Beruflich Dokumente

Kultur Dokumente

4325B Spiroform

Hochgeladen von

Raul PerezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4325B Spiroform

Hochgeladen von

Raul PerezCopyright:

Verfügbare Formate

T Th he e G Gl le ea as so on n S SP PI IR RO OF FO OR RM M

C Cu ut tt te er r S Sy ys st te em m

November 2000

The Gleason Works

1000 University Avenue

P. O. Box 22970

Rochester, New York 14692-2970

716-473-1000

- 3 -

The Gleason SPIROFORM

Cutter System

Dr. Hermann J. Stadtfeld

Vice President, Research & Development

The Gleason Works

1. Introduction

The new SPIROFORM

Cutter has stick type blades with a permanent front face and only

two surfaces that have to be resharpened. It solves the problem of face hobbing

(generating or Formate) a spiral bevel and hypoid flank surface identical to that using the

three face sharpened stick blade in an appropriate cutter head.

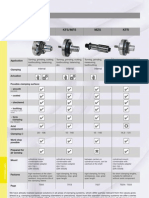

Figure 1: Different blade offsets

- 4 -

2. The Cutter System with Three Individually Sharpened Blade

Surfaces

Three face sharpened blades are known in face hobbing cutters from US Patent #

3,760,476. Those cutters may have three blades per blade group - one roughing or

bottom blade - one outside blade and one inside blade.

Figure 2: Effective offset angle is created by cutting velocity direction

The face hob cutter head has the following design specifications:

Slot Radius

Slot Offset

Number of Blade Groups

Blade Spacing

Built-In Hook Angle

Cutter Height

- 5 -

Figure 3: Zero effective hook angle by grinding the blade front face

There are some advantages of sharpening cutting edge side relief, clearance side relief

and front face.

A change of the cutting direction, as it happens for different job specifications, requires a

change in blade offset (Figure 1). A three side ground blade allows within some limits to

vary cutting direction (Figure 2) and effective hook angle (Figure 3 and Figure 4) without

any change in the cutter head. It is also possible to change the spacing between inside

and outside blade to some extent if the location of the front faces can be controlled

individually.

A disadvantage of the three-side ground blade is more complicated re-sharpening and

subsequently the removal of any coating on any of the three sides.

A coating of HSS or carbide blades is especially beneficial on the front face because of

the pressure and friction with hot chips.

- 6 -

Figure 4: Positive hook angle by grinding the blade front face

3. Cutter System with Two Individually-Sharpened Blade

Surfaces

If the cutter built-in offset angle is chosen in the middle of the possible variety of jobs,

then the blades built-in side rake angle accommodates the minimal deviation from the

optimal side rake. An optimal side rake angle is achieved if the effective offset and the

cutter built-in offset are identical (12

, the blade built-in side rake angle).

Only the cutting edge and clearance side - side relieves - are variable in their angle

relative to the blade shank which allows it to match them to different required offset

angles. In case of jobs on the two extreme ends of the spectrum; for example, the outer

blade has a higher side rake angle (e.g. 14), that makes the cutting edge sharper and

- 7 -

the inner blade has a lower side rake (e.g. 8), that makes the cutting edge duller (U.S.

Patent TRI-AC

). It has been proven that in case of a good choice of the cutter built-in

offset value, the compromise on the extreme ends of the job spectrum is negligible.

The cutter built-in hook angle is defined such that a 20 blade pressure angle, in

conjunction with the blade built-in side rake, provides a cutting edge with a zero effective

hook angle with respect to the motion direction.

In such a system, it is impossible to vary or control the hook angle individually. On the

other hand, the permanent geometry of the front face allows a permanent coating. Since

only the side reliefs are re-sharpened, the coating on the front face is not removed.

Due to re-sharpening, the cutting edge is moving down along the blade shank. The re-

sharpening removes the width of the worn coating, which results in a perfect fresh coating

on the front face along the new cutting edge.

4. Analysis of the Geometric Effects to the Flank Form by

Controlling the Front Face Orientation

The publications of Kotthaus ([1] and US Patent # 3,760,476) teach that maintaining a

sufficient side rake angle and especially to control the flank surface twist, the front face

has to be variable in two angular directions, the side rake angle and the hook angle. The

effective hook angle is the inclination around the normal radius (Figure 5) between the

cutting edge and the cutter head axis (Figure 4). The blade in Figure 4 is oriented such

that the relative cutting velocity vector lies in the presentation plane.

The effective hook angle is a function of the front face orientation with respect to the

blade shank, as well as the angle of the blade slot in the cutter head (built-in hook angle)

and the pressure angle of the cutting edge.

- 8 -

Figure 5: Relationship between hook angle and cycloidal path of different blade points

A change of the blade pressure angle has a direct influence onto the pressure angle of

the manufactured tooth flank.

A change of the hook angle in a face hobbing cutter blade causes a flank twist and

changes in profile crowning and pressure angle.

Figure 5 shows a blade with the Points A, B and C along a cutting edge that has a

positive hook angle. The figure also shows a cutting edge without any hook angle (Points

A

1

, B

1

and C

1

). The epicyclical path, generated by A is a different to the one generated

by A

1

. The curve associated with A

1

has a similar, but not identical, shape than the one

generated by A. The two curves are inclined and shifted relative to each other in Z-

direction. That means the spiral angle of curve A is increased relative to A

1

. The opposite

happens for curve B relative to B

1

.

- 9 -

The conclusion of the last paragraph is that the hook angle causes a positive flank twist

between heel and toe. This represents together with the already mentioned change in

profile crowning a rather complex flank form modification.

The blade systems that allow a change of the hook angle use this freedom for flank form

and V-H- movement (adjustability) optimizations. Studying the literature shows that the

inventor of those systems found it physically impossible to allow the same optimizations

by avoiding the individually-controlled front face. All attempts during the past 25 years to

develop a permanent front face cutter system with the same freedoms of the one with

front face ground blades remained without success.

5. New Cutter and Blade System

An interesting technical challenge was the attempt to develop a cutter and blade system

that allows all the freedoms of the three face sharpened blade, yet using a blade that is

shaped and sharpened on the two side relief surfaces only.

Finally, a discovery was made that relates the epicycloids, generated by different hook

and side rake angles. The idea is to find the radial location of one point along the cutting

edge of a given blade that lies on the same epicycloid, generated by a blade with different

hook and side rake angle. It is assumed that the given blade consists of a permanent

front face, no hook angle and a side rake that is constant along the shank. The hook

angle of this system is created by an inclination of the slot in the cutter head.

Figure 6 shows the two different blade types with the roll circle base circle kinematic

attached to the front face sharpened blade.

The Points B and B

1

of the two blade types are identical (Figure 5). The problem to solve

is to find the locations of the Points A

1

and C

1

, along the existing front face of the

simplified blade. The geographic height of the blade, with respect to the cutter head front

face remains constant.

To find the location of Point A

1

, the epicyclical kinematic with roll circle and base circle is

rotated clockwise until A contacts the front face of the new blade. This is the location of

- 10 -

A

1

. The movement from A to A

1

requires a rotation around the roll circle center,

superimposed by a rotation around the center of the base circle. The relationships for the

solution of this problem is shown in Figure 6 and expressed by the following equations:

E

X0x

+ R

B0x

= E

X3x

+ R

B3x

(1)

or:

S

*

sin(-

0

-j+

w

) + R

B0*

sin(

w

) = S

*

sin(-

0

-j+

w

+

w

) + R

B*

sin(

w

+

Hook

+

c

) (2)

Figure 6: Epicyclical kinematic of two different blade types

- 11 -

Where:

R

B0x

x-Component of Cutter Radius Vector (Blade without Hook)

R

B3x

x-Component of Cutter Radius Vector (Blade with Hook, rotated into

zero Hook Plane)

E

X0x

x-Component of Vector from Machine Center to Cutter Center (Blade

without Hook)

E

X3x

x-Component of Vector from Machine Center to Cutter Center (Blade

with Hook, rotated into zero Hook Plane)

S Radial Distance (Scalar of E

X0x

)

0

Cutter Phase Angle

j Swivel Angel

w

Offset Angle

R

B0

Scalar Cutter Radius (without Hook)

w

Rotation of Cutter Center around Base Circle

R

B

Scalar Cutter Radius (with Hook)

Hook

... Angle between R

B

and R

B0

c

Rotation of Blade with Hook Angle around Roll Circle (Cutter Center)

Between

w

and

c

is the following relationship:

w

=

c

/(1+z

generating gear

/z

cutter

) (3)

where:

z

generating gear

Number of Teeth Generating Gear

z

cutter

Number of Starts Cutter

Wanted is

w

out of formula (2). The mathematical solution is conducted with an iteration

algorithm. The difference between A

1

and A

2

is . is calculated as shown:

= I R

B3

- R

B0

I (4)

is the displacement of point A

2

along

normal radius (equal Z-Axis) to come to point A

1

,

that cuts the same epicycloid than point A. The epicycloid cut by A

1

will differ to some

extend from the desired one, cut by A. The shown approach is the physically closest

possible approximation, that infinitesimal observed represents a mathematical precise

solution. In practice it causes differences over the entire flank surface of only a few

microns and therefore can be neglected.

- 12 -

The analog scheme is applied to find Point C

1

(Figure 4), a rotation of the epicyclical

kinematic in counter clockwise direction brings C (Figure 3) to the front face of the new

blade.

According to the above shown solution any desired number of points along the cutting

edge with one particular hook angle can be converted into points on a cutting edge

without hook angle or any other chosen hook angle.

Depending on the mathematical function of the new cutting edge (circle, ellipse or higher

order), three, five or more points can be transformed from the original to the new cutting

edge. Three points, one on the tip, one in the center and one on the end of the cutting

edge, deliver a sufficient definition of the cutting edge function to capture the

characteristics of the different front face hook angles.

The possibility to influence the blade spacing in the cutter head by grinding the front face

of either inside- or outside- blade results in a tooth thickness or slot with change. The

SPIROFORM

blades can account for that feature also. A tooth thickness adjustment is

done by splitting the required amount and for example increasing the radius of the outer

blade cutting edge and decreasing the cutting edge radius of the inner blade by each half

the amount.

6. Summary

A method was found to convert a side relief and front face sharpened blade, held in a

face hob cutter head into a blade that has a permanent front face and is just profile

shaped or re-sharpened on the side relief surfaces.

The advantage of replacing the old style three face sharpened blade is in particular the

permanent character of the front face and its coating. The new carbide high speed cutting

depends to a large extend on the correct front face coating. Gear sets using three face

sharpened blades can only with high cost be converted into high speed carbide

manufacturing. To send a set of blades after re-sharpening to a coating facility requires

more expensive carbide blades in storage and includes the cost of up to 100 re-coatings

- 13 -

of each blade in the course of its life. This procedure increases the tooling cost by a

factor eight.

Figure 7: 160mm radius, 13 start SPIROFORM

cutter head

The new SPIROFORM

blades allow to convert all older three face ground jobs into a two

face sharpened blade system with a permanent front face coating. Gear sets have

not to be re-qualified after the conversion since the flank surface geometry stays

identically to the original.

Figure 7 shows a photo of a SPIROFORM

cutter with 160 mm radius and 13 starts. The

SPIROFORM

system uses no bottom blades. This provides a very solid and stiff cutter

construction. The used PENTAC

stick blades provide sufficient roughing action on the

secondary cutting edges (clearance sides).

- 14 -

Figure 8: Left side conventional, Right side cut with SPIROFORM

Front face coated blades provide good surface finish and improved productivity. The

SPIROFORM

blades are stepped in their building height, such that the tracks from outside

blade and inside blade blend smoothly together in the root fillet. Figure 8 shows to the

left an example of a conventionally cut ring gear. The gear to the right is cut using a

SPIROFORM

cutter and a Phoenix Free-Form machine. Surface finish and root blends

are superior for the SPIROFORM

gear.

- 15 -

7. Literature

[1] Kotthaus, E. Wirtschaftliches Herstellen von Spiralkegelrdern in kleinen und

groen Serien

Maschinenmarkt, 83. Jg. Heft 73, Sept. 1977, Wrzburg, Germany

Many of the described techniques and machines, as well as many applications of special

cycles and methods are protected worldwide by patents or patent applications of The

Gleason Works. The mentioned registered trademarks

of The Gleason Works are marked

as such.

The Gleason Works

1000 University Avenue

P.O. Box 22970

Rochester, New York USA 14692-2970

(716) 473- 1000

Cat. # 4325B

Das könnte Ihnen auch gefallen

- New L160-230 Series (Eng) U.S.A-S PDFDokument40 SeitenNew L160-230 Series (Eng) U.S.A-S PDFRaul PerezNoch keine Bewertungen

- 4319B - Flank Modifications in Bevel Gears Using A UMCDokument22 Seiten4319B - Flank Modifications in Bevel Gears Using A UMCRaul PerezNoch keine Bewertungen

- Hob ResharpeningDokument10 SeitenHob ResharpeningRaul PerezNoch keine Bewertungen

- Orientation Guide: MandrelsDokument2 SeitenOrientation Guide: MandrelsRaul PerezNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Em Waves and Transmission Lines - June-2015Dokument4 SeitenEm Waves and Transmission Lines - June-2015Veerayya JavvajiNoch keine Bewertungen

- Pharmaceutical Chemistry Answer Key Blue PacopDokument30 SeitenPharmaceutical Chemistry Answer Key Blue PacopJeannie UyNoch keine Bewertungen

- Fluid Mechanics by S K MondalDokument179 SeitenFluid Mechanics by S K MondalAghu AkzNoch keine Bewertungen

- Instruction ManualDokument140 SeitenInstruction ManualJerryChenNoch keine Bewertungen

- MHDDokument57 SeitenMHDAsifa AshrafNoch keine Bewertungen

- KKMehta-Pilot Plant Scale Up TechniqueDokument84 SeitenKKMehta-Pilot Plant Scale Up TechniqueAnkit PokarNoch keine Bewertungen

- Me6604 Gas Dynamics and Jet PropulsionDokument8 SeitenMe6604 Gas Dynamics and Jet PropulsionMohanraj SubramaniNoch keine Bewertungen

- A World Without Cause and Effect: Logic-Defying Experiments Into Quantum Causality Scramble The Notion of Time ItselfDokument3 SeitenA World Without Cause and Effect: Logic-Defying Experiments Into Quantum Causality Scramble The Notion of Time ItselfWalterHuNoch keine Bewertungen

- Snell Manuscript (Keelys Secrets)Dokument5 SeitenSnell Manuscript (Keelys Secrets)Gregg Martin100% (2)

- 4 - Rate Laws and Stoichiometry - StuDokument62 Seiten4 - Rate Laws and Stoichiometry - StuTiệp MatícNoch keine Bewertungen

- Lecture 1-2 PDFDokument49 SeitenLecture 1-2 PDFASHISH MEENANoch keine Bewertungen

- S.MORRIS 2006: This Powerpoint Is Hosted On Please Visit For 100's More Free PowerpointsDokument20 SeitenS.MORRIS 2006: This Powerpoint Is Hosted On Please Visit For 100's More Free PowerpointsDedy SatriyoNoch keine Bewertungen

- Geometric Shapes and TransformationsDokument10 SeitenGeometric Shapes and TransformationsisidroNoch keine Bewertungen

- Electron Irradiation Effect On Al2O3Dokument63 SeitenElectron Irradiation Effect On Al2O3younessinaNoch keine Bewertungen

- Silicon Controlled RectifierDokument148 SeitenSilicon Controlled RectifierSrinivasRaoNoch keine Bewertungen

- Chemistry Form Three Q&a1Dokument110 SeitenChemistry Form Three Q&a1MajaningumbaoNoch keine Bewertungen

- Introduction To Calculus Section Velocity and Distance (PageDokument32 SeitenIntroduction To Calculus Section Velocity and Distance (PageIhab AbdullahNoch keine Bewertungen

- Kinetics of Particles: Newton's Second LawDokument16 SeitenKinetics of Particles: Newton's Second Lawlil KamalNoch keine Bewertungen

- Final Exam Cheat SheetDokument1 SeiteFinal Exam Cheat SheetDanielle GuindonNoch keine Bewertungen

- Calculation of Air Pipe SizeDokument6 SeitenCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Sn003a en EuDokument13 SeitenSn003a en Eukopernik1977Noch keine Bewertungen

- Atwood MachineDokument4 SeitenAtwood MachineanisahNoch keine Bewertungen

- 11N90Dokument7 Seiten11N90rudra_1Noch keine Bewertungen

- Bus BarsDokument36 SeitenBus Barstceterex100% (1)

- 06 Train Track Dynamics June 08Dokument21 Seiten06 Train Track Dynamics June 08Charles KohNoch keine Bewertungen

- SHS General Chemistry 2Dokument350 SeitenSHS General Chemistry 2John Luis Reyes90% (20)

- Abhyudaya - Theme WriteupsDokument6 SeitenAbhyudaya - Theme WriteupsJuhi SinghNoch keine Bewertungen

- Revision Test PhysicsDokument56 SeitenRevision Test PhysicsAkshay Khanzode100% (4)

- Lab 4 Contamination Test FAIZUANDokument20 SeitenLab 4 Contamination Test FAIZUANfaizuanismailNoch keine Bewertungen