Beruflich Dokumente

Kultur Dokumente

Basic Troubleshooting (Disc Saveall)

Hochgeladen von

Daniel LieCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Basic Troubleshooting (Disc Saveall)

Hochgeladen von

Daniel LieCopyright:

Verfügbare Formate

Basic troubleshooting required to maintain disc filter reliability

Emmerling, Fred A

Disc filters have many applications in pulp and paper mills. The most widespread use

is for thickening of slow-draining stocks, such as mechanical pulps. Disc filters are

also commonly used in the paper mill as savealls for recovery of fiber and filler and

for clarification of whitewater.

One of the first disc filter units installed in paper mills for environmental reasons was

a paper machine saveall application. Justification for installation was recovery of

valuable fiber and fillers. A side benefit of the application was cleaner effluent

discharged to the river. Prior to the introduction of the disc filter, open cylinder

deckers, side-hill screens, vacuum drum filters, continuous precoat belt filters, and

air flotation separation cells were used as savealls.

The disc filter was introduced to the pulp and paper industry in the early 1950s for

use as a paper machine saveall. The disc filter was originally developed for the

chemical and mining industries to process slow-filtering materials. Consequently, the

disc filter was an ideal machine for use in filtering slow-draining paper machine

whitewater. By the mid-1960s, three major equipment suppliers were offering disc

filters designed especially for use in the pulp and paper industry. There are now

more than six major suppliers in the U.S. and Europe.

In the 1970s, paper machine water closeups became necessary due to

environmental pressures. Reuse of paper machine whitewater was necessary for

water conservation. A majority of the showers in the wire and press sections that

originally used freshwater were designed to use clear filtrate from the saveall.

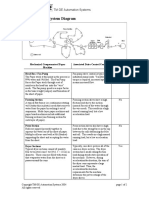

Disc filter operation. A disc filter unit consists of a series of discs mounted on a

hollow center shaft that is equipped with drainage channels terminating at a valve

assembly. Each individual disc is made of pie-shaped hollow sectors covered on both

sides with filter cloth.

The discs rotate in a vat filled to about the midpoint of the center shaft with a

mixture of whitewater and sweetener fiber. The center shaft is rotated by a variable-

speed drive. Figure 1 shows the operation of the disc and highlights a single sector

as it goes through one rotation.(Figure 1 omitted) The inlet box is shown opposite

the discharge for simplicity. The inlet box is located on the discharge end of the vat

on many disc filters.

When the disc enters the vat (1), a mat is formed from the fibers in the vat, first by

gravity and then by vacuum. This initial fiber mat, not the filter cloth, is the actual

filtering medium. Initially, the filtrate is rich in fines and inorganics.

As the sector rotates further in the vat (2), the mat thickens, and the filtrate

becomes clearer as fines and inorganics are retained in the fiber mat. A splitter

mechanism in the valve assembly separates the clear and cloudy filtrates, which are

carried to appropriate filtrate tanks via droplegs.

As the sector emerges from the vat (3), vacuum is cut off by a valve at the end of

the center shaft, and the cake is removed by knock-off showers. The cake discharges

into chutes and then to a conveyor that discharges to a stock chest. The knock-off

position is sometimes located at the top center position of the disc shaft.

Alternatively, the knock-off position may be 150 deg from emergence of the disc

from the vat.

As the disc rotates toward the point of entry into the vat (4), the filter cloth faces are

cleaned by a wire-cleaning shower. The clear wire-cleaning water is removed from

the end of the center shaft in the valve box by a gravity or atmospheric drain.

Operating environment and problems. The saveall is normally located above the

paper machine operating floor on a mezzanine. The operating environment is hot,

humid, and not conducive to operator supervision. The saveall is normally monitored

by a television cam. era from the operating control room. If properly designed and

installed, disc savealls are reliable equipment. However, wear on the component

parts must be monitored.

When a disc saveall operates well, it receives minimal attention. When the saveall

malfunctions, it normally cannot be repaired without outage time. Therefore, a mill

will often tolerate a poorly operating unit and use freshwater in the paper machine

process when clear whitewater from the saveall should be used.

Common problems encountered in the operation of a disc filter can normally be fixed

easily and relatively quickly during a shutdown. The key to minimum downtime is to

identify the problem, determine the causes, and have materials and tools to make

the repair during a scheduled outage.

Generally, disc filter problems and repairs are similar for all filter manufacturers. It is

essential that operating and maintenance personnel become familiar with the

manufacturer's manual and the equipment itself to successfully troubleshoot and

repair the disc filter.

Common problems encountered include the following:

* Low, no, or oscillating vacuum

*High operating level and rotational speed

* High filtrate solids

* Difficult cake release.

Many operating problems with disc filters are interrelated. Therefore, it is important

to comprehensively investigate all operating parameters during troubleshooting

efforts.

It is essential to verify that operating conditions are in accordance with the original

specifications for the disc filter. Changes in machine furnish, water reuse, sweetener

source, and other variables can cause changes in operation that sometimes can be

easily resolved by simply removing or adding discs.

Low, no, or oscillating vacuum. Low vacuum cannot be quantitatively defined, since

disc filters will operate at different vacuums on different furnishes. Symptoms of

inadequate vacuum on a disc filter ate low unit capacity, only partial cake formation

on the disc sectors, high solids in the clear filtrate, vat thickening, and high vat level.

The causes for vacuum problems are not always obvious. The following areas must

be considered:

Is there an air leak into the saveall? Examine and repair the following areas if leaks

are found:

* Seal between the disc filter core and the valve box. This seal is usually a deckle

strap between the core and a ring connected to the valve box or a lip-seal

arrangement between the core shaft and the valve box. An inspection of these seals

is necessary when the machine is not in service.

* Flexible joint between the valve box outlets and the drop legs. Leaks can be

detected by moving an open flame around the seal while watching for a drawing

force pulling the flame toward the leak.

* All bolts and cap screws on the valve box should be examined and tightened as

required.

* All gaskets on the valve box should be checked. Leaks in this area can be checked

using the open flame technique.

* Oscillating vacuum is usually the result of loose disc sectors. The bolts holding

down the individual disc sectors should be checked. If there are gaskets between the

sectors and the core, these should also be checked. The core covers over the

openings providing for future discs should be checked for possible leaks.

* Oscillating vacuum may also be caused by improper vat level control. This vacuum

problem is usually a cyclic phenomenon caused by the disc running at a fixed speed

or a level control that is not properly functioning. Typically, the vat level will

decrease to a point where air will be pulled into the vacuum system. Vacuum will be

broken, and the level will rise again until vacuum is restored. The cycle will repeat as

the vat level drops. The solution to this problem is to either slow down the disc or,

preferably, repair or install the disc speed vat-level control loop.

* Oscillating-or low-vacuum problems may be a result of improper dropleg

configuration, such as an offset in the leg, a leg that is not vertically plumb, or

choking in the leg due to excessive now for the dropleg diameter. Proper design of

the dropleg configuration will resolve this problem. The leg should be designed for a

velocity of 10 to 16 fps. A good dropleg should be at least 20 ft long from the

centerline of the disc to the level in the seal tank, should be vertically plumb, and

should have no offsets.

* Oscillating vacuum may also be caused by variations in the seal tank level. This

phenomenon usually occurs when the dropleg is sealed in the main tank, not in a

separate seal chamber. Proper control of the main seal tank level will resolve this

problem.

Is the filtrate system operating properly?

* Is there sufficient flow to the droplegs to create a good, stable vacuum? Flow to

the disc filter must be estimated to assure that liquid velocities in the droplegs are in

the range of 10 to 16 fps. If the liquid velocity in the dropleg is low, a smaller-

diameter dropleg may be required.

* Are the ends of the dropleg designed properly? Droplegs should be submerged in

the seal tank approximately 1 to 1-1/2 pipe dia. If the droplegs ate submerged too

deeply, the ends of the legs should be cut off to achieve proper submergence. If the

droplegs are not sealed 1 to 1-1/2 dia in the tank level, an extension should be

installed to the bottom of the dropleg.

High level and high speeds. If a disc filter has been in service for a long time,

operating conditions may have changed since installation. Revisions may be

necessary to restore efficient operation.

Verification of the original design specifications should be completed. If original

manufacturer specifications are not readily available, the manufacturer should be

consulted. If the manufacturer does not have the necessary information, drainage

tests (leaf tests) can be performed to determine the operating capacity of the disc

filter at various operating speeds.

If the operating conditions, manufacturer specifications, or leaf tests indicate that the

disc is properly sized for the application, a check should be completed for the

following parameters:

* Is the cake being released properly, or is the cake excessively thin? If the cake is

too thin, slowly increase the sweetener stock flow. This action should result in a

thicker cake that will release more easily.

*If the cake is not being released properly and is carrying over into submergence,

there may be a problem with the valve. Check the condition of the valve segment

(the face of the valve nearest the end of the core). The valve face may be worn to a

point where the vacuum is not being cut off completely. Consequently, the cake will

be held to the disc by residual vacuum. Repair or replacement of the valve face may

be necessary.

* Check the wire-cleaning shower nozzles for plugging and clear plugged showers.

These shower nozzles should be checked routinely. Even self-purging showers have

been known to plug.

* Check the knock-off showers to ensure that the nozzles are open and aimed to hit

the upper outer edge of the disc sector. Properly directed showers will start the cake

peeling off the disc as required. These shower nozzles should be routinely checked.

* Verify proper venting of the atmospheric port. There should be a flow of air at the

port. Unplug the vent if required.

* If the disc filter vacuum is excessively high, installation of a vacuum breaker or air

bleed to the droplegs or valve box may be necessary. Proper filter vacuum should be

5-to 8-in. mercury on free pulps and 8-to 12-in. mercury on highly filled or high-

wood furnishes. Caution: if the disc is operating at a lower vacuum than indicated

above and running well, don't fix it.

High solids in the clear filtrate. One of the more difficult problems to troubleshoot in

disc filter operation is high solids in the filtrate. This problem may be caused by

operating conditions, physical damage, or disrepair of disc filter components. The

following potential problem areas should be checked:

* Center-shaft deckle-strap or lip-seal leakage. Tighten or replace as required.

* Loose disc sector(s). Check by wiggling sectors. If they move an appreciable

amount, tighten the holding bolts.

* Bad gasket(s) between the bottom of the disc sector and the core. Replace as

required.

* Filtrate separator not set properly, with too little cloudy filtrate. Reset the

separator a few degrees at a time and check solids content of clear filtrate. Repeat

until desired clarity is reached.

* Leakage in valve box; cloudy and clear separator seals may be worn or missing. If

the separator is moved to give less clear filtrate with lower solids content and the

solids don't change, this is the problem.

* Hole in filter cloth. This requires careful inspection to find.

* Crack in disc sector body. This also requires careful inspection.

* Ratio of sweetener stock to whitewater may be low. Typically, the vat consistency

should be two to three times the consistency of the raw whitewater. This is usually a

matter of trial and error and requires testing of the filtrate solids content.

* Cross leakage between clear and cloudy filtrate chests. Occasionally, a loose tile or

hole in a baffle occurs and causes the leakage of cloudy filtrate into the clear side of

a combination chest.

Difficult cake release. Difficult or incomplete cake release from the disc is normally a

result of vacuum leaking past the cutoff point in the valve box. This phenomenon is

caused by a worn valve wear segment. The solution is replacement of the valve

segment.

A secondary cause of difficult cake release is improper positioning of the knock-off

shower nozzle The shower should be positioned so that it starts to peel the sheet off

at the upper corner or the sector. The sheer weight of the cake will cause it to drop

into the discharge chute and then into the discharge conveyor or stock chest.

Periodic cleaning. Successful operation of a disc saveall requires periodic cleaning.

Operating and environmental conditions vary widely from mill to mill. Various

chemicals, fillers, and organic compounds can blind the filter cloth, build up on the

inner surfaces of the disc segments, and reduce the drainage capacity of the saveall

unit.

If there are indications of saveall capacity loss, blinding of the filter cloth, or poor

pickup on any of the discs, then an inspection should be made of the disc sectors to

determine if buildup of scale, slime, or other foreign materials has occurred.

If severe disc scaling is found, the manufacturer of the disc should be contacted for

chemical cleaning recommendations that will not be harmful to the disc filter's

materials of construction. A chemical analysis of the scaling material is helpful in

making recommendations for the proper chemical cleaning agent.

If cleaning must be performed several times a year, it may be advantageous to

install a small, permanently piped chemical cleaning system. The cleaning system

may be piped into one of the seal tanks and into the inlet piping to the disc filter.

Showers should be routinely inspected and cleaned.

Fred A. Emmerling is senior pulping and bleaching specialist-PROBEK, BE&K

Engineering, Morrisville, N.C.

Miller Freeman Inc. Apr 1994

Provided by ProQuest Information and Learning Company. All rights Reserved

Das könnte Ihnen auch gefallen

- Notes On Sprockets and ChainsDokument6 SeitenNotes On Sprockets and Chainsjjoohhnn90Noch keine Bewertungen

- Steam and Kondensat For PapermachineDokument33 SeitenSteam and Kondensat For PapermachinesakarisoNoch keine Bewertungen

- Freeness of Pulper Test Method t227Dokument9 SeitenFreeness of Pulper Test Method t227sjvpdktNoch keine Bewertungen

- Calculate Press AnywheDokument7 SeitenCalculate Press Anywhemirza_adil99100% (1)

- Head Box TutorialDokument12 SeitenHead Box TutorialRakshak Nag100% (1)

- MAGNI 565: Product Data SheetDokument1 SeiteMAGNI 565: Product Data SheetjulianaNoch keine Bewertungen

- Headbox Control Maintenance GuideDokument22 SeitenHeadbox Control Maintenance GuideSukallan Dhar100% (1)

- Expertip 7 Paper Machine Water CalculationsDokument5 SeitenExpertip 7 Paper Machine Water Calculationsnotengofff100% (1)

- How To Determine Drive For Paper Machine (Simple Calculation) PDFDokument3 SeitenHow To Determine Drive For Paper Machine (Simple Calculation) PDFHgagselim Selim100% (1)

- Roisum2 Pres PDFDokument30 SeitenRoisum2 Pres PDFkochicomm0% (1)

- Vacuumpump TroubleshootingDokument5 SeitenVacuumpump TroubleshootingKelly RobertsNoch keine Bewertungen

- 3 Paper Machine Water Systems Scott Romenesko KadantDokument17 Seiten3 Paper Machine Water Systems Scott Romenesko KadantJeremy Lobo VillalobosNoch keine Bewertungen

- Montacargas KalmarDokument974 SeitenMontacargas KalmarJohn MkCito KI100% (12)

- Crowning Benefits - Paper, Film & Foil ConverterDokument3 SeitenCrowning Benefits - Paper, Film & Foil ConverteravgpaulNoch keine Bewertungen

- PowerMILL 5 Axis MachiningDokument2 SeitenPowerMILL 5 Axis MachiningRelu ChiruNoch keine Bewertungen

- Paper Manufacturing TrainingDokument183 SeitenPaper Manufacturing TrainingMazharul Islam100% (1)

- Scope: Approved by The Pulp Properties Committee of The Process and Product Quality DivisionDokument4 SeitenScope: Approved by The Pulp Properties Committee of The Process and Product Quality DivisionRaNoch keine Bewertungen

- New Drying and Dewatering Processes in PDokument23 SeitenNew Drying and Dewatering Processes in PvenkNoch keine Bewertungen

- Cleaning GuidelinesDokument10 SeitenCleaning GuidelinesMr. JahirNoch keine Bewertungen

- Voith-Paper Twogether24 enDokument76 SeitenVoith-Paper Twogether24 enPhi TiêuNoch keine Bewertungen

- Cleaning and Conditioning Forming and Press Section 3000 USDokument12 SeitenCleaning and Conditioning Forming and Press Section 3000 USF Cikal AntariksaNoch keine Bewertungen

- Mechanism of Cannizzaro ReactionDokument8 SeitenMechanism of Cannizzaro ReactionDaniel LieNoch keine Bewertungen

- Advanced Training Course On Deinking - Dispersion and KneadingDokument38 SeitenAdvanced Training Course On Deinking - Dispersion and KneadingGuido PeraltaNoch keine Bewertungen

- Scope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Dokument6 SeitenScope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Ashish ChourasiaNoch keine Bewertungen

- Topic 14 Papermaking Pressing TextDokument21 SeitenTopic 14 Papermaking Pressing Textronaldsacs100% (1)

- Practice Questions For API RP 577Dokument10 SeitenPractice Questions For API RP 577vamsikrishnaNoch keine Bewertungen

- PaperGrades VendittiDokument33 SeitenPaperGrades VendittiArif HasanNoch keine Bewertungen

- TAPPI 0404-07 - Paper Machine Drying RateDokument28 SeitenTAPPI 0404-07 - Paper Machine Drying RateSebastian Cardona GarciaNoch keine Bewertungen

- Brown Stock WashingDokument5 SeitenBrown Stock WashingDaniel LieNoch keine Bewertungen

- Tappi TIP 0404-63 PDFDokument25 SeitenTappi TIP 0404-63 PDFmd ibrahim100% (1)

- Valmetadvancedcalendertechnologies JapaneseJournalofPaperTechnology PDFDokument21 SeitenValmetadvancedcalendertechnologies JapaneseJournalofPaperTechnology PDFsukallan dharNoch keine Bewertungen

- Paper Machine System Diagram: TM GE Automation SystemsDokument2 SeitenPaper Machine System Diagram: TM GE Automation SystemsWudassie AyeleNoch keine Bewertungen

- Century Pul112Dokument48 SeitenCentury Pul112Shubh Prakash TiwariNoch keine Bewertungen

- 2 Stock Preparation & Approach SystemDokument73 Seiten2 Stock Preparation & Approach SystemSanjeev GautamNoch keine Bewertungen

- The Fabric of Paper Machine PerformanceDokument4 SeitenThe Fabric of Paper Machine Performancest7167Noch keine Bewertungen

- 2 Wire Fourdrinier Type Paper Machine For The Production of Corrugated Base Kraft Paper Width 2550mm PDFDokument35 Seiten2 Wire Fourdrinier Type Paper Machine For The Production of Corrugated Base Kraft Paper Width 2550mm PDFRahmath0% (1)

- Cleaning Forming FabricsDokument8 SeitenCleaning Forming Fabricsismail 811Noch keine Bewertungen

- Tappi 0502 17 Papermaker Formula PDFDokument19 SeitenTappi 0502 17 Papermaker Formula PDFHgagselim SelimNoch keine Bewertungen

- Chevron Lummus Global Ebullated Bed Bottom-Of-The-Barrel Hydroconversion (Lc-Fining) ProcessDokument18 SeitenChevron Lummus Global Ebullated Bed Bottom-Of-The-Barrel Hydroconversion (Lc-Fining) ProcessBharavi K SNoch keine Bewertungen

- Sulzer Pumps For Paper IndustryDokument4 SeitenSulzer Pumps For Paper IndustryBapu612345Noch keine Bewertungen

- TAPPI TIP0404-01 Calculo de Remocion de Agua en PrensasDokument8 SeitenTAPPI TIP0404-01 Calculo de Remocion de Agua en PrensasJean DiasNoch keine Bewertungen

- Paper Making Vacuum 3Dokument7 SeitenPaper Making Vacuum 3Santosh PoddarNoch keine Bewertungen

- Estimating Paper Machine CD Shrinkage Profiles From Headbox Actuator Data PDFDokument6 SeitenEstimating Paper Machine CD Shrinkage Profiles From Headbox Actuator Data PDFBiantoroKunartoNoch keine Bewertungen

- New Developments in Paper and Board DryingDokument10 SeitenNew Developments in Paper and Board DryingSahil DesaiNoch keine Bewertungen

- Toscotec - Pratical Applications For Energy Consumption ReductionDokument7 SeitenToscotec - Pratical Applications For Energy Consumption ReductionKoushik MadapatiNoch keine Bewertungen

- Modelo Doble Helice Watson y CrickDokument2 SeitenModelo Doble Helice Watson y Crickangelferp100% (2)

- 1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivDokument8 Seiten1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivelcarpaneziNoch keine Bewertungen

- Optical Properties in Papermaking: Pele OyDokument60 SeitenOptical Properties in Papermaking: Pele OyjjccmmaaNoch keine Bewertungen

- 1998 Lumiainen Ch4 PDFDokument59 Seiten1998 Lumiainen Ch4 PDFAnonymous K3FaYFlNoch keine Bewertungen

- Productos Andritz PDFDokument57 SeitenProductos Andritz PDFLUCERO VILLAMIL FRANCONoch keine Bewertungen

- Paper and Board Manufacture and Properties WorkshopDokument99 SeitenPaper and Board Manufacture and Properties WorkshopJJGNoch keine Bewertungen

- Optimization of Wire Vacuum by D K SinghalDokument7 SeitenOptimization of Wire Vacuum by D K SinghalnazeerNoch keine Bewertungen

- 15.quality Control System For Paper Machines (Read-Only) (Compatibility Mode)Dokument19 Seiten15.quality Control System For Paper Machines (Read-Only) (Compatibility Mode)Sudhakara RaoNoch keine Bewertungen

- FRIM Centrifugal CleanersDokument12 SeitenFRIM Centrifugal CleanersKristin WeberNoch keine Bewertungen

- Paper Fan PumpsDokument8 SeitenPaper Fan PumpsnazeerNoch keine Bewertungen

- Metering Size PressDokument22 SeitenMetering Size PressDaud ZamanNoch keine Bewertungen

- Shoe PressDokument4 SeitenShoe Presssushil kumar0% (1)

- Sealencer The Silent Suction Roll Design: Voith PaperDokument2 SeitenSealencer The Silent Suction Roll Design: Voith PapersakarisoNoch keine Bewertungen

- Vapour Pressure DataDokument44 SeitenVapour Pressure Dataramsrivatsan50% (2)

- Scope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Dokument6 SeitenScope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Samsung KzoomNoch keine Bewertungen

- 120 TPD Karft Paper MachineDokument32 Seiten120 TPD Karft Paper MachineYonas Mulu100% (1)

- t580 D 3 Sarg With Editorial Corrections IncorporatedDokument8 Seitent580 D 3 Sarg With Editorial Corrections IncorporatedRaNoch keine Bewertungen

- Fiber and Pulp Properties For Papermaking: Pekka KomulainenDokument35 SeitenFiber and Pulp Properties For Papermaking: Pekka KomulainenjjccmmaaNoch keine Bewertungen

- Introduction:-: Lars Nilsson.Dokument18 SeitenIntroduction:-: Lars Nilsson.Bharat PatilNoch keine Bewertungen

- Ecoflow FDokument1 SeiteEcoflow FPiotr SokolińskiNoch keine Bewertungen

- Rethinking Barometric LegsDokument25 SeitenRethinking Barometric LegsLeomar Pcheco100% (1)

- PIONEER Wet End Automation Training Material enDokument617 SeitenPIONEER Wet End Automation Training Material enRishikishore ReddyNoch keine Bewertungen

- TMX-Agitator Instruction Manual ENDokument84 SeitenTMX-Agitator Instruction Manual ENamitNoch keine Bewertungen

- Kraft process of pulping A Complete Guide - 2019 EditionVon EverandKraft process of pulping A Complete Guide - 2019 EditionNoch keine Bewertungen

- Bobbin Filters - Instructions and Operation ManualDokument37 SeitenBobbin Filters - Instructions and Operation Manual8nqm4p3veNoch keine Bewertungen

- 30-36 Filter ManualDokument10 Seiten30-36 Filter ManualDavid RodriguezNoch keine Bewertungen

- Edwin EmulsificationDokument3 SeitenEdwin EmulsificationDaniel LieNoch keine Bewertungen

- Material Safety Data Sheet U.S. Department of Labor: Section IDokument2 SeitenMaterial Safety Data Sheet U.S. Department of Labor: Section IDaniel LieNoch keine Bewertungen

- PSV Calculation Report - 2-Phase - Direct Method Sizing CaseDokument1 SeitePSV Calculation Report - 2-Phase - Direct Method Sizing CaseDaniel LieNoch keine Bewertungen

- PRD Calculation Report - Fire Load CaseDokument1 SeitePRD Calculation Report - Fire Load CaseDaniel LieNoch keine Bewertungen

- 2 ChlorobutaneDokument5 Seiten2 ChlorobutaneDaniel LieNoch keine Bewertungen

- Grands Evenements - EnglDokument14 SeitenGrands Evenements - EnglDaniel LieNoch keine Bewertungen

- Goal Seek 2Dokument1 SeiteGoal Seek 2Daniel LieNoch keine Bewertungen

- Implementation XBar-R ChartDokument10 SeitenImplementation XBar-R ChartDaniel LieNoch keine Bewertungen

- 2.c.5.a Copper Production GB2009Dokument20 Seiten2.c.5.a Copper Production GB2009Daniel LieNoch keine Bewertungen

- LucasDokument1 SeiteLucasDaniel LieNoch keine Bewertungen

- How Clothing Evolves: Daniel-XII IPA 3-7Dokument4 SeitenHow Clothing Evolves: Daniel-XII IPA 3-7Daniel LieNoch keine Bewertungen

- Imr Chart Example: Viscosity of Initial 20 Batches of Aircraft Primer PaintDokument2 SeitenImr Chart Example: Viscosity of Initial 20 Batches of Aircraft Primer PaintDaniel LieNoch keine Bewertungen

- Ekstraksi Senyawa Organik Asam, Basa, NetralDokument6 SeitenEkstraksi Senyawa Organik Asam, Basa, NetralDaniel LieNoch keine Bewertungen

- Log Portrait Letter 0x1Dokument1 SeiteLog Portrait Letter 0x1Daniel LieNoch keine Bewertungen

- NUS Math SyllabusDokument11 SeitenNUS Math SyllabusAgus LeonardiNoch keine Bewertungen

- Experiment PDFDokument4 SeitenExperiment PDFDaniel LieNoch keine Bewertungen

- DI Bio GMP Education ITB Apr 01 2014Dokument50 SeitenDI Bio GMP Education ITB Apr 01 2014Daniel LieNoch keine Bewertungen

- Blanco 1989 JoCEDokument3 SeitenBlanco 1989 JoCEDaniel LieNoch keine Bewertungen

- Vertical Termosyphon Reboiler: Light Naphtha (XDokument1 SeiteVertical Termosyphon Reboiler: Light Naphtha (XDaniel LieNoch keine Bewertungen

- 5 - I - C - Finding Laplace Transform Examples IIDokument2 Seiten5 - I - C - Finding Laplace Transform Examples IIDaniel LieNoch keine Bewertungen

- Enthalpy of Vaporization LabDokument5 SeitenEnthalpy of Vaporization LabDaniel LieNoch keine Bewertungen

- M.S - C P I E F: Name First Name Student Number SignatureDokument6 SeitenM.S - C P I E F: Name First Name Student Number SignatureDaniel LieNoch keine Bewertungen

- Aluminum Alkyl HalidesDokument6 SeitenAluminum Alkyl HalidesDaniel LieNoch keine Bewertungen

- Postgraduate Prospectus For 2014 EntryDokument296 SeitenPostgraduate Prospectus For 2014 EntryDaniel LieNoch keine Bewertungen

- Lanjutan FileDokument14 SeitenLanjutan FileavcjhavcjkvakxNoch keine Bewertungen

- Technical DocumentsDokument3 SeitenTechnical DocumentsRaluca MutuNoch keine Bewertungen

- Manual Intruction BathycorrometerDokument12 SeitenManual Intruction BathycorrometerIwan ChurniawanNoch keine Bewertungen

- Troubleshooting The ETR Full Protective System (OP, WT, OS)Dokument14 SeitenTroubleshooting The ETR Full Protective System (OP, WT, OS)Richard ChuaNoch keine Bewertungen

- Molded Case Circuit Breakers Vol04 - Tab02Dokument432 SeitenMolded Case Circuit Breakers Vol04 - Tab02susanalopzNoch keine Bewertungen

- Av en Valves PDFDokument246 SeitenAv en Valves PDFWahyuNoch keine Bewertungen

- 938H Series Spec Sheet PDFDokument24 Seiten938H Series Spec Sheet PDFLeandro SalNoch keine Bewertungen

- 141 000 Mi CN MST 0089Dokument33 Seiten141 000 Mi CN MST 0089Mehmet AtabayNoch keine Bewertungen

- Crane & Grab PMSDokument8 SeitenCrane & Grab PMSSukhvinder SinghNoch keine Bewertungen

- AEA-Pipe FitingDokument10 SeitenAEA-Pipe Fitingdechi MartinezNoch keine Bewertungen

- Thermal and Mechanical Analysis of Nylon 6 and Nylon 66 BlendsDokument96 SeitenThermal and Mechanical Analysis of Nylon 6 and Nylon 66 BlendsHung VuNoch keine Bewertungen

- Ipg 2016 Investor Day PresentationDokument122 SeitenIpg 2016 Investor Day PresentationyaacovNoch keine Bewertungen

- IS 3513 (Part-3) 1989Dokument15 SeitenIS 3513 (Part-3) 1989Asian Test EquipmentsNoch keine Bewertungen

- Biopolymers of Microbial Origins PDFDokument4 SeitenBiopolymers of Microbial Origins PDFManish SoniNoch keine Bewertungen

- Bowie - Pump Maintence ManualDokument36 SeitenBowie - Pump Maintence ManualThiago OliveiraNoch keine Bewertungen

- 3D Printed Desktop CNC Mill: Technology Workshop Living Food Play OutsideDokument13 Seiten3D Printed Desktop CNC Mill: Technology Workshop Living Food Play OutsideMladen PorubovicNoch keine Bewertungen

- AEC Air Eraser Parts ListDokument2 SeitenAEC Air Eraser Parts Listspaced_boyNoch keine Bewertungen

- 1KS 52771 en PDFDokument2 Seiten1KS 52771 en PDFbebeNoch keine Bewertungen

- Linear Drying Shrinkage of Concrete Masonry Units: Standard Test Method ForDokument6 SeitenLinear Drying Shrinkage of Concrete Masonry Units: Standard Test Method ForSalim ChahidNoch keine Bewertungen

- Manufacture of Alum PDFDokument450 SeitenManufacture of Alum PDFKimberly ConleyNoch keine Bewertungen

- 10.6 Schedule of Accreditation: Product Certification Body Accreditation No. APC0002Dokument16 Seiten10.6 Schedule of Accreditation: Product Certification Body Accreditation No. APC0002erwerwerwerwewNoch keine Bewertungen

- Hipon 20 DechloDokument3 SeitenHipon 20 DechloLopez GardoNoch keine Bewertungen