Beruflich Dokumente

Kultur Dokumente

5S

Hochgeladen von

Al Arafat RummanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5S

Hochgeladen von

Al Arafat RummanCopyright:

Verfügbare Formate

5S

Release date: 29

th

Feb, 2012 | Version 1.2 1

5S - Seiri , Seiton, Seiso, Seiketsu, Shitsuke

5S

Release date: 29

th

Feb, 2012 | Version 1.2 2

Introduction to Lean

5S

3 Release date: 29

th

Feb, 2012 | Version 1.2

This work is licensed under the Creative Commons Attribution-

NonCommercial-ShareAlike 3.0 Unported License.

To view a copy of this license,

visit http://creativecommons.org/licenses/by-nc-sa/3.0/ or send a

letter to Creative Commons, 171 Second Street, Suite 300, San

Francisco, California, 94105, USA.

Copyright License

5S

4 Release date: 29

th

Feb, 2012 | Version 1.2

What is Lean?

Lean manufacturing was developed by the Japanese automotive industry,

with a lead from Toyota and utilising the Toyota Production System (TPS),

following the challenge to re-build the Japanese economy after World War

II

The concept of lean thinking was introduced to the Western world in 1991

by the book The Machine That Changed the World written by Womack,

Jones, and Roos

Lean is a philosophy that seeks to eliminate waste in all aspects of a firms

production activities: human relations, vendor relations, technology, and

the management of materials and inventory

5S

5 Release date: 29

th

Feb, 2012 | Version 1.2

Lean is a term coined to describe the Toyota Production

System

Fujio Cho, Toyota Chairman, in a Business 2.0 interview, Jan/Feb 2005

..Some people think that if they just implement our techniques, they can

be as successful as we are. But those that try often fail. That's because no

mere process can turn a poor performer into a star. Rather, you have to

address employees' fundamental way of thinking. At Toyota, we start with

2 questions:

"Where are we wasting resources like time people or material?"

How can we be less wasteful?"

5S

6 Release date: 29

th

Feb, 2012 | Version 1.2

The Goal

Receive

Customer

Order

Receive

Payment

Maximize Value to Customer

Maximize Value to Shareholder

Eliminate Waste

Deliver

Service or

Product

5S

7 Release date: 29

th

Feb, 2012 | Version 1.2

The Goal

The unavoidable reality of business:

We will never be given more people and more time, to make less, at

greater cost. Business will continue to move in the direction of make

more, faster & cheaper, with fewer people

Eliminating waste (by implementing 5S) is a means towards this end

5S

8 Release date: 29

th

Feb, 2012 | Version 1.2

Other Lean Tools

Muda i.e. 7 Wastes

Pull Production and Kanban

Just-in-Time

Poka-Yoke i.e. Mistake Proofing

Jidoka i.e. Autonomation

Heijunka i.e. Levelling, Sequencing and Standadrization

Kaizen i.e. Continuous Improvement

Kaikaku i.e. Breakthrough Improvement

Single Minute Exchange of Dies (SMED)

Yamazumi

Andon

Value Stream Mapping (VSM)

.. and more

5S

Release date: 29

th

Feb, 2012 | Version 1.2 9

Introduction to 5S

5S

10 Release date: 29

th

Feb, 2012 | Version 1.2

The 5S

SEIRI

SEITON

SEISO

SEIKETSU

SHITSUKE

Sorting / Segregating

Set in Order / Arranging

Shine / Spic and Span

Standardize

Sustain / Self Discipline

5S

11 Release date: 29

th

Feb, 2012 | Version 1.2

The 5S

Sort - All unneeded tools, parts and supplies are removed from the area

Set in Order - A place for everything and everything is in its place

Shine - The area is cleaned as the work is performed

Standardize - Cleaning and identification methods are consistently applied

Sustain - 5S is a habit and is continually improved

Also work areas are safe and free of hazardous or dangerous items and

conditions

5S

12 Release date: 29

th

Feb, 2012 | Version 1.2

Relationships of the 5S+1 (6S) Pillars

5S

13 Release date: 29

th

Feb, 2012 | Version 1.2

Benefits of 5S

Maintain good product quality

Improve your quality, efficiency and productivity

Reduce lead time and cost, Improve profit

Maintain good control over the processes

Ensure safety and cleanliness

Reduce waste hidden in the plant

5S

14 Release date: 29

th

Feb, 2012 | Version 1.2

Some new words

Red Tag: Process for tagging, removing and disposing of items not needed

in the work area

Lean Manufacturing: concepts that seek continuous improvement by

removing waste in processes

Muda: (pronounced moo da) waste

Gemba: (pronounced gim ba) workplace

5S

15 Release date: 29

th

Feb, 2012 | Version 1.2

Red Tagging

Red Tagging is a method of identifying 5S related issues and tagging them

at the workplace for easy identification and resolution

Red Tags should be easily available around the work place

Red Tags can be placed by anyone, even if they are false reports once in a

while

Red Tags promotes the participation of employees to make the workplace

a 5S workplace

5S

16 Release date: 29

th

Feb, 2012 | Version 1.2

A Sample Red Tag

5S

17 Release date: 29

th

Feb, 2012 | Version 1.2

Some 5S examples

After 5S - Cleaned,

organized and drawers

labeled (less time and

frustration hunting)

Before 5S

5S

18 Release date: 29

th

Feb, 2012 | Version 1.2

Some 5S examples

See the difference?

1. Sort: All unneeded tools, parts and supplies are

removed from the area

2. Set in Order: A place for everything and everything is

in its place

5S

19 Release date: 29

th

Feb, 2012 | Version 1.2

Some 5S examples

3. Shine - The area is cleaned as the work is performed

(best) and\or there is a routine to keep the work

area clean

5S

20 Release date: 29

th

Feb, 2012 | Version 1.2

Where is the Business Sense?

While many improvements can be identified using 5S, that will make our

workplace a better place, it is also very critical to look for improvements

that have DIRECT BUSINESS IMPACT, such as:

Helping save Costs / Capital Investment, thus helping in cost

avoidance and profitability growth

Helping grow revenue

Helping improve customer satisfaction

5S

21 Release date: 29

th

Feb, 2012 | Version 1.2

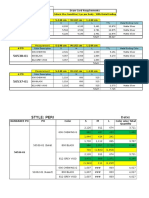

5S systems results:

5S

Release date: 29

th

Feb, 2012 | Version 1.2 22

The 1

st

S:

Seiri Sorting / Segregating

5S

23 Release date: 29

th

Feb, 2012 | Version 1.2

Seiri Sorting / Segregating

Junk & Waste

Separating the wanted and unwanted

Repairable Wanted Items

No Use

Repair

Sell as Scrap

To next step

Discard

5S

24 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiri keep in mind

Make sure you take care of:

What is needed

When it is needed

In the amount needed

What is not needed is moved / thrown out

5S

25 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiri keep in mind

How often things are used

What is the life of the material

Cost of the material

Be sure that you can throw the things, otherwise you may repent

How frequently do we dispose waste?

5S

26 Release date: 29

th

Feb, 2012 | Version 1.2

Consequences of not following Seiri

The wanted is hard to find, when required

More space is demanded and utilized

Unwanted items cause misidentification

Misidentification causes errors in operation

Maintenance cost of the equipments increases

5S

27 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

28 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

29 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

30 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

31 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

32 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

33 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

34 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

Release date: 29

th

Feb, 2012 | Version 1.2 35

The 2

nd

S:

Seiton Set in order / arranging

5S

36 Release date: 29

th

Feb, 2012 | Version 1.2

Seiton Set in order / arranging

Identifying places to arrange the things and placing them in proper order

for prompt usage

A place for every thing and

everything in its place

5S

37 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiton keep in mind

Organize things

Arrange needed items so that they are:

Easy to find

Easy to use

Easy to put away

5S

38 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiton keep in mind

The right location where the things / items will be used

FIFO (First in First out) arrangement

High Demand, Near Reach (HDNR) arrangement

Labeling of the area and the equipment is very important

Keep proper gaps between two things to avoid confusion

5S

39 Release date: 29

th

Feb, 2012 | Version 1.2

Seiton and Visual Controls

Good Seiton includes use of labels, signs, indications, display, cautions,

signals, symbols, etc. that at a glance show how things should be done or

where things should go

Use of labels signs, indications, display, cautions highlights, difference

between normality and abnormality

Non - users of the equipments also become aware of its use and

precautions

5S

40 Release date: 29

th

Feb, 2012 | Version 1.2

Visual Controls System Implementation

Develop a map identifying the access ways (aisles, entrances, walkways

etc.) and the action areas

Perform any necessary realignment of walkways, isles, entrances

Assign an address to each of the major action areas

Mark off the Walkways, aisles & entrances from the action areas

Apply flow-direction arrows to aisles & walkways

5S

41 Release date: 29

th

Feb, 2012 | Version 1.2

Visual Controls System Implementation

Perform any necessary realignment of action areas

Mark-off the inventory locations

Mark-off equipment/machine locations

Mark-off storage locations(Cabinets, shelves, tables)

Color-code the floors and respective action areas

5S

42 Release date: 29

th

Feb, 2012 | Version 1.2

Consequences of not following Seiton

The wanted is hard to find, when required, thereby resulting in lost time

More space is demanded and utilized

Lack of intuitive organization, leads to safety issues and loss of

productivity

Lack of intuitive display, leads to lack of knowledge of missing / low

inventory items

5S

43 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

44 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

45 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

46 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

47 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

48 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

49 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

50 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

51 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

52 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

53 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

54 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

Release date: 29

th

Feb, 2012 | Version 1.2 55

The 3

rd

S:

Seiso Shine / Spic and Span

5S

56 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiso keep in mind

Clean

Sweep floors

Wipe machinery and equipment

Paint and repair

Get it clean

Keep everything in good condition so it is always reliable and ready to be

used

5S

57 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiso keep in mind

Cleaning should be done regularly

Use the best cleaning agent

All the nooks and corners should be cleaned

Keep all the labels intact

All the labels should be correct, visible and legible to all

5S

58 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiso keep in mind

Repair, clean & shine work area

Important for safety

Maintenance problems such as oil leaks can identified before they cause

problems

Schedule for cleaning, sweeping, wiping off

Cleaning inspection checklists

Workspace always ready to work

See workspace through customers eyes

5S

59 Release date: 29

th

Feb, 2012 | Version 1.2

Consequences of not practicing Seiso

Performance of machines deteriorates

The quality / aesthetic quality deteriorates

Dirty place is unpleasant and hazardous to health

Sends uncaring and irresponsible message to the team members and

society at large

People working at dirty areas are generally found to have low desire to

excel and their motivation level is low

5S

60 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

61 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

62 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

63 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

64 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

65 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

66 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

67 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

68 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

69 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

70 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

71 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

72 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

73 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

Release date: 29

th

Feb, 2012 | Version 1.2 74

The 4

th

S:

Seiketsu Standardize

5S

75 Release date: 29

th

Feb, 2012 | Version 1.2

Seiketsu - Standardize

Always aim at maintaining the standard level of cleanliness, hygiene and

visual control

Keep all the 4 Ms (Man, Machine, Material and Method) intact, a lapse in

any one of them will make you loose the rest of the three

Without Standardized implementation of first 3S, improvements made

with the first three pillars do not last, and conditions go back to the way

they were

5S

76 Release date: 29

th

Feb, 2012 | Version 1.2

How to implement Seiketsu Standardize

Formalize procedures and practices to create consistency and ensure all

steps are performed correctly

Departments have weekly 5S tours

Every job has duties that use Sort, Set in Order and Shine

We all have common duties to do our part to keep all areas of the plant in

shape break room, restrooms, locker area, parking lot, etc

5S

77 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Seiketsu keep in mind

The standards should be arrived at unanimously

Always keep the standards flexible to changes and improvements

Standards should be known to all and displayed

5S

78 Release date: 29

th

Feb, 2012 | Version 1.2

Consequences of not following Seiketsu

Dual standards yield multiple results

Multiple results lead to conflicts and confusions

Rework increases

Rework increases the basic cost of the finished product without any value

addition

5S

79 Release date: 29

th

Feb, 2012 | Version 1.2

The Essence of Seiketsu

It is the proof that 3-S (SEIRI, SEITON, SEISO) are being religiously carried

out.

It is the barometer which indicates the control level based on the 5-S of all

the workers

5S

80 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

81 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

82 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

83 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

Release date: 29

th

Feb, 2012 | Version 1.2 84

The 5th S:

Shitsuke Sustain / Self Discipline

5S

85 Release date: 29

th

Feb, 2012 | Version 1.2

Shitsuke Sustain / Self Discipline

Role of Leadership

Educating, creating teams, providing time and resources, providing

motivation and recognition

Role of Operators

Participating in implementation, contributing ideas, talking about

strengths and areas for improvement, helping promote the Five Pillars

5S

86 Release date: 29

th

Feb, 2012 | Version 1.2

Shitsuke Sustain / Self Discipline

If you are disciplined:

Rules will always be followed

Laid down targets will be achieved

Improvements will be promoted

The no. of defects will be reduced

The cost will not increase

5S

87 Release date: 29

th

Feb, 2012 | Version 1.2

How to practice Shitsuke

Keep the processes going through

Train all team members on 4-S

Continued communication

Correct wrong practices on the spot

Punctuality is the backbone of 5S

Follow work instructions

Reward and recognitions

5S

88 Release date: 29

th

Feb, 2012 | Version 1.2

How to practice Shitsuke

5S Slogans

5S Posters

5S Maps

5S Newsletters

5S Tours

5S Audits

5S Story Board

5S

89 Release date: 29

th

Feb, 2012 | Version 1.2

How to practice Shitsuke

5S

90 Release date: 29

th

Feb, 2012 | Version 1.2

While doing Shitsuke keep in mind

Culture is not build overnight

Involve as many people as possible

Defining recommended behaviors is very important

Rewards and Recognitions play a key role

Similarly, unacceptable behaviors and penalties should be clearly laid

down

5S

91 Release date: 29

th

Feb, 2012 | Version 1.2

Consequences of not practicing Shitsuke

The 5S initiative will die a quick death

Organization moves back initial state

Employees loose trust on initiatives undertaken in the organization

Employees might not provide natural and immediate support any new

initiatives

5S

92 Release date: 29

th

Feb, 2012 | Version 1.2

Identify issues or best practices if any

5S

93 Release date: 29

th

Feb, 2012 | Version 1.2

Story Boards Identify issues or best practices if any

5S

94 Release date: 29

th

Feb, 2012 | Version 1.2

Rewards and Recognitions Identify issues or best

practices if any

5S

95 Release date: 29

th

Feb, 2012 | Version 1.2

Before & After charts Identify issues or best practices if

any

5S

96 Release date: 29

th

Feb, 2012 | Version 1.2

5S Posters Identify issues or best practices if any

5S

Release date: 29

th

Feb, 2012 | Version 1.2 97

Additional Resources and Sources

5S

98 Release date: 29

th

Feb, 2012 | Version 1.2

5S Rollout

Gradually too fast unsustainable

During slow time

Importance of training, Management commitment

Before & After photos

Change of mentality, not campaigns and slogans. Old way no longer OK

Management by walking around (MBWA / Gemba Walks), Patrols

5S

99 Release date: 29

th

Feb, 2012 | Version 1.2

Benefits of 5S

What are some benefits

of implementing 5s?

Workers have an

opportunity to provide

creative ideas about how

the workplace should be

organized

Higher job

satisfaction

Clear expectations

Reduced delays

mean timely

delivery of product

Reduced

changeover time =

higher productivity

Elimination of

cost causing

waste

Reduced defects

and higher

quality

Safer

environment

Maintained machinery

and equipment means

reduced downtime

Win customer

confidence and

trust

Growth

5S

100 Release date: 29

th

Feb, 2012 | Version 1.2

Where is the Business Sense?

While many improvements can be identified using 5S, that will make our

workplace a better place, it is also very critical to look for improvements

that have DIRECT BUSINESS IMPACT, such as:

Helping save Costs / Capital Investment, thus helping in cost

avoidance and profitability growth

Helping grow revenue

Helping improve customer satisfaction

5S

101 Release date: 29

th

Feb, 2012 | Version 1.2

Contact Us

WEBSITE

http://www.lassib.org/

EMAIL

contact@lassib.org

SOCIETY HEADQUARTERS

#5-70, V. V. Nagar, Street No. 8, Habsiguda,

Hyderabad, Andhra Pradesh, India - 500007

PHONE

India Landline: +91-40-40045614

India Fax:+91-40-40045615

India Toll-Free: 1-800-425-1388

5S

102 Release date: 29

th

Feb, 2012 | Version 1.2

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Physiology of Eye. Physiology of VisionDokument27 SeitenPhysiology of Eye. Physiology of VisionSmartcool So100% (1)

- Surge Protection Devices GuidesDokument167 SeitenSurge Protection Devices GuidessultanprinceNoch keine Bewertungen

- Week 1 Lab #2 - Microscopy & Microscopic Examination of Living MicroorganismsDokument53 SeitenWeek 1 Lab #2 - Microscopy & Microscopic Examination of Living MicroorganismsNgoc PhamNoch keine Bewertungen

- TodayDokument8 SeitenTodayAl Arafat RummanNoch keine Bewertungen

- Daily Routine at Corona LifeDokument9 SeitenDaily Routine at Corona LifeAl Arafat RummanNoch keine Bewertungen

- New Microsoft Excel WorksheetDokument4 SeitenNew Microsoft Excel WorksheetAl Arafat RummanNoch keine Bewertungen

- Yarn TestDokument1 SeiteYarn TestHunter KingNoch keine Bewertungen

- HRDokument34 SeitenHRAl Arafat RummanNoch keine Bewertungen

- New Microsoft Excel WorksheetDokument4 SeitenNew Microsoft Excel WorksheetAl Arafat RummanNoch keine Bewertungen

- Buyer Style Po No Order Qty Knitt - Issu Knitt - Receive LinkingDokument4 SeitenBuyer Style Po No Order Qty Knitt - Issu Knitt - Receive LinkingAl Arafat RummanNoch keine Bewertungen

- Quality Assurance Department (QAD)Dokument9 SeitenQuality Assurance Department (QAD)Al Arafat RummanNoch keine Bewertungen

- FFQCDokument64 SeitenFFQCAl Arafat RummanNoch keine Bewertungen

- Bengal Record Manual 1943 2Dokument10 SeitenBengal Record Manual 1943 2Al Arafat RummanNoch keine Bewertungen

- Step-1: Yarn Test: Quality Management System Pride GroupDokument2 SeitenStep-1: Yarn Test: Quality Management System Pride GroupAl Arafat RummanNoch keine Bewertungen

- nAhiD - Ns 09.04.2015 CH20Dokument40 SeitennAhiD - Ns 09.04.2015 CH20Al Arafat RummanNoch keine Bewertungen

- CV FinalDokument2 SeitenCV FinalAl Arafat RummanNoch keine Bewertungen

- PERI - Draw CordDokument4 SeitenPERI - Draw CordAl Arafat RummanNoch keine Bewertungen

- nAhiD - ns19.03.2015 BrandDokument16 SeitennAhiD - ns19.03.2015 BrandAl Arafat RummanNoch keine Bewertungen

- CommercialDokument1 SeiteCommercialAl Arafat RummanNoch keine Bewertungen

- HR Texile Ltd. (Pride Group) : BuyerDokument3 SeitenHR Texile Ltd. (Pride Group) : BuyerAl Arafat RummanNoch keine Bewertungen

- NAhiD - Ns C5 Kotler01Dokument30 SeitenNAhiD - Ns C5 Kotler01Al Arafat RummanNoch keine Bewertungen

- NAhiD - Ns - C4how Business and Marketing Are ChangingDokument1 SeiteNAhiD - Ns - C4how Business and Marketing Are ChangingAl Arafat RummanNoch keine Bewertungen

- nAhiD - ns19.03.2015 BrandDokument16 SeitennAhiD - ns19.03.2015 BrandAl Arafat RummanNoch keine Bewertungen

- NAhiD - Ns - C3the Marketing ProcessDokument58 SeitenNAhiD - Ns - C3the Marketing ProcessAl Arafat RummanNoch keine Bewertungen

- Customer Relationship ManagementDokument7 SeitenCustomer Relationship ManagementAl Arafat RummanNoch keine Bewertungen

- How Business and Marketing Are ChangingDokument5 SeitenHow Business and Marketing Are ChangingAl Arafat RummanNoch keine Bewertungen

- Calculation Formula Marker 1Dokument6 SeitenCalculation Formula Marker 1Al Arafat RummanNoch keine Bewertungen

- nAhiD - Ns 09.04.2015 CH20Dokument40 SeitennAhiD - Ns 09.04.2015 CH20Al Arafat RummanNoch keine Bewertungen

- NAhiD - Ns C5 Kotler02Dokument24 SeitenNAhiD - Ns C5 Kotler02Al Arafat RummanNoch keine Bewertungen

- nAhiD - ns19.03.2015 BrandDokument16 SeitennAhiD - ns19.03.2015 BrandAl Arafat RummanNoch keine Bewertungen

- NAhiD - Ns 26.03.2015 Chapter EightDokument17 SeitenNAhiD - Ns 26.03.2015 Chapter EightAl Arafat RummanNoch keine Bewertungen

- nAhiD - Ns 09.04.2015 CH20Dokument40 SeitennAhiD - Ns 09.04.2015 CH20Al Arafat RummanNoch keine Bewertungen

- NAhiD - Ns - C3marketing Management OrientationDokument20 SeitenNAhiD - Ns - C3marketing Management OrientationAl Arafat RummanNoch keine Bewertungen

- T-61.246 Digital Signal Processing and Filtering T-61.246 Digitaalinen Signaalink Asittely Ja Suodatus Description of Example ProblemsDokument35 SeitenT-61.246 Digital Signal Processing and Filtering T-61.246 Digitaalinen Signaalink Asittely Ja Suodatus Description of Example ProblemsDoğukan TuranNoch keine Bewertungen

- Multidimensional Scaling Groenen Velden 2004 PDFDokument14 SeitenMultidimensional Scaling Groenen Velden 2004 PDFjoséNoch keine Bewertungen

- ECDIS Presentation Library 4Dokument16 SeitenECDIS Presentation Library 4Orlando QuevedoNoch keine Bewertungen

- Bangalore Escorts Services - Riya ShettyDokument11 SeitenBangalore Escorts Services - Riya ShettyRiya ShettyNoch keine Bewertungen

- (Guide) Supercharger V6 For Everyone, Make Your Phone Faster - Xda-DevelopersDokument7 Seiten(Guide) Supercharger V6 For Everyone, Make Your Phone Faster - Xda-Developersmantubabu6374Noch keine Bewertungen

- PCI Secure Software Standard v1 - 0Dokument67 SeitenPCI Secure Software Standard v1 - 0Antonio ClimaNoch keine Bewertungen

- Applications of Remote Sensing and Gis For UrbanDokument47 SeitenApplications of Remote Sensing and Gis For UrbanKashan Ali KhanNoch keine Bewertungen

- Caracterisation D'une Entreprise anglosaxonne-ETLV - STMG1.Dokument2 SeitenCaracterisation D'une Entreprise anglosaxonne-ETLV - STMG1.meredith.licagaNoch keine Bewertungen

- Tutorial 4 QuestionsDokument3 SeitenTutorial 4 QuestionshrfjbjrfrfNoch keine Bewertungen

- Guide Rail Bracket AssemblyDokument1 SeiteGuide Rail Bracket AssemblyPrasanth VarrierNoch keine Bewertungen

- Spermatogenesis: An Overview: Rakesh Sharma and Ashok AgarwalDokument25 SeitenSpermatogenesis: An Overview: Rakesh Sharma and Ashok Agarwalumar umarNoch keine Bewertungen

- BMW Engine Wiring 2 OxDokument4 SeitenBMW Engine Wiring 2 OxTomáš TdcNoch keine Bewertungen

- MBF100 Subject OutlineDokument2 SeitenMBF100 Subject OutlineMARUTI JEWELSNoch keine Bewertungen

- Travel OrderDokument2 SeitenTravel OrderStephen EstalNoch keine Bewertungen

- I. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SADokument2 SeitenI. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SAMuhamad KhoerulNoch keine Bewertungen

- Engineering Economics1Dokument64 SeitenEngineering Economics1bala saiNoch keine Bewertungen

- Sci5 q3 Module3 NoanswerkeyDokument22 SeitenSci5 q3 Module3 NoanswerkeyRebishara CapobresNoch keine Bewertungen

- Green Team Work PlanDokument2 SeitenGreen Team Work PlanScott FranzNoch keine Bewertungen

- LS3954A LS3954 LS3955 LS3956 LS3958: Linear Integrated SystemsDokument3 SeitenLS3954A LS3954 LS3955 LS3956 LS3958: Linear Integrated SystemsJCMNoch keine Bewertungen

- What Is A Timer?Dokument12 SeitenWhat Is A Timer?Hemraj Singh Rautela100% (1)

- Lesson Plan Outline - Rebounding - Perez - JoseDokument7 SeitenLesson Plan Outline - Rebounding - Perez - JoseJose PerezNoch keine Bewertungen

- 04 10 ALINT DatasheetDokument2 Seiten04 10 ALINT DatasheetJoakim LangletNoch keine Bewertungen

- VSL Synchron Pianos Changelog en 1.1.1386Dokument4 SeitenVSL Synchron Pianos Changelog en 1.1.1386RdWingNoch keine Bewertungen

- Man of The House Faq: About MothDokument2 SeitenMan of The House Faq: About MothPrapya BarmanNoch keine Bewertungen

- VERITAS NetBackup 4 (1) .5 On UnixDokument136 SeitenVERITAS NetBackup 4 (1) .5 On UnixamsreekuNoch keine Bewertungen

- Nationalisation of Insurance BusinessDokument12 SeitenNationalisation of Insurance BusinessSanjay Ram Diwakar50% (2)

- Glossario - GETTY - IngDokument24 SeitenGlossario - GETTY - IngFabio ZarattiniNoch keine Bewertungen