Beruflich Dokumente

Kultur Dokumente

Thermal Insulating Foamy Geopolymers From Perlite

Hochgeladen von

Maverick BrandoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermal Insulating Foamy Geopolymers From Perlite

Hochgeladen von

Maverick BrandoCopyright:

Verfügbare Formate

Thermal insulating foamy geopolymers from perlite

V. Vaou, D. Panias

*

Laboratory of Metallurgy, School of Mining and Metallurgical Engineering, National Technical University of Athens, Athens, Greece

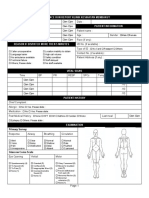

a r t i c l e i n f o

Article history:

Received 10 June 2010

Accepted 27 July 2010

Keywords:

Geopolymers

Perlite

Thermal insulation

Inorganic foams

a b s t r a c t

Geopolymerization is an emerging technology which utilizes solid aluminosilicate raw materials that are

easily soluble in caustic solutions, in order to produce inorganic polymers with excellent physical,

mechanical and thermal properties. In this paper is demonstrated the ability of geopolymerization tech-

nology for production of thermal insulating foamy inorganic polymers utilizing as solid raw material

ultrane perlite which is a by-product from comminution and sizing operations of perlite exploitation.

Hydrogen peroxide is used as a chemical blowing agent for the foaming of inorganic polymers. The effect

of addition of the blowing agent on the thermophysical properties of thermal insulating materials is dem-

onstrated and these properties are compared with the ones of the commercial thermal insulating mate-

rials indicating the high potentiality for the development of this new family of inorganic polymeric

materials.

2010 Elsevier Ltd. All rights reserved.

1. Introduction

The energy consumption in the sectors of households and ser-

vices for the European Union of 27 member states amounted

388.46 Mtoe in 1990 and increased further to 455.18 Mtoe in

2006, whichconstitutes anincrease of 17%(EUenergyandtransport,

2009). The major part of this consumption is attributed to the build-

ings heating, ventilation and air-conditioning. The gures in the

north European Mediterranean countries are even worse. For the

same time period, the increase in energy consumptionin the sectors

of households andservices was 101.6%inGreece, 93%inSpain, 86.5%

in Portugal, 184.2% in Cyprus, 30.6% in Italy and 16.66% in Malta (EU

energy and transport, 2009). In order to invert this trend in energy

consumption, EU adopted specic legislation on the energy perfor-

mance of buildings (Directives 2002/91/EC, 2005/32/EC and 2006/

32/EC), which is a cost effective way of improving energy security

and ghting against climate change. In this environment, the princi-

ples of bioclimatic design and thermal insulation in buildings

(Giama and Papadopoulos, 2007) grew up and became basic design

tools for the sector of building construction.

The most important thermal insulating materials for buildings

(Karamanos et al., 2005) are classied in two categories; (a) organ-

ic and (b) inorganic materials. The European market of organic

materials is dominated by the foamy polystyrene products ex-

truded polystyrene (XPS) and Expanded Polystyrene (EPS). The

most widely used inorganic materials are the brous glass wool

and stone wool which belong to the same group of mineral wool.

Although both organic and inorganic materials are good insulating

materials they have a number of technical limitations. Polystyrene

is highly ammable or easily ignited and is classied as a B2 or B3

product according to DIN4102. When polystyrene is burned

(Department of Energy 1; Department of Energy 2; Hawley et al.,

1984) at high temperatures (800900 C) or at lower temperatures

(as in case of household replace or in a campre) polycyclic

aromatic hydrocarbons (PAHs) can be produced creating serious

health effects. Although the available re-retardant grades are

inammable, they could possibly create health and environmental

risks due to the use of brominated ame retardants such as hexa-

bromocyclododecane (EPA, 2008). Expanded polystyrene breaks

down gradually when exposed to direct sunlight or to tempera-

tures higher than 80 C and reacts with common solvents (Bynum,

2001; Papadopoulos, 2005; Al-Homoud, 2005). The blowing agent

for the production of EPS is usually pentane which may pose a

ammability hazard in manufacturing and storage of new prod-

ucts. Carbon dioxide or hydrochlorouorocarbons (HCFCs) are used

as propellant gases for the production of XPS having obvious

effects on ozone depletion and global warming (Papadopoulos,

2005). Finally, the maximum temperature at which polystyrene

products can be exposed without losing their thermophysical

properties is 7580 C (Papadopoulos, 2005). Mineral wool insula-

tion is cheaper than the organic ones and is non-ammable classi-

ed as an A1 or A2 product according to DIN4102 (Papadopoulos,

2005; Karamanos et al., 2005). In addition, it can withstand very

high temperatures (500750 C) without losing its thermophysical

properties (Papadopoulos, 2005). Two are the main drawbacks

related to the utilization of brous mineral wool (Bynum, 2001;

Papadopoulos, 2005; Al-Homoud, 2005): (a) it has very low

0892-6875/$ - see front matter 2010 Elsevier Ltd. All rights reserved.

doi:10.1016/j.mineng.2010.07.015

* Corresponding author. Tel.: +30 2107722276; fax: +30 2107722168.

E-mail address: panias@metal.ntua.gr (D. Panias).

Minerals Engineering 23 (2010) 11461151

Contents lists available at ScienceDirect

Minerals Engineering

j our nal homepage: www. el sevi er. com/ l ocat e/ mi neng

resistance to vapour diffusion and therefore has the tendency to

increasing thermal conductivity upon vapour absorption and (b)

it has the potential to cause damage on humans health. It can irri-

tate the skin, eyes and respiratory system and therefore precau-

tions are needed during production and handling of material. The

material is reviewed by the International Agency for Research on

Cancer (IARC) as an agent belonging to group 3 not classiable

as to carcinogenicity to humans (IARC). Therefore, there is open

eld for development of a new thermal insulating material which

would potentially have the advantages of common organic and

inorganic insulating materials without having their drawbacks.

The geopolymerization technology is a low cost, green technol-

ogy (Davidovits, 2005) that can transform a variety of solid amor-

phous silicate and aluminosilicate raw materials (Panias et al.,

2007; Maragos et al., 2008; Dimas et al., 2009; Xu and van Devent-

er, 2000; Palomo et al., 1999) to useful products with high added

value (Panias et al., 2007; Maragos et al., 2008; Dimas et al.,

2009; Palomo et al., 1999; Cheng and Chiu, 2003; Wu and Sun,

2007; Pinto and Vieira, 2005). Perlite is an amorphous aluminosil-

icate volcanic glass which has the potential to be utilized as a raw

material in geopolymerization technology. Therefore, this paper

deals with the production of perlite based geopolymers which

comprise the skeleton of a newfamily of inorganic thermal insulat-

ing foamy materials that have excellent thermophysical properties,

are non-ammable and safe for humans and environment.

2. Experimental

2.1. Materials

The raw materials used for the synthesis of foamy geopolymers

were perlite, sodium hydroxide and hydrogen peroxide. The chem-

ical analysis of perlite determined by X-ray Fluorescence (XRF) is

given in Table 1 while its mineralogical analysis determined by

X-ray Diffraction (XRD) is presented in Fig. 1. Perlite is an amor-

phous volcanic glass rich in SiO

2

and Al

2

O

3

which contains some

crystalline phases as biotite, albite, quartz and calcite. The raw per-

lite used in this work was a by-product from comminution and siz-

ing operations of perlite exploitation and therefore was extremely

ne with mean particle size d

50

= 7.13 lm measured on a MAL-

VERN Laser Particle Size Analyzer. The specic gravity of perlite

measured according to the ASTM D854-06 standard using a water

pycnometer was 2.34.

The alkaline activator used for the synthesis of geopolymers

was a sodium hydroxide solution that was prepared by dissolving

anhydrous sodium hydroxide pellets (Merck Chemicals, 99.5% pur-

ity) in deionised water.

A hydrogen peroxide (H

2

O

2

) solution 30% w/w (Merck Chemi-

cals) was used as a chemical blowing agent for the foaming of

the geopolymeric pastes. H

2

O

2

is thermodynamically unstable

and therefore can be easily decomposed to water and oxygen gas

(reaction (1)) with the latter playing the role of the geopolymeric

paste blowing agent:

2H

2

O

2

!2H

2

O O

2

1

2.2. Experimental procedures

The geopolymeric viscous paste was prepared by mixing

mechanically perlite with sodium hydroxide solution. The pre-

pared paste remained at ambient temperature for 1 h and then

the necessary amount of the hydrogen peroxide (H

2

O

2

) solution

was added under mechanical mixing so that the sodium hydroxide

concentration in the aqueous phase to be 8 M and the solid to li-

quid ratio to be 1.2 g/mL. The % w/w H

2

O

2

content in the prepared

pastes was varied in-between 0.6% and 2.9%. The resulted paste

was molded in appropriate open plastic molds and was cured at

35 C for 2 h. During this period H

2

O

2

was decomposed rapidly

and the resulting oxygen blew up the paste forming the foamy

materials. Then, the curing procedure was continued at 65 C

where the materials remained for 24 h. After curing, the specimens

were de-molded and kept in a dry atmosphere. The foamy speci-

mens were prepared in two different geometries; discs with

110 mm diameter and 10 mm thickness for the measurement of

thermal conductivity and cubes with side 50 mm for the measure-

ment of compressive strength.

Table 1

Chemical analysis of perlite.

Species % w/w

SiO

2

71.58

Al

2

O

3

13.23

K

2

O 4.02

Na

2

O 3.36

CaO 2.12

Fe

2

O

3

1.83

MgO 1.04

H

2

O (chemical/combined) 2.5

Total 99.68

B

A

A

Q

C

B

B: Biotite KFeMg

2

(AlSi

3

O

10

)(OH)

2

A: Albite NaAlSi

3

O

8

Q: Quartz SiO

2

C: Calcite CaCO

3

Fig. 1. X-ray diffractogram of perlite.

V. Vaou, D. Panias / Minerals Engineering 23 (2010) 11461151 1147

2.3. Analysis and tests

The apparent density (q) of the foamy geopolymers was deter-

mined by measuring the weight of specimens with a precision bal-

ance as well as their dimensions with a precision electronic

calliper. The density (d) of the geopolymeric matrix was measured

according to the ASTM D854-06 standard using a water pycnome-

ter. The % cell volume (C) of the foamy materials was determined

according to the following formula:

C

1 q 100

d

2

The thermal conductivity was measured with a thermal conduc-

tivity analyser (Mathis TCi, SETARAM) utilizing the modied tran-

sient plane source technique. The compressive strength was

measured on a testing machine of the Structural Behavior Engineer-

ing Laboratories Inc. (PLT-10 model). For the determination of the

material properties two specimens were always tested and the

average value of measurements was reported as the result. Finally,

the cell structure was examined by scanning electron microscopy

(SEM) on a JOEL JSM-type scanning electron microscope.

3. Results and discussion

3.1. Properties of the foamy materials

The effect of H

2

O

2

content in the geopolymeric paste on the

apparent density as well as % cell volume of foamy materials is

shown in Fig. 2. Two regions can be seen; (a) the region I in-be-

tween 0.7% and 2% w/w H

2

O

2

where the apparent density de-

creases sharply from 665 kg/m

3

to 335 kg/m

3

as the H

2

O

2

content in the geopolymeric paste increases accompanied by a

substantial increase of the cell volume from almost 7487% and

(b) the region II for H

2

O

2

content higher than 2% w/w where the

change of the apparent density as well as the % cell volume is prac-

tically limited and the foamy materials tend to have an apparent

density a little bit higher or lower than 300 kg/m

3

and a cell vol-

ume varied in-between 87% and 89%. This behaviour can be under-

stood in view of the foaming mechanism of the geopolymeric

paste. The decomposition of hydrogen peroxide liberates oxygen

creating initially very small bubbles inside the mass of the very vis-

cous paste which behaves as a non-Newtonian plastic or pseudo-

plastic uid. The pressure exerted on the bubbles wall plays the

role of the shear stress for the viscous paste which is deformed

causing the bubbles expansion and the foaming of the paste. The

bubbles expansion causes a decrease of the oxygen pressure under

constant temperature eliminating gradually the shear stress and

therefore stopping the bubbles expansion and the pastes foaming.

When the oxygen volume per paste volume is low enough (the

case of low H

2

O

2

content), the spherical bubbles are discernible

and they have low population density in the geopolymeric paste.

As the H

2

O

2

content increases, the bubbles population density in-

creases as well as the amount of oxygen in each bubble do due to

the increased local oxygen concentration. Therefore, the bubble

size increases, the thickness of the cells as well as the apparent

density of foams decrease and the cell volume increases (region I

linear part with high gradient). When the oxygen volume per

paste volume exceeds a threshold, the bubbles population density

and the amount of oxygen per bubble increase substantially result-

ing the aggregation of a number of cells creating a network of cells

partially open to environment and thus causing marginal expan-

sion and marginal increase to the cell size (region II linear part

with small gradient).

The microstructure of foamy materials is presented in Fig. 3.

The cells are normally closed and almost spherical when the % con-

tent of H

2

O

2

in the paste is low. Aggregation among cells takes

place as the % content of H

2

O

2

increases changing the cells geo-

metrical shape from spherical to oval, creating a network of inter-

connecting cells and affecting the mean cell size as is seen in Figs. 3

and 4.

The mean cell size is 700 lm at the lowest studied H

2

O

2

content

of 0.7% increasing almost linearly with the H

2

O

2

content and reach-

ing at the value of 1.9 mm at 2.02% H

2

O

2

in the geopolymeric paste.

Further increase of H

2

O

2

content up to the highest studied value of

2.95% causes marginal changes on cell size, which reaches the va-

lue of 2.08 mm, explaining thus the limited increase of cell volume

as well as the decrease of apparent density (Fig. 2) of foamy mate-

rials in the same range of % H

2

O

2

content.

The thermal conductivity of foamy materials is shown in Fig. 5.

Thermal conductivity follows identical trend with apparent density

decreasing substantially from 0.053 W/m K to 0.03 W/m K as the

H

2

O

2

content ranging in-between 0.7% and 2.02%. Further increase

of the H

2

O

2

content in the geopolymeric paste to the studied value

of 2.95% w/w has not a measurable effect on the thermal conduc-

tivity value. The results showed that the thermal conductivity of

foamy geopolymers is correlated to their cellular structure and a

substantial decrease of the thermal conductivity value can be

achieved by controlling appropriately the cells type, size, shape

and volume. The results are in good agreement with the state-of-

the-art on thermal insulation foamed plastics where the thermal

conductivity is correlated rstly to the thermal conductivity of

the lling gas followed by the apparent density of foams and then

the morphology of the cellular structure (Weber et al., 2005).

The compressive strength of foamy materials is shown in Fig. 6.

The fracture of materials resembles the behaviour of rocks for H

2

O

2

content in the geopolymeric paste higher than 1.58%. In this case

the materials have almost the same compressive strength of

780 kPa. For H

2

O

2

content lower than 1.58%, the materials have

more plasticity due to incomplete geopolymerization because the

network of small and closed cells hinders the water removal during

the curing period. Therefore, the incomplete geopolymerized

foamed materials have compressive strength ranging in-between

250 and 780 kPa.

3.2. Comparison with the other current state-of-the-art insulating

materials

A comparison among the state-of-the-art commercially avail-

able organic and inorganic insulating materials as well as of the

best foamy perlite geopolymer produced in this work (with

72

74

76

78

80

82

84

86

88

90

0

100

200

300

400

500

600

700

0 0.5 1 1.5 2 2.5 3 3.5

%

C

e

l

l

V

o

l

u

m

e

A

p

p

a

r

e

n

t

d

e

n

s

i

t

y

o

f

f

o

a

m

y

m

a

t

e

r

i

a

l

s

,

K

g

/

m

3

2 2

content in geopolymeric paste, % w/w

Apparent Density

Cell Volume

o H

Fig. 2. Apparent density and % cell volume of foamy materials as a function of % w/w

H

2

O

2

content in the geopolymeric paste.

1148 V. Vaou, D. Panias / Minerals Engineering 23 (2010) 11461151

2.9% w/w H

2

O

2

in the geopolymeric paste) is shown in Table 2. The

foamy perlite geopolymer is a very good thermal insulating mate-

rial. Its thermal conductivity value of 0.03 W/m K is directly com-

parable with the lowest ones of the organic materials (XPS and

EPS) as well as of inorganic materials (glass and mineral wool).

The maximum application temperature of foamy perlite geopoly-

mer is 700 C which is substantially higher than the ones of organic

materials, higher than the one of glass wool and directly compara-

ble of the one of mineral wool. The foamy perlite geopolymer does

not melt in the temperature region in-between 700 and 1000 C

but it softens due to the glassy nature of perlite. The perlitic water

trapped in the structure of perlite particles vaporizes and therefore

expand the foamy geopolymer decreasing its apparent density

from 290 kg/m

3

to 160 kg/m

3

without affecting the value of ther-

mal conductivity. The geometrical features (shape and dimensions)

of foamy geopolymers change during the softening procedure and

for this reason the temperature of 700 C is chosen as the maxi-

mum application temperature.

The 100% inorganic nature of foamy perlite geopolymer renders

it totally non-combustible categorizing it in the Fire Class A1 in

accordance to the standard DIN4102. The foamy perlite geopoly-

mer has superior re resistant properties in comparison to the

other common organic and inorganic insulating materials shown

in Table 2. The commercial inorganic insulating materials such as

0.7 % w/w H

2

O

2

1.58 % w/w H

2

O

2

2.02 % w/w H

2

O

2

2.95 % w/w H

2

O

2

Fig. 3. SEM photos of foamy materials prepared with different % w/w H

2

O

2

content in the geopolymeric paste.

0

500

1000

1500

2000

2500

0 0.5 1 1.5 2 2.5 3 3.5

M

e

a

n

c

e

l

l

s

i

z

e

,

m

H

2

O

2

in geopolymeric paste, % w/w

Fig. 4. Mean cell size as a function % w/w H

2

O

2

content in the geopolymeric paste.

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0 0.5 1 1.5 2 2.5 3 3.5

T

h

e

r

m

a

l

c

o

n

d

u

c

t

i

v

i

t

y

,

W

/

m

.

K

H

2

O

2

content in geopolymeric paste , % w/w

Fig. 5. Thermal conductivity of foamy materials as function % w/w H

2

O

2

content in

the geopolymeric paste.

0

100

200

300

400

500

600

700

800

900

0 0.5 1 1.5 2 2.5 3 3.5

C

o

m

p

r

e

s

s

i

v

e

s

t

r

e

n

g

t

h

,

k

P

a

H

2

O

2

in geopolymeric paste, % w/w

Fig. 6. Compressive strength of foamy materials as function % w/w H

2

O

2

content in

the geopolymeric paste.

V. Vaou, D. Panias / Minerals Engineering 23 (2010) 11461151 1149

mineral and glass wool are often characterized in the A2 Fire Class

(about 98% non-combustible) because they contain a combustible

organic binder which binds the inorganic bres creating the mar-

ketable products in the form of panels or felts.

The fractural behaviour of foamy perlite geopolymers resembles

the one of rocks and is totally different from the behaviour of the

other commercial inorganic and organic insulating materials

shown in Table 2. The foamy geopolymer has not plasticity or elas-

ticity and has enough high compressive strength for the practical

application of buildings insulation. In general, it has superior

mechanical properties in relation to the other common insulating

materials.

The relative high value of apparent density is the most impor-

tant drawback of foamy perlite geopolymer in relation to the other

common insulating materials. The achieved value of 290 kg/m

3

is

almost 1.6 and 3.6 times higher than the corresponding ones of

mineral wool and extruded polystyrene which are commonly used

for buildings insulation. Improving apparent density is a target of

great importance for the commercial application of foamy perlite

geopolymers. This target could be achieved by the application of

one of the three following actions or by the synergetic effect of

all of them:

(a) Foaming of geopolymeric paste by blowing air under con-

trolled pressure and volumetric ow rate (mechanical foam-

ing) instead of blowing by chemical means as it was applied

in this work. Mechanical foaming can achieve better cells

structure and % cell volume higher than 90% decreasing the

apparent density of foamy materials up to 150200 kg/m

3

.

(b) Use of expanded instead of non-expanded perlite as a raw

material for synthesis of geopolymers. Taking into account

that the bulk density of expanded perlite is in-between 30

and 150 kg/m

3

while the bulk density of non-expanded per-

lite is about 1100 kg/m

3

, it could be assumed that foamy

geopolymers based on expanded perlite would have appar-

ent density in-between 20 and 100 kg/m

3

which is a value

directly comparable with the apparent densities of the com-

mon commercial insulating materials. Although this work

did not study the expanded perlite as a raw material for geo-

polymerization, the thermal tests for determination of the

maximum application temperature of foamy perlite geo-

polymer showed that at temperatures in-between 700 and

1000 C the apparent density of foamy materials decreased

to a value of 160 kg/m

3

due to incomplete perlite expansion.

Therefore, this result offer indirect evidence that the above

stated assumption is not an illusion and could be a good esti-

mate for the apparent density of foamy expanded perlite

geopolymers.

(c) The temperature at which the green foamy perlite geopoly-

mers are cured can affect the apparent density of nal mate-

rials. As is seen in Fig. 7, 810% of the weight of foamy

materials is physically adsorbed water which can be easily

removed at curing temperatures around 100 C decreasing

the apparent density of materials.

Finally, water absorption measured by the resistant to vapour

diffusion factor and/or humidity assimilation rate is a very impor-

tant physical property that can affect the thermal conductivity of

insulating materials. The foamy perlite geopolymers, especially

the ones that have been produced with high H

2

O

2

content in the

geopolymeric paste, can absorb water and have low resistant to va-

pour diffusion factor, because they are consisting of networks of

interconnecting cells some of which are partially open to the envi-

ronment, increasing their thermal conductivity value. This is the

other drawback of the foamy perlite geopolymer produced in this

work. To avoid this drawback, the foamy perlite geopolymer has

to be provided, where necessary, with a very thin geopolymeric

surface cover with very low permeability (Maragos et al., 2008).

Table 2

Typical values of the basic thermophysical properties of common insulating materials.

Material Glass

wool

Mineral wool Extruded polystyrene,

XPS

Expanded polystyrene,

EPS

Foamy perlite

geopolymer

Apparent density, kg/m

3

13100 30180 2080 1850 290

Thermal conductivity, W/m K 0.03

0.045

0.0330.045 0.0250.035 0.0290.041 0.03

Maximum application temperature, C 500 750 75 80 700

Fire Class A1A2 A1A2 B1B2 B1B2 A1

Compressive strength at 10% deformation,

kPa

16 (1) 0.0169 (1), (2),

(3)

100700 (4) 70450 (5), (6), (7) 780

a

The most values have been taken from Papadopoulos (2005).

(1) National Insulation Co.

(2) Buska and Maciulaitis (2007).

(3) Industrial Insulation Group.

(4) Extruded Polystyrene Foam Association.

(5) EPS Molders Association.

(6) Desjarlais and Zarr (2002).

(7) Quality Foam.

a

The material is fractured at 2% deformation.

-3

-2

-1

0

1

2

3

4

5

6

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

0 100 200 300 400 500 600 700 800 900

H

e

a

t

F

l

o

w

,

V

%

W

e

i

g

h

t

L

o

s

s

Temperature,

o

C

E

x

o

Fig. 7. Typical TG/DTA curves for foamy perlite materials which have been

synthesized with 2.98% w/w H

2

O

2

content in the geopolymeric paste.

1150 V. Vaou, D. Panias / Minerals Engineering 23 (2010) 11461151

4. Conclusions

Foamy geopolymers from non-expanded perlite proved to be

very good thermal insulating materials. In comparison with the

commercial organic (expanded and extruded polystyrene) and

inorganic (glass and stone wool) thermal insulating materials,

the foamy geopolymers from perlite have (a) almost similar ther-

mal conductivity (0.03 W/m K); (b) superior compressive strength

(780 kPa at 2% deformation) and a fracture behaviour resembling

the one of rocks; (c) superior re resistant properties (100% non-

combustible) categorizing them in the Fire Class A1 according to

DIN4102; (d) superior maximum application temperature

(700 C) only comparable with the one of mineral wool, which ren-

der the material proper not only for buildings thermal insulation

but also for industrial insulation applications where high temper-

atures occur.

At the current stage of development, foamy geopolymers from

non-expanded perlite have the two following drawbacks: (a) rela-

tively high apparent density (290 kg/m

3

) and (b) high water

absorption capacity. The most promising way to decrease the

apparent density at a level comparable to the ones of commercial

organic and inorganic thermal insulating materials is the synthesis

of foamy geopolymers utilizing (a) expanded instead of non-ex-

panded perlite as a solid raw material and (b) mechanical foaming

of geopolymeric paste by blowing air under controlled pressure

and volumetric ow rate. Finally, an effective way to increase the

resistant to vapour diffusion factor is to cover the surface of foamy

geopolymers with a thin layer from a compact geopolymer with

low permeability which is a practice always applied to materials

with open or partially open cellular structure.

References

Al-Homoud, M.S., 2005. Performance characteristics and practical applications of

common building thermal insulation materials. Building and Environment 40,

353366.

Buska, A., Maciulaitis, R., 2007. The compressive strength properties of mineral wool

slabs: inuence of structure anisotropy and methodological factors. Journal of

Civil Engineering and Management XIII (2), 97106.

Bynum, R.T., 2001. Insulation Handbook. McGraw-Hill.

Cheng, T.W., Chiu, J.P., 2003. Fire resistant geopolymer produced by granulated blast

furnace slag. Mineral Engineering 16, 205210.

Davidovits, J., 2005. Geopolymer chemistry and sustainable development. In:

Proceedings of the World Congress Geopolymer 2005, Saint-Quentin, France,

pp. 915.

Desjarlais, A.O., Zarr, R.R., 2002. Insulation Materials: Testing and Applications, vol.

4, ASTM Stock Number STP1426, ASTM International.

Department of Energy 1, USA. Polystyrene Foam Burning Danger. <http://

www.newton.dep.anl.gov/askasci/chem00/chem00053.htm>.

Department of Energy 2, USA. Burning Polystyrene Foam. <http://

www.newton.dep.anl.gov/askasci/chem00/chem00532.htm>.

Dimas, D., Giannopoulou, I., Panias, D., 2009. Utilization of alumina red mud for

synthesis of inorganic polymeric materials. Mineral Processing and Extractive

Metallurgy Review 30 (3), 211239.

Directive 2002/91/EC on the Energy Performance of Buildings, 2002.

Directive 2005/32/EC Establishing a Framework for the Setting of Ecodesign

Requirements for Energy-using Products, 2005.

Directive 2006/32/EC on Energy End-use Efciency and Energy Services, 2006.

EPA Information on HBCD, 2008. <http://www.epa.gov/hpvis/rbp/HBCD.3194556.

Web.RBP.31308.pdf>.

EPS Molders Association. <www.epsmolders.org/4-ftc.html>.

EU Energy and Transport in Figures Statistical Pocketbook, 2009.

Extruded Polystyrene Foam Association. <www.xpsa.com/tech/standards.html>.

Giama, E., Papadopoulos, A.M., 2007. Environmental performance evaluation of

thermal insulation materials and its impact on the building. Building and

Environment 42 (5), 21782187.

Hawley, R.A., Parsons, M.L., Karasek, F.W., 1984. Products obtained during

combustion of polymers under simulated incinerator conditions II.

Polystyrene. Journal of Chromatography 315, 201210.

IARC (<http://monographs.iarc.fr/ENG/Classication/Listagentsalphorder.pdf>).

Industrial Insulation Group. <www.iig-llc.com>.

Karamanos, A.K., Giama, E., Hadiarakou, S., Papadopoulos, A.M., 2005. Comparative

evaluation of stone wool and extruded polystyrene. In: Electronic Proceedings

Heleco 05, Technical Chamber of Greece, Athens, 36 February.

Maragos, I., Giannopoulou, I., Panias, D., 2008. Synthesis of ferronickel slag-based

geopolymers. Minerals Engineering 22, 196203.

National Insulation Co. (<http://ntlinsulation.com/images/compressive.pdf>).

Palomo, A., Grutzeck, M.W., Blanco, M.T., 1999. Alkali activated y ashes a cement

for the future. Cement and Concrete Research 29, 13231329.

Panias, D., Giannopoulou, I., Perraki, T., 2007. Effect of synthesis parameters on the

mechanical properties of y ash-based geopolymers. Colloids and Surfaces A:

Physicochemical Engineering Aspects 301, 246254.

Papadopoulos, A.M., 2005. State of the art in thermal insulation materials and aims

for future developments. Energy and Buildings 37, 7786.

Pinto, AT., Vieira, E., 2005. Repairing of damaged stone in monuments and stone

buildings. In: Proceedings of the World Congress Geopolymer 2005, Saint-

Quentin, France, pp. 173176.

Quality Foam <www.qualityfoam.com/expanded-polystyrene.asp>.

Weber, H., De Grave, I., Rhrl, E., 2005. Foamed Plastics, Ullmanns Encyclopedia of

Industrial Chemistry. Wiley-VCH Verlag GmbH & Co., KGaA, Weinheim.

Wu, H.C., Sun, P., 2007. New building materials from y ash-based lightweight

inorganic polymer. Construction and Building Materials 21, 211217.

Xu, H., van Deventer, J.S.J., 2000. The geopolymerization of alumino-silicate

minerals. International Journal of Mineral Processing 59, 247266.

V. Vaou, D. Panias / Minerals Engineering 23 (2010) 11461151 1151

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Anatomy Anal CanalDokument14 SeitenAnatomy Anal CanalBela Ronaldoe100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- How To Identify MQ Client Connections and Stop ThemDokument26 SeitenHow To Identify MQ Client Connections and Stop ThemPurushotham100% (1)

- ISO 9001 2015 AwarenessDokument23 SeitenISO 9001 2015 AwarenessSeni Oke0% (1)

- Famous Russian PianoDokument10 SeitenFamous Russian PianoClara-Schumann-198550% (2)

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFDokument41 SeitenTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarNoch keine Bewertungen

- Log Building News - Issue No. 76Dokument32 SeitenLog Building News - Issue No. 76ursindNoch keine Bewertungen

- Role of Losses in Design of DC Cable For Solar PV ApplicationsDokument5 SeitenRole of Losses in Design of DC Cable For Solar PV ApplicationsMaulidia HidayahNoch keine Bewertungen

- PMP Question BankDokument3 SeitenPMP Question BankOmerZiaNoch keine Bewertungen

- Chemistry Form 4 Daily Lesson Plan - CompressDokument3 SeitenChemistry Form 4 Daily Lesson Plan - Compressadila ramlonNoch keine Bewertungen

- Problem Set-02Dokument2 SeitenProblem Set-02linn.pa.pa.khaing.2020.2021.fbNoch keine Bewertungen

- Carob-Tree As CO2 Sink in The Carbon MarketDokument5 SeitenCarob-Tree As CO2 Sink in The Carbon MarketFayssal KartobiNoch keine Bewertungen

- Lecturenotes Data MiningDokument23 SeitenLecturenotes Data Miningtanyah LloydNoch keine Bewertungen

- UTP Student Industrial ReportDokument50 SeitenUTP Student Industrial ReportAnwar HalimNoch keine Bewertungen

- Oracle Forms & Reports 12.2.1.2.0 - Create and Configure On The OEL 7Dokument50 SeitenOracle Forms & Reports 12.2.1.2.0 - Create and Configure On The OEL 7Mario Vilchis Esquivel100% (1)

- The Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderDokument7 SeitenThe Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderJaime Ocampo SalgadoNoch keine Bewertungen

- Borang Ambulans CallDokument2 SeitenBorang Ambulans Callleo89azman100% (1)

- Iec TR 61010-3-020-1999Dokument76 SeitenIec TR 61010-3-020-1999Vasko MandilNoch keine Bewertungen

- AlpaGasus: How To Train LLMs With Less Data and More AccuracyDokument6 SeitenAlpaGasus: How To Train LLMs With Less Data and More AccuracyMy SocialNoch keine Bewertungen

- User S Manual AURORA 1.2K - 2.2KDokument288 SeitenUser S Manual AURORA 1.2K - 2.2KEprom ServisNoch keine Bewertungen

- Broken BondsDokument20 SeitenBroken Bondsapi-316744816Noch keine Bewertungen

- Dynamics of Machinery PDFDokument18 SeitenDynamics of Machinery PDFThomas VictorNoch keine Bewertungen

- DPSD ProjectDokument30 SeitenDPSD ProjectSri NidhiNoch keine Bewertungen

- History of The Sikhs by Major Henry Cour PDFDokument338 SeitenHistory of The Sikhs by Major Henry Cour PDFDr. Kamalroop SinghNoch keine Bewertungen

- DN Cross Cutting IssuesDokument22 SeitenDN Cross Cutting Issuesfatmama7031Noch keine Bewertungen

- Aptitude Number System PDFDokument5 SeitenAptitude Number System PDFharieswaranNoch keine Bewertungen

- OZO Player SDK User Guide 1.2.1Dokument16 SeitenOZO Player SDK User Guide 1.2.1aryan9411Noch keine Bewertungen

- Köppen Climate Classification - Wikipedia, The Free EncyclopediaDokument15 SeitenKöppen Climate Classification - Wikipedia, The Free EncyclopediaAndreea Tataru StanciNoch keine Bewertungen

- Impact of Advertising On Consumers' Buying Behavior Through Persuasiveness, Brand Image, and Celebrity EndorsementDokument10 SeitenImpact of Advertising On Consumers' Buying Behavior Through Persuasiveness, Brand Image, and Celebrity Endorsementvikram singhNoch keine Bewertungen

- MGMT Audit Report WritingDokument28 SeitenMGMT Audit Report WritingAndrei IulianNoch keine Bewertungen

- Application Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostDokument19 SeitenApplication Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostM Agus SudrajatNoch keine Bewertungen