch keine Bewertungen

- What Is Quadrature Axis Reactance PDFDokument11 SeitenWhat Is Quadrature Axis Reactance PDFRochdi BahiriNoch keine Bewertungen

- Readme 1 STDokument1 SeiteReadme 1 STRochdi BahiriNoch keine Bewertungen

- Risk Asses 118-Transformers Oil TreatmentDokument5 SeitenRisk Asses 118-Transformers Oil TreatmentRochdi BahiriNoch keine Bewertungen

- Lettre Recommandation Orascom ConstructionDokument1 SeiteLettre Recommandation Orascom ConstructionRochdi BahiriNoch keine Bewertungen

- Primavera: Contract Manager Functional OverviewDokument22 SeitenPrimavera: Contract Manager Functional OverviewIgor ČučekNoch keine Bewertungen

- 750-326 OM Blowdown Separator 04-10Dokument8 Seiten750-326 OM Blowdown Separator 04-10Rochdi BahiriNoch keine Bewertungen

- Install NotesDokument1 SeiteInstall NotesRochdi BahiriNoch keine Bewertungen

- 308 BeheraDokument6 Seiten308 BeheraRajneesh VachaspatiNoch keine Bewertungen

- BRD - Lean Manufacturing CaseDokument62 SeitenBRD - Lean Manufacturing CaseRochdi BahiriNoch keine Bewertungen

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDokument4 SeitenHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriNoch keine Bewertungen

- Boiler Design StepDokument3 SeitenBoiler Design StepRochdi BahiriNoch keine Bewertungen

- Project and O&M CostDokument2 SeitenProject and O&M CostRochdi BahiriNoch keine Bewertungen

- Dampers ExplanationDokument7 SeitenDampers ExplanationRochdi BahiriNoch keine Bewertungen

- Wmu 2013 - PPT - FinalDokument103 SeitenWmu 2013 - PPT - FinalRochdi BahiriNoch keine Bewertungen

- Civil & Environmental Engineering Lab Consolidation TestDokument14 SeitenCivil & Environmental Engineering Lab Consolidation TestSapria AdiNoch keine Bewertungen

- Specialized Epic EVO 2021Dokument3 SeitenSpecialized Epic EVO 2021MTB-VCONoch keine Bewertungen

- ExMED Debrief 2019Dokument16 SeitenExMED Debrief 2019Hamilton WintersNoch keine Bewertungen

- Konica Bizhub 7272 - User ManualDokument436 SeitenKonica Bizhub 7272 - User Manualfaco1723Noch keine Bewertungen

- Look at The Picture Carefully. Rearrange The Words To Form Correct SentencesDokument6 SeitenLook at The Picture Carefully. Rearrange The Words To Form Correct SentencesAdy PutraNoch keine Bewertungen

- Manual ReaperDokument466 SeitenManual ReaperJuan Camilo Arroyave ArangoNoch keine Bewertungen

- The Contemporary WorldDokument9 SeitenThe Contemporary WorldDennis RaymundoNoch keine Bewertungen

- 0806 02 Los5 - UgDokument124 Seiten0806 02 Los5 - Ugbmds kocakNoch keine Bewertungen

- User Home - MoneyEasilyDokument1 SeiteUser Home - MoneyEasilyEbenezer NyantakyiNoch keine Bewertungen

- Open-Ended CG Experiments Spark CreativityDokument9 SeitenOpen-Ended CG Experiments Spark CreativityArjun ShettyNoch keine Bewertungen

- 194 Sample ChapterDokument27 Seiten194 Sample ChapterVikas TiwariNoch keine Bewertungen

- .Anber Globe!Dokument20 Seiten.Anber Globe!Cristina GabaroiNoch keine Bewertungen

- Nmo & DmoDokument29 SeitenNmo & DmoJessica Julien100% (1)

- SmartPlant Instrumentation installation checklistDokument2 SeitenSmartPlant Instrumentation installation checklistmnoormohamed82Noch keine Bewertungen

- Binary PDFDokument13 SeitenBinary PDFbyprasadNoch keine Bewertungen

- Behaviour of Cold Formed Steel Single and Compound Plain Angles in CompressionDokument13 SeitenBehaviour of Cold Formed Steel Single and Compound Plain Angles in Compressionthiya123Noch keine Bewertungen

- Engineeringexperv 00000 I 00146Dokument60 SeitenEngineeringexperv 00000 I 00146LALENoch keine Bewertungen

- Process Management: Operating SystemsDokument48 SeitenProcess Management: Operating SystemsvidishsaNoch keine Bewertungen

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDokument3 SeitenBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaNoch keine Bewertungen

- Envea Dusty Manual enDokument26 SeitenEnvea Dusty Manual enmikiNoch keine Bewertungen

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDokument6 SeitenMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaNoch keine Bewertungen

- Samsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFDokument9 SeitenSamsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFreza_azadNoch keine Bewertungen

- Workman GTX: Utility VehicleDokument36 SeitenWorkman GTX: Utility VehicleDaniel Carrillo BarriosNoch keine Bewertungen

- KSSR - MatematikDokument6 SeitenKSSR - MatematikFaris FarhanNoch keine Bewertungen

- Manual, contact info and schematic for GSM moduleDokument10 SeitenManual, contact info and schematic for GSM modulethaiNoch keine Bewertungen