Beruflich Dokumente

Kultur Dokumente

Focus On Control Valves

Hochgeladen von

wmolinac5843660 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

88 Ansichten5 SeitenControl valves have a major impact on control loop performance and, therefore, improvements in valve performance can have significant economic benefits. This article shows how poor control-valve performance can be identified and corrected. The key to control valve performance is creating a measurable change in flow through the valve in response to small, input step changes.

Originalbeschreibung:

Originaltitel

Focus on Control Valves

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenControl valves have a major impact on control loop performance and, therefore, improvements in valve performance can have significant economic benefits. This article shows how poor control-valve performance can be identified and corrected. The key to control valve performance is creating a measurable change in flow through the valve in response to small, input step changes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

88 Ansichten5 SeitenFocus On Control Valves

Hochgeladen von

wmolinac584366Control valves have a major impact on control loop performance and, therefore, improvements in valve performance can have significant economic benefits. This article shows how poor control-valve performance can be identified and corrected. The key to control valve performance is creating a measurable change in flow through the valve in response to small, input step changes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Feature Report

CHEMICAL ENGINEERING WWW.CHE.COM OCTOBER 2010 41

I

mprovements to the performance

of basic, regulatory control sys-

tems have a great return on in-

vestment and are some of the least

expensive control improvements to

make [1]. Control valves have a major

impact on control loop performance

and, therefore, improvements in valve

performance can have significant eco-

nomic benefits. This article shows how

poor control-valve performance can

be identified and corrected to achieve

these benefits. A plant example is

used to demonstrate these methods.

In addition to corrective actions,

comprehensive control-valve speci-

fications, based on process require-

ments for new applications, can

provide quicker plant startups and

immediate economic savings.

The control valve system

In this article, the control valve is con-

sidered to be a dynamic system, from

the input signal through to the flow

coefficient that determines the fluid

flowrate through the pipe. The con-

trol valve system includes the valve,

actuator, motion conversion mecha-

nism, stem or shaft, closure member

(such as plug, ball or disc) and other

valve accessories. Examples of valve

accessories include current to pres-

sure transducer (I/P), positioner, air

booster relay, dampener and air set.

So, when a change of the input signal

to the control valve occurs, the I/P and

positioner must respond to move the

actuator, which must move the motion

conversion mechanism, which must

move the stem or shaft, which must

move the closure member, which must

change the flow coefficient. As you

can see, there is a lot of opportunity

for problems.

The key to control valve performance

is creating a measurable change in

flow through the valve in response

to small, input step changes (1% and

less). A change in flow indicates that

the valves flow coefficient has actu-

ally changed in response to a change

in the input signal. If the actual flow

through the control valve is not avail-

able or is not measured, then the valve

stem, shaft or actuator movement may

be used to estimate the response of the

valve. However, the movement of the

valve stem, shaft or actuator may not

be an accurate representation of the

actual change in the valve flow coef-

ficient for all changes of the input sig-

nal to the valve. For example, the in-

board end of the shaft of a rotary valve

might move in response to a change

in the input to the control valve but

the actual flow coefficient might not

change because shaft windup occurs

and the valve closure member does

not move. In some cases the actuator

position may be used to measure the

control valve response and this adds

yet another potential discrepancy be-

tween the input to the control valve

and the actual change in the valve

flow coefficient. However, it is impor-

tant to note that the response of the

valve flow coefficient can be no better

than that of the stem, shaft or actua-

tor position.

Control valve performance

The performance of a control loop will

be limited by the poorest performing

component in the loop, such as the

transmitter, the controller tuning or

the final control element. Note that

for most control loops, the final control

element is a control valve. One study

of over 5,000 control loops revealed

Feature Report

James Beall

Emerson Process Management

The control valve

is a focal point for

improvements to both

process performance

and economics

Improving Control

Valve Performance

Input

a < resolution b

c dead band < d

c

d

Time

Dynamics are not shown

A

m

p

l

i

t

u

d

e

a

b

Output

FIGURE 1.

Dead band and

resolution, il-

lustrated here,

are key static-

response param-

eters for control

valves

Feature Report

42 CHEMICAL ENGINEERING WWW.CHE.COM OCTOBER 2010

that poor control-valve performance

negatively impacted control loop per-

formance on 30% of these loops [2].

Important aspects of control valve

performance include the static re-

sponse, the dynamic response and the

valve trim size and flow characteris-

tics. The International Society of Au-

tomations (ISA) technical reference,

ANSI-ISA-TR75-25-02, explains the

concepts of control-valve static- and

dynamic-response metrics [3]. ISA

standard ANSI-ISA-75-25-01 is a test

procedure to measure the static and

dynamic response of a control valve

system [4]. However, this standard

does not prescribe what response re-

quirements should be specified in

order to achieve the desired control-

valve performance for a particular ap-

plication. The EnTech Control Valve

Dynamic Specification V3.0 provides

guidance on specifying the static- and

dynamic-response parameters and the

valve trim size and flow characteris-

tics to achieve the desired process con-

trol performance [5].

Static response. So, what are these

control-valve response parameters

and what do they mean to process

control performance? Static response

refers to measurements that are made

with data points that are recorded

after the device has come to a rest. Key

static-response parameters for control

valves include travel gain, dead band

and resolution [3]. Travel gain, Gx, is

the change in closure member position

divided by the change in input signal,

both expressed in percentage of full

span. The closure member is the por-

tion of the valve trim that moves to

change the flow through the valve.

If there is no signal characterization

inside the valve system, the travel

gain should be 1.0. In other words,

travel gain is a measure of how well

the valve system positions its closure

member compared to the input signal.

Dead band is defined as the range

through which an input signal may be

varied, with reversal of direction, with-

out initiating an observable change

in output signal [6]. With respect to

control valve performance, if the pro-

cess controller attempts to reverse the

position of the control valve, the valve

will not begin to move until after the

controller output has reversed an

amount greater than the dead band.

A large dead band will negatively im-

pact control performance.

Another key static-response param-

eter is resolution. Resolution is defined

as the smallest step increment of

input signal in one direction for which

movement of the output is observed

[3]. Resolution will cause the control

valve to move in discrete steps in re-

sponse to small, step input changes in

the same direction. This occurs as the

valve travel sticks for the amount of

resolution after completing the previ-

ous step in the same direction. Simi-

lar to dead band, a larger resolution

will negatively impact control perfor-

mance. Figure 1 illustrates dead band

and resolution.

Dynamic response. The second as-

pect of control valve performance

is the dynamic response. Dynamic

response is the time-dependant re-

sponse resulting from a time-varying

input signal [4], and includes dead

time, step response time and over-

shoot. The ISA technical reference

ANSI-ISA-TR75-25-02 [3] provides

the following definitions for these dy-

namic response parameters:

Dead time The time after the ini-

tiation of an input change and before

the start of the resulting observable

response

Step response time The interval of

time between initiation of an input-

signal step change and the moment

that the dynamic response reaches

86.5% of its full, steady state value.

The step response time includes

the dead time before the dynamic

response

Overshoot The amount by which

a step response exceeds its final,

steady state value (refer to Figure

24 of ANSI/ISA-51.1-1979 (R1993)).

Usually expressed as a percentage of

the full change in steady state value

Figure 2 shows the dead time, step

response time and overshoot for a

I

n

p

u

t

,

s

t

e

m

%

35

0 10

Travel gain = 0.91

Time to steady state, T

ss

= 18.3 s

Time, s

Final steady state

average values

input = 37.84, stem = 37.65

Initial overshoot to 38.11 = 23%

Stem

Input

86.5% of response, T

86

= 2.06 s

Dead time T

d

=1.6 s

Initial steady state average values, input and stem = 35.67

20 30

36

37

38

39

LV-2

R-1

LC-1

LC-2

LV-1

R-2

Variation of

valve position

represents

variation

in flow to

downstream

reactor

Level

variation

~

20%

~

120 days

FIGURE 2. This graphs shows the re-

sponse of a control valve to a step input

(reprinted with permission from EnTech

Control Valve Dynamic Specifcation V3.0)

FIGURE 3. In this plant example, the

level controller output went directly to

the control valve positioner

FIGURE 4. In the plant example, the re-

actor level was not well-controlled

CHEMICAL ENGINEERING WWW.CHE.COM OCTOBER 2010 43

control valve response to a step input

change. In this case, stem position in

percent of travel is used as the control

valve output.

It is important to note that the dy-

namic response of a control valve var-

ies depending upon the size of the input

step change. Four ranges of step sizes

to help understand the static- and dy-

namic-response metrics are defined in

the technical reference [3]:

Region 1 is defined as small input

steps that result in no measurable

movement of the closure member

within the specified wait time

Region 2 is defined as the input step

changes that are large enough to re-

sult in some control-valve response

with each input signal change, but

the response does not satisfy the

requirements of the specified time

and linearity

Region 3 is defined as step changes

that are large enough to result in

flow coefficient changes, which sat-

isfy both the specified maximum re-

sponse time and the specified maxi-

mum linearity

Region 4 is defined as input steps

larger than in Region 3 where the

specified magnitude-response lin-

earity is satisfied but the specified

response time is exceeded

Region 1 is directly related to dead band

and resolution. Region 2 is a highly non-

linear region that causes performance

problems and should be minimized. Re-

gion 3 is the range of input movements

that are important to control perfor-

mance. The dynamic response param-

eters, dead time and response time, are

applicable in this region. Regions 1, 2, 3

and 4 correspond to regions A, B, C and

D as defined in Ref. 5.

Process control issues

A very important aspect of process

control is the process gain, which is

defined as the ratio of the change in

process variable to the change in con-

troller output that caused the change.

For good process control, it is desir-

able for the process gain to be within

a certain range and to be consistent

throughout the operating range of the

valve. If the process gain is too high,

valve non-linearities are amplified by

the process gain and process control

performance deteriorates. If the pro-

cess gain is too low, the range of con-

trol is reduced. Changes in the pro-

cess gain over the range of operation

result in poorly performing regions in

the closed-loop controller response.

Two characteristics of a control valve

impact the process gain: the size of

the valve trim and the inherent flow

characteristic of the valve. If the valve

trim is oversized, the process gain will

be higher than it would be for an ap-

propriately sized valve. The inherent

flow characteristic of the valve typ-

ically linear, quick opening or equal

percentage will impact both the

magnitude and the consistency of the

process gain over the operating range.

Therefore, proper valve sizing and

trim characteristics are important in

achieving good control-valve and pro-

cess-control performance.

Plant example

An actual plant example will be used

to illustrate some key aspects of con-

trol valve performance. In this ex-

ample, a valve that is typically used

for on-off applications was modified

to also perform as a throttling control

valve. There are good on-off valves

and there are good throttling valves,

but it is very difficult to have a valve

that is good at both functions. Some

of the characteristics of a good on-off

valve are as follows:

Low leakage shutoff

Line size (usually)

Compact and light weight

No positioner required

Trim options not required (nor

available)

Actuation is usually open or closed

with little positioning capability

Less-expensive purchase price

Some of the characteristics of a good

throttling control valve are as follows:

May have significant leakage when

closed

The body is smaller than line size

(usually)

Valve and accessories require more

space

Valve positioner is usually included

Various trim size and characteris-

tics available

Actuation has positioning capability

More expensive purchase price

In this plant example, the on-off valve

was outfitted with a high-performance,

digital valve positioner and tight fit-

ting shaft-to-actuator keyways and

keys in an effort to provide good throt-

tling performance. The valve was used

for level control of a reactor where the

level controller output went directly to

the control valve positioner as shown

in Figure 3. In this process, it is im-

portant to control the level in reactor

R-1 Level

8% variation of level

R-1 Level controller output

1% change in controller output

before level responds

LCV-1 Valve (actuator) position

Note spikes in actuator position

11

9

R-1 Level controller set point

Constant

50

70

59.99

11

9

60.01

6 hours

6 hours

6 hours

6 hours

10

Change in slope

of level confirms

valve shaft rotation

9.5

9

8.5

8

7.5

%

7

6.5

6

0 500 1,000

~0.3% Shaft rotation

changes level slope

~0.4% Shaft rotation

changes level slope

~1% Dead band

~1% Offset

2,000

Time, s

3,000 4,000

20

25

30

L

e

v

e

l

,

%

35

40

45

50

55

LC-1

Level PV

60

3,500 2,500 1,500

LC-1

Output

LV-1

Actuator

position

LV-1

Valve shaft

position

FIGURE 5. Trend plots suggest that the

control-valve closure member may not

be moving until the controller output has

moved more than 1% after a direction

reversal

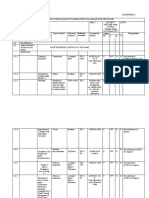

FIGURE 6. Tests of the control valve, LV-1, revealed a problem with positioner per-

formance, and excessive dead band and resolution

44 CHEMICAL ENGINEERING WWW.CHE.COM OCTOBER 2010

R-1 to maintain a consistent residence

time. It is also important to avoid

large changes in the flow from R-1 to

R-2 that will upset the R-2 level. The

control valve, LV-1, provided tight

shutoff as desired, but the control per-

formance of the level loop was poor

and caused level disturbances and

unplanned reactor shutdowns. Figure

4 shows the poor performance of the

reactor level control.

One of the first questions that arose

in this plant example was whether or

not the level controller, LC-1, was prop-

erly tuned. The tuning was checked

and, although it was not optimum, it

was not the source of the level varia-

tions. A closer look at the trends of the

LC-1 process variable and output as

well as the actuator position in Figure

5 suggests that the control-valve clo-

sure member may not be moving until

the controller output has moved more

than 1% after a direction reversal. In

other words, the control valve had a

combined dead band and resolution of

approximately 1%, which represents

10% of rate since the valve is operat-

ing at about 10% of full travel.

Testing the control valve. A special

test apparatus was installed on the

control valve to measure the rotation

of the valve shaft. The valve design

was such that the valve closure mem-

ber, a disc, was solidly attached to the

valve shaft and the shaft was large in

diameter so that shaft windup should

not be significant. Assuming there

were no other process disturbances

during the test, the slope of the level

process variable can be used to de-

tect a change in the actual flow coef-

ficient of the valve. The response of

the actuator position, the valve shaft

and the change in flow coefficient can

be compared to the input signal. The

input signal to the control valve (the

output of the controller) was stepped

in increments of 0.1% and 0.2% with

a reversal in direction. Figure 6 shows

a plot of key variables during the test.

The test revealed that the actuator

position was hunting with about a

0.3% peak-to-peak magnitude. Fur-

thermore, the valve shaft response

exhibited a dead band of about 0.8%

and a resolution of about 0.2%. Since

the control valve was only operating

at 810% of its capacity, 1% of com-

bined dead band and resolution is a

very large non-linearity. And, for a

process with an integrating response,

the presence of a dead band will cause

a continuous limit cycle in the level

and the flow through the valve. In

summary, this test revealed a problem

with positioner performance and ex-

cessive dead band and resolution. The

tuning test performed earlier showed

that the process gain was excessively

high, which amplified the control valve

problems. The fact that the valve only

operated at 810% of its capacity in-

dicates that it is oversized, which con-

tributed to the high process gain.

The role of control-valve construc-

tion. Figure 7 shows details of the

construction of the control valve and

its actuator. The construction has

several characteristics that can cause

dead band. First, any clearance in the

key ways and keys in the coupling will

cause dead band. When the valve was

initially built, set screws had been used

to press into the keys in an attempt to

reduce slippage between the coupling

and the shafts. Another source of dead

band in this design is the scotch-yoke

assembly that converts the linear mo-

tion of the actuator to the rotary mo-

tion of the actuator shaft. By design,

the scotch-yoke assembly must have

clearance between the moving parts,

but clearance creates dead band [7].

Note that the position of the actua-

tor shaft, not that of the valve shaft,

is used for position feedback to the

digital valve positioner. Thus, the po-

sitioner will measure the position of

the actuator shaft and is unaware of

the fact that the valve shaft position

may differ from the actuator shaft by

as much as 1%.

Many of the features of this control-

valve construction were appropriate

for on-off valve performance, but were

inherently problematic for throttling

performance. In summary, the inves-

tigation revealed the following prob-

lems with the valve:

Oversized valve creates high pro-

cess gain, which amplifies valve

non-linearities

Slack in actuator-to-valve shaft cou-

pling, which creates dead band

Slack in the scotch yoke assembly,

which results in dead band

Poor tuning in digital valve posi-

tioner, which results in excessive

dead band, resolution and a varia-

tion in travel gain

The solution. The recommended so-

lution for this plant example was to

Piston

actuator Scotch-yoke assembly

converts linear motion

to rotary motion

Actuator shaft

Keyed coupling

Valve shaft

Position transmitter (ZT)

attached to valve shaft

to detect actual valve

shaft rotation

Digital valve

positioner measures

actuator shaft

position for feedback

Disc

Valve body

Keys

Keyway

Before After

Keyway

Keyway

Keyway

Key

Key

Key

Valve

shaft

3/8 in.

setscrew

Actuator shaft

Coupling

1/2 in.

setscrew

1/2 in.

setscrew

5/8 in.

setscrew

Keyway

Keyway

Keyway

Keyway

Key

Note Drilled access holes to all 3 setscrews so

that they could be tightened from 0 to 20% position.

Custom key

Key

Valve

shaft

Actuator shaft

Coupling

FIGURE 7. Many of the features of this control valve

construction were appropriate for on-off valve perfor-

mance, but were inherently problematic for throttling

performance

FIGURE 8. Improvements were made to the actuator coupling sys-

tem on the control valve, LV-1

CHEMICAL ENGINEERING WWW.CHE.COM OCTOBER 2010 45

replace the control valve with one that

is properly sized and has better throt-

tling control performance and suf-

ficient on-off characteristics (in this

case a tight shut-off). And, the valve

positioner should be tuned properly

for the optimum response.

In an effort to provide more immedi-

ate improvement in the reactor level

control, the following interim improve-

ments were made to the control valve:

reduce the slack in the actuator cou-

pling system; and improve the tuning

of the digital valve positioner. To re-

duce the slack in the actuator coupling

system, new keys were machined with

a tighter fit in the keyways. Then, ad-

ditional and larger set screws were

installed in the coupling to press on

the keys. Figure 8 shows the changes

made to the actuator coupling system.

The valve positioner was tuned to pro-

vide a faster response time, improve

its travel-gain performance and to re-

duce the tendency to hunt or oscillate.

The interim efforts to improve the

control valve performance were benefi-

cial and helped to improve the reactor-

level-control performance and reduce

the frequency of unplanned reactor

trips due to level control disturbances.

Figure 9 shows the reactors level con-

trol performance before and after the

interim improvements were made.

The complete recommended solu-

tion was to replace the original 18-in.

valve with a 12-in. high-performance,

segmented-ball, throttling control

valve with a spring and diaphragm

actuator. This control valve system,

similar to the one shown in Figure 10,

is specifically designed for throttling

applications. A high-performance,

digital valve positioner was included

and was properly tuned to achieve

the optimum performance. The new

control valve provided even better re-

actor level performance and allowed

a 10% production-rate increase and a

significant economic benefit.

Edited by Dorothy Lozowski

After improvements

Reactor

level

~

50% less

variation in

valve position

and flow to

downstream

reactor

Before improvements

~

120 days

FIGURE 9.

The reactor

level control

improved

with interim

control-valve

improve-

ments

The BEST screening machines

just got BETTER!

325 Waverly Avenue Mamaroneck, NY 10543

1 800 AT ELCAN 914-381-7500

sales@virto-elcan.com www.virto-elcan.com

Eliminates Blinding

Superior throughputs

Increased efficiencies

Exceptional Performance on

Dense Powders Damp feeds

Liquids/Slurries Sticky materials

Screening down to 10 microns

is now

VirtoElcan_2:Layout 1 11/10/09 2:15 PM Page 1

Circle 48 on p. 66 or go to adlinks.che.com/29255-48

FIGURE 10.

A high-performance,

segmented-ball control-

valve system, similar to

the one pictured here,

provided better level

performance

Author

James Beall is a principal

process control consultant at

Emerson Process Manage-

ment (12301 Research Blvd.,

Research Park Plaza, Bldg.

III, Austin, TX, 78759; Phone:

9032357935; Email: James.

Beall@Emerson.com) with 29

years of experience in process

control. His areas of expertise

include process instrumenta-

tion, control strategy analysis

and design, control optimization, control valve

performance and advanced process control.

References

1. Tolliver, Terry, Process Analysis for Improved

Operation and Control, Fisher-Rosemount

Systems Advanced Control Seminar, 1996.

2. Bialkowski, W. L., Dreams Versus Reality, A View

From Both Sides of the Gap, Keynote Address,

Control Systems 92, Whistler, British Columbia,

1992, published Pulp Pap. Can. 94(11), 1993.

3. ANSI-ISA-TR75-25-02-2000 Control Valve

Response Measurement from Step Inputs

4. ANSI-ISA-75-25-01-2000 Test Procedure for

Control Valve Response Measurement from

Step Inputs.

5. EnTech Control Valve Dynamic Specification V3.0.

6. ANSI/ISA 51.1-1979 (R1993) Process Instru-

mentation Terminology.

7. Fitzgerald, Bill, Control Valves for the Chemical

Process Industries, McGraw-Hill, New York, 1995.

Fisher Controls International

Das könnte Ihnen auch gefallen

- Ebook PDF Engineering Graphics Essentials 5th Edition by Kirstie PlantenbergDokument61 SeitenEbook PDF Engineering Graphics Essentials 5th Edition by Kirstie Plantenbergdeborah.sheehan548100% (42)

- Control Valve Characteristics - International Site For Spirax Sarco PDFDokument15 SeitenControl Valve Characteristics - International Site For Spirax Sarco PDFLoganathan KrishnanNoch keine Bewertungen

- AOLT-4000 OAM Manual PDFDokument546 SeitenAOLT-4000 OAM Manual PDFBrenden CarvalhoNoch keine Bewertungen

- Control Valve OcrDokument14 SeitenControl Valve OcrpathakshashankNoch keine Bewertungen

- Control Valve Actuators and PositionersDokument23 SeitenControl Valve Actuators and PositionersPg LisenNoch keine Bewertungen

- Contractor List 3Dokument6 SeitenContractor List 3ALI KHALID0% (1)

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDokument32 Seiten02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisNoch keine Bewertungen

- CM44PDokument52 SeitenCM44PSadot GutierrezNoch keine Bewertungen

- Control Valve PerformanceDokument11 SeitenControl Valve PerformancenjennsNoch keine Bewertungen

- Alfasud 8v EngineDokument6 SeitenAlfasud 8v EngineAlexandru IonescuNoch keine Bewertungen

- 1.3 Plant Operation SystemDokument32 Seiten1.3 Plant Operation Systemarunkumar23101Noch keine Bewertungen

- Big Data Analytics Methods and Applications Jovan PehcevskiDokument430 SeitenBig Data Analytics Methods and Applications Jovan Pehcevskihizem chaima100% (2)

- Vibration Monitoring System-3500 PDFDokument27 SeitenVibration Monitoring System-3500 PDFer_sanjaypatel100% (1)

- Advanced Fieldbus Diagnostics Without FieldbusDokument12 SeitenAdvanced Fieldbus Diagnostics Without FieldbusMarcio RochaNoch keine Bewertungen

- .Process Instrument and Control (Week1 - 2) - 1681659856000Dokument230 Seiten.Process Instrument and Control (Week1 - 2) - 1681659856000NonsoNoch keine Bewertungen

- DRESSER ControlValveCavitationDokument10 SeitenDRESSER ControlValveCavitationLindsey PatrickNoch keine Bewertungen

- Training - FlowDokument32 SeitenTraining - FlowTimothy LeonardNoch keine Bewertungen

- TC Electronic Support - Which Expression Pedal To Use With TC Devices-1Dokument3 SeitenTC Electronic Support - Which Expression Pedal To Use With TC Devices-1sarag manNoch keine Bewertungen

- PS Valve ServiceDokument40 SeitenPS Valve ServiceamojodiNoch keine Bewertungen

- Magnetrol TypesDokument20 SeitenMagnetrol Typesbhargav103Noch keine Bewertungen

- Coriolis Flowmeters Are Relatively New Compared To Other Flowmeters. They WereDokument9 SeitenCoriolis Flowmeters Are Relatively New Compared To Other Flowmeters. They WereAyu AgustinaNoch keine Bewertungen

- TC FLS Sihi LPHX 65000 en PDFDokument11 SeitenTC FLS Sihi LPHX 65000 en PDFyuanNoch keine Bewertungen

- Importance of Control ValvesDokument31 SeitenImportance of Control ValvesIndranil Hatua100% (1)

- Valves & Controls: Crosby Safety Valves Style HSLDokument12 SeitenValves & Controls: Crosby Safety Valves Style HSLeborresonNoch keine Bewertungen

- 2010-11-12/ V42 - Jen SAMSON Valve Series 3250 + 3280 1Dokument45 Seiten2010-11-12/ V42 - Jen SAMSON Valve Series 3250 + 3280 1pmmparana100% (1)

- API - Valve StandardsDokument38 SeitenAPI - Valve StandardsK LandryNoch keine Bewertungen

- 18/07/2022 Java Homework-1: Core Java Test Papers - Day 1 (Class, Objects, Methods)Dokument13 Seiten18/07/2022 Java Homework-1: Core Java Test Papers - Day 1 (Class, Objects, Methods)praveen murugesanNoch keine Bewertungen

- Control Loop Hardware and TroubleshootingDokument51 SeitenControl Loop Hardware and TroubleshootingAhmed ElsayedNoch keine Bewertungen

- Control Valves: Rejath Jacob ThomasDokument77 SeitenControl Valves: Rejath Jacob Thomasshakti sindhuNoch keine Bewertungen

- Ipc 15 Valve CharacteristicsDokument41 SeitenIpc 15 Valve CharacteristicsHarsh RavalNoch keine Bewertungen

- Control Valve OpeningDokument3 SeitenControl Valve OpeningConnor SailorNoch keine Bewertungen

- API 6A and 6D Ball ValvesDokument27 SeitenAPI 6A and 6D Ball ValveszayerirezaNoch keine Bewertungen

- Flow Measurement Techniques: Brijesh B Menon C&I DepartmentDokument15 SeitenFlow Measurement Techniques: Brijesh B Menon C&I DepartmentLiji BrijeshNoch keine Bewertungen

- Control Valves - International Site For Spirax SarcoDokument12 SeitenControl Valves - International Site For Spirax SarcoOzawa MagooNoch keine Bewertungen

- Industrial Instrumentation IIDokument15 SeitenIndustrial Instrumentation IIHarsha_2994Noch keine Bewertungen

- Instructivodel Actuador Masoneilan Serie 88Dokument14 SeitenInstructivodel Actuador Masoneilan Serie 88Jhon SanabriaNoch keine Bewertungen

- Orifice Assembly With Flange TapsDokument1 SeiteOrifice Assembly With Flange TapsDhanny MiharjaNoch keine Bewertungen

- O-Ring Kits: Product DescriptionDokument7 SeitenO-Ring Kits: Product DescriptionRonildo DuarteNoch keine Bewertungen

- General Industrial Pressure Gauges: ・Type A‥‥ ・Type B‥‥ ・Type C‥‥ ・Type D‥‥Dokument50 SeitenGeneral Industrial Pressure Gauges: ・Type A‥‥ ・Type B‥‥ ・Type C‥‥ ・Type D‥‥wiyoto 369Noch keine Bewertungen

- S-Mass Series Coriolis Mass Flow and Density Meters and SMT Series TransmittersDokument14 SeitenS-Mass Series Coriolis Mass Flow and Density Meters and SMT Series TransmittersazitaggNoch keine Bewertungen

- Masoneilan 21000 CntrlValve Techspec 0912 PDFDokument34 SeitenMasoneilan 21000 CntrlValve Techspec 0912 PDFsabNoch keine Bewertungen

- DPI610 615 ManualDokument90 SeitenDPI610 615 ManualAbd Al-Rahmman Al-qatananiNoch keine Bewertungen

- ASCO Filter RegulatorDokument4 SeitenASCO Filter RegulatorSamuel JohnsonNoch keine Bewertungen

- Pressure Measurement Theory and Application GuideDokument32 SeitenPressure Measurement Theory and Application GuidePrateek Raj0% (1)

- V-Cone DP PDFDokument6 SeitenV-Cone DP PDFhotnatkapoorNoch keine Bewertungen

- Valves in Piping DesignDokument5 SeitenValves in Piping DesigndasubhaiNoch keine Bewertungen

- FD-BF-001 Foxboro FieldDevices 010715 LowRes PDFDokument24 SeitenFD-BF-001 Foxboro FieldDevices 010715 LowRes PDFThiago FernandesNoch keine Bewertungen

- GE Druck DPI610 615 Is ManualDokument96 SeitenGE Druck DPI610 615 Is Manualqasim_maqboolNoch keine Bewertungen

- Good-Comparison of Friction Models Applied To A Control ValveDokument13 SeitenGood-Comparison of Friction Models Applied To A Control ValvesayproNoch keine Bewertungen

- از ميترينگ PDFDokument5 Seitenاز ميترينگ PDFazitaggNoch keine Bewertungen

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDokument3 SeitenEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNoch keine Bewertungen

- Trusted Field Loop ConfigurationDokument56 SeitenTrusted Field Loop Configurationjaysonlkh100% (1)

- TORQUES Actuator For Ball Valve PDFDokument12 SeitenTORQUES Actuator For Ball Valve PDFChaerul AnwarNoch keine Bewertungen

- Fisher Volume BoosterDokument16 SeitenFisher Volume Boosterpawank_kswnNoch keine Bewertungen

- ID-017 Instrument Communications PDFDokument70 SeitenID-017 Instrument Communications PDFФизули АбиловNoch keine Bewertungen

- Control ValvesDokument26 SeitenControl ValvesSandi Aslan100% (1)

- PICV Guide SpecificationDokument7 SeitenPICV Guide Specificationrio jeffryNoch keine Bewertungen

- AUMADokument24 SeitenAUMAVenkatesh GangadharNoch keine Bewertungen

- 10 - Creation of Logic FunctionDokument6 Seiten10 - Creation of Logic FunctionFelipeNoch keine Bewertungen

- Automation 4Dokument84 SeitenAutomation 4heru hsNoch keine Bewertungen

- Pds Deltav Sis CslsDokument57 SeitenPds Deltav Sis CslslimresNoch keine Bewertungen

- 2600T Basic Transmitter Theory (TI - 266-En - B-09 - 2013)Dokument32 Seiten2600T Basic Transmitter Theory (TI - 266-En - B-09 - 2013)JGlobexNoch keine Bewertungen

- Using Rod Drop Monitor To Prevent Cyliner and Piston Rod RepairDokument2 SeitenUsing Rod Drop Monitor To Prevent Cyliner and Piston Rod Repairkalam2k2Noch keine Bewertungen

- Readme E111Dokument1 SeiteReadme E111MOHAMEDELHELALYNoch keine Bewertungen

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979Von EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNoch keine Bewertungen

- Process Control System A Complete Guide - 2020 EditionVon EverandProcess Control System A Complete Guide - 2020 EditionNoch keine Bewertungen

- Funcionamiento de Válvulas de ControlDokument1 SeiteFuncionamiento de Válvulas de ControlRobert MontoyaNoch keine Bewertungen

- Economics of Short Sea ShippingDokument39 SeitenEconomics of Short Sea ShippingRodrigo Figueiredo ChapoutoNoch keine Bewertungen

- Chapter 1Dokument31 SeitenChapter 1PramodNoch keine Bewertungen

- Vipul Bansal: Career ObjectiveDokument3 SeitenVipul Bansal: Career ObjectiveVipul BansalNoch keine Bewertungen

- CIRWATT C 3PH Energy Meter ManualDokument33 SeitenCIRWATT C 3PH Energy Meter ManualdsffgdsgsgasfgasfgNoch keine Bewertungen

- Question Bank Unit 2 SepmDokument2 SeitenQuestion Bank Unit 2 SepmAKASH V (RA2111003040108)Noch keine Bewertungen

- Bitcoin Hunter Strings FileDokument5 SeitenBitcoin Hunter Strings Filevictor jamesNoch keine Bewertungen

- Pci 1750Dokument36 SeitenPci 1750Nguyen Danh HuyNoch keine Bewertungen

- Unitech Cable TrunkingDokument4 SeitenUnitech Cable TrunkingAFSALNoch keine Bewertungen

- CHP 530 To 660 KW PDFDokument16 SeitenCHP 530 To 660 KW PDFJunifero1Noch keine Bewertungen

- Model QAP For Plates1Dokument3 SeitenModel QAP For Plates1tarun kaushalNoch keine Bewertungen

- Dlcoa - May - 2023 (Rev-2019-C Scheme)Dokument1 SeiteDlcoa - May - 2023 (Rev-2019-C Scheme)hajimastanbaapNoch keine Bewertungen

- Time Relay Off Delay Datasheet - 3rp1540-1an30 - enDokument3 SeitenTime Relay Off Delay Datasheet - 3rp1540-1an30 - enJUAN CARLOS BERNAL MEJIANoch keine Bewertungen

- 7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DataDokument7 Seiten7PA22/23/26/27/30 Auxiliary Relays For Various Applications: Technical DatasoltaniNoch keine Bewertungen

- Using The KneeboardDokument2 SeitenUsing The KneeboardDenis CostaNoch keine Bewertungen

- EK 2109 Airframe Structures (General Concepts)Dokument30 SeitenEK 2109 Airframe Structures (General Concepts)Menara TegasNoch keine Bewertungen

- Symantec Netbackup ™ For Vmware Administrator'S Guide: Unix, Windows, and LinuxDokument118 SeitenSymantec Netbackup ™ For Vmware Administrator'S Guide: Unix, Windows, and Linuxlyax1365Noch keine Bewertungen

- Gods Cab ManualDokument11 SeitenGods Cab ManualKenneth CastilloNoch keine Bewertungen

- Balachandar Sridharan: Devops EngineerDokument3 SeitenBalachandar Sridharan: Devops EngineerVishnu SelvamNoch keine Bewertungen

- Sundeep Yedida IllinoisDokument2 SeitenSundeep Yedida Illinoisapi-3280552Noch keine Bewertungen

- V1NotebookDownload2 SuperNote Notebook Template Linked PDF GeneratorDokument31 SeitenV1NotebookDownload2 SuperNote Notebook Template Linked PDF Generatorh5gts3rx4Noch keine Bewertungen

- Super Manual 4.3 PDFDokument60 SeitenSuper Manual 4.3 PDFJohnkevinGarcia C. JohnkevinGarciaNoch keine Bewertungen

- Bescherelle École - Mon Maxi Cahier D'anglais CP, CE1, CE2, CM1, CM2 (Bescherelle Langues) (French Edition)Dokument1 SeiteBescherelle École - Mon Maxi Cahier D'anglais CP, CE1, CE2, CM1, CM2 (Bescherelle Langues) (French Edition)Anna Maciejewska0% (2)

- Katalog Dílů RKS 125 150 - GS Engine - 2011 Ver - 131031Dokument181 SeitenKatalog Dílů RKS 125 150 - GS Engine - 2011 Ver - 131031VictorNoch keine Bewertungen