Beruflich Dokumente

Kultur Dokumente

2013 WSF ATL Readling

Hochgeladen von

murdicksOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2013 WSF ATL Readling

Hochgeladen von

murdicksCopyright:

Verfügbare Formate

Hurricanes, Earthquakes & Tornados

WOOD DESIGN FOR EXTREME FORCES

Bryan Readling, P.E.

National Sponsors

The Wood Products Council

is a Registered Provider with The American Institute of Architects

Continuing Education Systems (AIA/CES). Credit(s) earned on

completion of this program will be reported to AIA/CES for AIA

members. Certicates of Completion for both AIA members and non-

AIA members are available upon request.

This program is registered with AIA/CES for continuing professional

education. As such, it does not include content that may be deemed

or construed to be an approval or endorsement by the AIA of any

material of construction or any method or manner of handling, using,

distributing, or dealing in any material or product.

Questions related to specic materials, methods, and services will be

addressed at the conclusion of this presentation.

Copyright Materials

This presentation is protected by US and

International Copyright laws. Reproduction,

distribution, display and use of the presentation

without written permission of the speaker is

prohibited.

The Wood Products Council 2013

Learning Objectives

At the end of this program, participants will be able to:

1. Explain the fundamental behavior of wood structures especially as it pertains

to diaphragms, shear walls, and the connections therein.

2. Identify new technologies such as designing wood structural panel wall

sheathing to resist simultaneous shear and uplift forces.

3. Recognize common failure modes using photographs from APA post-disaster

evaluations.

4. Identify the relationship between load-path discontinuity and structural

damage by viewing common failure modes.

Governing Codes for Wood Design

2006 IBC (International Building Code)

Chapter 16 Loads

Chapter 23 Wood

Governing Codes for Wood Design

SEI/ASCE 7-05

Design Loads

2005 NDS

Load Resistance

Code Adopted ANSI Process

Governing Codes for Wood Design

2005 NDS

(National Design

Specification for

Wood

Construction)

Governing Codes for Wood Design

2005 & 2008 SDPWS (Special Design Provisions for Wind and Seismic)

Available at: http://www.awc.org/Standards/SDPWS.html

Free download!

Provisions for wood

members, fasteners, and

assemblies for resisting wind

and seismic forces ASD/

LRFD

SDPWS Referenced in IBC

2006 IBC

Permitted Alternative to IBC 2305

Reference to 2005 SDPWS

2009 IBC

2008 SDPWS Mandatory

in IBC 2305 for Lateral Design

2008 Edition - SDPWS

WSP Combined Shear and Uplift

Unblocked Shearwalls

2-Sided Shearwalls

Perforated Shearwalls- SCAF Equation

Increased Strength Limit for PSW

High-load Diaphragms

Governing Codes for Wood Design

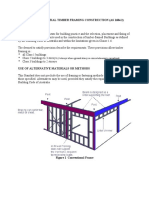

Wood Frame Construction Manual

For One- and Two-Family Dwellings

Prescriptive Wind Standards

For One- and Two-Family Dwellings

Wood Frame Construction Manual

90 130 MPH

High Wind Guides

Prescriptive Standards

ICC 600-2008 Standard for

Residential Construction in High

Wind Regions

ICC 500-2008 Standard for

the Design and Construction

of Storm Shelters

Introducing: New APA Publication!

Load Path

(IBC 2006 1604.4)

Any system of method of construction to be used shall be based on a rational

analysis in accordance with well established principles of mechanics. Such

analysis shall result in a system that provides a complete load path capable of

transferring loads from their point of origin to the load-resisting elements.

Vertical Load Path Lateral Load Path

Lateral Load Systems

Less Intuitive

More Circuitous

Interruptions in

Load-path less

obvious

Lateral Loads

(Wind)

F = PA

Effort is devoted to

determining

P wind pressure

Lateral Loads

(Seismic)

F = ma

Effort is devoted to

determining:

a acceleration

Force =(Mass) x (Acceleration)

Seismic Performance for Wood

Structures

Advantages

Lightweight

Flexible

Highly redundant

Good Balance of

Strength and

Stiffness

Good Energy

Dissipation

Hurricane Katrina

Fully Sheathed Box

Prescriptive

Bracing

International Res. Code

Limitations:

3-stories max.

Wind < 100 mph*

Uses Braced wall panels

without hold downs

Engineered

Shearwalls

International Bldg. Code

Applications:

Any size/shape

Wind - No limit

Uses Shear walls

with hold downs

* In hurricane regions, <110 mph otherwise

Prescriptive designs for wind speeds over 100 are provided by:

Wood Frame Construction Manual American Wood Council

IBHS Guidelines for Hurricane Resistant Residential

Construction or SSTD-10

F-5 Tornado Oklahoma 1999

Why Build to Resist Tornados?

Facts

90% of all tornados are EF2 and below

70% of tornados are <110 mph

Damaging winds outside vortex are slower than max.

Unrealistic to protect against EF4, EF5, and some EF3.

Safe rooms are NOT a panacea.

Provide recomendations to protect building shell.

Tornado loads more unknown than seismic!

Enhanced Fujita Scale

EF-Scale

Tornado

description

Wind Speed

(3-sec gust) Description of Expected Damage

EF-0 Gale tornado 65-85

Minor or no damage. Peels surface off some roofs; some

damage to gutters or siding; branches broken off trees;

shallow-rooted trees pushed over.

EF-1 Moderate tornado 86-110

Moderate damage. Roofs severely stripped; mobile homes

overturned or badly damaged; loss of exterior doors; windows

and other glass broken.

EF-2

Significant

tornado

111-135

Considerable damage. Roofs torn off well-constructed

houses; foundations of frame homes shifted; mobile homes

completely destroyed; large trees snapped or uprooted; light-

object missiles generated; cars lifted off ground.

EF-3 Severe tornado 136-165

Severe damage. Entire stories of well-constructed houses

destroyed; trains overturned; trees debarked; heavy cars

lifted off the ground and thrown

EF-4

Devastating

tornado

166-200

Extreme damage. Well-constructed and whole frame houses

completely leveled; cars and other large objects thrown and

small missiles generated.

EF-5

Incredible

tornado

>200

Total Destruction. Strong framed, well built houses leveled off

foundations and swept away;

Percentage of Occurrence

EF-Scale Wind Speed

(3-sec gust)

Relative

Frequency

Cumulative

Percentage

EF-0

65-85

53.5 % 53.5 %

EF-1

86-110

31.6 % 85.1

EF-2

111-135

10.7 % 95.8

EF-3

136-165

3.4 % 99.2

EF-4

166-200

0.7 % 99.9

EF-5

>200

< 0.1 100

Tornado Intensity Along Path

Building for High-Wind Resistance

in Light-Frame Wood Construction

Roof Sheathing Attachment

Gable end connections

Cladding attachment

Roof to wall connection

Wall to wall continuity

Wall sheathing attachment

Wall sheathing continuity

Wall connection to sill plate

Sill plate anchorage

Roof Sheathing Attachment

Nail roof sheathing with 8d ring shank (0.131" x 2-1/2" )

or deformed shank nails at 4" on center at panel ends

and edges and 6" on center in the intermediate framing

8d Common nails - 6"

on center along

intermediate framing

8d Common nails

- 4" on center at

panel ends

Roof sheathing Roof framing

Step Down Trusses

More Challenging Connections!

Fayetteville, NC

Gable-end Framing

Tie gable end walls back to the structure

Gable end truss top chord

Tension-tie strap, attach with (8) 10d common nails, each end of

strap

Roof Trusses

(3) 10d Common

nails (typical)

2" x 4" continuous lateral brace

@ 6' on center. Lateral brace

sized to extend from end wall to

over 3 interior trusses plus 6".

2x4 flatwise

blocking

between truss

bottom chords

Gable end

truss bottom

chord

Gable-end Framing

2011 Fayetteville, NC

Gable-end Framing

2011 Pleasant Grove, AL

Resisting Pressure on Components and

Cladding

Sheath gable end walls with wood structural panels,

such as plywood or oriented strand board (OSB)

8d Common nails - 4" on

center perimeter of

panel

Wood structural panel

sheathing

8d Common nails - 4" on

center perimeter of panel

nailed to the top of the

double top plate

Gable end truss top

chord

Gable end truss

vertical web member

Gable end truss bottom

chord

8d Common nails - 6" on

center along intermediate

framing

Components and Cladding Loads

Wind Pressure Resistance

(APA form TT-105)

Table 1. Maximum wind speed (mph - 3 second gust) permitted for wood structural panel

sheathing used as wall covering to meet IRC Table R301.2(2) requirements

1, 2, 3

Minimum Nail

Minimum

Wood

Structural

Panel

Span

Rating

Minimum

Nominal

Panel

Thicknes

s (inches)

Wall

Stud

Spacing

(inches)

Panel Nail Spacing

Maximum Wind Speed

(mph)

Size Penetration Edges Field

Wind Exposure

Category

-- (inches)

(inches

o.c.)

(inches

o.c.)

B C D

6d

(0.113"

x 2.0")

1.5

24/0 3/8 16 6

12 110 90 85

6 110 90 85

24/16 7/16 16 6

12 110 100 90

6 150 125 110

8d

(0.131"

x 2.5")

1.75 24/16 7/16

16 6

12 130 110 105

6 150 125 110

24 or

less

6

12 110 90 85

6 110 90 85

1. Panel strength axis parallel or perpendicular to supports. Three-ply plywood sheathing with

studs spaced more than 16 inches o.c. shall be applied with panel strength axis perpendicular

to supports.

2. Table is based on wind pressures acting toward and away from building surfaces per

R301.2, lateral bracing requirements shall be in accordance with R602.10.

Deformed Shank Nails

Enhanced pullout is

achieved with ring or spiral

shanks nails for enhanced

uplift resistance

Not code required!

Larger heads enhance

pull-thru resistance

Forces to Resist: Uplift

Roof to Wall Connection

Roof framing to wall connection with hurricane/seismic

framing anchor or equivalent connector attached on

sheathing side of the exterior walls

Uplift

Shear

Roof framing - trusses or lumber framing

Framing anchors with uplift and shear capacity

Double top plate

Must be driven straight into

middle of rafter tail.

Wind zone and local

building code

requirements can be met

using code evaluation

reports (i.e. Fastenmaster

ESR-1078)

Rafter to Top Plate

Structural Screws

WSPs Used to Resist

Combined Uplift and Shear

Using WSP to Eliminate Metal Hardware

Lower Cost

Reduced Construction Time

Sized for 8, 9, 10 ft. walls

Eliminates blocking

Easy to inspect

Less air infiltration

More direct uplift and

lateral load-path

Oversize OSB Wall Sheathing

Wal l Sheat hi ng used f or

Upl i f t

Metal straps still needed

around windows and door

openings

Combined Shear and Uplift

Tension Transferred by Studs

Nail pattern

at each stud

Tension Splice at Rim J oist

Tension splice at

horizontal wall

sheathing joint

Nail pattern at

rim joist

Ri m Boar d

Tension Transferred by Splice Plate

WSP Tension Splice

space

Lumber

Uplift Nailing

Wall Sheathing Attachment

Nail wall sheathing with 8d common

(0.131" x 2-1/2") nails at 4" on center in

the boundary of wood structural panel

wall sheathing and 6" on center in the

intermediate studs

8d Common nails at 4" on center

at panel ends and edges

8d Common nails at 6" on center

at intermediate supports

Fully Sheathed Walls

Sheath all walls with wood structural panels

Building

paper

Even with the loss of wall

covering and building

paper, continuous plywood

and OSB sheathing offers

Building

paper

Fully Sheathed Walls

Hurricane Katrina

2011 - Pleasant Grove, AL 2011 - Pleasant Grove, AL

2011 - Raleigh, NC 2011 - Raleigh, NC

Flying Debris

Components and Cladding Loads

Reference: Requirements for Wall Coverings and Wind

Pressures, APA publication TT-105

NC Tornados 4-16-11

Non-Structural Sheathing

2011 - Wilson, NC

Corner Bracing

2011 - Wilson, NC

Wilson, NC

Non-Structural Sheathing

2011 - Raleigh, NC

Non-Structural Sheathing

Wall Framing to Sill Plate Connection

Extend wood structural panel sheathing at bottom of

wall to sill plate intersection

I-joist

Rim Board

Wall sheathing

Other connections are

not shown for clarity

2011 - Raleigh, NC

Raleigh, NC 2011 - Raleigh, NC

Raleigh, NC

Bottom Plate Anchorage

Space 1/2" anchor bolts 32" to 48" on center with 0.229" x 3" x 3"

slotted square plate washers at the wall to sill plate intersection

I-joist

Rim Board

Wall sheathing

1/2" anchor bolts at 32" to 48

on center tie the structure

to the foundation

Anchor-Bolt Connection to Foundation

Limited by steel-

to-wood bearing

area

Allowable stress

perpendicular to

grain often

controls

Material Properties of Wood

Very strong parallel to grain

Material Properties of Wood

Relatively weak perpendicular to grain

Vocabulary word for today! Anisotropic

Larger Washer Increases Uplift

Capacity

Large plate washers (3 x3 x0.229 ) prevent

cross-grain splitting of sill plate

Required for SDC D, E or F (IBC 2305.3.11)

Plate washer

Sill plate

Cross grain

bending is

Restrained by

Plate Washer

Wood

structural

panel - uplift

2011 - Raleigh, NC

Foundation Anchorage

2011 - Raleigh, NC

2011 - Raleigh, NC 2011 - Coaling, AL

Foundation Anchorage

2011 - Coaling, AL Coaling, AL

2011 - Coaling, AL 2011 - Coaling, AL

2011 - Coaling, AL

Square Plate Washer

Dramatically Increases Uplift Capacity

Large plate washers (3 x3 x0.229 ) prevent

cross-grain splitting of sill plate

Required for SDC D, E or F (IBC 2305.3.11)

Plate washer

Sill plate

Cross grain

bending is

Restrained by

Plate Washer

Wood structural

panel - uplift

Combined Uplift & Shear

APA Pub. SR101

Anchor Bolt Spacing for Combined Shear and

Wind Uplift from SR-101

Based on Full-scale Test Results

Eliminate splitting of bottom plate as a failure mode

Podium Construction

Town Brookhaven Atlanta, GA

Anchoring to Concrete Podium Slab

Anchor Connection to Concrete Podium

at Steel Embed

Dia. Threaded

Stud Anchor Bolt

1 Diameter Steel

Pipe Sleeve pack

with epoxy grout.

Steel Embed Plate w/

Welded Headed

Studs

1 Diameter Steel Pipe Sleeve

1 Packed with expansive epoxy grout

Increases wood bearing area

Threaded rod welded to steel embed

Follow the Load

PLAN VIEW

Idealize sloped wood roof diaphragms as if

they are flat

Sloped Roofs

Blocked Diaphragm Unblocked Diaphragm

Unblocked Shearwalls

Shear capacity reductions

16 Maximum wall height

Based on cyclic testing

Up to 2:1 aspect ratio

Flexible vs. Rigid Diaphragms

Flexible

diaphragm > 2shearwalls

Diaphragm load is distributed to shear walls by tributary area

Diaphragm acts like series of simply supported beams

Rigid

diaphragm < 2shearwalls

Diaphragm load is distributed to shear walls by wall stiffness

Torsion considered in design

Provides more flexibility for shearwall layout

More complicated analysis

Prescribed Rigid Wood Diaphragms

(IBC 2305.2.5)

Open front and

Cantilevered diaphragms

w

L/2

L/2

Di aphr agm (Pl an Vi ew )

Fl ex i bl e Di aphr agm

sw

di

w

L/2

L/2

.25wL

.25wL

.50wL

Flexible

sw

w

L/2

L/2

.333wL

.333wL

.333wL

Ri gi d - Al l Wal l s I dent i c al

Rigid (no

Torsion)

w

L/2

L/2

2K

2K

K

Stiffness

.25wL

.25wL

.50wL

Flexible

Rigid (no

Torsion)

.40wL

.40wL

.20wL

Fl ex i bl e v. Ri gi d

Prescribed Rigid Wood Diaphragms

(IBC 2305.2.5)

Torsion Effects

Shear Transfer from Roof Diaphragm -

to Shearwall

2012 IRC

Roof Framing

Force Transfer from

Diaphragm to Shearwall

F

B C

G

Overturning of Shearwalls Shearwall Hold-Down Anchors

Holddown

Anchor

Holddown

Anchor

Low-slip fasteners

Pre-deformed base

A plus in seismic loading

Holddown

Anchor

Multi-story apps.

Self-tightening

A plus in taller

structures

Continuous Threaded Rod

Timbers carry

Compression forces

at holddown

Overturning Forces

Only 0.6 x design dead load can be used to resist

overturning from wind or earthquake (IBC

1605.3, ASCE 7 Sec. 2.4)

Shear Wall Capacity

Based on:

Specific nail

size and

spacing

requirements

APA wood

structural

panels of

specific grade

and thickness

Specific

stud species

anchor bolts

Hold-down

anchors

Shearwall Minimum Aspect Ratios

w = h/3.5 for wind

w = h/2 for seismic

exception: 3.5:1 can be

used with penalty (2w/h)

h

w

40% Increase for Wind Capacity - 2006 IBC 2306.3.2

and 2306.4.1

The current shear wall and diaphragm tables

are based on a 2.8 min. safety factor

Code authors agreed that a 2.0 safety factor is

adequate due to confidence in wind load

accuracy - thus a 40% increase in tabulated

values

Summing Shear Capacities of Dissimilar

Materials

Section 2305.3.8

For wind design, adding the gypsum capacity on

the inside face of wall is allowed

How about composite action using

Adhesives?

Theoretically possible!

But true composite action requires rigid structural

adhesive.

Rigid structural adhesives are not suitable for field

application.

(Construction adhesives creep under load and do not

give 100% composite action.)

Wind v. Seismic

Shear Walls

Wind Design:

40% increased capacity

Gypsum strength can be added

3.5:1 max. aspect ratio

Seismic Design:

Requires 3x framing more often (SDC D-F)

2:1 max. aspect ratio without penalty

3.5:1 permitted with penalty (2w/h)

Wind v. Seismic

Shear Walls

Given:

7/16 OSB

8d common

3 / 6 edge/field nail

spacing

Gypsum on opposite face

H H

v

V

8

2.25

Wind v. Seismic

Shear Walls

Wind Capacity:

V=(450 plf x 1.4+100 plf) x 2.25 =1640 lb

Length of wall

WSP capacity from table

40% increase for wind

For gypsum from table

When less than 2:1 aspect ratio, 2w/h

adjustment

Seismic Capacity:

V=450 plf x 2(2.25)/8 x 2.25 =570 lb

Site-Built Portal Frame

Bracing Methods

St ur d-I -Fr ame w i t h Hol d Dow ns

Ref er enc e: APA Repor t TT-100

Overdriven Fasteners

Overdriven Fasteners

APA Recommendations

If <20% fasteners overdriven by <1/8", then they may be ignored.

If >20% fasteners overdriven by >1/8", then:

Prescriptive add 1 additional fastener for every 2 overdriven

Mechanics based re-analyze capacity based on average

thickness of panel measured from the bottom of the nail head. (5/8"

panel with fasteners overdriven by 1/8" =capacity of 1/2" panel.)

Reference Publication: APA Technical Topics: Power-

Driven Fastener Considerations, (Form TT-056, 1 page)

Reducing Hold-Down Anchorage

Segmented Shearwalls Continuous Shearwalls

Shearwall Design Methods

Segmented

1. Aspect Ratio for

seismic 2:1

2. Aspect ratio up to

3.5:1, if allowable

shear is reduced by

2w/h

IBC 2305.3.3

Force Transfer

1. Code does not

provide guidance for

this method

2. Different approaches

using rational

analysis are used

IBC 2305.3.8.1

Perforated

1. Code provides

specific requirements

2. The capacity is

determined based on

empirical equations

and tables

IBC 2305.3.8.2

Segmented (Traditional) Wood Shear Walls

(IBC 2305.3)

Only full height

segments are

considered

Max aspect ratio

2:1 for seismic

3.5:1 for wind

Current Code design

values based on data

dating back to 1950s.

H H H H

v v

V

Aspect ratio applies to full

height segment (dotted)

Shear Wall With Openings

Force Transfer Around Openings

(IBC 2305.3.7.1)

Shear around

openings accounted

for by strapping or

framing

based on a rational

analysis

H/w ratio defined by

wall pier

V

H

H

v

Wall

Pier

Aspect ratio applies to wall

pier segment (dotted)

Shear Wall With Opening

Force Transfer Around Opening

Hold-downs only at

ends

Extra calculations

and added

construction details

(connections &

blocking)

Uses traditional

design values

V

H

H

v

Shear Wall With Opening

Perforated Shear Wall

(IBC 2305.3.7.2)

Openings accounted for by

empirical adjustment

factor

Hold-downs only at ends

Uplift between hold downs,

t, at full height segments is

required

Limited to 490 plf

980 plf Seismic

1370 plf - Wind

V

H H

v

t

Aspect ratio applies to full

height segment (dotted)

X

Shear Capacity Adjustment

Shear Capacity Adjustment

Equation for Perforated Shearwalls

Shear Capacity Adjustment

Equation for Perforated Shearwalls

Suggested

References

Hold-Down Placement

Traditional

Hold-Down Placement

Perforated

Performance Based Seismic

Design

PBSD offers owners/operators the opportunity to limit

business interruption, economic loss, and other

consequences for less severe but more probable

earthquake hazards

Necessitates accurate modeling of structures under

seismic loading which for wood light-frame structures, this

is complex because the load path is not as discrete

NEESWood Capstone Tests

APA Publications and Website

For free publications

go to:

www.apawood.org

and enter the

Publications Store

A Sampling of APA Publications available at:

www.apawood.org

T300 Glulam connection details

E30 Engineered Wood Const. Guide

L350 Diaphragms and Shear Walls

T325 Roof fastening for wind uplift

Y250 Shear transfer at engineered

floors

A410 Roof retrofitting for wind uplift

D485 Corrosion resistant fasteners

A Sampling of APA Technical Topics - available at

www.apawood.org

TT-035 Corrosion resistant fasteners

TT-036 Glued floors

TT-039 Nail withdrawal

TT-070 Nail pull through

TT-045 Min. nail penetration

TT-012 Overdriven fasteners

TT-056 Power driven fasteners

TT-050/051 Screw withdrawal

TT-058 Slant nailing

TT-061- Nailing thin flange I-joists

TT-020 Dowel bearing strength

This concludes The

American Institute of

Architects Continuing

Education Systems Course

Quest i ons?

Bryan Readling, P.E.

bryan.readling@apawood.org

APA Help Desk

help@apawood.org

253-620-7400

Das könnte Ihnen auch gefallen

- Roof Sheathing FasteningDokument4 SeitenRoof Sheathing Fasteningnumber_25Noch keine Bewertungen

- Load Path Continuity : Not New!Dokument27 SeitenLoad Path Continuity : Not New!Zoha KhanNoch keine Bewertungen

- FOG9 All NoCoverP-30May22Dokument364 SeitenFOG9 All NoCoverP-30May22Plano Vertical SASNoch keine Bewertungen

- TJ 9003Dokument16 SeitenTJ 9003AnthonyNoch keine Bewertungen

- FOG8-1 All-No cover-24Jul16P PDFDokument368 SeitenFOG8-1 All-No cover-24Jul16P PDFOuctho LandNoch keine Bewertungen

- Shoring Operations Guide: Urban Search & RescueDokument152 SeitenShoring Operations Guide: Urban Search & Rescuetalavera507Noch keine Bewertungen

- Steel Roof Truss TutorialDokument6 SeitenSteel Roof Truss Tutorialsundar_s_2k100% (1)

- About Elematic Hollowcore PlankDokument32 SeitenAbout Elematic Hollowcore PlankManish Khandelwal0% (1)

- Drift Demand On FacadesDokument10 SeitenDrift Demand On FacadesNor Hasni TaibNoch keine Bewertungen

- Wall Frame Installation Guide V1.4 2015Dokument28 SeitenWall Frame Installation Guide V1.4 2015stevenmolisaNoch keine Bewertungen

- Res Wind SeismicDokument25 SeitenRes Wind SeismicAmity HwangNoch keine Bewertungen

- GA1381 Fasteners Guide 0909Dokument56 SeitenGA1381 Fasteners Guide 09094U6ogj8b9snylkslkn3nNoch keine Bewertungen

- Residential Wall - Eng ReviewDokument8 SeitenResidential Wall - Eng ReviewNathan Van BetuwNoch keine Bewertungen

- Woodframemultistory Article PDFDokument19 SeitenWoodframemultistory Article PDFLouis AndersonNoch keine Bewertungen

- Roof Truss Installation Guide V1.4 2015Dokument36 SeitenRoof Truss Installation Guide V1.4 2015DM Andrade0% (1)

- Anchorage of Wood Shear Walls To Concrete For Tension and Shear PDFDokument6 SeitenAnchorage of Wood Shear Walls To Concrete For Tension and Shear PDFIonFlorentaNoch keine Bewertungen

- 4010A Timber Framing Manual IntroductionDokument15 Seiten4010A Timber Framing Manual IntroductionDejan KarapandžićNoch keine Bewertungen

- FEMA E-74 Part7Dokument93 SeitenFEMA E-74 Part7Davo Duran EugenioNoch keine Bewertungen

- Insulation Retrofit DesignDokument23 SeitenInsulation Retrofit Designivan.barberoNoch keine Bewertungen

- Long Span Beams Span TablesDokument36 SeitenLong Span Beams Span Tableszzlesleyzz100% (1)

- TF SYSTEM MASTER SPEC As of 28feb18Dokument10 SeitenTF SYSTEM MASTER SPEC As of 28feb18StevenAronNoch keine Bewertungen

- US Army USAR FOG Manual 3-2009Dokument316 SeitenUS Army USAR FOG Manual 3-2009DJBruce2167% (3)

- TT 102Dokument5 SeitenTT 102Osvaldo Marques100% (1)

- SR-102 APA System Report 102 APA Simplified Wall Bracing Method PDFDokument15 SeitenSR-102 APA System Report 102 APA Simplified Wall Bracing Method PDFAbdurrahman CinarNoch keine Bewertungen

- Metal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsDokument5 SeitenMetal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsAlvaro MejiaNoch keine Bewertungen

- Design of Coastal Revetments, Seawalls and Bulkheads - Army Corps of Engineers (1995)Dokument9 SeitenDesign of Coastal Revetments, Seawalls and Bulkheads - Army Corps of Engineers (1995)Vishal Parashuram MiskinNoch keine Bewertungen

- Building in High Wind and Seismic Zones (APA)Dokument8 SeitenBuilding in High Wind and Seismic Zones (APA)IonFlorentaNoch keine Bewertungen

- TEDDS Engineering Library (AU)Dokument18 SeitenTEDDS Engineering Library (AU)Chesho ChitoboloNoch keine Bewertungen

- Designing Diaphragms Over Existing Board Floors or Roofs: Technical TopicsDokument4 SeitenDesigning Diaphragms Over Existing Board Floors or Roofs: Technical Topicsyoshdog@gmail.comNoch keine Bewertungen

- Hoist LoadsDokument44 SeitenHoist Loadslords3Noch keine Bewertungen

- PPC Catálogo Aislador Soporte ANSIDokument28 SeitenPPC Catálogo Aislador Soporte ANSIMateo AlvezNoch keine Bewertungen

- StAccMill Stack DesignDokument3 SeitenStAccMill Stack Designkselvan_1Noch keine Bewertungen

- Using Lysaght Roofing and Walling PDFDokument70 SeitenUsing Lysaght Roofing and Walling PDFkh88hmiNoch keine Bewertungen

- CSR Roofing ArchManual S1-S8Dokument127 SeitenCSR Roofing ArchManual S1-S8k2v1n5100% (1)

- Exterior Cladding DetailsDokument13 SeitenExterior Cladding DetailsMuhammad irfan javaidNoch keine Bewertungen

- Truss InformationDokument33 SeitenTruss InformationSarah LovegroveNoch keine Bewertungen

- CUEE DhakalandMacRae CeilinglessonsDokument10 SeitenCUEE DhakalandMacRae Ceilinglessonsumar khalifa shehuNoch keine Bewertungen

- Timber Roof Truss AnalysisDokument66 SeitenTimber Roof Truss AnalysisOmaidTanhaNoch keine Bewertungen

- Long-Span, Open-Web TrussesDokument8 SeitenLong-Span, Open-Web Trussesmina saadatNoch keine Bewertungen

- Shear Transfer at Engineered Wood FloorsDokument12 SeitenShear Transfer at Engineered Wood FloorsIonFlorentaNoch keine Bewertungen

- T 01WFCM08Dokument24 SeitenT 01WFCM08Jemna TudorNoch keine Bewertungen

- Design of Diaphram & Shear WallsDokument36 SeitenDesign of Diaphram & Shear WallsChidi HenryNoch keine Bewertungen

- Presentation Lightning Protection System by JMV LPSDokument62 SeitenPresentation Lightning Protection System by JMV LPSMahesh Chandra ManavNoch keine Bewertungen

- KLH SpecsDokument6 SeitenKLH Specsbob burgerNoch keine Bewertungen

- Solar Power PV Presentation by JMV LPS LTDDokument69 SeitenSolar Power PV Presentation by JMV LPS LTDMahesh Chandra ManavNoch keine Bewertungen

- Advanced Framing. Energy EfficiencyDokument3 SeitenAdvanced Framing. Energy EfficiencyUriel PeñaNoch keine Bewertungen

- Catalogue Solid Core PDFDokument16 SeitenCatalogue Solid Core PDFtholgasenelNoch keine Bewertungen

- 2 Principles of Roof Truss DesignDokument8 Seiten2 Principles of Roof Truss Designnaveenbaskaran1989Noch keine Bewertungen

- 2013 Mason Ancon MDC BracketsDokument36 Seiten2013 Mason Ancon MDC BracketsalwezalokNoch keine Bewertungen

- 0421 Roofing - CombinedDokument6 Seiten0421 Roofing - CombinedRiski SuhardinataNoch keine Bewertungen

- As 1684 Residential Timber Framing ConstructionDokument5 SeitenAs 1684 Residential Timber Framing ConstructionPopa0% (1)

- CH 1Dokument49 SeitenCH 1Gurinder PalsinghNoch keine Bewertungen

- TB 90 Performance Considerations For IMPs Rev.12140715Dokument4 SeitenTB 90 Performance Considerations For IMPs Rev.12140715SameerKhanNoch keine Bewertungen

- Design of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresVon EverandDesign of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresBewertung: 3.5 von 5 Sternen3.5/5 (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Small Wind: Planning and Building Successful InstallationsVon EverandSmall Wind: Planning and Building Successful InstallationsBewertung: 5 von 5 Sternen5/5 (2)

- FireplaceDokument16 SeitenFireplacemurdicksNoch keine Bewertungen

- Structural Wood ScrewsDokument13 SeitenStructural Wood ScrewsmurdicksNoch keine Bewertungen

- ICC-ES Listing Report ESL-1070: Csi: Product Certification SystemDokument1 SeiteICC-ES Listing Report ESL-1070: Csi: Product Certification SystemmurdicksNoch keine Bewertungen

- Forcefiled PopopDokument2 SeitenForcefiled PopopmurdicksNoch keine Bewertungen

- ICC-ES Listing Report ESL-1082: Csi: Product Certification SystemDokument2 SeitenICC-ES Listing Report ESL-1082: Csi: Product Certification SystemmurdicksNoch keine Bewertungen

- Firerock VentDokument16 SeitenFirerock VentmurdicksNoch keine Bewertungen

- Concrete CrackDokument3 SeitenConcrete CrackmurdicksNoch keine Bewertungen

- ICC-ES Listing Report ESL-1064: Csi: Product Certification SystemDokument2 SeitenICC-ES Listing Report ESL-1064: Csi: Product Certification SystemmurdicksNoch keine Bewertungen

- Cali Bamboo TruorganicsDokument2 SeitenCali Bamboo TruorganicsmurdicksNoch keine Bewertungen

- Ecoark Lightweight ConstructionDokument2 SeitenEcoark Lightweight ConstructionmurdicksNoch keine Bewertungen

- Solarpol Expandable Polystyrene BeadsDokument2 SeitenSolarpol Expandable Polystyrene BeadsmurdicksNoch keine Bewertungen

- FlameOFF Fire Barrier PaintDokument2 SeitenFlameOFF Fire Barrier PaintmurdicksNoch keine Bewertungen

- Reflective Plastic Core InsulationDokument2 SeitenReflective Plastic Core InsulationmurdicksNoch keine Bewertungen

- Kikgard ShieldDokument2 SeitenKikgard ShieldmurdicksNoch keine Bewertungen

- ICC-ES Listing Report ESL-1033: Csi: Product Certification SystemDokument1 SeiteICC-ES Listing Report ESL-1033: Csi: Product Certification SystemmurdicksNoch keine Bewertungen

- Daggerz Brand Construction FastenersDokument3 SeitenDaggerz Brand Construction FastenersmurdicksNoch keine Bewertungen

- Sanitary Cove Base Product Number S3619TDokument2 SeitenSanitary Cove Base Product Number S3619TmurdicksNoch keine Bewertungen

- Fabreeka Thermal Insulation MaterialDokument2 SeitenFabreeka Thermal Insulation MaterialmurdicksNoch keine Bewertungen

- ESR 1301 PacificDokument12 SeitenESR 1301 PacificmurdicksNoch keine Bewertungen

- Flamebar Bw11 Riser Duct SystemDokument2 SeitenFlamebar Bw11 Riser Duct SystemmurdicksNoch keine Bewertungen

- Seismic Wire RopeDokument6 SeitenSeismic Wire RopemurdicksNoch keine Bewertungen

- ICC-ES Listing Report ESL-1048: Most Widely Accepted and TrustedDokument3 SeitenICC-ES Listing Report ESL-1048: Most Widely Accepted and TrustedmurdicksNoch keine Bewertungen

- Metal Composite MaterialDokument2 SeitenMetal Composite MaterialmurdicksNoch keine Bewertungen

- ESR 1331 MaineDokument4 SeitenESR 1331 MainemurdicksNoch keine Bewertungen

- Esr 1170 StudDokument4 SeitenEsr 1170 StudmurdicksNoch keine Bewertungen

- Esr 1082 Eagle MetalsDokument9 SeitenEsr 1082 Eagle MetalsmurdicksNoch keine Bewertungen

- Joint Evaluation Report: Roseburg Forest Products CoDokument7 SeitenJoint Evaluation Report: Roseburg Forest Products ComurdicksNoch keine Bewertungen

- ESR 1153 WfyhafuserDokument22 SeitenESR 1153 WfyhafusermurdicksNoch keine Bewertungen

- Esr 1094 Stud WeldingDokument4 SeitenEsr 1094 Stud WeldingmurdicksNoch keine Bewertungen

- Esr 1040 Boise CascadeDokument8 SeitenEsr 1040 Boise CascademurdicksNoch keine Bewertungen

- Tal's Winning Chess Combinations PDFDokument411 SeitenTal's Winning Chess Combinations PDFioangely0% (2)

- Paper CI56Dokument5 SeitenPaper CI56getNoch keine Bewertungen

- Crisis Management 1Dokument9 SeitenCrisis Management 1kemerutNoch keine Bewertungen

- Abes Con Plan 2022 EarthquakeDokument36 SeitenAbes Con Plan 2022 EarthquakeSweetselle Karen Amoroso MontehermozoNoch keine Bewertungen

- An Explanatory Handbook On Is 875 Part 1987Dokument108 SeitenAn Explanatory Handbook On Is 875 Part 1987SourabhAdikeNoch keine Bewertungen

- The Great Chicago FireDokument11 SeitenThe Great Chicago FireClara MacielNoch keine Bewertungen

- Earthquake Load CalculationDokument3 SeitenEarthquake Load CalculationashishpanigrahiNoch keine Bewertungen

- The Impact of The Perception of Risk On International TravellersDokument11 SeitenThe Impact of The Perception of Risk On International TravellersPedro TrindadeNoch keine Bewertungen

- Role of Media in Disaster ManagementDokument12 SeitenRole of Media in Disaster ManagementCDMP BangladeshNoch keine Bewertungen

- UntitledDokument109 SeitenUntitledapi-284745434Noch keine Bewertungen

- Typhoon RaiDokument4 SeitenTyphoon Raichloe24Noch keine Bewertungen

- Fire and IceDokument7 SeitenFire and IceIrin Eliza ArunNoch keine Bewertungen

- Local Government of Imus City, Cavite: (CSWDO), City Health Office, and Human Resource & Management Unit (HRMU)Dokument2 SeitenLocal Government of Imus City, Cavite: (CSWDO), City Health Office, and Human Resource & Management Unit (HRMU)Chelsea SabadoNoch keine Bewertungen

- School Contigency Plan For Earthquake Asinan Elementary School 101372Dokument28 SeitenSchool Contigency Plan For Earthquake Asinan Elementary School 101372CONNIE AVELLANONoch keine Bewertungen

- EQ Hazard Analysis & Building Vulnerability Assessment To Determine The Seismic Risk of Existing Buildings in An Urban Area (2014) - Thesis Pamphlet PDFDokument16 SeitenEQ Hazard Analysis & Building Vulnerability Assessment To Determine The Seismic Risk of Existing Buildings in An Urban Area (2014) - Thesis Pamphlet PDFJulio Humberto Díaz RondánNoch keine Bewertungen

- Longitudinal Studi Merapi Korea ParipurnoDokument17 SeitenLongitudinal Studi Merapi Korea ParipurnoNABELLA NURUL FITRINoch keine Bewertungen

- Study Material For Disaster ManagementDokument205 SeitenStudy Material For Disaster ManagementsruthiNoch keine Bewertungen

- Social Tsunami ProjectDokument2 SeitenSocial Tsunami ProjectBhargavi ViraNoch keine Bewertungen

- DRR Integration in School Curricula PDFDokument229 SeitenDRR Integration in School Curricula PDFCarol LaconsayNoch keine Bewertungen

- Collision Check ListDokument2 SeitenCollision Check ListcatalinNoch keine Bewertungen

- C6 Weather & Climate CXC GeographyDokument60 SeitenC6 Weather & Climate CXC GeographyKyñg ShākëëlNoch keine Bewertungen

- Groupthink and Hurricane KatrinaDokument13 SeitenGroupthink and Hurricane Katrinaapi-437022299Noch keine Bewertungen

- A Rose For Emily (Analysis)Dokument4 SeitenA Rose For Emily (Analysis)Do Re Mi50% (2)

- Knowledge Skills Attitudes Values: OptionalDokument3 SeitenKnowledge Skills Attitudes Values: OptionalMARA SORONIONoch keine Bewertungen

- Soil Improvement in The Hilly Areas of District Mandi (H.P.)Dokument4 SeitenSoil Improvement in The Hilly Areas of District Mandi (H.P.)girithakurNoch keine Bewertungen

- Kids Box New Generation Level 5 Unit 4 Students Book Sample ContentDokument10 SeitenKids Box New Generation Level 5 Unit 4 Students Book Sample ContentAncuta ProcaNoch keine Bewertungen

- FEMA Org ChartDokument1 SeiteFEMA Org ChartAgung AdiputraNoch keine Bewertungen

- ACI 341-C Retrofit Presentation - Part 1Dokument65 SeitenACI 341-C Retrofit Presentation - Part 1raffikbashaNoch keine Bewertungen

- FEMA HANDBOOK On Infrastructure Support ProgramDokument70 SeitenFEMA HANDBOOK On Infrastructure Support ProgramGustavBlitzNoch keine Bewertungen

- Trainees Manual-Introductory Course On DRRM - 2022-03-11-09-54-27-AmDokument36 SeitenTrainees Manual-Introductory Course On DRRM - 2022-03-11-09-54-27-AmCrisanta Agoo100% (1)