Beruflich Dokumente

Kultur Dokumente

Turning Bracelets

Hochgeladen von

SundarPrabhaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Turning Bracelets

Hochgeladen von

SundarPrabhaCopyright:

Verfügbare Formate

Turning Bracelets

By Gary R. Smith

In honor of my father who was turning wooden bracelets in the 1950s on a spindle

lathe with a 3 step pulley, spur center, dead tail stock center and home made tools.

In 1993, when I retired, I had more time for wood working. Having my fathers

old lathe I thought I would try turning. This demo is the evolution of the turning

that my father did.

First is to work safely. Wear a face shield or at least safety glasses and respect

your lathe.

The tools will be described as we go along. Use what ever tool that works best for

you.

Sizing bracelets: Inside range from 60 mm to 80mm. After determining the inside

diameter add about 20mm for the outside diameter.

Good Luck

Keep turning

I use a 3 in (about 90mm) template

with a center hole. Select your wood

and draw the circle and mark the

center.

Cut the circles out on a band saw.

Mount the block to the lathe using

the front of the chuck jaws as a jam

chuck. True up the outside to the

desired diameter.

True up the face of the block to the

desired width, marking the center

with an indentation.

Fill any cracks or voids with CA glue.

With a compass set to the inside

diameter draw a line to mark for the

parting tool.

Use a narrow parting tool that has a

modified tip.

Part in just over half way, opening the

kerf as you go.

Turn the blank around and repeat.

True up the face, mark center and

mark the parting line.

Part in until the core is free.

With a 3/8 round nose scraper clean

up the inside. Tilt the tool handle

down to give a shear scraping cut.

Turn blank around and clean the other

half. The blue tape is a depth gage so I

dont go in to far.

A piece of a small tire tube is cut and

put over the jaws of the chuck to

protect the inside of the bracelet.

Note: I also use a larger piece to

protect my hands and tools from the

chuck.

Insert the bracelet over the jaws and

expand (not to tight) it doesnt take

much to hold it.

Shape the outside and inside edge, turn

around and do the other edge. Sand

until youre satisfied. I do not finish

on the lathe.

Put on one or two coats of sanding

sealer and hand sand. With a 3 prong

spring holder I spray 2 to 3 coats of

lacquer.

Inlaying

Use skew chisel to cut the fibers where

the inlay will be placed. I made a tool

with two blades. Made from saber saw

blades and pointed, then sharpened on

the inside. This will cut the same each

time.

Remove the wood to the depth of the

inlay with a standard parting tool.

Stick the inlay strip to 2 or 3 layers of

masking tape. Apply contact to the

strip and the grove on the bracelet

blank.

After the glue dries remove with a

hobby knife or razor blade.

Clamp one end in the grove and work

around. Trim off end and reposition

clamp and leave to dry.

Remove tape and mount on lathe.

Shape and sand.

Segmented Bracelet

Start with a waste block the thickness

of the bracelet you want to make.

Mark the center as close as possible. I

have marked the center off for

illustration purposes. Drill a in hole

and countersink this will hold the piece

at center each time it is remounted.

Use a pointed tool or pencil to mark

the largest diameter that you can get.

Note: material needs to be removed on

the right and bottom of the waste block

to meet the center. This will keep

everything centered.

Using a disk sander remove the

material up to the line.

Waste block is ready for glue up.

1

st

glue up. Use in. thick material,

this is Rose Wood. Make each segment

long enough to cover when the corners

are cut off. I use Epoxy in most of my

lay-ups. Clean all surfaces with

Acetone especially on exotic woods.

2

nd

glue up.

Ready for the 3

rd

and 4

th

glue ups.

Note: Another ring has been marked.

Remove material down to that mark.

This will keep everything centered.

3

rd

and 4

th

ring complete.

Ready to turn.

Center removed.

Turn to shape desired.

Spring hanger for holding and

hanging for finishing. You can get

tempered wire at a hobby store.

1 coat of sanding sealer 2 coats gloss lacquer

Youre only limited by your imagination. Good Luck

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Carpet Floorring-Method StatementDokument6 SeitenCarpet Floorring-Method StatementA19944100% (7)

- Building A Cedar Strip CanoeDokument8 SeitenBuilding A Cedar Strip CanoecagedraptorNoch keine Bewertungen

- FDG0199 DLU Windmill InstructionsDokument12 SeitenFDG0199 DLU Windmill InstructionspisofNoch keine Bewertungen

- WaterproofingDokument14 SeitenWaterproofingAfzal MohamedNoch keine Bewertungen

- Analysis of The Passionate Shepherd To His Love - CttoDokument3 SeitenAnalysis of The Passionate Shepherd To His Love - CttoLigie Morales50% (2)

- Chapter 03 Orthographic ProjectionDokument14 SeitenChapter 03 Orthographic Projectionrahul555555Noch keine Bewertungen

- Bali & Beyond Magazine December 2011Dokument92 SeitenBali & Beyond Magazine December 2011Bali and Beyond MagazineNoch keine Bewertungen

- Drawing Book - First Year Technical DrawingDokument138 SeitenDrawing Book - First Year Technical DrawingSamson ManyanyeNoch keine Bewertungen

- Berio Aronne Analisi PDFDokument31 SeitenBerio Aronne Analisi PDF1111qwerasdfNoch keine Bewertungen

- Make Green 2Dokument7 SeitenMake Green 2cronox447Noch keine Bewertungen

- Global Warming and The Greenland Ice Sheet: Petr Chylek, Jason E. Box and Glen LesinsDokument22 SeitenGlobal Warming and The Greenland Ice Sheet: Petr Chylek, Jason E. Box and Glen LesinsSundarPrabhaNoch keine Bewertungen

- 7127.help For Breezeway Bangle-Beadwork-OctNov2014Dokument2 Seiten7127.help For Breezeway Bangle-Beadwork-OctNov2014SundarPrabhaNoch keine Bewertungen

- Giwa Regional Assessment 1b 15 16Dokument80 SeitenGiwa Regional Assessment 1b 15 16SundarPrabhaNoch keine Bewertungen

- Ipad Report Karsenti-Fievez enDokument56 SeitenIpad Report Karsenti-Fievez enGlobal_MontrealNoch keine Bewertungen

- Baubles, Bangles, and Biotypes: A Critical Review of The Use and Abuse of The Biotype ConceptDokument18 SeitenBaubles, Bangles, and Biotypes: A Critical Review of The Use and Abuse of The Biotype ConceptSundarPrabhaNoch keine Bewertungen

- 7 Things You Should Know About IpadsDokument2 Seiten7 Things You Should Know About IpadsCre8iveChalkieNoch keine Bewertungen

- Humanities-The Rajput Policy of Famous Mughal-Kalam Chouhan - 2Dokument4 SeitenHumanities-The Rajput Policy of Famous Mughal-Kalam Chouhan - 2Impact JournalsNoch keine Bewertungen

- How To Measure Your Bangle Size: 2.125 Inches 2.1875 Inches 2.25 InchesDokument2 SeitenHow To Measure Your Bangle Size: 2.125 Inches 2.1875 Inches 2.25 InchesSundarPrabha100% (1)

- BirdsDokument50 SeitenBirdsSundarPrabhaNoch keine Bewertungen

- Glass BanglesDokument10 SeitenGlass BanglesSundarPrabhaNoch keine Bewertungen

- Tsunami DescriptionDokument15 SeitenTsunami DescriptionSundarPrabhaNoch keine Bewertungen

- PollinationDokument84 SeitenPollinationSundarPrabhaNoch keine Bewertungen

- BirdsDokument14 SeitenBirdsSundarPrabhaNoch keine Bewertungen

- FlowerDokument17 SeitenFlowerRainiel Victor M. CrisologoNoch keine Bewertungen

- Reproduction in Flowering PlantsDokument10 SeitenReproduction in Flowering PlantsSundarPrabhaNoch keine Bewertungen

- PollinationDokument84 SeitenPollinationSundarPrabhaNoch keine Bewertungen

- Reproduction in Flowering PlantsDokument10 SeitenReproduction in Flowering PlantsSundarPrabhaNoch keine Bewertungen

- Flower BasicsDokument4 SeitenFlower BasicsAndrae GenusNoch keine Bewertungen

- Microsoft WordDokument17 SeitenMicrosoft WordAngeline Perez MacabentaNoch keine Bewertungen

- Separata Computacion 2016 Photoshop OkDokument50 SeitenSeparata Computacion 2016 Photoshop OkJ.A García ChoqueNoch keine Bewertungen

- Subodh Public School: Learners 4Dokument9 SeitenSubodh Public School: Learners 4Shresth GourNoch keine Bewertungen

- LRN Level B2 January 2019 Exam PaperDokument18 SeitenLRN Level B2 January 2019 Exam PaperZizi FotiadouNoch keine Bewertungen

- Everyman by Anonymous PDFDokument2 SeitenEveryman by Anonymous PDFMarkNoch keine Bewertungen

- 01A-2 Power Supply Before Contact XLRTEH4300G038443Dokument6 Seiten01A-2 Power Supply Before Contact XLRTEH4300G038443НиколайNoch keine Bewertungen

- Does It Look The Same Class 5 Notes CBSE Maths Chapter 5 (PDF)Dokument7 SeitenDoes It Look The Same Class 5 Notes CBSE Maths Chapter 5 (PDF)krishna GNoch keine Bewertungen

- Kata Heian YondanDokument2 SeitenKata Heian YondanAisyah Nur PutriNoch keine Bewertungen

- Why Wai Kru?Dokument3 SeitenWhy Wai Kru?wwhelan2385Noch keine Bewertungen

- Partitura Them BassesDokument16 SeitenPartitura Them BassespgbiogeoNoch keine Bewertungen

- 2009학년도 고3 9월모의고사 외국어영역Dokument8 Seiten2009학년도 고3 9월모의고사 외국어영역이상준Noch keine Bewertungen

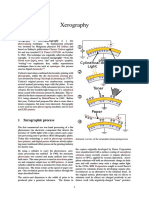

- Xer OgraphyDokument5 SeitenXer OgraphyPaula ZorziNoch keine Bewertungen

- Water Drop Splash PowerPoint TemplatesDokument48 SeitenWater Drop Splash PowerPoint TemplatesAnnisa PujiatiNoch keine Bewertungen

- Luanda Multisports PavilionDokument5 SeitenLuanda Multisports PavilionJushua EvangelistaNoch keine Bewertungen

- Electrophysiological Research of The Dynamics of Ki Energy Using The AMI DeviceDokument39 SeitenElectrophysiological Research of The Dynamics of Ki Energy Using The AMI Devicechucara2004Noch keine Bewertungen

- Lighting Catalogue 2021 Single PagesDokument125 SeitenLighting Catalogue 2021 Single PagessarahNoch keine Bewertungen

- Post Augustan Poetry PDFDokument851 SeitenPost Augustan Poetry PDFDicu AndreiArmand100% (1)

- Karate ChampionshipDokument2 SeitenKarate ChampionshipsanthoshinouNoch keine Bewertungen

- Moral Context in Relation To OthersDokument6 SeitenMoral Context in Relation To OthersMonria FernandoNoch keine Bewertungen

- Q1-W5 (Teachers Materials)Dokument13 SeitenQ1-W5 (Teachers Materials)RoVz Ferolino CabralesNoch keine Bewertungen

- Harga Tinta & TonerDokument26 SeitenHarga Tinta & TonerViesal NestaNoch keine Bewertungen

- Pablo PicassoDokument2 SeitenPablo PicassoAnastasia ChernatNoch keine Bewertungen