Beruflich Dokumente

Kultur Dokumente

CNG Engine Technology For Passenger Cars - DR Hubert Friedl

Hochgeladen von

Vikas GargOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CNG Engine Technology For Passenger Cars - DR Hubert Friedl

Hochgeladen von

Vikas GargCopyright:

Verfügbare Formate

AVL ITC 24.4.

2007, Advanced CNG Engine Technology Page 1

Entwicklungstrends

Entwicklungstrends

Ottomotor

Ottomotor

DaimlerChrysler DaimlerChrysler, Stuttgart 20.April 2004 , Stuttgart 20.April 2004

AVL ITC, Technical Seminar

24. April 2007

Dr. Hubert FRIEDL

Highly

Highly

Advanced

Advanced

CNG

CNG

Engine

Engine

Technology

Technology

for

for

Passenger

Passenger

Cars

Cars

Higher

Higher

Fuel

Fuel

Efficiency

Efficiency

and

and

lower

lower

Emissions

Emissions

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 2

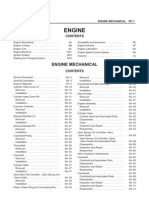

1. Market Trends

1. Market Trends

2. Configurations of CNG SI

2. Configurations of CNG SI

-

-

Engines

Engines

Turbo Charged Bi

Turbo Charged Bi

-

-

Fuel

Fuel

Mono Fuel CNG Direct Injection

Mono Fuel CNG Direct Injection

3. Conclusion and Outlook

3. Conclusion and Outlook

Content of Presentation

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 3

1.Market Trends

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 4

Volvo

BMW

Mercedes

Audi

Mazda

Nissan

Kia

Hyundai

Honda

Suzuki

Toyota

VW

Opel

Skoda

Ford

Peugeot

Seat

Renault

Citroen

Fiat

European European

CO CO

2 2

Fleet Fleet Data Data

2005 2005

2012 2012

CO

CO

2 2

Legislation

Legislation

as Technology Driver

as Technology Driver

for

for

all

all

Passenger

Passenger

Car Brands in Europe

Car Brands in Europe

100 110 120 130 140 150 160 170 180 190 200

CO

CO

2 2

[g/km] [g/km]

Extreme pressure

to invest into high

efficient powertrain

technology as well

as to promote

alternative fuels

EUROPE

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 5

Volvo

BMW

Mercedes

Audi

Mazda

Nissan

Kia

Hyundai

Honda

Suzuki

Toyota

VW

Opel

Skoda

Ford

Peugeot

Seat

Renault

Citroen

Fiat

European European

CO CO

2 2

Fleet Fleet Data Data

2005 2005

2012 2012

100 110 120 130 140 150 160 170 180 190 200

CO

CO

2 2

[g/km] [g/km]

Super / Super / Turbo Turbo- -

Charging Charging

Cylinder Cylinder

Deactivation Deactivation

Variable Variable

Charge Motion Charge Motion

GDI GDI

Stratified Stratified

Variable Variable Valve Valve

Actuation Actuation

Controlled Controlled

Auto Auto- -Ignition Ignition

Reduced Reduced

parasitic parasitic

losses losses

Improved Improved

energy energy

manage manage- -

ment ment

Energy Energy

recovery recovery

Start / Start /

Stop Stop

Hybrid Hybrid- -

ization ization

Alternative Alternative

Fuels Fuels

Technologies

Technologies

for

for

Gasoline

Gasoline

Engines

Engines

to

to

comply

comply

with

with

forthcoming

forthcoming

CO2

CO2

Targets

Targets

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 6

Global PC and LD Vehicle Production

by Propulsion Technology

15

30

45

60

75

90

1995 2000 2005 2010 2015

E

n

g

i

n

e

s

p

r

o

d

u

c

e

d

[

m

i

o

.

]

DIESEL CHARGED

DIESEL NA

CNG/LPG/

ALCOHOL/FLEX FUEL

ALTERNATIVE FUELS

GASOLINE GDI

HYBRID

GASOLINE PFI

GASOLINE Charged

Source: Global Insight

Gasoline

Gasoline

Diesel

Diesel

2007 2007

GDI GDI

charged charged

A

l

t

e

r

n

a

t

i

v

e

A

l

t

e

r

n

a

t

i

v

e

F

u

e

l

s

F

u

e

l

s

:

:

C

N

G

,

E

t

h

a

n

o

l

C

N

G

,

E

t

h

a

n

o

l

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 7

0%

20%

40%

60%

80%

100%

S

o

u

t

h

A

m

.

2

0

0

6

E

U

R

O

P

E

2

0

0

6

N

A

F

T

A

2

0

0

6

A

S

I

A

2

0

0

6

J

A

P

A

N

2

0

0

6

R

O

W

2

0

0

6

G

l

o

b

a

l

2

0

0

6

2

0

1

0

2

0

1

0

2

0

1

0

2

0

1

0

2

0

1

0

2

0

1

0

2

0

1

0

2

0

1

5

2

0

1

5

2

0

1

5

2

0

1

5

2

0

1

5

2

0

1

5

2

0

1

5

Region/Year

M

a

r

k

e

t

S

h

a

r

e

H2/Electric

Hybrid

FlexFuel,

Alcohol

CNG/LPG

Diesel

Gasoline

Global Vehicle Production by

Propulsion Technology

Source: Global Insight, AVL

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 8

2. Configurations for

CNG SI-Engines

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 9

Diesel Gaso- Metha- Etha- LPG CNG DME

line nol nol

Chemical Formula (-) C

15

H

28

C

7

H

15

CH

3

OH C

2

H

5

OH C

3

H

9

CH

4

C

2

H

6

O

Molecular Weight (-) 208 99 32 46 45 16 46

Carbon Content (%m) 86.1 84.9 37.5 52.2 80.0 75.0 52.2

Hydrogen Content (%m) 13.9 15.1 12.5 13.0 20.0 25.0 13.0

Oxygen Content (%m) 0 0 50.0 34.8 0 0 34.8

Density Liquid at 20 (kg/l) 0.840 0.740 0.795 0.790 0.540 - 0.668

Lower Heating Value (MJ/kg) 42.7 42.5 19.7 26.8 46.0 47.7 28.4

Heat of Evaporation (kJ/MJ) 6.0 8.0 56.4 33.8 8.6 - 14.4

Octane Rating RON (-) - 95 >110 >100 100 130 -

Cetane Number CN (-) 45-55 - - - - - >55

CO

2

Emission (g/MJ) 74.2 73.3 70.0 71.5 63.8 57.7 67.5

LPG: Liquified Petroleum mGas (50%mass C

3

H

8

+ 50% C

4

H

10

)

CNG: Compressed Natural Gas (mainly Methane CH4)

DME: Dimethylether

Properties of Fuels

Properties of CNG Properties of CNG

most attractive most attractive

for SI for SI- -Engines ! Engines !

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 10

High knock resistance of CNG (RON 120-140) allows high

compression ratio, but this leads to higher combustion pressure and

higher mechanical loads

Higher ignition energy and different ignition timing compared to

liquid fuels

CNG lacks cooling effect unlike other liquid fuels, but due to higher

compression ratio the exhaust temperatures are lower

As CNG is gaseous and combustion is without soot formation,

special attention has to paid for valve seat material

Max torque with CNG occurs very close to =1 and enrichment /

leaning leads to drop in torque

Power drop in CNG 10 ~ 12 % (due to lower volumetric efficiency)

Lean burn power drop 20 ~ 30% (partially compensated by turbocharging)

CNG in Combustion Process

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 11

Bi Bi fuel fuel

(Petrol or Gas) (Petrol or Gas)

Stoichiometric Stoichiometric

( ( = = 1) 1)

SI Spark Ignition SI Spark Ignition

Lean burn ( Lean burn ( > 1) > 1)

Mono fuel Mono fuel

(Optimized for gas) (Optimized for gas)

Most common solution Most common solution

Development Paths for CNG SI-Engines

Potential for higher Potential for higher

fuel efficiency fuel efficiency

Turbo Charging Turbo Charging

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 12

Bi-Fuel vs. Dedicated Mono-Fuel CNG Engines

High compression ratio

CH4 optimized catalyst

CH4 optimized lambda control

CH4 tolerant O2 sensors

One set of fuel injectors

Pressure regulator instead of

fuel pump

Monofuel PC gas engines

Knock limited CR (for gasoline)

is compromising thermal efficiency

Gasoline optimized catalyst

Lambda control optimized for

gasoline

Cold start usually with gasoline

Two sets of fuel injectors and dual

tank infrastructure required

Bi-fuel PC gas engines

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 13

2.1 Turbo Charged

Bi-Fuel Application

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 14

Development Tasks:

Integration of CNG fuel system

adapt mechanical system for specific

requirement when running engine with

CNG (e.g. valve seat rings)

Key Tasks and Challenges for

Turbo-charging Bi-Fuel CNG Engine

Challenges:

provide similar power and torque for

CNG as with gasoline fuel

Fulfill stringent emission standards

(ULEV, Euro 5) even maintaining

with gasoline dedicated exhaust

aftertreatment

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 15

BOSCH Natural Gas System (Bi BOSCH Natural Gas System (Bi- -Fuel) Fuel)

Source: Robert BOSCH GmbH, GS/EVP

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 16

Integration of CNG Fuel System to Engine

A combined CNG / gasoline fuel rail was designed for

optimized packaging

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 17

Full Load Performance of 2.0L Turbo Engine

CNG compared to Gasoline Fuel

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

0 1000 2000 3000 4000 5000 6000 7000

Engine speed [rpm]

T

o

r

q

u

e

[

N

m

]

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

P

o

w

e

r

[

k

W

]

CNG Torque [Nm]

Gasoline Torque [Nm]

CNG Power [kW]

Gasoline Power[kW]

Low end torque is lower on

CNG compared to Gasoline.

CNG calibrated to 125kW

Gasoline std calibration 135kW

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 18

TEMPERATURES, PRESSURES

CNG compered with gasoline at full load

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1

1,1

1,2

1,3

1,4

1,5

1,6

0 1000 2000 3000 4000 5000 6000 7000

Engine [rpm]

P

_

p

l

e

n

u

m

[

b

a

r

]

300

400

500

600

700

800

900

1000

T

e

m

p

e

r

a

t

u

r

e

[

C

]

Full Load Conditions of 2.0L Turbo Engine

CNG compared to Gasoline Fuel

Gasoline P Plenum

CNG P Plenum

Gasoline Cat 1 end

CNG Cat 1 end

Catalyst Temperature Limit 950 C

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 19

Measures to reduce Exhaust Temperatures

Measures to reduce Exhaust Temperatures

with Turbo

with Turbo

-

-

charged CNG Engines

charged CNG Engines

Integrated Exhaust Manifold

Integrated Exhaust Manifold

Water Cooled Turbine

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 20

Slightly reduced power (7,5%) in CNG operation with 2.0L

engine due to compromised layout for gasoline

Equalizing of performance gap to gasoline fuel operation

feasible with higher compression ratio and further

secondary measures (integrated exhaust manifold, cooled

turbine)

Euro 5/ULEV Emission limits achieved in CNG operation

due to optimized catalyst design and by calibrating

lambda control as well as transient A/F control.

Results for Turbo charged Bi-Fuel

CNG Application Project

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 21

2.2 Mono Fuel CNG

Direct Injection

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 22

Key Features of CNG Direct Injection

Combustion System Application

Engine Capacity 450 ccm/cylinder

Compression ratio: 1:13

Injector: AVL proprietary DMI-Injector

(Piezo Injector as Option)

CNG System Feed Pressure: 12 bar

Standard CNG pressure regulator

and CNG system components as

commercially available

Operation with homogeneous (=1)

and stratified lean (>1) air/fuel ratio

Such dedicated system is able

Such dedicated system is able

to utilize the full potential and

to utilize the full potential and

advantages of CNG Fuel !

advantages of CNG Fuel !

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 23

CNG-supply

CNG / Mixture chamber (for pure CNG

operation and DMI operation)

Nozzle (different geometries)

HP-oil supply

solenoid valve

Actuation piston

Lift adjustment (0.6 and 0.3mm variant)

Oil leakage draining

CNG - DI Injector for combustion development

(AVL Research Injector, no series product)

Key Features of CNG Direct Injection

Combustion System Application

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 24

Principle of stratified CNG-DI Combustion Process

TDC

Swirl charge

motion of intake

air supports

stratification of

mixture cloud

[m

2

/s

2

]

0.0 100

Turbulent Kinetic Energy

20 CA bTDC 20 CA bTDC

CFD simulation shows toroidal

rotation of mixture cloud

Key Features of CNG Direct Injection

Combustion System Application

Central Injector Position,

spark plug close to injector tip

Piston Bowl design for Wall-

guided Mixture Formation

High turbulence due to gas-jet

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 25

CNG - DI Combustion CFD Simulation

CFD- Simulation for mixture formation in stratified and

homogeneous operation (2000rpm / 3bar IMEP)

5 DEG CRA bTDC

x

y

30 DEG CRA bTDC

z

z

y

z

x

y

x

y

x

z

x

z

y

30 DEG CRA bTDC

z

y

z

x

y

x

5 DEG CRA bTDC

y

x

z

x

z

y

Homogeneous early injection, A/F 1.0 Stratified late injection, A/F 2.6

Spark Plug

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 26

2000rpm / 3bar imep - isfc [g/kWh]

M

F

B

5

0

%

[d

e

g

C

A

a

T

D

C

]

S

O

I

[

d

e

g

C

A

b

T

D

C

]

isfc - OPT:

SOI.....63 deg CA bTDC

EGR...20 %

MAP...810 mbar

IGN....19 deg CA bTDC

Restrictions:

CoV <3 %

isNOx <3 g/kWh

i

s

f

c

[

g

/

k

W

h

]201 g/kWh

2000rpm / 3bar imep - CoV [%]

M

F

B

5

0

%

[d

e

g

C

A

a

T

D

C

]

S

O

I

[

d

e

g

C

A

b

T

D

C

]

C

o

V

[

%

]

3%

isfc - OPT

isfc - OPT:

SOI.....63 deg CA bTDC

EGR...20 %

MAP...810 mbar

IGN....19 deg CA bTDC

Restrictions:

CoV <3 %

isNOx <3 g/kWh

2000rpm / 3bar imep - isNOx [g/kWh]

M

F

B

5

0

%

[d

e

g

C

A

a

T

D

C

]

S

O

I

[

d

e

g

C

A

b

T

D

C

]

isfc - OPT:

SOI.....63 deg CA bTDC

EGR...20 %

MAP...810 mbar

IGN....19 deg CA bTDC

Restrictions:

CoV <3 %

isNOx <3 g/kWh

i

s

N

O

x

[

g

/

k

W

h

]

3

g

/

k

W

h

isfc - OPT

2000rpm / 3bar imep - isHC [g/kWh]

M

F

B

5

0

%

[d

e

g

C

A

a

T

D

C

]

S

O

I

[

d

e

g

C

A

b

T

D

C

]

isfc - OPT:

SOI.....63 deg CA bTDC

EGR...20 %

MAP...810 mbar

IGN....19 deg CA bTDC

Restrictions:

CoV <3 %

isNOx <3 g/kWh

i

s

H

C

[

g

/

k

W

h

]

14 g/kWh (at isfc - OPT)

Stratified CNG-DI: Very stable Operation

(Part Load Optimisation with DoE)

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 27

Combustion simulation with different operation strategies in part load

The 3D-CFD combustion

simulation shows the same

tendency regarding combustion

speed as the measurements.

Due to the turbulence introduced

by the DI-gas-jet the combustion

speed increases significantly with

late injection.

Heat release curves for different combustion strategies

(CFD Simulation)

-1,0

0,0

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

-40 -30 -20 -10 0 10 20 30 40 50 60

Crank Angle [deg CA]

R

a

t

e

o

f

H

e

a

t

r

e

l

e

a

s

e

[

%

/

d

e

g

C

A

]

Homogeneous early - CFD Simulation

Homogeneous late - CFD Simulation

Stratified lean - CFD Simulation

Heat release curves for different combustion strategies

(Measurement)

-1,0

0,0

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

-40 -30 -20 -10 0 10 20 30 40 50 60

Crank Angle [deg CA]

R

a

t

e

o

f

H

e

a

t

r

e

l

e

a

s

e

[

%

/

d

e

g

C

A

]

Homogeneous early - Measurement

Homogeneous late - Measurement

Stratified lean - Measurement

Homogeneous early

Homogeneous late

Stratified lean

Flamefront 20deg CA after Ignition

CNG - DI Combustion CFD Simulation

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 28

0%

20%

40%

60%

80%

100%

Combustion Efficiency CO2 Emission

Homogeneous

Gasoline DI

Homogeneous

CNG DI

Stratified lean with EGR

CNG DI

-40%

-25%

Part Load:

2000 rpm

3 bar IMEP

Improvement Potential for CNG Direct Injection

compared to stoichiometric homogeneous GDI

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 29

Part load: Part load:

The CNG The CNG - - DI combustion system shows 25% better efficiency DI combustion system shows 25% better efficiency

compared with homogeneous compared with homogeneous stoichiometric stoichiometric combustion combustion

Compared to homogeneous Compared to homogeneous stoichiometric stoichiometric combustion with combustion with

gasoline a CO2 reduction of more than 40% is possible due to gasoline a CO2 reduction of more than 40% is possible due to

beneficial H/C ratio of CNG beneficial H/C ratio of CNG

Full Load: Full Load:

Reduced volumetric efficiency as it is known from manifold gas Reduced volumetric efficiency as it is known from manifold gas

injection can be fully compensated by late direct injection (aft injection can be fully compensated by late direct injection (after er

intake closing), which results in +12% charge mass in cylinder intake closing), which results in +12% charge mass in cylinder

No necessity for spark retardation due to high knock resistance No necessity for spark retardation due to high knock resistance

of CNG, possibility to use a CR of 13, which gives 13% higher of CNG, possibility to use a CR of 13, which gives 13% higher

efficiency in low end WOT compared to gasoline operation efficiency in low end WOT compared to gasoline operation

Together with the beneficial H/C ratio of CNG also at full load Together with the beneficial H/C ratio of CNG also at full load a a

CO2 advantage of more than 30% is possible CO2 advantage of more than 30% is possible

Results Achieved for CNG Direct Injection

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 30

3. Conclusion

and Outlook

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 31

CNG is highly attractive fuel for vehicles and will become more CNG is highly attractive fuel for vehicles and will become more

important due to the demand of CO2 reduction and have less important due to the demand of CO2 reduction and have less

dependency on crude oil dependency on crude oil

Bi Bi- -fuel vehicles represent a short term solution to introduce fuel vehicles represent a short term solution to introduce

CNG into the market on bigger scale CNG into the market on bigger scale

CNG in combination with turbo charging reduces power gap CNG in combination with turbo charging reduces power gap

compared to gasoline operation by achieving better volumetric compared to gasoline operation by achieving better volumetric

efficiency, and turbo charging opens door for downsizing and efficiency, and turbo charging opens door for downsizing and

achieving higher fuel efficiency achieving higher fuel efficiency

New mono New mono- -fuel systems and technologies (e.g. Direct Injection) fuel systems and technologies (e.g. Direct Injection)

are under development to utilize even more advantages of CNG are under development to utilize even more advantages of CNG

operation for passenger cars in near future operation for passenger cars in near future

Conclusion and Outlook

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 32

Thank

Thank

you

you

very

very

much

much

for

for

your

your

kind

kind

attention

attention

!

!

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 33

Abbreviations (1/2)

A/F Air-/Fuel Ratio of Mixture (Lambda)

CA Crank Angle

BMEP Brake Mean Effective Pressure

CNG Compressed natural Gas

CR Compression Ratio

DI Direct Injection

DeNOx Nitrogen oxide reducing catalyst

DMI Direct Mixture Injection (Air +Fuel pre-mixed)

DoE Design of Experiments

EGR Exhaust Gas Recirculation

EURO5 European Emission Limit Stage 5

FE Fuel Economy

FTP Federal Test Procedure (USA)

GDI Gasoline Direct Injection

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 34

Gen.1 Generation 1 (first development stage of engine technology)

HSDI High Speed Direct Injection (Diesel)

IMEP Indicated Mean Effective Pressure

LDV Light Duty Vehicle

LPG Liquified Petrol Gas

NA Naturally Aspirated

NEDC New European Driving Cycle

PC Passenger Cars

PFI Port Fuel Injection

ROW Rest of the World

SI Spark Ignition

SULEV Super Ultra LowEmission Vehicle

TWC 3-Way Catalyst

ULEV Ultra LowEmission Vehicle

Abbreviations (2/2)

AVL ITC 24.4.2007, Advanced CNG Engine Technology Page 35

Das könnte Ihnen auch gefallen

- PSCB Recruitment 2021 for 856 Posts of Senior Managers, Managers, IT Officers, Clerks & StenosDokument16 SeitenPSCB Recruitment 2021 for 856 Posts of Senior Managers, Managers, IT Officers, Clerks & StenosGurjeetNoch keine Bewertungen

- Answer KeyDokument1 SeiteAnswer KeyVikas GargNoch keine Bewertungen

- AIIMS ElectrochemistryDokument2 SeitenAIIMS ElectrochemistryVikas GargNoch keine Bewertungen

- Cannon LPB3010Dokument0 SeitenCannon LPB3010lenceNoch keine Bewertungen

- Apps On NT Best PracticesDokument11 SeitenApps On NT Best PracticesVikas GargNoch keine Bewertungen

- Alpha Chemistry Classes: Alkaline Earth MetalsDokument14 SeitenAlpha Chemistry Classes: Alkaline Earth MetalsVikas GargNoch keine Bewertungen

- AIIMS - Structure of AtomDokument3 SeitenAIIMS - Structure of AtomVikas GargNoch keine Bewertungen

- Windows Firewall: If You Are Not Using A Network Environment (I.e. USB Connection Only)Dokument0 SeitenWindows Firewall: If You Are Not Using A Network Environment (I.e. USB Connection Only)Milan KrcmarNoch keine Bewertungen

- WWW - Ppsc.gov - in PDF Pscscce2013 PresylDokument3 SeitenWWW - Ppsc.gov - in PDF Pscscce2013 PresylVikas GargNoch keine Bewertungen

- Office of The Registering and Licensing Authority, U.T, Chandigarh Press NoteDokument1 SeiteOffice of The Registering and Licensing Authority, U.T, Chandigarh Press NoteVikas GargNoch keine Bewertungen

- Isothermal ExpansionDokument8 SeitenIsothermal Expansionsoumalya481Noch keine Bewertungen

- Benefits of DefragmentationDokument4 SeitenBenefits of DefragmentationVikas GargNoch keine Bewertungen

- Fast Color Scan To A PDF File - 3Dokument1 SeiteFast Color Scan To A PDF File - 3Vikas GargNoch keine Bewertungen

- The Punjab Cooperative Agricultural Development Banks Rules, 1959Dokument14 SeitenThe Punjab Cooperative Agricultural Development Banks Rules, 1959Vikas GargNoch keine Bewertungen

- Defrag TutorialDokument20 SeitenDefrag TutorialVikas GargNoch keine Bewertungen

- 104 GK FactsDokument5 Seiten104 GK FactsankitbhargavakietNoch keine Bewertungen

- Amc GuideDokument2 SeitenAmc GuideVikas GargNoch keine Bewertungen

- Invoice HP Deskjet 2645Dokument1 SeiteInvoice HP Deskjet 2645Vikas GargNoch keine Bewertungen

- Panjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CDokument1 SeitePanjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CVikas GargNoch keine Bewertungen

- General knowledge document covering important facts about IndiaDokument141 SeitenGeneral knowledge document covering important facts about IndiaMudassir ShahNoch keine Bewertungen

- Detailed Advst. & Information of 1192 Posts of ClerksDokument9 SeitenDetailed Advst. & Information of 1192 Posts of ClerksVikas GargNoch keine Bewertungen

- History of Modern IndiaDokument12 SeitenHistory of Modern IndiaTanmay JagetiaNoch keine Bewertungen

- Panjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CDokument1 SeitePanjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CVikas GargNoch keine Bewertungen

- Panjab University, Chandigarh PUTHAT-2013 Answers Key: B A D A C C C C D BDokument1 SeitePanjab University, Chandigarh PUTHAT-2013 Answers Key: B A D A C C C C D BVikas GargNoch keine Bewertungen

- CET (PG) - 2013: Panjab University, Chandigarh Answers / KeyDokument35 SeitenCET (PG) - 2013: Panjab University, Chandigarh Answers / KeyVikas GargNoch keine Bewertungen

- It Specialist Officers General Awarness Solved PaperDokument15 SeitenIt Specialist Officers General Awarness Solved PaperVikas GargNoch keine Bewertungen

- CompscDokument11 SeitenCompscVikas GargNoch keine Bewertungen

- It Officer Central Bank of IndiaDokument6 SeitenIt Officer Central Bank of IndiaMondar DebNoch keine Bewertungen

- It Specialist Officers General Awarness Solved PaperDokument15 SeitenIt Specialist Officers General Awarness Solved PaperVikas GargNoch keine Bewertungen

- IBPS Computer Awareness Sample Questions 4Dokument6 SeitenIBPS Computer Awareness Sample Questions 4Brundaban MohapatraNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Error CodesDokument72 SeitenError CodesAnthony Tiriba100% (3)

- Gathering Instrument For Trainee's CharacteristicsDokument35 SeitenGathering Instrument For Trainee's CharacteristicsDina Torreon CatantanNoch keine Bewertungen

- Sm-Perkins 4000 Series 4006-23 Tag1a, Tag2a and Tag3a Inline Diesel Engine PDFDokument34 SeitenSm-Perkins 4000 Series 4006-23 Tag1a, Tag2a and Tag3a Inline Diesel Engine PDFelnido dpp100% (1)

- O&M Manual For 4.12TCA & 6.12TCADokument101 SeitenO&M Manual For 4.12TCA & 6.12TCAniceashwin7933% (3)

- Parts Manual: CMP15/18/20s L FX15/18 L-2Dokument157 SeitenParts Manual: CMP15/18/20s L FX15/18 L-2Marcio50% (2)

- BMW Engine B37B47 PDFDokument184 SeitenBMW Engine B37B47 PDFdjiki21100% (2)

- Group 0.001A Engine Conversion Packages: Chevrolet 60° V6Dokument5 SeitenGroup 0.001A Engine Conversion Packages: Chevrolet 60° V6Jackson LaRoseNoch keine Bewertungen

- Fuel Combustion Processes in SI & Diesel EnginesDokument21 SeitenFuel Combustion Processes in SI & Diesel Engineshemant sainiNoch keine Bewertungen

- 1GR-FE Engine Tech OverviewDokument4 Seiten1GR-FE Engine Tech OverviewRenat VeedgamNoch keine Bewertungen

- Aft SpecDokument1 SeiteAft SpecJaime MelladoNoch keine Bewertungen

- Daf Brochure xf105 PowerDokument6 SeitenDaf Brochure xf105 PowerНедељко АнђелићNoch keine Bewertungen

- 950H - Sebp3866-24 - K5K - Vol 2Dokument735 Seiten950H - Sebp3866-24 - K5K - Vol 2Nilder Rojas100% (4)

- DA-40NG Airframe and PPDokument282 SeitenDA-40NG Airframe and PPYohannes SetegnNoch keine Bewertungen

- Celitron - IsS - Technical Book - QA12-0009 v1.1.Dokument91 SeitenCelitron - IsS - Technical Book - QA12-0009 v1.1.Yura50% (4)

- John Deere Service Manual JD S ctm3 PDFDokument25 SeitenJohn Deere Service Manual JD S ctm3 PDFDavid Ramirez0% (1)

- 2GR-FE FuelDokument45 Seiten2GR-FE FuelwidiNoch keine Bewertungen

- Diagrama Hidraulico 420E CATERPILLAR PDFDokument4 SeitenDiagrama Hidraulico 420E CATERPILLAR PDFWilmer0% (1)

- CH 05Dokument20 SeitenCH 05Sahab HafeezNoch keine Bewertungen

- How A Discharge Relief Valve Controls PressureDokument6 SeitenHow A Discharge Relief Valve Controls Pressureمحمد مجديNoch keine Bewertungen

- FSI Enginee SSP - 322Dokument24 SeitenFSI Enginee SSP - 322Milan Radakovic100% (1)

- 2G Torque SpecsDokument37 Seiten2G Torque SpecsLuke Litten50% (6)

- المصطلحات الفنية للسياراتDokument20 Seitenالمصطلحات الفنية للسياراتRiahi RezegNoch keine Bewertungen

- Bahasa Inggris Motor Injection ServiceDokument23 SeitenBahasa Inggris Motor Injection ServicewahyudiartaNoch keine Bewertungen

- Isuzu Trooper 2000 Service Manual MotorDokument544 SeitenIsuzu Trooper 2000 Service Manual MotorNotengoNombre TampocoApellido100% (5)

- SOFIM Engine Repair Manual PDFDokument126 SeitenSOFIM Engine Repair Manual PDFkeiner cassiani100% (1)

- Data-Tech 2012 Toyota Camry 2.4L 2AR-FE Cabeza de Motor LIBRODokument61 SeitenData-Tech 2012 Toyota Camry 2.4L 2AR-FE Cabeza de Motor LIBRORuben100% (1)

- Audi FSI Engine GuideDokument44 SeitenAudi FSI Engine Guidebogd3200075% (4)

- Advanced Ic Engines Unit 3Dokument82 SeitenAdvanced Ic Engines Unit 3Ravi RajanNoch keine Bewertungen

- K 737 Jul06 Engine Dxi 11 PDFDokument73 SeitenK 737 Jul06 Engine Dxi 11 PDFStirb Adrian50% (2)

- Pgmfi WorksDokument34 SeitenPgmfi WorksAndriyan Gtg100% (2)