Beruflich Dokumente

Kultur Dokumente

Chapter 08 - Powder Metallurgy

Hochgeladen von

Mukaram AliCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter 08 - Powder Metallurgy

Hochgeladen von

Mukaram AliCopyright:

Verfügbare Formate

Powder Metallurgy

Chapter 16

Manufacturing Processes

Ref: M. P. Groover)

1

POWDER METALLURGY

1. The Characterization of Engineering Powders

2. Production of Metallic Powders

3. Conventional Pressing and Sintering

4. Alternative Pressing and Sintering Techniques

5. Materials and Products for PM

6. Design Considerations in Powder Metallurgy

2

Powder Metallurgy (PM)

Metal processing technology in which parts are

produced from metallic powders

Modern powder metallurgy dates only back to the early

1800

PM parts can be mass produced to net shape or near net

shape, eliminating or reducing the need for subsequent

machining

Certain metals that are difficult to fabricate by other

methods can be shaped by PM

Tungsten filaments for lamp bulbs are made by PM

PM process wastes very little material - ~ 97% of starting

powders are converted to product

PM parts can be made with a specified level of porosity, to

produce porous metal parts

Examples: filters, oil-impregnated bearings and gears

3

Limitations and Disadvantages

High tooling and equipment costs

Metallic powders are expensive

Problems in storing and handling metal powders

Degradation over time, fire hazards with certain

metals

Limitations on part geometry because metal powders

do not readily flow laterally in the die during pressing

Variations in density throughout part may be a

problem, especially for complex geometries

4

Usual PM production sequence

Blending and mixing (Rotating drums, blade

and screw mixers)

Pressing - powders are compressed into

desired shape to produce green compact

Accomplished in press using punch-and-die

tooling designed for the part

Sintering green compacts are heated to

bond the particles into a hard, rigid mass

Performed at temperatures below the

melting point of the metal

5

PM Work Materials

Largest tonnage of metals are alloys of iron, steel, and

aluminum

Other PM metals include copper, nickel, and

refractory metals such as molybdenum and tungsten

Metallic carbides such as tungsten carbide are often

included within the scope of powder metallurgy

6

A collection of powder metallurgy parts.

PM Parts

7

Engineering Powders

A powder can be defined as a finely divided particulate solid

Engineering powders include metals and ceramics

8

Particle shapes

Measuring Particle Size

Most common method uses screens of different mesh sizes

Mesh count - refers to the number of openings per linear inch of

screen

A mesh count of 200 means there are 200 openings per linear inch

Higher mesh count = smaller particle size

Figure 16.2 Screen mesh for

sorting particle sizes.

9

Interparticle Friction and Powder Flow

Friction between particles

affects ability of a powder to

flow readily and pack tightly

A common test of interparticle

friction is the angle of repose,

which is the angle formed by a

pile of powders as they are

poured from a narrow funnel.

Figure 16.4 Interparticle friction as indicated by the angle of repose of a pile of

powders poured from a narrow funnel. Larger angles indicate greater

interparticle friction.

10

Observations

Easier flow of particles correlates with lower interparticle

friction

Lubricants are often added to powders to reduce interparticle

friction and facilitate flow during pressing

11

Lets check!

Smaller particle sizes show steeper angles or

larger particle sizes?!

Smaller particle sizes generally show

greater friction and steeper angles!

Finer

particles

12

Lets check!

Which shape has the lowest interpartical

friction?

Spherical shapes have the lowest

interpartical friction!

Little friction between

spherical particles!

As shape deviates

from spherical,

friction between

particles tends to

increase

13

Particle Density Measures

True density - density of the true volume of the

material

The density of the material if the powders

were melted into a solid mass

Bulk density - density of the powders in the

loose state after pouring

Which one is smaller?!

Because of pores between particles, bulk density is less

than true density

14

Packing Factor

Typical values for loose

powders range between 0.5

and 0.7

Bulk density

true density

Packing factor =

If powders of various sizes are present, smaller

powders will fit into spaces between larger ones,

thus higher packing factor

Packing can be increased by vibrating the

powders, causing them to settle more tightly

Pressure applied during compaction greatly

increases packing of powders through

rearrangement and deformation of particles

How can we increase the bulk density?

15

Porosity

Ratio of volume of the pores (empty spaces) in the powder to

the bulk volume

In principle

Porosity + Packing factor = 1.0

16

A highly porous ceramic material

(http://www.glass-ceramics.uni-

erlangen.de/)

PM Materials

Metallic powders are classified as either

Elemental - consisting of a pure metal

Pre-alloyed - each particle is an alloy

17

Figure 16.6 Iron powders produced by decomposition of iron pentacarbonyl (photo courtesy of GAF Chemical Corp); particle

sizes range from about 0.25 - 3.0 microns (10 to 125 -in).

PM Materials Elemental Powders

A pure metal in particulate form

Applications where high purity is important

Common elemental powders:

Iron

Aluminum

Copper

Elemental powders can be mixed with other metal

powders to produce alloys that are difficult to formulate

by conventional methods

Example: tool steels

18

PM Materials Pre-Alloyed Powders

Each particle is an alloy comprised of

the desired chemical composition

Common pre-alloyed powders:

Stainless steels

Certain copper alloys

High speed steel

19

PM Products

Gears, bearings, sprockets, fasteners, electrical contacts,

cutting tools, and various machinery parts

Advantage of PM: parts can be made to near net shape

or net shape

When produced in large quantities, gears and bearings

are ideal for PM because:

The geometry is defined in two dimensions (cross

section is uniform)

There is a need for porosity in the part to serve as a

reservoir for lubricant

20

Production of Metallic Powders

In general, producers of metallic powders are not the

same companies as those that make PM parts

Any metal can be made into powder form

Three principal methods by which metallic powders are

commercially produced

1. Atomization (by gas, water, also centrifugal one)

2. Chemical

3. Electrolytic

21

High velocity gas stream flows through expansion nozzle,

siphoning molten metal from below and spraying it into

container

Figure 16.5 (a) gas

atomization method

Check other figures

as well (page 344)

Gas Atomization Method

22

Conventional Press and Sinter

After metallic powders have been produced, the

conventional PM sequence consists of:

1. Blending and mixing of powders

2. Compaction - pressing into desired shape

3. Sintering - heating to temperature below melting point

to cause solid-state bonding of particles and

strengthening of part

In addition, secondary operations are sometimes performed to improve

dimensional accuracy, increase density, and for other reasons

23

Blending and Mixing of Powders

For successful results in compaction and sintering,

the starting powders must be homogenized

(powders should be blended and mixed)

Blending - powders of same chemistry but possibly

different particle sizes are intermingled

Different particle sizes are often blended to reduce

porosity

Mixing - powders of different chemistries are combined

24

Compaction

Application of high pressure to the powders to form them into

the required shape

Conventional compaction method is pressing, in which

opposing punches squeeze the powders contained in a die

The workpart after pressing is called a green compact, the

word green meaning not yet fully processed

The green strength of the part when pressed is adequate

for handling but far less than after sintering

25

Conventional Pressing in PM

Figure 16.9 Pressing in PM:

(1) filling die cavity with

powder by automatic feeder;

(2) initial and (3) final

positions of upper and lower

punches during pressing, (4)

part ejection.

Watch the single- and double-punch operations

Fill

Press Eject

26

Sintering

Heat treatment to bond the metallic particles, thereby

increasing strength and hardness

Usually carried out at between 70% and 90% of the

metal's melting point (absolute scale)

27

particle bonding is initiated at contact points

Densification and Sizing

Secondary operations are performed to increase density, improve

accuracy, or accomplish additional shaping of the sintered part

Repressing - pressing sintered part in a closed die to

increase density and improve properties

Sizing - pressing a sintered part to improve dimensional

accuracy

Coining - pressworking operation on a sintered part to

press details into its surface

Machining - creates geometric features that cannot be

achieved by pressing, such as threads, side holes, and

other details

28

Impregnation and Infiltration

Porosity is a unique and inherent characteristic of PM

technology

It can be exploited to create special products by filling the

available pore space with oils, polymers, or metals

Two categories:

1. Impregnation

2. Infiltration

29

Impregnation

The term used when oil or other fluid is permeated into

the pores of a sintered PM part

Common products are oil-impregnated bearings, gears,

and similar components

Alternative application is when parts are impregnated with

polymer resins that seep into the pore spaces in liquid form

and then solidify to create a pressure tight part

30

Infiltration

Operation in which the pores of the PM part are filled

with a molten metal

The melting point of the filler metal must be below that of the

PM part

Resulting structure is relatively nonporous, and the infiltrated

part has a more uniform density, as well as improved

toughness and strength

T

M

(filler)<T

M

(Part)

31

Summary

32

Das könnte Ihnen auch gefallen

- 3D Beam Bending Due to Transverse Shear Loads (FEMDokument8 Seiten3D Beam Bending Due to Transverse Shear Loads (FEMMukaram AliNoch keine Bewertungen

- Case Studies - OHT2Dokument7 SeitenCase Studies - OHT2Mukaram AliNoch keine Bewertungen

- Chap 012Dokument18 SeitenChap 012Mukaram AliNoch keine Bewertungen

- Mechanics & Manufacturing Lab –II Assignment 1 ReportDokument7 SeitenMechanics & Manufacturing Lab –II Assignment 1 ReportMukaram AliNoch keine Bewertungen

- Case Solving MethodologyDokument8 SeitenCase Solving MethodologyMukaram AliNoch keine Bewertungen

- Read MeDokument1 SeiteRead MeMukaram AliNoch keine Bewertungen

- Study Programmes Eligible Final Web1602151624Dokument523 SeitenStudy Programmes Eligible Final Web1602151624Mukaram AliNoch keine Bewertungen

- Case Study 1 PDFDokument14 SeitenCase Study 1 PDFMukaram AliNoch keine Bewertungen

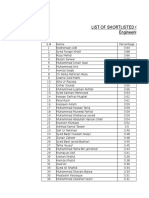

- Top 15 Shortlisted Candidates Graduate Trainee EngineerDokument6 SeitenTop 15 Shortlisted Candidates Graduate Trainee EngineerMukaram AliNoch keine Bewertungen

- Naziat Part 1Dokument33 SeitenNaziat Part 1Mukaram AliNoch keine Bewertungen

- Weekly Report (Spe Event Management Team) : Name Department Comments Fazeel AhmedDokument2 SeitenWeekly Report (Spe Event Management Team) : Name Department Comments Fazeel AhmedMukaram AliNoch keine Bewertungen

- MTI Advent CorporationDokument21 SeitenMTI Advent Corporationmahtaabk100% (3)

- Activate Windows, Office with KMSAuto Net PortableDokument6 SeitenActivate Windows, Office with KMSAuto Net Portableiitgn007Noch keine Bewertungen

- Advent SkimmedDokument4 SeitenAdvent SkimmedMukaram AliNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmeمحمد السيدNoch keine Bewertungen

- GLC Sec A GradesDokument6 SeitenGLC Sec A GradesMukaram AliNoch keine Bewertungen

- Advent SkimmedDokument4 SeitenAdvent SkimmedMukaram AliNoch keine Bewertungen

- FYP Proposal Template for SMME ProjectsDokument1 SeiteFYP Proposal Template for SMME ProjectsMukaram AliNoch keine Bewertungen

- BS Materials Engg UG FYP List ME05Dokument5 SeitenBS Materials Engg UG FYP List ME05Mukaram AliNoch keine Bewertungen

- Best Gre MaterialDokument1 SeiteBest Gre MaterialMukaram AliNoch keine Bewertungen

- Terms of Oil and GasDokument7 SeitenTerms of Oil and GasMukaram AliNoch keine Bewertungen

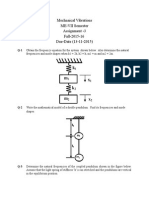

- Mechnaical Vibrations ME-VII Semester Assignment - 3 Fall-2015-16 Due-Date (13-11-2015)Dokument2 SeitenMechnaical Vibrations ME-VII Semester Assignment - 3 Fall-2015-16 Due-Date (13-11-2015)Sarah RachelNoch keine Bewertungen

- ME 04 B TimeTableDokument1 SeiteME 04 B TimeTableMukaram AliNoch keine Bewertungen

- GLC Sec B GradesDokument3 SeitenGLC Sec B GradesMukaram AliNoch keine Bewertungen

- ICE Assignment 1Dokument153 SeitenICE Assignment 1Mukaram AliNoch keine Bewertungen

- Job Details - InternshipDokument1 SeiteJob Details - InternshipMukaram AliNoch keine Bewertungen

- SMME FYP Guidelines v3p1Dokument15 SeitenSMME FYP Guidelines v3p1Mukaram AliNoch keine Bewertungen

- ME-331 Refrigeration and Air Conditioning Assignment-2, Date: 25 March, 2015Dokument1 SeiteME-331 Refrigeration and Air Conditioning Assignment-2, Date: 25 March, 2015Mukaram AliNoch keine Bewertungen

- Jab Zindagi Shiroh Ho Gi by Abu YahahDokument139 SeitenJab Zindagi Shiroh Ho Gi by Abu YahahHaider AliNoch keine Bewertungen

- Control Systems EE-475: Steady State Error and Routh's Stability CriteriaDokument37 SeitenControl Systems EE-475: Steady State Error and Routh's Stability CriteriaMukaram AliNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Concept MappingDokument8 SeitenConcept MappingRashid LatiefNoch keine Bewertungen

- Phil of DepressDokument11 SeitenPhil of DepressPriyo DjatmikoNoch keine Bewertungen

- Atuador Ip67Dokument6 SeitenAtuador Ip67Wellington SoaresNoch keine Bewertungen

- DX DiagesDokument36 SeitenDX DiagesBpbd Kota BengkuluNoch keine Bewertungen

- Energy Engineering SyllabusDokument49 SeitenEnergy Engineering SyllabusKarthiik88Noch keine Bewertungen

- Design TheoryDokument2 SeitenDesign Theoryhamidreza mohseniNoch keine Bewertungen

- Caso de Estudio 14.1, 14.2 y 14.3Dokument6 SeitenCaso de Estudio 14.1, 14.2 y 14.3Rodolfo G. Espinosa RodriguezNoch keine Bewertungen

- XG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial NumbersDokument153 SeitenXG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial Numbersalexandre donizetiNoch keine Bewertungen

- Standard 2Dokument10 SeitenStandard 2Bridget GumboNoch keine Bewertungen

- LG - Week 1 - Operations - ManagementDokument4 SeitenLG - Week 1 - Operations - ManagementMechaella Shella Ningal ApolinarioNoch keine Bewertungen

- NFA To DFA Conversion: Rabin and Scott (1959)Dokument14 SeitenNFA To DFA Conversion: Rabin and Scott (1959)Rahul SinghNoch keine Bewertungen

- Discrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebraDokument6 SeitenDiscrete Math Assignment on Recurrence Relations, Graph Theory and Boolean AlgebralakkajaoNoch keine Bewertungen

- Ata 47-NGS R25Dokument148 SeitenAta 47-NGS R25NadirNoch keine Bewertungen

- GF - 4 - GF - 6 - 790 700 337 - 01 - enDokument2 SeitenGF - 4 - GF - 6 - 790 700 337 - 01 - enAdrianNoch keine Bewertungen

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDokument15 SeitenPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisNoch keine Bewertungen

- Sunward Rotary Drilling Rig Maintenance ManualDokument35 SeitenSunward Rotary Drilling Rig Maintenance ManualPaul Kenneth AbayataNoch keine Bewertungen

- Catalogo Novik NeoDokument32 SeitenCatalogo Novik NeorafaelciceliniNoch keine Bewertungen

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Dokument6 SeitenWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaNoch keine Bewertungen

- Organizational Change & Development - VIL2021 - 22Dokument3 SeitenOrganizational Change & Development - VIL2021 - 22Rahul TRIPATHINoch keine Bewertungen

- Oxford Exam Trainer: Oetmintaunit PDFDokument2 SeitenOxford Exam Trainer: Oetmintaunit PDFКатерина ПетрушевськаNoch keine Bewertungen

- Install Steinitz Fractal Breakout Indicator MT4 (39Dokument10 SeitenInstall Steinitz Fractal Breakout Indicator MT4 (39florin_denys-1Noch keine Bewertungen

- PGSuperDokument71 SeitenPGSuperVietanh PhungNoch keine Bewertungen

- Activities For Responding To Reading in Year 2Dokument59 SeitenActivities For Responding To Reading in Year 2lancashireliteracy100% (1)

- Simulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaDokument3 SeitenSimulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaKrisumraj PurkaitNoch keine Bewertungen

- Balino, Shedina D. Beed 2-CDokument5 SeitenBalino, Shedina D. Beed 2-CSHEDINA BALINONoch keine Bewertungen

- Daily Dawn Newspaper Vocabulary with Urdu MeaningsDokument4 SeitenDaily Dawn Newspaper Vocabulary with Urdu MeaningsBahawal Khan JamaliNoch keine Bewertungen

- CE QB - All Units PDFDokument38 SeitenCE QB - All Units PDFkurian georgeNoch keine Bewertungen

- SOLID-LIQUID EXTRACTIONDokument4 SeitenSOLID-LIQUID EXTRACTIONHarshal Agrawal100% (1)

- Fire Risk Assessment FormDokument16 SeitenFire Risk Assessment Formmukamat safiiNoch keine Bewertungen

- Eco 201Dokument23 SeitenEco 201Tâm TítNoch keine Bewertungen