Beruflich Dokumente

Kultur Dokumente

Inspection Pirate P V Insp Report Check List 2008 11 15

Hochgeladen von

api-26988647Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inspection Pirate P V Insp Report Check List 2008 11 15

Hochgeladen von

api-26988647Copyright:

Verfügbare Formate

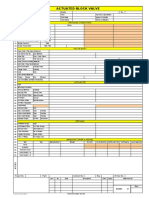

Date:

Unfired Pressure Vessel Inspection

Report Page: 1

Vessel Information

Unit: Location: P&ID No.: Wo/Not.No:

Equipment No.: Equipment Name: :

Type:r Tower r Drum r Tubular Shell r Filter r Fin – Fan Reactor Other ______________

Orientation:rHorizontal rVertical rOn stm r Off stm NDE: r UT r PT r MT r RT r ET r VT r AE

Insulation:rYes rNo rPartially Thk:____ Type:_____ r API r ASME (R) r Plant Spec’s r NBIC

External Visual Inspection Results

Item Condition Comments

No. Item Good Fair Poor N/A (by item no.)

1 Shell

2 Heads, Chann. or Bonnets

3 Nozzles & Bolts, Flanges

4 Manways & Flange Bolts

5 Welds & Seams

6 Platforms & Handrails

7 Ladders & Cages

8 Stairway & Treads

9 Weatherproofing

10 Insulation

11 Coatings % of failure

12 Fireproofing

13 Supports & Foundation

14 Support Base Plate & Bolts

15 Davits

16 Sightglass & Level Gauges

17 Associated Piping

18 Jacket Mat. ___________

19 CUI Evaluation

20 UT Review

21 Expansion joint

22 Safety Valve Discharge RV #- Size Disch to

Lines

Yes No

23 Safety Valve Removed Date of Last Test Setting PSIG

24 RV Anti tamper seal Intact

25 Corrosion (L x W x S x D)

26 Ground Wire Attached

27 Name Plate Attached

28 Visible Leaks

29 Screwed Fittings

30 Visible Distortion

31 Weep Holes Okay

32 FE Leak Tags

33 Shell & Head magnetic?

34 Blistering

35 Photographs

36 Diamond Placard attached

37 OK for Continued Service

38 Nameplate data Nat Bd # Const. Date: Stamped r Yes r No

mawp@temp: S/N: Other:

39 Field operating parameters Temperature *F: Pressure psig Gauge Level: %

Inspector Information

Signature: Printed Name Attachments r Yes r No

Date:

Unfired Pressure Vessel Inspection

Report Page: 2

Internal Visual Inspection Results

Item Condition Comments

No. Item Good Fair Poor N/A (by item no.)

40 Shell

41 Heads, Transitions

42 Trays

43 Tray Supports

44 Caps & Risers

45 Downcomers

46 Weirs & Seal Pans

47 Bolting, Bars, & Clips

48 Piping, Baffles, & Sprays

49 Manway & Flange Seats

50 Demister Pad

51 Tube Ends

52 Tube Sheet

53 Tube I.D.

54 Tube O.D.

55 Bonnet(s) & Channel(s)

56 Vortex Breaker

57 Gasket Surfaces

58 Nozzles (cond. and clear)

58 Liquid level &/or Boot

areas

60 Cleaness (How Cleaned?)

61 Associated Piping IDs

62 Supports

63 Distortion

64

65 Ok for continued Service? Yes No

65 Lining Type: % Lined:

66 Liner Damage % Damaged: Exposed Metal:

67 Hydro. Test Test Pressure PSIG Result

68 Corrosion Noted Location Depth Size

69 Errosion Depth: Size:

70 NDT Used Type: Outcome:

Defect Sketching Area

Service Information

Total Service (yrs): Interval: Ext: Int Next Inspection: Years

Signature: Date of Next Inspection:

Das könnte Ihnen auch gefallen

- Itr-Pgr (GRP Piping)Dokument10 SeitenItr-Pgr (GRP Piping)mahmoudNoch keine Bewertungen

- ITR-CNI (Instrument)Dokument21 SeitenITR-CNI (Instrument)mahmoudNoch keine Bewertungen

- Reactor - For SwitchayrdDokument10 SeitenReactor - For SwitchayrdSindhuKumarNoch keine Bewertungen

- DSS2060D Actuated Block Valve DatasheetDokument1 SeiteDSS2060D Actuated Block Valve Datasheetkrishna kumarNoch keine Bewertungen

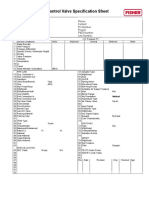

- Motorised Valve: Instrument Datasheet Tag NoDokument1 SeiteMotorised Valve: Instrument Datasheet Tag Nokrishna kumarNoch keine Bewertungen

- Ut FormDokument1 SeiteUt FormTrung Tinh Ho100% (1)

- Magnetic Particle Testing ReporDokument2 SeitenMagnetic Particle Testing ReporGabriela MotaNoch keine Bewertungen

- MT Form Asme PDFDokument1 SeiteMT Form Asme PDFTrung Tinh HoNoch keine Bewertungen

- Magnetic Particle Examination: DateDokument2 SeitenMagnetic Particle Examination: DateAbhishek SharmaNoch keine Bewertungen

- Itr-Pag (Ag Piping)Dokument24 SeitenItr-Pag (Ag Piping)mahmoudNoch keine Bewertungen

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDokument24 SeitenCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNoch keine Bewertungen

- KURDISTAN PETROCHEMICAL COMPANY Inspection PlanDokument1 SeiteKURDISTAN PETROCHEMICAL COMPANY Inspection Planbehrooz rajabshehniNoch keine Bewertungen

- Combustible Gas Detector Datasheet PDFDokument4 SeitenCombustible Gas Detector Datasheet PDFUğur ZoroğluNoch keine Bewertungen

- Inspection Report Ultrasonic ExaminationDokument2 SeitenInspection Report Ultrasonic ExaminationJindarat KasemsooksakulNoch keine Bewertungen

- Draft Final Inspection Report (New 2582011)Dokument2 SeitenDraft Final Inspection Report (New 2582011)abhiNoch keine Bewertungen

- Itr-Pug (Ug Piping)Dokument12 SeitenItr-Pug (Ug Piping)mahmoudNoch keine Bewertungen

- Paver Blocks FixingDokument1 SeitePaver Blocks FixingBharathraj RajNoch keine Bewertungen

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDokument1 SeitePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNoch keine Bewertungen

- Form Motor Solo Run Interlock FuncDokument1 SeiteForm Motor Solo Run Interlock FuncImam HanafiNoch keine Bewertungen

- Ultrasonic Examination ReportDokument2 SeitenUltrasonic Examination ReportAbhishek SharmaNoch keine Bewertungen

- Liquid Penetrant Examination Report: Asme Sec-Viii 10 Minute Spray 32 CDokument4 SeitenLiquid Penetrant Examination Report: Asme Sec-Viii 10 Minute Spray 32 CEngr Saeed AnwarNoch keine Bewertungen

- Client: Job No.: Job Title: Client's Job No.:: Company NameDokument13 SeitenClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNoch keine Bewertungen

- 35.60.02F - Ballast Tank Inspection ReportDokument3 Seiten35.60.02F - Ballast Tank Inspection ReportaleventNoch keine Bewertungen

- Report - Form - MT - PT - RT - Ut - Cal - 2015Dokument9 SeitenReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlNoch keine Bewertungen

- PT - ReportDokument3 SeitenPT - ReportNaveen KumarNoch keine Bewertungen

- Surge Arrestor Commissioning ChecklistDokument7 SeitenSurge Arrestor Commissioning ChecklistSyed Abbas100% (1)

- 1710F01 - Side Stream Filter - PDSDokument4 Seiten1710F01 - Side Stream Filter - PDSAkram VhoraNoch keine Bewertungen

- Transformer Test Report: Transformers Technical Data Field Service RepresentiveDokument14 SeitenTransformer Test Report: Transformers Technical Data Field Service RepresentiveAldhi PriambudiNoch keine Bewertungen

- Lay0ut 1nspection ReportDokument1 SeiteLay0ut 1nspection ReportDaniel PradityaNoch keine Bewertungen

- QAR-QD405-800 Rod As-Hoist CylinderDokument6 SeitenQAR-QD405-800 Rod As-Hoist CylinderIrwanto ManafNoch keine Bewertungen

- Pressure Transmitter Spec Form 403 - KWDokument1 SeitePressure Transmitter Spec Form 403 - KWsurendharNoch keine Bewertungen

- 0ZVPULS051 Sump Pit LS S-W Data SheetDokument1 Seite0ZVPULS051 Sump Pit LS S-W Data Sheetjean-marie BOGUYNoch keine Bewertungen

- FORM-AT-MANU-017-E Hydrostatic Test RaportDokument3 SeitenFORM-AT-MANU-017-E Hydrostatic Test RaportBOUZAIDANoch keine Bewertungen

- 4.pour Card For RCC WorkDokument1 Seite4.pour Card For RCC WorkMuthu Kumar palaniNoch keine Bewertungen

- Adapters and Drilling SpoolsDokument2 SeitenAdapters and Drilling SpoolsKaleem UllahNoch keine Bewertungen

- Tofd & Pe ReportDokument1 SeiteTofd & Pe ReportLuong Ho VuNoch keine Bewertungen

- Form Report PTDokument2 SeitenForm Report PTUtiliti DrawingNoch keine Bewertungen

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorDokument2 SeitenIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorKaleem Ullah0% (1)

- Ultrasonic Testing Report Format Based On IACSDokument1 SeiteUltrasonic Testing Report Format Based On IACSDeepak100% (6)

- Example For Brindle RolllDokument1 SeiteExample For Brindle RolllIrwanto ManafNoch keine Bewertungen

- Visual Inspection PV FormDokument2 SeitenVisual Inspection PV FormGibson FisherNoch keine Bewertungen

- QAR-QD405-1179 Liquid Penetrant Testing Report-Oil Pan EH4500Dokument2 SeitenQAR-QD405-1179 Liquid Penetrant Testing Report-Oil Pan EH4500Irwanto ManafNoch keine Bewertungen

- Field Inspection ReportDokument14 SeitenField Inspection ReportRanjit SinghNoch keine Bewertungen

- HV Power Cable TestDokument9 SeitenHV Power Cable TestMohammad Nasar100% (1)

- FORM 99c PDFDokument2 SeitenFORM 99c PDFराजकुमार यादवNoch keine Bewertungen

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDokument1 SeiteInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNoch keine Bewertungen

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NDokument25 SeitenPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraNoch keine Bewertungen

- Inspection Check ListDokument6 SeitenInspection Check ListNagesh RaoNoch keine Bewertungen

- Pumps Final TeDokument48 SeitenPumps Final Tegharsallah mounaNoch keine Bewertungen

- Checklist ForkliftDokument1 SeiteChecklist Forkliftlaurdesfatima999Noch keine Bewertungen

- Liquid Penetrant Testing Report SummaryDokument1 SeiteLiquid Penetrant Testing Report SummaryAbdul NaveedNoch keine Bewertungen

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNoch keine Bewertungen

- QC-577-23 Dimensional and Surface Roughness Form (Flange) Rev 1Dokument4 SeitenQC-577-23 Dimensional and Surface Roughness Form (Flange) Rev 1Irma Handayani0% (1)

- Control Valve Specification SheetDokument1 SeiteControl Valve Specification SheetGlorie Mae BurerosNoch keine Bewertungen

- Release For Concrete Placement ChecklistDokument2 SeitenRelease For Concrete Placement ChecklistMochamad RomiNoch keine Bewertungen

- Magnetic-Particle Test Report: Equipment & ParticlesDokument1 SeiteMagnetic-Particle Test Report: Equipment & Particlesibrahim hegazyNoch keine Bewertungen

- Power Transformer TestDokument27 SeitenPower Transformer Testm khNoch keine Bewertungen

- Tank Certificate SampleDokument1 SeiteTank Certificate SampleYajaira Hernández GómezNoch keine Bewertungen

- Saudi Pipe System Co. Mold Final Inspection ReportDokument8 SeitenSaudi Pipe System Co. Mold Final Inspection ReportNADEEM AHMEDNoch keine Bewertungen

- Pressuremeter Testing: Methods and InterpretationVon EverandPressuremeter Testing: Methods and InterpretationBewertung: 5 von 5 Sternen5/5 (2)

- 11 Iso 10110Dokument28 Seiten11 Iso 10110fmeylanNoch keine Bewertungen

- Topic 3Dokument25 SeitenTopic 35p6zzgj4w9Noch keine Bewertungen

- Face Recognization and Detection System For Attendance.Dokument39 SeitenFace Recognization and Detection System For Attendance.Deepanshu Sharma33% (3)

- BCN 3224 - Exam 3 ReviewDokument34 SeitenBCN 3224 - Exam 3 Reviewmgwin17Noch keine Bewertungen

- High-Efficiency Controllers for Notebook ComputersDokument28 SeitenHigh-Efficiency Controllers for Notebook ComputerscNoch keine Bewertungen

- Monthly Internship Report 2 (Biniyam Assefa and Tensae Degu)Dokument9 SeitenMonthly Internship Report 2 (Biniyam Assefa and Tensae Degu)biniyam assefaNoch keine Bewertungen

- Kurd Live - PastebinDokument2 SeitenKurd Live - PastebinMmmmohNoch keine Bewertungen

- Apelco Fishfinder 365Dokument83 SeitenApelco Fishfinder 365Ivan Campione100% (1)

- Ship Rudder Types and Design FeaturesDokument10 SeitenShip Rudder Types and Design FeaturesAurvin SinghNoch keine Bewertungen

- LaptopDokument20 SeitenLaptopNeeraj SinghNoch keine Bewertungen

- 2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Dokument13 Seiten2012 JBLM MILCON Tacoma Chamber of Commerce Oct2012Brackett427Noch keine Bewertungen

- Nagios Enable NRPEDokument2 SeitenNagios Enable NRPEMartin RuswandaNoch keine Bewertungen

- IGCSE Topical Past Papers PhysicsDokument64 SeitenIGCSE Topical Past Papers PhysicsHubert DMelloNoch keine Bewertungen

- Geotech Final ReportDokument38 SeitenGeotech Final Reportapi-320590292Noch keine Bewertungen

- IBM-Tandy Guide for Secret Weapons of the LuftwaffeDokument41 SeitenIBM-Tandy Guide for Secret Weapons of the Luftwaffetestinghb100% (1)

- Problem Statement: Designing of Pump System For Multi Story Residential BuildingDokument23 SeitenProblem Statement: Designing of Pump System For Multi Story Residential Buildingmehtab ul hassanNoch keine Bewertungen

- SemaphoreDokument29 SeitenSemaphoreSaranya ThangarajNoch keine Bewertungen

- The Existence of An External Redundancy ASM DiskgroupDokument55 SeitenThe Existence of An External Redundancy ASM Diskgroupsidd_aish@yahoo.comNoch keine Bewertungen

- Chrome Group PolicyDokument37 SeitenChrome Group PolicyvksatyanNoch keine Bewertungen

- ASTM D5199 Nominal ThicknessDokument4 SeitenASTM D5199 Nominal ThicknessCharleneTaneoNoch keine Bewertungen

- Fluid Mechanics Subjective QuestionsDokument3 SeitenFluid Mechanics Subjective QuestionsCrewdex ProNoch keine Bewertungen

- Ion Thruster GuideDokument16 SeitenIon Thruster GuideMimsisiNoch keine Bewertungen

- Accenture Robotic Process Auto POV FinalDokument12 SeitenAccenture Robotic Process Auto POV FinalJake RuksNoch keine Bewertungen

- SSP421 Body BasicsDokument76 SeitenSSP421 Body Basicsmamuko100% (3)

- An Introduction To Orgone Matrix Material (Jon Logan)Dokument42 SeitenAn Introduction To Orgone Matrix Material (Jon Logan)Jose CiprianiNoch keine Bewertungen

- GaAs solar cell modeling improves efficiencyDokument4 SeitenGaAs solar cell modeling improves efficiencyTarak BenslimaneNoch keine Bewertungen

- Lars Part Ix - Safety Managment System Requirements-SmsDokument24 SeitenLars Part Ix - Safety Managment System Requirements-SmssebastienNoch keine Bewertungen

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDokument24 SeitenMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNoch keine Bewertungen

- John Deere 9650 Sts Parts CatalogDokument20 SeitenJohn Deere 9650 Sts Parts CatalogDennis100% (56)