Beruflich Dokumente

Kultur Dokumente

Keystone Fig. AR1-AR2 Butterfly Valve

Hochgeladen von

pca970 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

746 Ansichten4 SeitenValvula mariposa

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenValvula mariposa

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

746 Ansichten4 SeitenKeystone Fig. AR1-AR2 Butterfly Valve

Hochgeladen von

pca97Valvula mariposa

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Keystone Figure AR1/AR2

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0025-US-0904

General Application

Ideally suited for many high

performance applications, such as fire

protection, water treatment, cooling

systems, food and beverage and bulk

product handling. Consult your sales

representative for appropriate materials

and specific services.

Technical Data

Size Range:

Figure AR1 (wafer style) 2" to 36"

Figure AR2 (lugged style) 2" to 24"

Flange Standard:

ANSI Class 125/150

(Consult your sales representative for additional

drilling standards.)

Resilient seated butterfly valves

sizes 2" to 12" to 175 psi

sizes 14" to 36" to 150 psi

Features and Benefits

Triple function resilient seat helps

provide bi-directional drop-tight shutoff,

designed to totally isolate the valve

body and stem from the line media.

Molded-in O-ring seat design serves

as flange seals, eliminating the need

for gaskets between the flanges and

the valve.

Unique dovetail seat retention design

allows for convenient and economical

field replacement.

Superior one-piece through shaft

design provides high strength and

positive disc control.

Internal shaft seal is designed to

prevent external media from entering

valve and it also adjusts for pressure

and shaft rotation.

Heavy-duty, corrosion resistant top

bushing delivers upper stem support,

absorbs actuator side-loading and

extends valve cycle life.

Polished disc edge helps ensure

optimal performance and maximum

seat life.

Stainless steel torque plug (2" to 12"),

disc screws (14" to 20") and taper

pins (24" to 36") provide positive leak-

proof connections while allowing for

quick and easy disassembly.

One-piece body with extended neck

allows clearance for flanges

and insulation.

Each valve is factory-tested to

110 percent of the manufacturers

pressure rating.

Keystone is either trademark or registered trademark of Tyco International Services AG or its affiliates in

the United States and/or other countries. All other brand names, product names, or trademarks belong

to their respective holders.

0904648_n_0025-02:CLKMC-0142-US 5/6/09 9:41 AM Page 1

Keystone Figure AR1/AR2

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0025

2

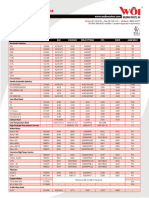

Materials

Part Standard Material Material Specification Optional Material

1. Body Cast iron ASTM A-126, Class B Carbon steel

Ductile iron ASTM A-395 GR 60/40/18 Stainless steel

2. Disc Ductile iron ASTM A-536 GR 65/45/12

Aluminum bronze ASTM B-148, UNS C95200 Grade A

316 Stainless steel ASTM A-743, CF8M

3. Stem 316 Stainless steel (2" to 12") ASTM A-276 UNS S31600

18-8 Stainless steel (14" to 20") ASTM A-276 UNS S30400

17-4 PH Stainless steel (24" to 36") ASTM A-564 UNS S17400 Phosphate treated steel

(2" to 20") ASTM A-108 UNS G10450

4. Seat NBR food grade (0F to 212F) Fluoroelastomer (FKM)

EPDM food grade (-40F to 250F) White NBR

5. Upper stem bushing Polyester (2" to 20")

Bronze (24" to 36")

6. Stem packing NBR

7. Torque plug (2" to 12") 316 Stainless steel ASTM A-276 UNS S31600 condition A

7. Disc screws (14" to 20") 316 Stainless steel ASTM F-593 Group 2 condition CW1

7. Taper pins (24" to 36") 17-4 PH Stainless steel ASTM A564 UNS S17400 H1075

8. Bearings (2" to 12") Sintered metal

3

5

6

1

8

7

2

4

8

Parts and Materials

0904648_n_0025-02:CLKMC-0142-US 5/6/09 9:42 AM Page 2

Keystone Figure AR1/AR2

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0025

3

E

D

45

H

Figure AR2 Lugged

Notes

1. H Dimension refers to flat on stem.

2. Q dimension is the minimum allowable pipe or flange inside diameter at the centered body face to

protect the disc sealing edge against damage when opening the valve.

H

G

F

C

Q A

B

2 2 4

1

/8 5

1

/2 1

5

/8 4 1

1

/4

9

/16

3

/8 1

3

/8 N/A 3

1

/4 4

7

/16 6.3 BAB

2

1

/2 2

1

/2 4

5

/8 6 1

3

/4 4 1

1

/4

9

/16

3

/8 2

1

/16 N/A 3

1

/4 4

7

/16 8.5 BAB

3 3 5

1

/8 6

1

/4 1

3

/4 4 1

1

/4

9

/16

3

/8 2

9

/16 N/A 3

1

/4 4

7

/16 10.0 BAB

4 4 6

3

/8 7 2 4 1

1

/4

5

/8

7

/16 3

5

/8 N/A 3

1

/4 4

7

/16 14.0 BAC

5 5 7

3

/8 7

1

/2 2

1

/8 4 1

1

/4

3

/4

1

/2 4

3

/4 N/A 3

1

/4 4

7

/16 18.0 BAD

6 5

3

/4 8

1

/2 8 2

1

/8 4 1

1

/4

3

/4

1

/2 5

1

/2 N/A 3

1

/4 4

7

/16 22.0 BAD

8 7

3

/4 10

11

/16 9

1

/2 2

1

/2 6 1

1

/4

7

/8

5

/8 7

1

/2 N/A 5 4

9

/16 38.0 CAE

10 9

3

/4 13 10

3

/4 2

1

/2 6 2 1

1

/8 N/A 9

19

/32

1

/4 x

1

/4 5 4

9

/16 51.0 CAF

12 11

3

/4 14

13

/16 12

1

/4 3 6 2 1

1

/8 N/A 11

9

/16

1

/4 x

1

/4 5 4

9

/16 71.0 CAF

14 13

1

/4 16

3

/4 12 3 6 3 1

3

/8 N/A 13

1

/8

5

/16 x

5

/16 5 4

9

/16 114.0 CAG

16 15

1

/4 19

1

/4 12

61

/64 4 6 3 1

5

/8 N/A 15

3

/8 x

3

/8 5 4

9

/16 193.0 CAH

18 17

1

/4 21

1

/2 14

1

/2 4

1

/4 8 4

1

/4 1

7

/8 N/A 16

7

/8

1

/2 x

3

/8 6

1

/2 4

13

/16 222.0 DAJ

20 19

1

/4 23

3

/4 15

7

/8 5 8 4

1

/4 1

7

/8 N/A 18

3

/4

1

/2 x

3

/8 6

1

/2 4

13

/16 315.0 DAJ

24 23

1

/4 28

1

/4 19

1

/2 5

15

/16 8 4

1

/4 1

7

/8 N/A 22

5

/8

1

/2 x

3

/8 6

1

/2 4

13

/16 506.0 DAJ

30 29

1

/4 34

5

/8 23 6

9

/16 8 4

1

/4 2

1

/4 N/A 28

11

/16

1

/2 x

3

/8 6

1

/2 4

13

/16 610.0 DAK

36 35

1

/4 41

1

/4 27

3

/4 7

7

/8 8 5

1

/4 2

7

/8 N/A 34

1

/2

3

/4 x

1

/2 6

1

/2 4

13

/16 1,185.0 DAV

Figure AR1 Wafer

2 2 4

1

/8 5

1

/2 1

5

/8 4 1

1

/4

9

/16

3

/8 1

3

/8 N/A 3

1

/4 4

7

/16 4

3

/4 4

5

/8 - 11 UNC 7.0 BAB

2

1

/2 2

1

/2 4

5

/8 6 1

3

/4 4 1

1

/4

9

/16

3

/8 2

1

/16 N/A 3

1

/4 4

7

/16 5

1

/2 4

5

/8 - 11 UNC 10.0 BAB

3 3 5

3

/16 6

1

/4 1

3

/4 4 1

1

/4

9

/16

3

/8 2

9

/16 N/A 3

1

/4 4

7

/16 6 4

5

/8 - 11 UNC 11.5 BAB

4 4 6

3

/8 7 2 4 1

1

/4

5

/8

7

/16 3

5

/8 N/A 3

1

/4 4

7

/16 7

1

/2 8

5

/8 - 11 UNC 18.0 BAC

5 5 7

3

/8 7

1

/2 2

1

/8 4 1

1

/4

3

/4

1

/2 4

3

/4 N/A 3

1

/4 4

7

/16 8

1

/2 8

3

/4 - 10 UNC 22.5 BAD

6 5

3

/4 8

1

/2 8 2

1

/8 4 1

1

/4

3

/4

1

/2 5

1

/2 N/A 3

1

/4 4

7

/16 9

1

/2 8

3

/4 - 10 UNC 28.5 BAD

8 7

3

/4 10

11

/16 9

1

/2 2

1

/2 6 1

1

/4

7

/8

5

/8 7

1

/2 N/A 5 4

9

/16 11

3

/4 8

3

/4 - 10 UNC 49.0 CAE

10 9

3

/4 13 10

3

/4 2

1

/2 6 2 1

1

/8 N/A 9

19

/32

1

/4 x

1

/4 5 4

9

/16 14

1

/4 12

7

/8 - 9 UNC 69.0 CAF

12 11

3

/4 14

13

/16 12

1

/4 3 6 2 1

1

/8 N/A 11

9

/16

1

/4 x

1

/4 5 4

9

/16 17 12

7

/8 - 9 UNC 107.0 CAF

14 13

1

/4 16

3

/4 12 3 6 3 1

3

/8 N/A 13

1

/8

5

/16 x

5

/16 5 4

9

/16 18

3

/4 12 1 - 8 NC 143.0 CAG

16 15

1

/4 19 12

61

/64 4 6 3 1

5

/8 N/A 15

3

/8 x

3

/8 5 4

9

/16 21

1

/4 16 1 - 8 NC 238.0 CAH

18 17

1

/4 21

3

/8 14

1

/2 4

1

/4 8 4

1

/4 1

7

/8 N/A 16

7

/8

1

/2 x

3

/8 6

1

/2 4

13

/16 22

3

/4 16 1

1

/8 - 7 NC 261.0 DAJ

20 19

1

/4 23

1

/2 15

7

/8 5 8 4

1

/4 1

7

/8 N/A 18

3

/4

1

/2 x

3

/8 6

1

/2 4

13

/16 25 20 1

1

/8 - 7 NC 366.0 DAJ

24 23

1

/4 28

1

/4 19

1

/2 5

15

/16 8 4

1

/4 1

7

/8 N/A 22

5

/8

1

/2 x

3

/8 6

1

/2 4

13

/16 29

1

/2 20 1

1

/4 - 7 NC 576.0 DAJ

Figure AR1 - Dimensions (inches)

Top Plate Drilling

Bolt No. Hole Weight Adapt.

Size A B C D E F G H Q Key Circle Holes Dia. (lbs) Code

Figure AR2 - Dimensions (inches)

Top Plate Drilling Tapped Lug Data

Bolt No. Hole Bolt No. Weight Adapt.

Size A B C D E F G H Q Key Circle Holes Dia. Circle Holes Tap (lbs) Code

45

E

D

H

0904648_n_0025:CLKMC-0142-US 5/1/09 1:50 PM Page 3

Copyright 2009 Tyco Flow Control. All rights reserved. CLKMC-0142

4

Keystone Figure AR1/AR2

Copyright 2009 Tyco Flow Control. All rights reserved. KEYMC-0025

4

www.tycoflowcontrol.com

Tyco Flow Control (TFC) provides the information herein in good faith but makes no representation as to its comprehensiveness or accuracy. This data sheet is intended only as a guide to TFC products and services.

Individuals using this data sheet must exercise their independent judgment in evaluating product selection and determining product appropriateness for their particular purpose and system requirements. TFC MAKES NO

REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO

THE INFORMATION SET FORTH HEREIN OR THE PRODUCT(S) TO WHICH THE INFORMATION REFERS. ACCORDINGLY, TFC WILL NOT BE RESPONSIBLE FOR DAMAGES (OF ANY KIND OR NATURE, INCLUDING

INCIDENTAL, DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES) RESULTING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION. Patents and Patents Pending in the U.S. and foreign countries. Tyco

reserves the right to change product designs and specifications without notice. All registered trademarks are the property of their respective owners. Printed in the USA.

0904648_n_0025:CLKMC-0142-US 5/1/09 1:50 PM Page 4

Das könnte Ihnen auch gefallen

- Catálogo Válvulas de Control Red Valve PDFDokument30 SeitenCatálogo Válvulas de Control Red Valve PDFFranciscoNoch keine Bewertungen

- Maint Mech Chem Plant.150164641Dokument29 SeitenMaint Mech Chem Plant.150164641swami061009Noch keine Bewertungen

- AsmeDokument1 SeiteAsmesimplexmNoch keine Bewertungen

- 6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportDokument12 Seiten6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportSalimNoch keine Bewertungen

- 15no03 Ds 020 008 Portable Loading Diesel Pump (3322 P 003)Dokument7 Seiten15no03 Ds 020 008 Portable Loading Diesel Pump (3322 P 003)bagus handokoNoch keine Bewertungen

- Shot Blasting Machine GA DrawingDokument1 SeiteShot Blasting Machine GA DrawingToniNoch keine Bewertungen

- CI3164 Work OrderDokument16 SeitenCI3164 Work OrderTauasiNoch keine Bewertungen

- Codes Standards For YANBU ProjectDokument7 SeitenCodes Standards For YANBU ProjectBehçet Serdal CanbazNoch keine Bewertungen

- Douglas Chero Catalogue Valve 6-2003Dokument89 SeitenDouglas Chero Catalogue Valve 6-2003Yurizki LhzNoch keine Bewertungen

- Solder Metal: Standard Specification ForDokument11 SeitenSolder Metal: Standard Specification Foranurag yadavNoch keine Bewertungen

- 213-Astm A 388 2001 Ultrasonic Examination of Heavy Steel Forgings PDFDokument7 Seiten213-Astm A 388 2001 Ultrasonic Examination of Heavy Steel Forgings PDFgraduate100% (1)

- Cameron Fully Welded Ball Valves PDFDokument36 SeitenCameron Fully Welded Ball Valves PDFCARLOSNoch keine Bewertungen

- Comparación Mangueras Hidráulicas SAE e ISODokument5 SeitenComparación Mangueras Hidráulicas SAE e ISOJuan David Barrera FlorezNoch keine Bewertungen

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedDokument22 Seiten1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoNoch keine Bewertungen

- Sp-Me-0103 - Specification For Drain Transfer Pumps (Rev.a) - Returned (P-1401)Dokument9 SeitenSp-Me-0103 - Specification For Drain Transfer Pumps (Rev.a) - Returned (P-1401)Panisa BanimaNoch keine Bewertungen

- Presentation DelcorteDokument15 SeitenPresentation Delcortecarlos2685Noch keine Bewertungen

- KSB Ball Valve 2 inDokument8 SeitenKSB Ball Valve 2 inrusli bahtiarNoch keine Bewertungen

- (DS2-010112) Y:/Proyecto/2090/PLANOS/04-Piping/Estandares/En Trabajo/4C/4C-01.03 C Rev-0Dokument3 Seiten(DS2-010112) Y:/Proyecto/2090/PLANOS/04-Piping/Estandares/En Trabajo/4C/4C-01.03 C Rev-0Christian Martínez G.Noch keine Bewertungen

- Material P NumberDokument1 SeiteMaterial P Numberrameez khanNoch keine Bewertungen

- Pressure Vessels Carbon Steel: Standard Specification 3-11-6Dokument26 SeitenPressure Vessels Carbon Steel: Standard Specification 3-11-6minh nguyenNoch keine Bewertungen

- DrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsDokument1 SeiteDrillMaster ISO 9001 - 2000 Hydraulic Hose and FittingsmarcotplNoch keine Bewertungen

- Anwesha Chinese CheckerDokument34 SeitenAnwesha Chinese CheckerdxcsksansNoch keine Bewertungen

- Simbologia OlehidraulicaDokument20 SeitenSimbologia Olehidraulicajorge Diaz Rodriguez100% (1)

- TB27a ENDokument4 SeitenTB27a ENandy131078Noch keine Bewertungen

- Piping Specification: Piping Class: A2ADokument30 SeitenPiping Specification: Piping Class: A2AAbhijeet WayaseNoch keine Bewertungen

- VALVULA VAPOR Joseestrada PDFDokument5 SeitenVALVULA VAPOR Joseestrada PDFRaulRodriguezNoch keine Bewertungen

- From ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitDokument10 SeitenFrom ASME B31.3 para 304.5.3: T D SQRT (3P/ (16SE) ) +C: Variable Description Variable Value UnitSong TaoNoch keine Bewertungen

- SA-105 - ASME BPVC 2021 Sección II Parte A-1Dokument8 SeitenSA-105 - ASME BPVC 2021 Sección II Parte A-1Mohammad TaherNoch keine Bewertungen

- Catalogo Stock VogtVogtDokument10 SeitenCatalogo Stock VogtVogtmmaldonado10Noch keine Bewertungen

- SBC (Safety Break-Away Couplings) v140630Dokument16 SeitenSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Ball Valve - CameronDokument36 SeitenBall Valve - CameronMeet JaniNoch keine Bewertungen

- Valvulas PDFDokument32 SeitenValvulas PDFMilena Lemus FonsecaNoch keine Bewertungen

- E.13 - Tylok (SM) SS-12-DMC-12Dokument1 SeiteE.13 - Tylok (SM) SS-12-DMC-12PercyAlexanderNoch keine Bewertungen

- Polyken 2036Dokument2 SeitenPolyken 2036nrd9771Noch keine Bewertungen

- WKM 370d4 Trunnion Mounted Ball Valves Brochure PDFDokument40 SeitenWKM 370d4 Trunnion Mounted Ball Valves Brochure PDFAdhie WaelacxhNoch keine Bewertungen

- Anexo I - Típicos de Soportes Metálicos PDFDokument174 SeitenAnexo I - Típicos de Soportes Metálicos PDFAngely CanalesNoch keine Bewertungen

- To Show Pipe Inch Diameter Calculation On IsometricDokument3 SeitenTo Show Pipe Inch Diameter Calculation On IsometricAbhijeet WayaseNoch keine Bewertungen

- C22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualsDokument173 SeitenC22-Yb60-M-4763 - 0 Sa3-Ps2, Butterfly Valve, Operating ManualssartajNoch keine Bewertungen

- Retriever Manual PDFDokument49 SeitenRetriever Manual PDFJanneth Herrera FloresNoch keine Bewertungen

- Engrasadora NEUMATICAFLOWSERVERDokument16 SeitenEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarNoch keine Bewertungen

- Technical Data: Foam Chambers Model FCDokument5 SeitenTechnical Data: Foam Chambers Model FCjhoger2012Noch keine Bewertungen

- PIL 181 Package Tie-Down Options Rev 4Dokument7 SeitenPIL 181 Package Tie-Down Options Rev 4ganesh100% (1)

- Ficha Tecnica de Valvula de Seguridad 19KGGA150Dokument1 SeiteFicha Tecnica de Valvula de Seguridad 19KGGA150mynor8josh8juarezNoch keine Bewertungen

- Caso Codigo 2541 - Asme VDokument1 SeiteCaso Codigo 2541 - Asme VMiguel Angel Aguilar MenaNoch keine Bewertungen

- Eska Valve ERG-S Series Double Stage Pressure RegulatorDokument4 SeitenEska Valve ERG-S Series Double Stage Pressure RegulatorRONAL QUISPE MAMANINoch keine Bewertungen

- QT 16Cr PDFDokument1 SeiteQT 16Cr PDFYaroslav RuizNoch keine Bewertungen

- ASME B16.9 INTERPRETACION - Accesorios para Soldadura A Tope de Acero ForjadoDokument13 SeitenASME B16.9 INTERPRETACION - Accesorios para Soldadura A Tope de Acero ForjadoAlexis MontoyaNoch keine Bewertungen

- Trunnion Ball Valve - Class 150#Dokument6 SeitenTrunnion Ball Valve - Class 150#adrianioantomaNoch keine Bewertungen

- Spools and Adapters Flanges, Tees and Crosses,: One Company Unlimited SolutionsDokument8 SeitenSpools and Adapters Flanges, Tees and Crosses,: One Company Unlimited SolutionsdeepakpotdarNoch keine Bewertungen

- 8-1280-13 Pipe Class HF-1Dokument4 Seiten8-1280-13 Pipe Class HF-1Jesus MendezNoch keine Bewertungen

- An Intro To Med Plumb & GasDokument45 SeitenAn Intro To Med Plumb & Gasangel darioNoch keine Bewertungen

- HEAT-TRACE Hoja CalculoDokument1 SeiteHEAT-TRACE Hoja CalculotineohNoch keine Bewertungen

- Body Wall Thickness of Pressure Safety Valves - SetPoint InstructionDokument3 SeitenBody Wall Thickness of Pressure Safety Valves - SetPoint InstructionFabio Peres de LimaNoch keine Bewertungen

- Piping Material Classes MiningDokument113 SeitenPiping Material Classes MiningRamiro RamirezNoch keine Bewertungen

- Series FB: Floating Ball ValveDokument12 SeitenSeries FB: Floating Ball ValveCarlos Alberto Aguilera MendezNoch keine Bewertungen

- Carbon Steel Strainer Fig 34 HP-Technical InformationDokument3 SeitenCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferNoch keine Bewertungen

- Ed M 01.00 I 05Dokument18 SeitenEd M 01.00 I 05joseellargo100% (1)

- Piping Section T003: U - Bolt Measurement F + TDokument1 SeitePiping Section T003: U - Bolt Measurement F + TsivaNoch keine Bewertungen

- ButterflyDokument6 SeitenButterflysachin2010Noch keine Bewertungen

- Series VL Air Cylinders For Valve Actuation: Catalog HY08-0947-1/NA April, 2004Dokument12 SeitenSeries VL Air Cylinders For Valve Actuation: Catalog HY08-0947-1/NA April, 2004Anthony Saavedra AbarulloNoch keine Bewertungen

- Chapter02-Handbook of Polyethylene PipeDokument27 SeitenChapter02-Handbook of Polyethylene Pipepca97Noch keine Bewertungen

- Forged FittingsDokument7 SeitenForged Fittingspca97Noch keine Bewertungen

- Chapter03-Handbook of Polyethylene PipeDokument61 SeitenChapter03-Handbook of Polyethylene Pipepca97Noch keine Bewertungen

- Industrial PumpingDokument59 SeitenIndustrial Pumpingpca97100% (1)

- Cutting Costs: in Pump and Pipe SizingDokument4 SeitenCutting Costs: in Pump and Pipe Sizingpca97Noch keine Bewertungen

- Valve Sizing TablesDokument5 SeitenValve Sizing Tablespca97Noch keine Bewertungen

- Choke Flow CVDokument5 SeitenChoke Flow CVpca97Noch keine Bewertungen

- Pipe Stress Analysis Using CAESAR IIDokument42 SeitenPipe Stress Analysis Using CAESAR IIpca97100% (1)

- AFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIDokument24 SeitenAFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIpca97Noch keine Bewertungen

- Goulds 3196 2x3-13 200HPDokument2 SeitenGoulds 3196 2x3-13 200HPpca97Noch keine Bewertungen

- Formal Letter LPDokument2 SeitenFormal Letter LPLow Eng Han100% (1)

- Test Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen DownloadDokument74 SeitenTest Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen Downloadmichaelmarshallmiwqxteyjb100% (28)

- Course Projects PDFDokument1 SeiteCourse Projects PDFsanjog kshetriNoch keine Bewertungen

- Brochure International ConferenceDokument6 SeitenBrochure International ConferenceAnubhav Sharma sf 12Noch keine Bewertungen

- LG Sigma+EscalatorDokument4 SeitenLG Sigma+Escalator강민호Noch keine Bewertungen

- Lecture Notes 3A - Basic Concepts of Crystal Structure 2019Dokument19 SeitenLecture Notes 3A - Basic Concepts of Crystal Structure 2019Lena BacaniNoch keine Bewertungen

- Freshers Jobs 26 Aug 2022Dokument15 SeitenFreshers Jobs 26 Aug 2022Manoj DhageNoch keine Bewertungen

- Technical Data Sheet TR24-3-T USDokument2 SeitenTechnical Data Sheet TR24-3-T USDiogo CNoch keine Bewertungen

- Dialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Dokument1 SeiteDialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Al ImranNoch keine Bewertungen

- Lista de Precios Agosto 2022Dokument9 SeitenLista de Precios Agosto 2022RuvigleidysDeLosSantosNoch keine Bewertungen

- Hetal Patel: Team Leader - SalesDokument2 SeitenHetal Patel: Team Leader - SalesPrashant kumarNoch keine Bewertungen

- TMPRO CASABE 1318 Ecopetrol Full ReportDokument55 SeitenTMPRO CASABE 1318 Ecopetrol Full ReportDiego CastilloNoch keine Bewertungen

- Microeconomics Term 1 SlidesDokument494 SeitenMicroeconomics Term 1 SlidesSidra BhattiNoch keine Bewertungen

- Automated Dish Washer v1.1Dokument21 SeitenAutomated Dish Washer v1.1Anonymous XXCCYAEY6M67% (3)

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisDokument283 SeitenThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxNoch keine Bewertungen

- CEN and CENELEC Position Paper On The Proposal For CPR RevisionDokument15 SeitenCEN and CENELEC Position Paper On The Proposal For CPR Revisionhalexing5957Noch keine Bewertungen

- Lect.1-Investments Background & IssuesDokument44 SeitenLect.1-Investments Background & IssuesAbu BakarNoch keine Bewertungen

- Bajaj CNSDokument3 SeitenBajaj CNSAbhijit PaikarayNoch keine Bewertungen

- Minuets of The Second SCTVE MeetingDokument11 SeitenMinuets of The Second SCTVE MeetingLokuliyanaNNoch keine Bewertungen

- MECANISMOS de Metais de TransicaoDokument36 SeitenMECANISMOS de Metais de TransicaoJoão BarbosaNoch keine Bewertungen

- Research On Export Trade in BangladeshDokument7 SeitenResearch On Export Trade in BangladeshFarjana AnwarNoch keine Bewertungen

- 2 AcknowledgementDokument8 Seiten2 AcknowledgementPadil KonamiNoch keine Bewertungen

- GTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerDokument1 SeiteGTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerThanuja DilshanNoch keine Bewertungen

- The International Poker RulesDokument2 SeitenThe International Poker RulesOutontheBubbleNoch keine Bewertungen

- Pest of Field Crops and Management PracticalDokument44 SeitenPest of Field Crops and Management PracticalNirmala RameshNoch keine Bewertungen

- Uneb U.C.E Mathematics Paper 1 2018Dokument4 SeitenUneb U.C.E Mathematics Paper 1 2018shafickimera281Noch keine Bewertungen

- Power Control 3G CDMADokument18 SeitenPower Control 3G CDMAmanproxNoch keine Bewertungen

- N50-200H-CC Operation and Maintenance Manual 961220 Bytes 01Dokument94 SeitenN50-200H-CC Operation and Maintenance Manual 961220 Bytes 01ANDRESNoch keine Bewertungen

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Dokument6 SeitenRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNoch keine Bewertungen

- Schneider Contactors DatasheetDokument130 SeitenSchneider Contactors DatasheetVishal JainNoch keine Bewertungen