Beruflich Dokumente

Kultur Dokumente

Wago - Device Net Coupler With AB ControlLogix

Hochgeladen von

Marcelo Fiod Hasman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten24 SeitenUsing WAGO Series 750 DeviceNet IO with an A-B ControlLogix 1756-DNB Scanner Application note A100103, English Version 1.0. Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time. The software and hardware terms as well as the trademarks of companies used and / or mentioned in the present manual are generally trademark or patent protected.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenUsing WAGO Series 750 DeviceNet IO with an A-B ControlLogix 1756-DNB Scanner Application note A100103, English Version 1.0. Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time. The software and hardware terms as well as the trademarks of companies used and / or mentioned in the present manual are generally trademark or patent protected.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten24 SeitenWago - Device Net Coupler With AB ControlLogix

Hochgeladen von

Marcelo Fiod HasmanUsing WAGO Series 750 DeviceNet IO with an A-B ControlLogix 1756-DNB Scanner Application note A100103, English Version 1.0. Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time. The software and hardware terms as well as the trademarks of companies used and / or mentioned in the present manual are generally trademark or patent protected.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 24

Using WAGO Series 750

DeviceNet IO with an A-B

ControlLogix 1756-DNB

Scanner

Application note

A100103, English

Version 1.0.0

2 General

Application note

A100103

Copyright 2009 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastrae 27

D-32423 Minden

Phone: +49 (0) 571/8 87 0

Fax: +49 (0) 571/8 87 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 5 55

Fax: +49 (0) 571/8 87 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and

completeness of this documentation. However, as errors can never be

fully excluded we would appreciate any information or ideas at any time.

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual

are generally trademark or patent protected.

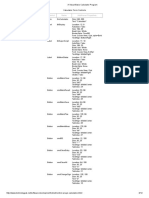

Table of Contents 3

Application note

A100103

TABLE OF CONTENTS

1 Important comments.................................................................................. 4

1.1 Legal principles...................................................................................... 4

1.1.1 Copyright ............................................................................................... 4

1.1.2 Personnel qualification........................................................................... 4

1.1.3 Intended use ........................................................................................... 4

1.2 Range of validity.................................................................................... 5

1.3 Symbols.................................................................................................. 5

2 Description.................................................................................................. 6

3 Reference Material..................................................................................... 6

4 Solution ....................................................................................................... 7

4.1 Determining the Process Image ............................................................. 7

4.2 Registering the EDS File ....................................................................... 9

4.3 Selecting & Associating Network Devices.......................................... 13

4.4 Editing I/O Parameters for Polled Operation....................................... 17

4.5 Mapping to Controller Memory........................................................... 18

5 Other Considerations............................................................................... 22

5.1 Putting the Scanner in Run Mode ........................................................ 22

4 Important comments

Application note

A100103

1 Important comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanation is

carefully read and adhered to.

1.1 Legal principles

1.1.1 Copyright

This manual is copyrighted, together with all figures and illustrations con-

tained therein. Any use of this manual which infringes the copyright provisions

stipulated herein, is not permitted. Reproduction, translation and electronic

and photo-technical archiving and amendments require the written consent of

WAGO Kontakttechnik GmbH & Co. KG. Non-observance will entail the

right of claims for damages.

1.1.2 Personnel qualification

The use of the product detailed in this manual is exclusively geared to special-

ists having qualifications in PLC programming, electrical specialists or per-

sons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH & Co. KG declines all liability re-

sulting from improper action and damage to WAGO products and third party

products due to non-observance of the information contained in this manual.

1.1.3 Intended use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only admit-

ted within the framework of the possibilities documented in the manuals. All

other changes to the hardware and/or software and the non-conforming use of

the components entail the exclusion of liability on part of WAGO Kon-

takttechnik GmbH & Co. KG.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH & Co.

KG.

5 Important comments

Application note

A100103

1.2 Range of validity

This application note is based on the stated hardware and software of the spe-

cific manufacturer as well as the correspondent documentation. This applica-

tion note is therefore only valid for the described installation.

New hardware and software versions may need to be handled differently.

Please note the detailed description in the specific manuals.

1.3 Symbols

Danger

Always observe this information to protect persons from injury.

Warning

Always observe this information to prevent damage to the device.

Attention

Marginal conditions must always be observed to ensure smooth operation.

ESD (Electrostatic Discharge)

Warning of damage to the components by electrostatic discharge. Observe the

precautionary measure for handling components at risk.

Note

Routines or advice for efficient use of the device and software optimisation.

More information

References to additional literature, manuals, data sheets and INTERNET

pages

6 Description

Application note

A100103

2 Description

This document illustrates the various steps taken to configure an Allen-

Bradley 1756-DNB Scanner Module for polled communications with a node

of WAGO Series 750 DeviceNet I/O. This document should serve as a sup-

plement to the appropriate WAGO DeviceNet product manual when installing

and/or commissioning a node of WAGO Series 750 DeviceNet I/O.

3 Reference Material

This procedure has been tested with, but is not limited to, the following hard-

ware and software:

Allen Bradleys RSNetWorx for DeviceNet, Revision 8.00.01 (CPR7)

Allen Bradleys 1756-DNB DeviceNet Scanner Module for the ControlLogix PLC

WAGO Series 750 DeviceNet Node, consisting of:

- 750-306 Ethernet Fieldbus Coupler

- 750-402 4-point 24VDC Digital Input Module

- 750-504 4-point 24VDC Digital Output Module

- 750-467 2-point 0-10VDC Analog Input Module

- 750-550 2-point 0-10VDC Analog Output Module

- 750-600 End Module

There are five main steps in configuring the 1756-DNB Scanner Module:

1) Determining the Process Image of the WAGO DeviceNet Node

2) Registering the WAGO EDS File using the EDS Wizard within RSNetWorx

3) Selecting and Associating Network Devices

4) Editing I/O Parameters for Polled Operation

5) Mapping Nodes of WAGO I/O to Controller Memory

7 Solution

Application note

A100103

4 Solution

4.1 Determining the Process Image

When the WAGO Series 750 DeviceNet buscoupler is powered up, it auto-

matically addresses the I/O modules of the node. The data for complex mod-

ules (modules using 2 or more bytes) are mapped first in the process image.

They are mapped in the order of their physical position after the coupler. As

such, they start at byte address 0. Following this, the digital modules are

grouped into bytes (8-bits per byte). The bits are arranged in the order of the

modules location. When the number of digital points exceeds eight (8-bits),

the coupler automatically starts the next byte.

The figure below illustrates the hardware of the WAGO node (digital and ana-

log I/O) used in this example. The process image table (I/O map) is displayed

in byte format below the figure. In order to properly configure the 1756-DNB

Scanner Module, the process image of the WAGO node must be determined.

Input Process Image (6 Bytes of Produced Data)

Byte 0 - 750-467 Channel 1 Analog Input, Low Byte

Byte 1 - 750-467 Channel 1 Analog Input, High Byte

Byte 2 - 750-467 Channel 2 Analog Input, Low Byte

Byte 3 - 750-467 Channel 2 Analog Input, High Byte

Byte 4 - 750-402 4-Channel 24VDC Digital Input (bits 0 through 3)

(bits 4-7 of Byte 4 are not filled)

Byte 5 - Status Byte

8 Solution

Application note

A100103

Output Process Image (5 Bytes of Consumed Data)

Byte 0 - 750-550 Channel 1 Analog Output, Low Byte

Byte 1 - 750-550 Channel 1 Analog Output, High Byte

Byte 2 - 750-550 Channel 2 Analog Output, Low Byte

Byte 3 - 750-550 Channel 2 Analog Output, High Byte

Byte 4 - 750-504 4-Channel 24VDC Digital Output (bits 0 through 3)

(bits 4-7 of Byte 4 are not filled)

The process image of this node occupies 6 bytes of input and 5 bytes of output.

The status byte is always the last byte produced by the DeviceNet node. Note

that the status byte can be disabled. Instructions on how to disable the status

byte can be found in WAGO application note A207000 Altering Attributes in

the DeviceNet coupler 750-306 Version 3.0.

Note: In this example, the WAGO Series 750 I/O modules occupy either input

or output memory, either producing or consuming data. Be aware that many

WAGO modules, such as discrete output modules w/ diagnostics or most spe-

cialty modules, occupy both input and output memory. Consult the manual or

datasheet for the corresponding WAGO module to determine the bit width oc-

cupied by the module in memory.

9 Solution

Application note

A100103

4.2 Registering the EDS File

Start RSNetWorx for DeviceNet.

From the main menu toolbar, select Tools and EDS Wizard

The EDS Wizard opening screen will appear:

Select Next to proceed with the EDS Wizard, which will assist with register-

ing the WAGO EDS file.

NOTE: WAGO EDS files are available for download from the WAGO

website (www.wago.com). To navigate to the download area from the

WAGO homepage, under the Service menu select Downloads, then

Automation. Proceed to download Article No. 750-912 EDS Files for

DeviceNet / Series 750, 752, 755 and 767.

10 Solution

Application note

A100103

With the option Register an EDS file(s) selected, click Next to continue.

You can register a single file, or an entire directory of EDS files. For this ex-

ample, the option Register a single file will be chosen. Enter the path and file-

name (browse if necessary) of the EDS file for the WAGO 750-306 product

(WAGO 750-306_4_19.eds). Click Next to continue.

11 Solution

Application note

A100103

The contents of the EDS file are verified by the EDS Wizard. Minor warnings

may be reported. Click Next to continue.

The EDS Wizard allows you to change the graphic image associated with a

device. If necessary, change the icon to one resembling the WAGO-I/O-

SYSTEM as shown. Click Next to continue.

12 Solution

Application note

A100103

Click Next to confirm your entries and proceed with device registration.

The EDS Wizard completes the registration. Click Finish to exit the EDS

Wizard.

The EDS file for the WAGO 750-306 DeviceNet buscoupler has now been

registered, and it is possible to proceed with configuring a node of WAGO I/O

for use on a DeviceNet network.

13 Solution

Application note

A100103

4.3 Selecting & Associating Network Devices

Start RSNetWorx for DeviceNet. (If EDS files have not been installed for the

WAGO product, please complete the previous section before proceeding.)

From the main menu toolbar, select File and New.

Click on the + sign next to Communication Adapter. A list of devices will

appear. This list will vary depending on the EDS files that have been installed.

Click on the + sign next to 1756-DNB Scanner Module. A revision list will

appear.

14 Solution

Application note

A100103

Select (double-click) the Major (and Minor revision levels if necessary) for the

1756-DNB Scanner Module in your system. For this example, Major Rev 07

is selected. The selected device will be displayed graphically.

Click on the - sign next to Communication Adapter to collapse the device

list.

Click on the + sign next to Vendor to expand the list of installed vendor de-

vices.

Click on the + sign next to WAGO Corporation.

Click on the + sign next to Communication Adapter to expand the list of

WAGO devices.

Select (double-click) the latest version (V04.19) for the WAGO 750-306 bus-

coupler. A WAGO I/O node will be displayed graphically. When completed,

the screen should appear as follows:

15 Solution

Application note

A100103

In the graphical area, double-click on the icon for the DeviceNet scanner

(Node 00). The following window should appear:

Click on the Scanlist tab. The following should appear:

16 Solution

Application note

A100103

De-select the Automap on Add checkbox available here. This feature will not

be used for this example.

DeviceNet allows multiple scanners to reside on the same network. Therefore,

it is necessary to associate other network devices to a particular scanner. To

create this association, click on a device from the list of available devices, and

click the right-arrow button. To quickly associate all devices shown, click the

dual right-arrow button. The list of associated devices will appear in the

Scanlist to the right.

Note: If there are multiple scanners in the same rack, click on the Module tab

and change the rack position to the correct value for each scanner.

The WAGO DeviceNet I/O Node has now been associated to the selected

scanner, and it is possible to proceed with defining the I/O parameters for

polled operation.

17 Solution

Application note

A100103

4.4 Editing I/O Parameters for Polled Operation

Click on the WAGO node shown in the Scanlist. Click on Edit I/O Parame-

ters

A screen will appear, allowing changes to the amount of data produced and

consumed by this node.

Position the cursor in the Input Size entry field, and change the value to 6.

This is the number of bytes of input that the WAGO DeviceNet node in this

example will produce. *

Then position the cursor in the Output Size field, and change the value to 5.

This is the number of bytes of output that the WAGO DeviceNet node in this

example will consume. *

Also, make sure that Polled is checked.

After making these changes, click OK.

The configuration of the WAGO DeviceNet node is now defined.

* Reference section 4.1 for an explanation of how to determine the number of

bytes produced/consumed by a WAGO DeviceNet I/O node.

Note: When editing I/O

parameters for polled

operation, the default values

shown in the editor are

Input Size: 6 Bytes and

Output Size: 5 Bytes.

Coincidentally, this is the

I/O image size required for

this example. Typically,

these numbers will have to

be edited by the user. It

should not be assumed that

these values are pre-

determined by the editor.

18 Solution

Application note

A100103

4.5 Mapping to Controller Memory

Now that the node has been associated to the scanner and the configuration has

been defined, the data for the node needs to be mapped to controller memory,

so the controller will know how to address the I/O data.

Click on the Input tab. The node is listed.

Click on the node. Then click AutoMap.

19 Solution

Application note

A100103

The mapping is displayed. The input process image and status byte will be

automatically mapped to controller memory as follows:

Byte 0 - 750-467 Channel 1 Analog Input, Low Byte

Byte 1 - 750-467 Channel 1 Analog Input, High Byte

Byte 2 - 750-467 Channel 2 Analog Input, Low Byte

Byte 3 - 750-467 Channel 2 Analog Input, High Byte

Byte 4 - 750-402 4-Channel 24VDC Digital Input (bits 0 through 3)

(bits 4-7 of Byte 4 are not filled)

Byte 5 - Status Byte

20 Solution

Application note

A100103

Click on the Output tab. The node is listed.

Click on the node. Then click AutoMap.

21 Solution

Application note

A100103

The mapping is displayed. The output process image will be automatically

mapped to the controller memory as follows:

Byte 0 - 750-550 Channel 1 Analog Output, Low Byte

Byte 1 - 750-550 Channel 1 Analog Output, High Byte

Byte 2 - 750-550 Channel 2 Analog Output, Low Byte

Byte 3 - 750-550 Channel 2 Analog Output, High Byte

Byte 4 - 750-504 4-Channel 24VDC Digital Output (bits 0 through 3)

(bits 4-7 of Byte 4 are not filled)

The input and output process images of the WAGO DeviceNet node have now

been mapped to the controller. Notice that under the Summary tab, the

Mapped columns now display Yes for the WAGO device.

The scanner configuration is now completed for use with WAGO Series 750

DeviceNet I/O, and the configuration is ready for download.

22 Other Considerations

Application note

A100103

5 Other Considerations

5.1 Putting the Scanner in Run Mode

The 1756-DNB DeviceNet Scanner requires a command from the Control-

Logix controller logic to put the scanner in Run mode. This is accomplished

by setting the Run bit of the scanner CommandRegister. A rung of logic

similar to the following will put the scanner in Run mode:

If the Run bit is not set, the 1756-DNB scanner will display a message indi-

cating that it is Idle.

23 Other Considerations

Application note

A100103

WAGO Kontakttechnik GmbH & Co. KG

Postfach 2880 D-32385 Minden

Hansastrae 27 D-32423 Minden

Phone: 05 71/8 87 0

Telefax: 05 71/8 87 1 69

E-Mail: info@wago.com

Internet: http://www.wago.com

Das könnte Ihnen auch gefallen

- RobotWare DieCastDokument2 SeitenRobotWare DieCastMarcelo Fiod HasmanNoch keine Bewertungen

- Software Instalation R-J2Dokument213 SeitenSoftware Instalation R-J2Marcelo Fiod HasmanNoch keine Bewertungen

- Diagramaeletrico IRC5ControladorDokument154 SeitenDiagramaeletrico IRC5ControladorMarcelo Fiod HasmanNoch keine Bewertungen

- FANUC Robotics SYSTEM R-J3 Troubleshooting and Maintenance ManualDokument39 SeitenFANUC Robotics SYSTEM R-J3 Troubleshooting and Maintenance Manualdrdover100% (2)

- Agilus System Partner IntroductionDokument38 SeitenAgilus System Partner IntroductionMarcelo Fiod HasmanNoch keine Bewertungen

- Operating and Mantenance HP20DDokument98 SeitenOperating and Mantenance HP20DMarcelo Fiod HasmanNoch keine Bewertungen

- Concurrent IO XRCDokument340 SeitenConcurrent IO XRCMarcelo Fiod Hasman100% (1)

- Robot HP20DDokument2 SeitenRobot HP20DMarcelo Fiod HasmanNoch keine Bewertungen

- Dx100 - Intructions For North American (Ansiria) StandardDokument329 SeitenDx100 - Intructions For North American (Ansiria) StandardMarcelo Fiod HasmanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Allplan 2015 StepsToSmartPartsDokument158 SeitenAllplan 2015 StepsToSmartPartsjeacovjece100% (1)

- QDPDokument94 SeitenQDPtrestresbizarreNoch keine Bewertungen

- How To Spell Numbers Using ABAP SpellDokument2 SeitenHow To Spell Numbers Using ABAP SpellKabil Rocky100% (1)

- Beginners Python Cheat Sheet PCC AllDokument22 SeitenBeginners Python Cheat Sheet PCC Allyahya100% (1)

- Applications - Parasol and Solar IrradiationDokument4 SeitenApplications - Parasol and Solar IrradiationPedro Henrique Mundim TanaNoch keine Bewertungen

- Brother PT-1650 PDFDokument152 SeitenBrother PT-1650 PDFbongio2007Noch keine Bewertungen

- A Visual Basic Calculator ProgramDokument10 SeitenA Visual Basic Calculator Programmohed ahmedNoch keine Bewertungen

- FT C++ PDFDokument123 SeitenFT C++ PDFkavyaNoch keine Bewertungen

- Deep Sea Electronics PLC: 5120 Automatic Mains Failure Module Operating ManualDokument63 SeitenDeep Sea Electronics PLC: 5120 Automatic Mains Failure Module Operating ManualJose R. AlvarezNoch keine Bewertungen

- The Cool Reference Manual: 1995-2004 by Alex Aiken. All Rights ReservedDokument30 SeitenThe Cool Reference Manual: 1995-2004 by Alex Aiken. All Rights ReservedGabriel TonioniNoch keine Bewertungen

- CPT 168 HW#9 Answer KeyDokument14 SeitenCPT 168 HW#9 Answer KeyJordan50% (4)

- JHTP 06 MethodsDokument8 SeitenJHTP 06 MethodshiiNoch keine Bewertungen

- ComputerDokument2 SeitenComputeransu dasNoch keine Bewertungen

- B Tech Integrated Mtech ECE 2012 ProposedDokument204 SeitenB Tech Integrated Mtech ECE 2012 Proposedshashm024Noch keine Bewertungen

- Ge2115 - Computer Practice Lab - Practice Programs: Courtesy VRB PublishersDokument51 SeitenGe2115 - Computer Practice Lab - Practice Programs: Courtesy VRB PublishersuserscrybdNoch keine Bewertungen

- PullSDK User Guide-EN V2.0-201201Dokument43 SeitenPullSDK User Guide-EN V2.0-201201Andrei PavalachiNoch keine Bewertungen

- Oracle Utilities Customer Care and Billing: Batch Operations and Configuration Guide Ver 2.3.1 E18372-01Dokument68 SeitenOracle Utilities Customer Care and Billing: Batch Operations and Configuration Guide Ver 2.3.1 E18372-01LakshmiNarayana PuttamchettyNoch keine Bewertungen

- NetLogo Tutorial Notes PDFDokument106 SeitenNetLogo Tutorial Notes PDFDejan DraganNoch keine Bewertungen

- ZK Access 5 User ManualDokument82 SeitenZK Access 5 User ManualsohaibsindhuNoch keine Bewertungen

- COAL FALL 15 Lecture 11 and 12 Procedure CallDokument17 SeitenCOAL FALL 15 Lecture 11 and 12 Procedure CallMuhammadHumzaNoch keine Bewertungen

- HOG detectMultiScale Parameters Explained - PyImageSearchDokument1 SeiteHOG detectMultiScale Parameters Explained - PyImageSearchntphuoc694Noch keine Bewertungen

- Programming Guide: VLT® AQUA Drive FC 202Dokument246 SeitenProgramming Guide: VLT® AQUA Drive FC 202yudiar djamaldilliahNoch keine Bewertungen

- B305 FastexportDokument26 SeitenB305 Fastexportsarferazul_haque0% (1)

- Andrew Beekhof - Pacemaker Configuration ExplainedDokument54 SeitenAndrew Beekhof - Pacemaker Configuration ExplainedSergio Tocalini JoergNoch keine Bewertungen

- Javascript Notes For ProfessionalsDokument490 SeitenJavascript Notes For ProfessionalsDragos Stefan NeaguNoch keine Bewertungen

- How TO Program in GSCDokument3 SeitenHow TO Program in GSCTakasur AzeemNoch keine Bewertungen

- Dorna AC Servo ManualDokument189 SeitenDorna AC Servo ManualShazib Shaukat SroyaNoch keine Bewertungen

- Khwaja Moinuddin Chishti Language UniversityDokument30 SeitenKhwaja Moinuddin Chishti Language UniversityShivam ShuklaNoch keine Bewertungen

- Aikido: Programming Language Reference ManualDokument327 SeitenAikido: Programming Language Reference ManualMaria AndreeaNoch keine Bewertungen

- IdroMOP EN 6.02.32 REV02Dokument26 SeitenIdroMOP EN 6.02.32 REV02Service AgroMONDONoch keine Bewertungen