Beruflich Dokumente

Kultur Dokumente

Definition of Terms

Hochgeladen von

ArielInopia0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten3 SeitenSchool

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSchool

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten3 SeitenDefinition of Terms

Hochgeladen von

ArielInopiaSchool

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Ice - is water frozen into a solid state.

It can appear transparent or opaque bluish-white color, depending

on the presence of impurities such as soil particles or air inclusions.

Flake ice - is made of the mixture of brine and water (max 500g salt per ton of water), in some cases can

be directly made from brine water. Thickness between 1mm-15mm, irregular shape with diameters

from 12mm to 45mm.

Cube ice - is created in a cubic shape, with each edge usually between 15mm and 35mm. The surface

area of every ton of cube ice is approximately 1,383 square metres (14,890 sq ft).

Tube ice - can be used in the cooling process, such as temperature controlling, fish fresh freezing, and

beverage bottle freezing. It can be consumed alone and with food or beverages.

A ton of refrigeration - (commonly abbreviated as TR) is a unit of power used in some countries

(especially in North America) to describe the heat-extraction capacity of refrigeration and air

conditioning equipment. It is defined as the heat of fusion absorbed by melting 1 short ton (0.893 long

ton; 0.907 t) of pure ice at 0 C (32 F) in 24 hours.

Brine - is a solution of salt (usually sodium chloride) in water.

Brine agitator used for regular circulation or flow of water for cooling of products like milk ,beer,

chemicals, mainly used in Food Processing to keep the temperature of the rooms and chambers intact

where products are kept for long time.

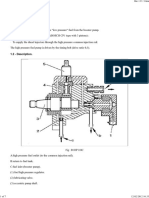

Compressor

Gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An

air compressor is a specific type of gas compressor.

Centrifugal compressors use a rotating disk or impeller in a shaped housing to force the gas to the rim

of the impeller, increasing the velocity of the gas. A diffuser (divergent duct) section converts the

velocity energy to pressure energy. They are primarily used for continuous, stationary service in

industries such as refineries, chemical and petrochemical plants and natural gas processing plants.

Axial-flow compressors - are dynamic rotating compressors that use arrays of fan-like airfoils to

progressively compress the working fluid. They are used where there is a requirement for a high flow

rate or a compact design.

Reciprocating compressors - use pistons driven by a crankshaft. They can be either stationary or

portable, can be single or multi-staged, and can be driven by electric motors or internal combustion

engines. Small reciprocating compressors from 5 to 30 horsepower (hp) are commonly seen in

automotive applications and are typically for intermittent duty.

Rotary vane compressors - consist of a rotor with a number of blades inserted in radial slots in the rotor.

The rotor is mounted offset in a larger housing that is either circular or a more complex shape. As the

rotor turns, blades slide in and out of the slots keeping contact with the outer wall of the housing. Thus,

a series of decreasing volumes is created by the rotating blades.

Rotary screw compressors - use two meshed rotating positive-displacement helical screws to force the

gas into a smaller space. These are usually used for continuous operation in commercial and industrial

applications and may be either stationary or portable.

Condenser

Evaporative condenser Most industrial ammonia refrigerating plants are equipped with evaporative

condensers. The refrigerant vapor flows through the closed tube system of a heat exchanger. The

outside surface of the heat exchanger is constantly sprinkled with water. Air is conducted with aspirating

or forced draught fans through the heat exchanger, thereby the tube system is cooled and the

circulating water evaporates partly.

Hybrid Condensers are the combination of an evaporative condenser and an air-cooled condenser. The

refrigerant vapor flows through a finned heat exchanger or through a combination of finned and non-

finned heat exchanger. Due to the large surface of the integrated finned heat exchanger it is possible to

operate this system up to a defined ambient temperature (e.g. 15 C) without using a water spray

system.

Air-cooled condensers Most refrigerating plants with non-natural refrigerants are equipped with air-

cooled condensers. During the past years, the use of air-cooled condensers for ammonia refrigerating

plants has increased, especially in regions with high costs for water and wastewater. In air-cooled

condensers refrigerant vapor flows through the tube system of a finned heat exchanger. The fans

aspirate the air through the heat exchanger so that the refrigerant vapor is cooled down and condensed.

The condensing heat is only dissipated by the means of the cooling of the heat exchanger with air.

Evaporator

Evaporator - is a device used to turn the liquid form of a chemical into its gaseous form. The liquid is

evaporated, or vaporized, into a gas.

Bare tube evaporators - are usually used for liquid chilling. In blast cooling and freezing operations the

atmospheric air flows over the bare tube evaporator and the chilled air leaving it used for the cooling

purposes.

Day tank

A day tank is typically sized to provide a day's worth of usage. (Hindi ako sure dito ha.)

Hoist Winch

Winch - is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust

the "tension" of a rope or wire rope (also called "cable" or "wire cable"). In its simplest form it consists

of a spool and attached hand crank. In larger forms, winches stand at the heart of machines as diverse

as tow trucks, steam shovels and elevators.

Das könnte Ihnen auch gefallen

- 37 Keys Electronic Keyboard For Kids / Pick Up: 74184200 JPVDDCDokument1 Seite37 Keys Electronic Keyboard For Kids / Pick Up: 74184200 JPVDDCArielInopiaNoch keine Bewertungen

- Goyanko, Jr. v. United Coconut Planters BankDokument2 SeitenGoyanko, Jr. v. United Coconut Planters BankArielInopiaNoch keine Bewertungen

- CAÑEZO vs. ROJASDokument2 SeitenCAÑEZO vs. ROJASpotbatangkalawakanNoch keine Bewertungen

- Goyanko, Jr. v. United Coconut Planters BankDokument2 SeitenGoyanko, Jr. v. United Coconut Planters BankArielInopiaNoch keine Bewertungen

- Cases in TrustDokument1 SeiteCases in TrustArielInopiaNoch keine Bewertungen

- Kids' Swim Vest - Torquoise: 87623295 QklupnDokument1 SeiteKids' Swim Vest - Torquoise: 87623295 QklupnArielInopiaNoch keine Bewertungen

- Litonjua V EternitDokument2 SeitenLitonjua V EternitAnonymous BvmMuBSwNoch keine Bewertungen

- Nego San Beda Mem AidDokument24 SeitenNego San Beda Mem Aidngtolentino100% (2)

- TCAT2 VoucherDokument1 SeiteTCAT2 VoucherArielInopiaNoch keine Bewertungen

- Conflict of Laws NotesDokument13 SeitenConflict of Laws NotesArielInopiaNoch keine Bewertungen

- Agency Reviewer - VillanuevaDokument31 SeitenAgency Reviewer - VillanuevaYerdXXNoch keine Bewertungen

- Supreme Court: Priscilo Evangelista For Appellee. Brigido G. Estrada For AppellantDokument3 SeitenSupreme Court: Priscilo Evangelista For Appellee. Brigido G. Estrada For AppellantArielInopiaNoch keine Bewertungen

- Luz Pineda v. CA (Digest)Dokument1 SeiteLuz Pineda v. CA (Digest)Allan TolentinoNoch keine Bewertungen

- Conflict of Laws NotesDokument13 SeitenConflict of Laws NotesArielInopiaNoch keine Bewertungen

- New DesignDokument1 SeiteNew DesignArielInopiaNoch keine Bewertungen

- Singapore Hotel ComparisonDokument4 SeitenSingapore Hotel ComparisonArielInopiaNoch keine Bewertungen

- Litonjua Vs FernandezDokument2 SeitenLitonjua Vs FernandezJL A H-Dimaculangan50% (4)

- Tan vs. Gullas - Case DigestDokument1 SeiteTan vs. Gullas - Case Digestmansikiabo100% (1)

- Litonjua V EternitDokument2 SeitenLitonjua V EternitAnonymous BvmMuBSwNoch keine Bewertungen

- EternDokument2 SeitenEternArielInopiaNoch keine Bewertungen

- 8-The Executive Secretary vs. CADokument16 Seiten8-The Executive Secretary vs. CAArielInopiaNoch keine Bewertungen

- Sia Vs People PDFDokument8 SeitenSia Vs People PDFCarlo AfNoch keine Bewertungen

- NSTPDokument2 SeitenNSTPArielInopiaNoch keine Bewertungen

- 9.25 TR Ice Plant: A Thesis Proposal Submitted in Final Fulfillment of The Course Requirements inDokument4 Seiten9.25 TR Ice Plant: A Thesis Proposal Submitted in Final Fulfillment of The Course Requirements inArielInopiaNoch keine Bewertungen

- How To Change Wifi PasswordDokument1 SeiteHow To Change Wifi PasswordArielInopiaNoch keine Bewertungen

- Jobs of OfficersDokument1 SeiteJobs of OfficersArielInopiaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- CLASSIFICATION of AIR COMPRESSORS An Air Compressor May Be Classified According To PressureDokument2 SeitenCLASSIFICATION of AIR COMPRESSORS An Air Compressor May Be Classified According To PressureRohit Kumar Kushwaha0% (1)

- Automotive Vehicles: Supercharging & Turbo ChargingDokument19 SeitenAutomotive Vehicles: Supercharging & Turbo ChargingVinodDahiyaNoch keine Bewertungen

- BackdraftDokument6 SeitenBackdraftMarwan MalekNoch keine Bewertungen

- Service Manual-Versati III-Compact Mono Block R32Dokument135 SeitenService Manual-Versati III-Compact Mono Block R32arsing007Noch keine Bewertungen

- CB-B2,5 PompaDokument2 SeitenCB-B2,5 PompaÖzgür BiliciNoch keine Bewertungen

- Inverter Swimming Pool Heat PumpDokument2 SeitenInverter Swimming Pool Heat PumpMawin EstudioNoch keine Bewertungen

- Jet Engines - ExplainedDokument12 SeitenJet Engines - ExplainedAsamir AlHaidarNoch keine Bewertungen

- Condenser Feedwater Heater BrochureDokument5 SeitenCondenser Feedwater Heater Brochureendri2000Noch keine Bewertungen

- SingrauliDokument26 SeitenSingrauliamitshukla1991Noch keine Bewertungen

- GE6251-Basic Civil and Mechanical Engineering-1 - 258 PDFDokument21 SeitenGE6251-Basic Civil and Mechanical Engineering-1 - 258 PDFSwetha RameshNoch keine Bewertungen

- 794 - Metso HH 200 C5 Curve RELDokument1 Seite794 - Metso HH 200 C5 Curve RELHumberto GoncalvesNoch keine Bewertungen

- Gledhill Vented Installer Brochure 2019 v11.6 WEBDokument13 SeitenGledhill Vented Installer Brochure 2019 v11.6 WEBzourawar khanNoch keine Bewertungen

- KKS Keys PDFDokument381 SeitenKKS Keys PDFJonathan Alexi Molina Roa100% (1)

- Otto&DieselDokument7 SeitenOtto&DieselChelsea HermosaNoch keine Bewertungen

- GAS TURBINE (50 Hz/60 HZ) : Industrial-Strength, Field-Proven ReliabilityDokument2 SeitenGAS TURBINE (50 Hz/60 HZ) : Industrial-Strength, Field-Proven ReliabilityMarutisinh RajNoch keine Bewertungen

- Turbo Machine: Ioe, T CDokument35 SeitenTurbo Machine: Ioe, T CCalcgen EngineeringNoch keine Bewertungen

- Power Generation and Transmission: Instructors: Dr. M. Zahir Paracha/Hafiz Ahsan SaidDokument39 SeitenPower Generation and Transmission: Instructors: Dr. M. Zahir Paracha/Hafiz Ahsan Saidmujtabaiftikhar156Noch keine Bewertungen

- 750-237 OM ProFire-VDokument94 Seiten750-237 OM ProFire-VUmar MajeedNoch keine Bewertungen

- Hydroelectric Power Tutorial Question Updated AnswerDokument5 SeitenHydroelectric Power Tutorial Question Updated AnswerAdreana AmirahNoch keine Bewertungen

- Ducted Blower System (ADB-B/AMC) Ducted Blower System (ADB-B/AMC)Dokument1 SeiteDucted Blower System (ADB-B/AMC) Ducted Blower System (ADB-B/AMC)Azrul AzimNoch keine Bewertungen

- Fans and Capacity ControlDokument4 SeitenFans and Capacity ControlneilratheramNoch keine Bewertungen

- Poseidon High Pressure Compressor (P 135)Dokument5 SeitenPoseidon High Pressure Compressor (P 135)rmaffireschoolNoch keine Bewertungen

- 1 C-ME-HM-009R3-Calculation Sheet For Main Transformer and HAVC Equipments Cooling Water System R3Dokument17 Seiten1 C-ME-HM-009R3-Calculation Sheet For Main Transformer and HAVC Equipments Cooling Water System R3rotimi olalekan fataiNoch keine Bewertungen

- BTR-1.0IM Internal Mount Conventional Mandrel: Gas Lift Technical UnitDokument3 SeitenBTR-1.0IM Internal Mount Conventional Mandrel: Gas Lift Technical UnitLUIS. F RuizNoch keine Bewertungen

- Bosch CP1Dokument7 SeitenBosch CP1rodolfo100% (2)

- Activity - 221130 - Exploration Geologist - MKEDokument8 SeitenActivity - 221130 - Exploration Geologist - MKESetia WirawanNoch keine Bewertungen

- Mathcad - Q5Dokument2 SeitenMathcad - Q5Desejo SozinandoNoch keine Bewertungen

- Advanced Overfire Air Systems For Corner-Fired Boilers Economically Reduce NOX EmissionsDokument4 SeitenAdvanced Overfire Air Systems For Corner-Fired Boilers Economically Reduce NOX EmissionsudayagirimuralimohanNoch keine Bewertungen

- Fans and Blowers Part I ModuleDokument26 SeitenFans and Blowers Part I ModuleCharlyn Flores67% (3)

- Sealed Lead-Acid Battery Maintenance PracticeDokument2 SeitenSealed Lead-Acid Battery Maintenance PracticeUsman Mustafa SyedNoch keine Bewertungen