Beruflich Dokumente

Kultur Dokumente

University of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)

Hochgeladen von

Arvind Bhosale0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

64 Ansichten3 SeitenThis document outlines the course objectives, outcomes, units, and requirements for the Metrology and Quality Control course offered at the University of Pune for mechanical engineering students. The key objectives are selection and use of measurement tools, calibration, quality control techniques, and quality management concepts. Over six units, students will learn measurement standards, gauges, interferometers, thread and gear metrology, quality tools, statistical process control, and total quality management. Assessment includes theory exams, term work experiments in measurement, statistical quality control, and an industry visit. The course aims to develop skills in precision measurement, data analysis, gauge design, and understanding quality systems.

Originalbeschreibung:

Pune University

Originaltitel

TE_MQC-Syllabus PU

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document outlines the course objectives, outcomes, units, and requirements for the Metrology and Quality Control course offered at the University of Pune for mechanical engineering students. The key objectives are selection and use of measurement tools, calibration, quality control techniques, and quality management concepts. Over six units, students will learn measurement standards, gauges, interferometers, thread and gear metrology, quality tools, statistical process control, and total quality management. Assessment includes theory exams, term work experiments in measurement, statistical quality control, and an industry visit. The course aims to develop skills in precision measurement, data analysis, gauge design, and understanding quality systems.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

64 Ansichten3 SeitenUniversity of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)

Hochgeladen von

Arvind BhosaleThis document outlines the course objectives, outcomes, units, and requirements for the Metrology and Quality Control course offered at the University of Pune for mechanical engineering students. The key objectives are selection and use of measurement tools, calibration, quality control techniques, and quality management concepts. Over six units, students will learn measurement standards, gauges, interferometers, thread and gear metrology, quality tools, statistical process control, and total quality management. Assessment includes theory exams, term work experiments in measurement, statistical quality control, and an industry visit. The course aims to develop skills in precision measurement, data analysis, gauge design, and understanding quality systems.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

University of Pune

T.E. (Mechanical) - 2012 Course

Metrology and Quality Control [302044]

PREREQUI SI TI ES

1. Fundamentals of Manufacturing processes

COURSE OBJ ECTI VES

1. Selection of tool and techniques for determining geometry and dimensions.

2. Design and calibration of measuring tools and equipments.

3. Application of Quality Control Techniques.

4. Application of Quality Management Concept.

COURSE OUTCOMES

1. An ability to apply knowledge of various tools and techniques used to determine geometry and

dimensions of components in engineering applications.

2. An ability to perform experiments, as well as to analyze and interpret data.

3. An ability to design gauges to meet desired needs within realistic constraints.

4. An understanding of Quality Control Techniques and its applications in engineering industries.

Unit I Measurement standards and comparators

Principles of Engineering metrology, Measurement standards, Types and sources of errors, Accuracy and

Precision, introduction to uncertainty in measurement, linear and angular measuring instruments and their

applications.

Calibration: Concept and procedure, traceability, Gauge R&R

Comparators: Mechanical, Pneumatic, Optical, Electrical (LVDT).Checking all geometrical forms.

(06 hrs)

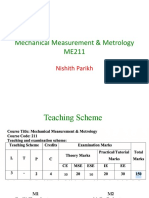

Code Subject

Teaching Scheme

(Weekly Load in hrs)

Examination Scheme (Marks)

Lect. Tut Pract. Theory TW PR OR Total

In-Sem.

(60 Min.)

End Sem.

(150 Min.)

302044

Metrology and

Quality Control

3 -- 2 30 70 -- -- 50 150

University of Pune

Unit I I Design of gauges, Interferometers and Surface Roughness measurements

Design of Gauges: Tolerances, Limits and Fits, Taylors principle, Types of gauges and gauge design

(numerical).

Interferometer: Principle, NPL Interferometer, Laser Interferometer and their applications.

Surface Roughness Measurement: Surface texture, Parameters for measuring surface roughness, Contact &

non-contact type surface roughness measuring instruments. (08 hrs)

Unit I I I Metrology of Thread, Gears and Advance Metrology

Measurement of Thread form: Thread form errors, Measurement of Minor, Major and Effective diameter

(Three Wire Method), Flank angle, pitch, Floating Carriage Micrometer (Numerical).

Gear Metrology: Types of errors, Gear tooth Vernier, Constant chord, Base tangent (Numerical), Gear

Rolling Tester.

Profile Projector, Tool makers microscope and their applications.

Advancements in Metrology: Introduction & applications of: Co-ordinate Measuring Machine, Universal

Measuring Machine, Laser in Metrology, Automatic inspection system, Machine vision for online-offline

inspection. (06 hrs)

Unit I V I ntroduction to Quality and Quality Tools

Quality: Dimensions, Statements, Cost of quality & value of quality, Demings cycles & 14 Points, Juran

Trilogy approach, Seven Quality Tools, Introduction to N Seven Tools, Quality Circle, Criteria for Quality

Award (National & International). (06 hrs)

Unit V Statistical quality control

Statistical quality control: Statistical concept, Frequency diagram, Concept of variance analysis, Control

Chart for Variable (X & R Chart) & Attribute (P & C Chart), Process capability(Indices: c

p

, c

pk

, p

pk

),

Statistical Process Control (Numerical). Production Part Approval Method (PPAP).

Acceptance Sampling: Sampling Inspection, OC Curve and its characteristics, sampling methods, Sampling

Plan: Single, Double (Numerical), Multiple, Comparison of Plan, calculation of sample size, AOQ,

Probability of Acceptance (Numerical). (08 hrs)

Unit VI Total Quality Management

Quality Function Deployment, 5S, Kaizen, Poka yoke, Kanban, JIT, QMS (ISO 9000, TS16949, ISO14000),

Quality Audit, FMECA, Zero defect, TPM. Six Sigma: DMAIC - Concept and Applications. (06 hrs)

Term-Work

LIST OF EXPERIMENTS

A] Any Four from experiment no. 1 to 5 & Any Four from experiment no. 6 to 10

1. Determination of linear and angular dimensions of given composite part using precision/non

precision measuring instruments.

2. Error determination with linear / angular measuring instruments.

University of Pune

3. Calibration of measuring instrument. Example Dial gauge, Micrometer, Vernier (any one)

(Refer ISO 17025).

4. Verification of dimensions & geometry of given components using Mechanical & Pneumatic

comparator.

5. Machine tool alignment testing on any two machines.

6. Identification of surfaces using optical flat/interferometers and measure surface roughness using

surface roughness tester.

7. Determination of geometry & dimensions of given composite object using profile projector and

measurement of various angles of single point cutting tool using tool makers microscope.

8. Measurement of thread parameters using floating carriage diameter measuring machine.

9. Measurement of spur gear parameters using Gear Tooth Vernier, Span, Gear Rolling Tester.

10. Determination of given geometry using coordinate measuring machine (CMM).

B] Statistical Quality Control (SQC) (Any Two)

Note - Use of computational tools are recommended

1. Analyze the fault in given batch of specimens by using Seven quality control tools for

engineering application.

2. Determination of process capability from given components and plot variable control chart/

attribute chart.

3. Case study on various tools in Total Quality Management (TQM).

C] Industrial visit to Calibration lab /Quality control lab / Gear manufacturing unit / Automotive Industry /

Engineering Industry.

Text Books:

1. Hume K.J., Engineering Metrology, Macdonald Publications

2. Jain R.K., Engineering Metrology, Khanna Publication.

3. Juran J. M., Quality Handbook, McGraw Hill Publications.

4. Grant S.P., Statistical Quality Control, Tata McGraw hill Publication.

5. Kulkarni V. A. and Bewoor A. K., Quality Control, John Wiley Publication.

Reference Books:

1. Narayana K.L., Engineering Metrology.

2. Galyer J.F & Shotbolt C.R., Metrology for engineers

3. Gupta I.C., Engineering Metrology, Dhanpatrai Publiartions

4. Judge A.W., Engineering Precision Measurements, Chapman and Hall

5. Francis T. Farago, Mark A. Curtis, Handbook of dimensional measurement.

6. ASTME, Handbook of Industrial Metrology, Prentice Hall of India Ltd.

7. Basterfield Quality control

8. Harrison M. Wordsworth, Stefeen Godfrey, Modern Methods for Quality control and

Improvement, Willy publication.

Das könnte Ihnen auch gefallen

- MQC SyllDokument2 SeitenMQC SyllAandy KhasdarNoch keine Bewertungen

- TE Mechanical and TE Automobile (2015 Course)Dokument7 SeitenTE Mechanical and TE Automobile (2015 Course)A SNoch keine Bewertungen

- Metrlogy CurriculumDokument3 SeitenMetrlogy CurriculumDj GAMINGNoch keine Bewertungen

- MEC601 Metrology and Quality Engineering 3+1: ObjectivesDokument1 SeiteMEC601 Metrology and Quality Engineering 3+1: ObjectivesHoney SinghNoch keine Bewertungen

- Metrology & Quality ControlDokument127 SeitenMetrology & Quality ControlArnav PandeyNoch keine Bewertungen

- Metrology and Mechanical MeasurementsDokument118 SeitenMetrology and Mechanical MeasurementsNihar ApteNoch keine Bewertungen

- 9097 - Metrology & Quality ControlDokument7 Seiten9097 - Metrology & Quality ControlAhmed Abu-SinnaNoch keine Bewertungen

- CH 1 - Metrology and MeasurementDokument51 SeitenCH 1 - Metrology and MeasurementRahul PathakNoch keine Bewertungen

- Syllabus Sem 8 - MMMDokument4 SeitenSyllabus Sem 8 - MMMAkash PatilNoch keine Bewertungen

- Gujarat Technological University - MeasurementDokument4 SeitenGujarat Technological University - MeasurementA SNoch keine Bewertungen

- Mechanical Measurement and MetrologyDokument2 SeitenMechanical Measurement and MetrologyNarayanarao PalagaraNoch keine Bewertungen

- Introduction To MetrologyDokument26 SeitenIntroduction To MetrologyDimon HeNoch keine Bewertungen

- 15hc04 Metrology and Computer Aided InspectionDokument1 Seite15hc04 Metrology and Computer Aided Inspectionarun2386Noch keine Bewertungen

- Engineering Metrology and Measurements Unit 1 2Dokument82 SeitenEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- Metrology and Computer Aided InspectionDokument2 SeitenMetrology and Computer Aided InspectionROOSSVELT PRABHU K A VNoch keine Bewertungen

- MEC601 Metrology and Quality Engineering 3+1: ObjectivesDokument1 SeiteMEC601 Metrology and Quality Engineering 3+1: Objectivesnavneetkpatil8409Noch keine Bewertungen

- MetrologyDokument3 SeitenMetrologySachi DhanandamNoch keine Bewertungen

- Metrology Course Oulines.10batchDokument4 SeitenMetrology Course Oulines.10batchTariq AslamNoch keine Bewertungen

- Toaz - Info Engineering Metrology PRDokument129 SeitenToaz - Info Engineering Metrology PRB05Vedant BarpandeNoch keine Bewertungen

- 1 MQC SyllabusDokument5 Seiten1 MQC SyllabusAnilChauvanNoch keine Bewertungen

- Engineering Metrology and MeasurementsDokument128 SeitenEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Cousrse Plan MetrologyDokument2 SeitenCousrse Plan MetrologySiva ShankarNoch keine Bewertungen

- 070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFDokument2 Seiten070 - ME8501 Metrology and Measurements - Anna University 2017 Regulation Syllabus PDFSidhu Vev Sidhu0% (1)

- Term-Work / List of Experiments: DIT Pimpri StudentsDokument1 SeiteTerm-Work / List of Experiments: DIT Pimpri StudentsA SNoch keine Bewertungen

- Mechanical Engineering VI Sem SyllabusDokument25 SeitenMechanical Engineering VI Sem Syllabussaurabh1116Noch keine Bewertungen

- M & I PDFDokument13 SeitenM & I PDFvirendraNoch keine Bewertungen

- MQCDokument8 SeitenMQCnavneetkpatil8409Noch keine Bewertungen

- PDFDokument210 SeitenPDFquyen2012Noch keine Bewertungen

- State Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeDokument15 SeitenState Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeIsrael Dharmaraj100% (1)

- Amm 657 1006Dokument7 SeitenAmm 657 1006விக்னேஷ் வரன்Noch keine Bewertungen

- MM SyllabusDokument2 SeitenMM SyllabusS.Bharani KumarNoch keine Bewertungen

- Engineering Metrology and Measurements NotesDokument131 SeitenEngineering Metrology and Measurements NotesBALAMUGUNDAN91% (32)

- MEPR205C - El 1 Metrology & Computer Aided InspectionDokument3 SeitenMEPR205C - El 1 Metrology & Computer Aided Inspectionዘረአዳም ዘመንቆረርNoch keine Bewertungen

- Module 1 - MMM - F - 2022Dokument37 SeitenModule 1 - MMM - F - 202202jahnavi YADAVNoch keine Bewertungen

- SyllubusDokument1 SeiteSyllubuskssudhagarNoch keine Bewertungen

- TOTEVA Pavlina and MIHAYLOVA Nadezhda: Methods For Selection of Measuring Instruments, Vasileva DimkaDokument6 SeitenTOTEVA Pavlina and MIHAYLOVA Nadezhda: Methods For Selection of Measuring Instruments, Vasileva DimkaGerman David Lozano GarzonNoch keine Bewertungen

- Mechanical Measurement & Metrology ME211: Nishith ParikhDokument18 SeitenMechanical Measurement & Metrology ME211: Nishith ParikhDrMohamed MansourNoch keine Bewertungen

- Gujarat Technological University: Mechanical (Advance Manufacturing System) (50) Subject CodeDokument2 SeitenGujarat Technological University: Mechanical (Advance Manufacturing System) (50) Subject CodeccritamNoch keine Bewertungen

- Engineering Metrology and Measurements NotesDokument127 SeitenEngineering Metrology and Measurements NotesNagendar SelvakumarNoch keine Bewertungen

- Mechanical Measurement and Metrology PDFDokument2 SeitenMechanical Measurement and Metrology PDFsuhas_SCEM0% (1)

- MI SyllabusDokument2 SeitenMI SyllabusVikas KumarNoch keine Bewertungen

- Detailed Content SEM 6Dokument16 SeitenDetailed Content SEM 6HIMANSHU KUMARNoch keine Bewertungen

- Applied Metrology for Manufacturing EngineeringVon EverandApplied Metrology for Manufacturing EngineeringBewertung: 5 von 5 Sternen5/5 (1)

- Proction Engineering TopicsDokument17 SeitenProction Engineering TopicsBuddha Prakash100% (1)

- 18ME7F2-Metrology and Quality ControlDokument2 Seiten18ME7F2-Metrology and Quality ControlXaf FarNoch keine Bewertungen

- Me6504 Metrology and Measurements L T P CDokument1 SeiteMe6504 Metrology and Measurements L T P CajitsssNoch keine Bewertungen

- IP5SEMSYLLABUSDokument6 SeitenIP5SEMSYLLABUSAditya RaoNoch keine Bewertungen

- MetrologyDokument1 SeiteMetrologyMeet BakotiaNoch keine Bewertungen

- ProdDokument9 SeitenProdapi-236544093Noch keine Bewertungen

- Applied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIDokument5 SeitenApplied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIPRASENJIT MUKHERJEENoch keine Bewertungen

- 5TH 6TH Final As Per Bos Adjuen Meetin On 21-08-21 210824 164803Dokument28 Seiten5TH 6TH Final As Per Bos Adjuen Meetin On 21-08-21 210824 164803DigvijayNoch keine Bewertungen

- Measurements & Metrology BasicsDokument208 SeitenMeasurements & Metrology BasicsPrabakaran Caleb0% (1)

- In-Process Dimensional Inspection Sensors: K. Vacharanukul, S. MekidDokument15 SeitenIn-Process Dimensional Inspection Sensors: K. Vacharanukul, S. MekidAbhishek UniyalNoch keine Bewertungen

- Magnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryVon EverandMagnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryNoch keine Bewertungen

- Introduction to N.C.M., a Non Contact Measurement ToolVon EverandIntroduction to N.C.M., a Non Contact Measurement ToolNoch keine Bewertungen

- Measurement and Instrumentation: Theory and ApplicationVon EverandMeasurement and Instrumentation: Theory and ApplicationBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsVon EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsBewertung: 4.5 von 5 Sternen4.5/5 (3)

- A Review of Low-Temperature Plasma-Assisted Machining: From Mechanism To ApplicationDokument19 SeitenA Review of Low-Temperature Plasma-Assisted Machining: From Mechanism To ApplicationArvind BhosaleNoch keine Bewertungen

- Experiment No 7-MQCDokument7 SeitenExperiment No 7-MQCArvind Bhosale100% (1)

- Multi-Phase-Field Approach To Fracture Demonstrating The Role of Solid-Solid Interface Energy On Crack PropagationDokument13 SeitenMulti-Phase-Field Approach To Fracture Demonstrating The Role of Solid-Solid Interface Energy On Crack PropagationArvind BhosaleNoch keine Bewertungen

- M.E (2019 PATTERN) - Part1Dokument5 SeitenM.E (2019 PATTERN) - Part1Arvind BhosaleNoch keine Bewertungen

- 02 KljuceviDokument26 Seiten02 KljuceviEkwere Wilfred UdohNoch keine Bewertungen

- Experiment 4Dokument3 SeitenExperiment 4Arvind BhosaleNoch keine Bewertungen

- Development of TQM in Steel Manufacturers' Production: KeywordsDokument8 SeitenDevelopment of TQM in Steel Manufacturers' Production: Keywordsdede_xNoch keine Bewertungen

- Calibration of Measuring Instrument: Experiment No: 3 DateDokument4 SeitenCalibration of Measuring Instrument: Experiment No: 3 DateArvind BhosaleNoch keine Bewertungen

- Experiment 4Dokument3 SeitenExperiment 4Arvind BhosaleNoch keine Bewertungen

- Calibration of Measuring Instrument: Experiment No: 3 DateDokument4 SeitenCalibration of Measuring Instrument: Experiment No: 3 DateArvind BhosaleNoch keine Bewertungen

- Engineering Metrology and MeasurementsDokument128 SeitenEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- BME Unit IV Machine ToolsDokument41 SeitenBME Unit IV Machine ToolsArvind BhosaleNoch keine Bewertungen

- Principios de MetrologiaDokument4 SeitenPrincipios de MetrologiaJonatan BuitragoNoch keine Bewertungen

- BME Unit V ThermodynamicsDokument22 SeitenBME Unit V ThermodynamicsArvind Bhosale100% (3)

- Bolted PlatesDokument13 SeitenBolted PlatesDan WolfNoch keine Bewertungen

- ExtrusionDokument26 SeitenExtrusionArvind BhosaleNoch keine Bewertungen

- Signals and SystemsDokument59 SeitenSignals and SystemsArvind BhosaleNoch keine Bewertungen

- Daftar Ebook Tentang LeanDokument2 SeitenDaftar Ebook Tentang LeanChilmar Buchari100% (1)

- Jurnal Ari Maulana Ullum Sasmi 1801038Dokument12 SeitenJurnal Ari Maulana Ullum Sasmi 180103803. Ari Maulana Ullum Sasmi / TD 2.10Noch keine Bewertungen

- Apple Witness ListDokument30 SeitenApple Witness ListMikey CampbellNoch keine Bewertungen

- Digital Thermometer Using Arduino: Mini Project Report ONDokument5 SeitenDigital Thermometer Using Arduino: Mini Project Report ONNeha PintoNoch keine Bewertungen

- Erich Segal Doctors PDFDokument2 SeitenErich Segal Doctors PDFAlicia13% (8)

- SOM-based Generating of Association RulesDokument5 SeitenSOM-based Generating of Association RulesKishor PeddiNoch keine Bewertungen

- Technical Data Sheet: BS-510 All Pressure Solvent CementDokument1 SeiteTechnical Data Sheet: BS-510 All Pressure Solvent CementBuwanah SelvaarajNoch keine Bewertungen

- Bc63kb8a Dy152 - 153 Vendor Drawing n001 Air Compressors SperreDokument60 SeitenBc63kb8a Dy152 - 153 Vendor Drawing n001 Air Compressors SperreSimonaMauna33% (3)

- Star WarsDokument28 SeitenStar Warsalex1971Noch keine Bewertungen

- Pre Delivery Inspection Checklist For Home Oxygen ConcentratorDokument2 SeitenPre Delivery Inspection Checklist For Home Oxygen ConcentratorPranavKaisthaNoch keine Bewertungen

- Legislation Statutory Inspection ChecklistDokument2 SeitenLegislation Statutory Inspection ChecklistAry PutraNoch keine Bewertungen

- CES Wrong Answer SummaryDokument2 SeitenCES Wrong Answer SummaryВладислав КомаровNoch keine Bewertungen

- DAC AnalysisDokument19 SeitenDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుNoch keine Bewertungen

- Shallow FoundationsDokument44 SeitenShallow FoundationsAjay SinghNoch keine Bewertungen

- Oct2020 GCE Final PDFDokument30 SeitenOct2020 GCE Final PDFGavinNoch keine Bewertungen

- Bistable Relays RXMVB 2, RXMVB 4: FeaturesDokument4 SeitenBistable Relays RXMVB 2, RXMVB 4: FeaturesGabriel Maxo PapagalloNoch keine Bewertungen

- Purposive Communication NotesDokument33 SeitenPurposive Communication NotesAlexis DapitoNoch keine Bewertungen

- Fame and FortuneDokument8 SeitenFame and FortuneNguyễn Đình Tuấn ĐạtNoch keine Bewertungen

- Nassaji - Schema TheoryDokument37 SeitenNassaji - Schema TheoryAtiq AslamNoch keine Bewertungen

- Missouri Department of Transportation: Standard Inspection and Testing Plan (ITP)Dokument32 SeitenMissouri Department of Transportation: Standard Inspection and Testing Plan (ITP)mohamedamine.zemouriNoch keine Bewertungen

- Audio Level Meter - ProjectDokument4 SeitenAudio Level Meter - ProjectMircea PanzariuNoch keine Bewertungen

- Daftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceDokument2 SeitenDaftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceMochammad Fauzian RafsyanzaniNoch keine Bewertungen

- Laundry Center Dryer Tech Data Sheet: NO - Normally Open NTC - NTC Thermistor MCF - Machine Configuration FileDokument40 SeitenLaundry Center Dryer Tech Data Sheet: NO - Normally Open NTC - NTC Thermistor MCF - Machine Configuration FilePedro IsmaelNoch keine Bewertungen

- Nature'S Numbers: - BasicbooksDokument39 SeitenNature'S Numbers: - Basicbooksyeol pacisNoch keine Bewertungen

- Activity Diagram Airline Reservation System PDFDokument4 SeitenActivity Diagram Airline Reservation System PDFAnonymous zSn6IALuabNoch keine Bewertungen

- METR3210 Clausius ClapeyronDokument28 SeitenMETR3210 Clausius Clapeyronshubhang2392Noch keine Bewertungen

- So You Want To Have Your Own Cosmetics BrandDokument3 SeitenSo You Want To Have Your Own Cosmetics BrandCarlosNoch keine Bewertungen

- ISMR B-School BrochureDokument28 SeitenISMR B-School Brochurerahul kantNoch keine Bewertungen

- ReflectionDokument1 SeiteReflectionHeaven GuzmanNoch keine Bewertungen

- Aesa Vs PesaDokument30 SeitenAesa Vs Pesakab11512100% (1)