Beruflich Dokumente

Kultur Dokumente

80i Derated PDF

Hochgeladen von

catalinbloajeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

80i Derated PDF

Hochgeladen von

catalinbloajeCopyright:

Verfügbare Formate

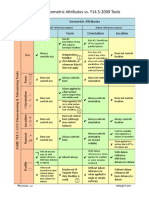

92 93 Refer to the Planning Section on p 212 for help with planning and design

Material Versions

You can choose the following versions of drum body components and electrical connection. The versions depend

on the material of the components.

Component Version Material

Aluminium Mild

steel

Stainless

steel

Brass /

Nickel

Techno-

polymer

Shell Crowned 9 9

Cylindrical 9 9

Cylindrical + key, for using sprockets 9 9

Special crowns and grooves 9 9

End housing Standard 9 9

With V-grooves 9

With O-grooves 9

With chain sprockets 9 9

Shaft Standard 9

Cross-drilled and threaded, M6 9

External seal Galvanised labyrinth 9

Labyrinth 9

Labyrinth with FPM 9

Electrical

connector

Straight connector (for cables see p 266) 9 9

Elbow connector (for cables see p 266) 9 9

Please contact your Interroll customer consultant for further versions.

Options

Lagging for plastic modular belts, see p 146

Lagging for thermoplastic non-modular belts, see p 150

Sprockets for plastic modular belts, see p 152

Backstops, see p 158

Balancing, see p 159

Electromagnetic brakes, see p 160

Rectiers, see p 162

Encoders, see p 166

Food-grade oil (FDA and USDA), see p 268

Low temperature oil, see p 268

UL/cUL safety certications, see p 265

Non-horizontal mounting (more than 5), see p 248

Note: Combination of encoder and electromagnetic brake is not possible.

Accessories

Mounting brackets, see p 174

Idler pulleys, see p 188 to p 198

Drive pulleys, see p 198

Conveyor rollers, see p 202

Product Description

This cool-running drum motor is suitable for positive drive belts, like plastic modular belts or thermoplastic

non-modular belts. It is also suitable for non-belt applications.

9 Small feed conveyors with high-duty cycles

9 Packaging equipment

9 Dynamic weighing equipment

9 Metal detectors

9 Pharmaceutical handling

9 Food processing

9 Steel or plastic modular belt applications

9 Dry, wet and wash-down applications

9 Salt-water-resistant aluminium bearing housings

9 3-phase AC induction motor

9 Dual voltage

9 Integral motor protection

9 Steel-hardened helical spur gear

9 Low noise

9 Maintenance-free

9 Lifetime lubricated

9 Reversible

9 Reinforced shaft for SL above 543 mm

Note: When using a frequency converter please choose a standard drum motor.

Technical Data

Motor data

Motor type Asynchronous squirrel cage motor, IEC 34 (VDE 0530)

Insulation class of motor windings Class F, IEC 34 (VDE 0530)

Voltage 230/400 V 5 % (IEC 34/38)

Special voltage on request

Frequency 50/60 Hz

Internal shaft sealing system Double-lipped, FPM or NBR

Protection rate IP66

Thermal protection Bi-metal switch

Ambient temperature, 3-phase motor +5 to +25 C

General technical data

Max. shell length SL 943 mm

All data and values in this catalogue refer to 50 Hz operation.

Order Information

Please refer to fold-out page at the end of the catalogue.

Applications

Characteristics

I nterrol l Drum motor

80i DerateD

Cool-Running

Drum Motors

80i derated

Compact and robust drive for small feed conveyors

with high-duty cycles

Overview of Cool-Running Drum Motors p 90 Options p 138 Accessories p 170

94 95 Refer to the Planning Section on p 212 for help with planning and design

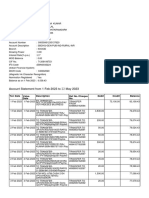

Electrical data for 3-phase motors, derated

P

N

np U

N

I

N

cos J

R

I

S

/I

N

M

S

/M

N

M

P

/M

N

M

B

/M

N

R

M

U

SH delta

U

SH star

kW V A kgcm

2

V DC V DC

0.033 4 230 0.30 0.62 0.45 0.4 1.7 2.73 2.48 2.74 286.5 27 -

400 0.17 0.62 0.45 0.4 1.7 2.73 2.48 2.74 286.5 - 45

0.06 4 230 0.40 0.68 0.56 0.6 1.3 2.48 2.15 2.56 191.0 26 -

400 0.23 0.68 0.56 0.6 1.3 2.48 2.15 2.56 191.0 - 45

2 230 0.26 0.78 0.75 0.4 2.4 2.15 1.90 2.26 183.5 19 -

400 0.15 0.78 0.75 0.4 2.4 2.15 1.90 2.26 183.5 - 32

0.1 2 230 0.45 0.78 0.71 0.6 2.4 2.31 2.15 2.13 106.4 19 -

400 0.26 0.78 0.71 0.6 2.4 2.31 2.15 2.13 106.4 - 32

P

N

Rated power

np Number of poles

U

N

Rated voltage

I

N

Rated current

cos Power factor

Efciency

J

R

Rotor moment of inertia

I

S

/I

N

Ratio of starting current to rated current

M

S

/M

N

Ratio of starting torque to rated torque

M

P

/M

N

Ratio of pull-up torque to rated torque

M

B

/M

N

Ratio of break-down torque to rated torque

R

M

Phase resistance

U

SH delta

Preheating voltage in delta connection

U

SH star

Preheating voltage in star connection

Cable Specications

Available cables for connectors (see also p 266):

Standard, screened

Standard, unscreened

Halogen-free, screened

Halogen-free, unscreened

Available length: 1 / 3 / 5 / 10 m

Connection Diagrams

For connection diagrams, see Planning Section on p 270.

Product Range

The following tables give an overview of the possible motor versions. When ordering, please specify the version in

accordance with the congurator on the fold-out page.

Mechanical data for 3-phase motors, derated

P

N

np gs i v n

A

M

A

F

N

TE SL

min

App.

kW m/s min

-1

Nm N N mm

0.033 4 3 54.73 0.11 25.3 11.8 293 3,250 193 9

38.18 0.15 36.2 8.3 204 3,250 193 9

31.09 0.19 44.5 6.7 166 3,250 193 9

2 21.28 0.28 65.0 4.7 116 3,250 193 9

14.85 0.40 93.2 3.3 81 3,250 193 9

12.09 0.49 114.5 2.7 66 3,250 193 9

0.06 4 3 54.73 0.10 23.9 22.7 560 3,250 243 9

38.18 0.15 34.3 15.8 390 3,250 243 9

31.09 0.18 42.1 12.9 318 3,250 243 9

2 21.28 0.26 61.6 9.0 222 3,250 243 9

14.85 0.37 88.2 6.3 155 3,250 243 9

12.09 0.46 108.3 5.1 126 3,250 243 9

2 3 54.73 0.21 50.2 10.8 267 3,250 193 9

38.18 0.31 72.0 7.5 186 3,250 193 9

31.09 0.38 88.5 6.1 152 3,250 193 9

2 21.28 0.55 129.2 4.3 106 3,250 193 9

14.85 0.79 185.2 3.0 74 3,250 193 9

12.09 0.96 227.4 2.4 60 3,250 193 9

0.1 2 3 54.73 0.21 49.8 18.0 445 3,250 243 9

38.18 0.30 71.4 12.6 311 3,250 243 9

31.09 0.37 87.7 10.2 253 3,250 243 9

2 21.28 0.54 128.1 7.2 177 3,250 243 9

14.85 0.78 183.7 5.0 123 3,250 243 9

12.09 0.96 225.5 4.1 100 3,250 243 9

P

N

Rated power

np Number of poles

gs Gear stages

i Gear ratio

v Rated velocity of the shell

n

A

Rated revolutions of the shell

M

A

Rated torque of drum motor

F

N

Rated belt pull of drum motor

TE Max. belt tension

SL

min

Min. shell length

App.

9: Suitable for all applications. This version will ensure lowest cost and fast delivery

: Not suitable for all applications. Please contact your Interroll customer consultant

Motor versions

I nterrol l Drum motor

80i DerateD

Cool-Running

Drum Motors

80i derated

Compact and robust drive for small feed conveyors

with high-duty cycles

Overview of Cool-Running Drum Motors p 90 Options p 138 Accessories p 170

96 97 Refer to the Planning Section on p 212 for help with planning and design

3

4

1

5

10

20

2

5

20

2

2

20 12.5

Fig.: Elbow connector, techno-polymer Fig.: Shaft for encoder (special connector required)

10

Fig.: Special cable slot connector

6.25

M6

12.5

Fig.: Shaft, cross-drilled and threaded

The following options increase the minimum length of the drum motor.

Option Min. SL with option

mm

Brake Min. SL + 50

Encoder Min. SL + 50

Special cable slot connector Min. SL + 50

The drum motors weight depends on its length.

Shell length SL in mm 193 243 293 343 393 443 493 543

Average weight in kg 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

Shafts for xing

Min. length with

option

Standard length

and weight

Dimensions

6

2 2

12.5 12.5

6

1/3 1/3 1/3

13.5

EL = SL + 12

FW = SL + 7

AGL = SL + 37

SL

4

3

1

7

Fig.: Drum motor with straight connector

Type A

mm

B

mm

80i crowned shell 81.5 80.5

80i cylindrical shell 81.0 81.0

80i cylindrical shell + key 81.7 81.7

1

6

17

1

6

17.5

Fig.: Straight connector, brass/nickel Fig.: Straight connector, stainless steel

3

0

17.5

24

4

5

3

5

33

24

Fig.: Elbow connector, stainless steel Fig.: Straight/elbow connector, techno-polymer

Standard

dimensions

Connector

dimensions

I nterrol l Drum motor

80i DerateD

Cool-Running

Drum Motors

80i derated

Compact and robust drive for small feed conveyors

with high-duty cycles

Overview of Cool-Running Drum Motors p 90 Options p 138 Accessories p 170

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Communication Skills PPT Effective Communication TechniquesDokument17 SeitenCommunication Skills PPT Effective Communication Techniquescharles7777777Noch keine Bewertungen

- IBM 4690 User Guide v1998Dokument40 SeitenIBM 4690 User Guide v1998Richard ChuaNoch keine Bewertungen

- Lenten Adult ClassDokument2 SeitenLenten Adult ClasscatalinbloajeNoch keine Bewertungen

- META Cantilever RacksDokument24 SeitenMETA Cantilever RacksRaj KumarNoch keine Bewertungen

- Microsoft Word - Rules 2001Dokument5 SeitenMicrosoft Word - Rules 2001catalinbloajeNoch keine Bewertungen

- GD&T Further PDFDokument1 SeiteGD&T Further PDFnmjboseNoch keine Bewertungen

- FMEA Webinar 30 Nov 2011Dokument74 SeitenFMEA Webinar 30 Nov 2011David SigalinggingNoch keine Bewertungen

- Catalog - 4 - Conventional-Pallet-Racking - en - UNDokument44 SeitenCatalog - 4 - Conventional-Pallet-Racking - en - UNcatalinbloaje100% (1)

- Research Talk 101: Lucia DettoriDokument34 SeitenResearch Talk 101: Lucia DettoriHương QuỳnhNoch keine Bewertungen

- BerryhillDokument21 SeitenBerryhillcatalinbloajeNoch keine Bewertungen

- How To Conduct TrainingDokument57 SeitenHow To Conduct TrainingRamesh GurumoorthyNoch keine Bewertungen

- PptexamplesDokument31 SeitenPptexamplesapi-297904544Noch keine Bewertungen

- PresentationDokument22 SeitenPresentationRadhika FulpagarNoch keine Bewertungen

- 5S Workshop: What Is It?Dokument9 Seiten5S Workshop: What Is It?catalinbloajeNoch keine Bewertungen

- Autom Kata 2014-12 Web ENDokument104 SeitenAutom Kata 2014-12 Web ENcatalinbloaje100% (1)

- Effective PresentationsDokument53 SeitenEffective PresentationsShreesh Chandra100% (1)

- Fairy Tale Lecture IIDokument11 SeitenFairy Tale Lecture IIsintamelya7Noch keine Bewertungen

- Module 6 2 Training Users On HINARI English 2011 04Dokument21 SeitenModule 6 2 Training Users On HINARI English 2011 04catalinbloajeNoch keine Bewertungen

- 5S - House KeepingDokument20 Seiten5S - House KeepingRawinder100% (2)

- Booklet 1Dokument33 SeitenBooklet 1catalinbloajeNoch keine Bewertungen

- WrkshpAgendaTemplate BillBirdDokument41 SeitenWrkshpAgendaTemplate BillBirdcatalinbloajeNoch keine Bewertungen

- 2013 Metagenomics Teaching Workshop ScheduleDokument2 Seiten2013 Metagenomics Teaching Workshop SchedulecatalinbloajeNoch keine Bewertungen

- Jolivelu 2Dokument11 SeitenJolivelu 2catalinbloajeNoch keine Bewertungen

- The Making of The Encyclopaedia Judaica and The JDokument21 SeitenThe Making of The Encyclopaedia Judaica and The JcatalinbloajeNoch keine Bewertungen

- Implementation PhasesDokument4 SeitenImplementation PhasescatalinbloajeNoch keine Bewertungen

- Jolivelu 2Dokument11 SeitenJolivelu 2catalinbloajeNoch keine Bewertungen

- Fairy Tales Art Lesson PlanDokument9 SeitenFairy Tales Art Lesson PlancatalinbloajeNoch keine Bewertungen

- Workshop Schedule Efes 2013: Time Event VenueDokument2 SeitenWorkshop Schedule Efes 2013: Time Event VenuecatalinbloajeNoch keine Bewertungen

- Church School Registration FormDokument2 SeitenChurch School Registration FormcatalinbloajeNoch keine Bewertungen

- Saint Sava Serbian Orthodox Church: Sunday of St. Thomas, Also The Day of St. Basil of Ostrog - Sveti Vasilije OstroskiDokument1 SeiteSaint Sava Serbian Orthodox Church: Sunday of St. Thomas, Also The Day of St. Basil of Ostrog - Sveti Vasilije OstroskicatalinbloajeNoch keine Bewertungen

- Pnational Construction-Profile - 21 2 1Dokument23 SeitenPnational Construction-Profile - 21 2 1Cold ExecuTionNoch keine Bewertungen

- 04 - FA31324EN32GLA0 - CrossConnect Multiplexer PDFDokument40 Seiten04 - FA31324EN32GLA0 - CrossConnect Multiplexer PDFAmina WedwedNoch keine Bewertungen

- 440K-T11090 - Tongue Switches - Allen-BradleyDokument6 Seiten440K-T11090 - Tongue Switches - Allen-BradleyJosé Santiago Miranda BernaolaNoch keine Bewertungen

- GS-101B Data Sheet 181009 PDFDokument2 SeitenGS-101B Data Sheet 181009 PDFLeonardoNoch keine Bewertungen

- 2012-Tcot-008-S.o.w-001 Rev.2Dokument150 Seiten2012-Tcot-008-S.o.w-001 Rev.2denyNoch keine Bewertungen

- Nzs 4297 1998 PDFDokument63 SeitenNzs 4297 1998 PDFjuan jose100% (1)

- Linked List: Singly, Doubly and CircularDokument53 SeitenLinked List: Singly, Doubly and CircularMia SamNoch keine Bewertungen

- Proposal Pengajuan Tempat UsahaDokument1.544 SeitenProposal Pengajuan Tempat Usahalionnade aremaNoch keine Bewertungen

- Maxsb PresentationDokument41 SeitenMaxsb PresentationjaneshkumarNoch keine Bewertungen

- Nihon Kohden 9010K Service Manual PDFDokument130 SeitenNihon Kohden 9010K Service Manual PDFJumbo JamesNoch keine Bewertungen

- Author Instructions For Publication in IOSR JournalDokument2 SeitenAuthor Instructions For Publication in IOSR JournalSwati Shahi100% (1)

- Unilever CaseDokument2 SeitenUnilever CaseElly DangNoch keine Bewertungen

- Bsi BS 88-2 - 2013Dokument208 SeitenBsi BS 88-2 - 2013alferedNoch keine Bewertungen

- Visual Basic Assignment IndexDokument3 SeitenVisual Basic Assignment Indexprofessor_manojNoch keine Bewertungen

- Plumbing Code QuestionsDokument3 SeitenPlumbing Code QuestionsJhay DomdomNoch keine Bewertungen

- GH TXu Yyfls 73 IDumDokument15 SeitenGH TXu Yyfls 73 IDumdabu choudharyNoch keine Bewertungen

- Pi White Paper Profinet It en v1 0Dokument28 SeitenPi White Paper Profinet It en v1 0Rafiul IslamNoch keine Bewertungen

- LogcatDokument881 SeitenLogcatNabeelNoch keine Bewertungen

- ADMSDokument6 SeitenADMSNick SalomoneNoch keine Bewertungen

- Sgs SSC Apqp and Ppap en 07Dokument3 SeitenSgs SSC Apqp and Ppap en 07vaishrahul07Noch keine Bewertungen

- Mission VisionDokument4 SeitenMission VisionmohammadNoch keine Bewertungen

- Vol39No7 Full PDFDokument68 SeitenVol39No7 Full PDFdeviationzNoch keine Bewertungen

- BRD TemplateDokument11 SeitenBRD TemplateHussain ManzoorNoch keine Bewertungen

- Flow Meter ManualDokument70 SeitenFlow Meter Manualrommel duranNoch keine Bewertungen

- Cadilac Gage V-300Dokument11 SeitenCadilac Gage V-300Bill SmithNoch keine Bewertungen

- ITB-KEOC-2013-009 - Section VIII C - Mechanical SpecificationsDokument151 SeitenITB-KEOC-2013-009 - Section VIII C - Mechanical SpecificationsMACOYNoch keine Bewertungen

- Series 6 & 7: Rehabilitation ProductsDokument33 SeitenSeries 6 & 7: Rehabilitation ProductsMileNoch keine Bewertungen

- DPS Calculation SheetDokument133 SeitenDPS Calculation SheetKraiwan AranyawatNoch keine Bewertungen

- Solution For Improving Bit Error Rates (BER) in Microwave Long Haul LinksDokument5 SeitenSolution For Improving Bit Error Rates (BER) in Microwave Long Haul LinksJournal of Telecommunications100% (2)