Beruflich Dokumente

Kultur Dokumente

Tracks & Treads Summer 2014

Hochgeladen von

Venture PublishingCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tracks & Treads Summer 2014

Hochgeladen von

Venture PublishingCopyright:

Verfügbare Formate

Northern

EXPOSURE

*Program applies to select Cat Excavators (312E, 314E, 316E, 318E, 320D, 320E, 321D, 324E, 326F, 328D, 329E, 329F, 335F, 336F, 349E). See your Finning Sales Representative or visit fnning.ca for Finning Fuel Guarantee,Guaranteed

Machine Delivery Date, Great Prices and Competitive Financing details. Finance programs may vary over promotion period. Demo program available at select Finning branches. Promotion runs from January 1, 2014 to December 31, 2014.

000TT-Finning-FP.indd 1 2014-06-10 9:03 AM

On a Roll

How a family-owned logging

rm in Dawson Creek is making

a go of it in Gas Country

Ice Road Truckers

The Tibbitt to Contwoyto

ice highway is in it for

the long haul

A year-round highway

stretching from Inuvik to

Tuktoyaktuk will open up

the northern NWT

SUMMER 2014

A FINNING CANADA PUBLICATION PM #40020055 www.nning.ca

H

o

c

k

e

y

fa

n

s

s

c

o

re

s

ta

r

tre

a

tm

e

n

t

T&T_Summer_14_p01-32.indd 1 2014-06-19 2:15 PM

Get 0% interest for 48 months fnancing on the purchase of a NEW Cat compact machine, which includes Cat Skid Steer Loaders (216, 226, 236, 246, 252, 256, 262, 272), Cat Compact Wheel Loaders(906-914), Mini Excavators (303.5 - 308), Cat Backhoe Loaders, Cat

Multi Terrain Loaders (257, 277, 287), Cat Compact Track Loaders (259, 279, 289, 299), Cat Mini Excavators (Under 3 ton), Cat Small Wheel Loaders (924-938) and Cat Small Track Type Tractors (D3-D5K). Offer does not include Cat Telehandlers. Offer valid from July 1,

2014 to September 30, 2014 on select new Cat Compact Machines. Offer available only at participating Cat Dealers. Flexible payment terms available. Offer is available to customers in Canada only and cannot be combined with any other offers. Financing and

published rate are subject to credit approval through Cat Financial. Offer is subject to machine availability and may change without prior notice. Additional terms and conditions may apply.

FOR 48

MONTHS

*

Turn up the heat and contact your local Finning sales representative today.

*Only until September 30, 2014

ON SELECT CAT

SKID STEER LOADERS, COMPACT WHEEL

LOADERS, MINI EXCAVATORS, BACKHOE LOADERS, MULTI

TERRAIN LOADERS, COMPACT TRACK LOADERS, SMALL

WHEEL LOADERS AND SMALL TRACK TYPE TRACTORS.

Days are long but time is short.

Count on Finning to have the right

machines, parts and service to

keep you going this summer.

000TT-Finning-FP.indd 1 2014-06-10 9:02 AM T&T_Summer_14_p02-03.indd 2 2014-06-19 2:17 PM

Get 0% interest for 48 months fnancing on the purchase of a NEW Cat compact machine, which includes Cat Skid Steer Loaders (216, 226, 236, 246, 252, 256, 262, 272), Cat Compact Wheel Loaders(906-914), Mini Excavators (303.5 - 308), Cat Backhoe Loaders, Cat

Multi Terrain Loaders (257, 277, 287), Cat Compact Track Loaders (259, 279, 289, 299), Cat Mini Excavators (Under 3 ton), Cat Small Wheel Loaders (924-938) and Cat Small Track Type Tractors (D3-D5K). Offer does not include Cat Telehandlers. Offer valid from July 1,

2014 to September 30, 2014 on select new Cat Compact Machines. Offer available only at participating Cat Dealers. Flexible payment terms available. Offer is available to customers in Canada only and cannot be combined with any other offers. Financing and

published rate are subject to credit approval through Cat Financial. Offer is subject to machine availability and may change without prior notice. Additional terms and conditions may apply.

FOR 48

MONTHS

*

Turn up the heat and contact your local Finning sales representative today.

*Only until September 30, 2014

ON SELECT CAT

SKID STEER LOADERS, COMPACT WHEEL

LOADERS, MINI EXCAVATORS, BACKHOE LOADERS, MULTI

TERRAIN LOADERS, COMPACT TRACK LOADERS, SMALL

WHEEL LOADERS AND SMALL TRACK TYPE TRACTORS.

Days are long but time is short.

Count on Finning to have the right

machines, parts and service to

keep you going this summer.

000TT-Finning-FP.indd 1 2014-06-10 9:02 AM

On the Cover

Caterpillar equipment is behind

the building of a two-lane highway

connecting Tuktoyaktuk and Inuvik.

Photo copyright Tawna Brown.

Summer 14 Contents

14 Full Speed Ahead

Te Mackenzie Valley Highway will nally

connect Inuvik and Tuktoyaktuk all year long

18 Northwest Passage

Te seasonal highway between Tibbitt

and Contwoyto lakes is the worlds longest

heavy-haul winter road

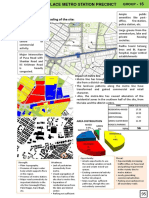

20 New Hub of the North

Finnings Yellowknife branch is lling

a void in northern NWT

25 Mission Possible

Finning employees gain as much as they

give, while donating time to a community

outreach centre

26 Loggers in Gasland

Te Bassett brothers proudly maintain

a third-generation logging rm in

ever-changing Dawson Creek

25

18

Columns & Departments

4 Finning Focus

A word from Finning

5 Letter to the Editor

6 Groundbreaker

A life-size Jenga game; CNC honours one

of Finnings own; Fox Creek fundraiser;

E series tested; Hockey Night in Edmonton;

Lethbridge ground breaking; Helping Habitat

10 By the Numbers

11 Yesterday & Today

Most vehicles are easy to steer, but that

wasnt always the case with crawler tractors

12 Operators Tips

To step up productivity, step aside

13 Managers Tips

Managing y-in workers is easier with

planning, selective hiring and training

22 Service Spotlight

Customers know technology is at the leading

edge in the downtime war

23 Safety First

Near misses are serious business

24 Tech Spotlight

Finning technology day in Surrey

28 Portrait

Meet Chad Besuyen

29 Phils Business

Tools of the trade geared at the North

30 Count on Us

14

26

www.nning.ca 3 Summer 2014

T&T_Summer_14_p02-03.indd 3 2014-06-19 2:17 PM

BY HILARY ANAKA,

FINNING EDITOR

Lethbridge branch celebrates 14 years without a lost-time injury

My job takes me to many interesting places and

events, but visiting our Finning branches has to be

one of my favourite things to do. A few months ago,

I had the opportunity to attend a safety celebration at

our Lethbridge branch.

Tis celebration was a special one for a couple of

reasons. First, they were celebrating an impressive

14 years without a lost-time injury and second, they

were inviting employees families to the celebration

something Id never heard of before.

In talking with Lethbridge branch manager Brent

McDowell before the event, he explained that the in-

clusion of family members was nothing new for them

and a natural move, given the family culture they

had within the branch. He said, Our safety culture

is something we take home with us and thats why we

invite family members, friends and past employees.

Were safe so we can go home to our loved ones and

friends.

So I hit the road for Lethbridge and was thrilled to

be a part of the celebration. While I was there I had

the chance to talk to Lana Caldwell, product support

sales rep Abe Caldwells spouse, about what it means

to her that Abe works for a safety-conscious compa-

ny. She told me, Its reassuring because you know

theyre doing everything possible every day to keep

their employees safe and to ensure theyre going to

come home every night to spend their time with the

family. Teir adorable young son, Jaxon, nodded in

agreement with his mom.

After spending a couple days in the branch and

talking to employees from dierent areas, it was

clear that the Lethbridge crew thought of themselves

as a family and took care of each other like a family.

Tey believe, and so do I, that its that family attitude

that got them to 14 years without a lost-time injury.

Noel Hill, Finnings general manager of health and

safety, said: Safety performances like Lethbridges

prove that dangerous work doesnt have to be un-safe

work. On page 23 of this issue of Tracks & Treads,

Hill expands on that idea and talks about the risk

pyramid and how reporting near-misses and pre-

venting less-severe incidents decreases the number

of serious injuries or fatalities. If that isnt incentive

to change the small things like a bumpy entry rug or

clutter in the shop, I dont know what is.

Making Safety a

Family Matter

www.nning.ca 4 Summer 2014 tracks & treads

T&T_Summer_14_p04-05.indd 4 2014-06-20 10:26 AM

FROM THE ARCHIVES:

A postcard of the original Caterpillar factory in Peoria, Illinois.

SUMMER 2014 Volume 55, No. 2

PUBLISHER

Ruth Kelly

rkelly@venturepublishing.ca

FINNING EDITOR

Hilary Anaka

hanaka@nning.ca

DIRECTOR OF CUSTOM CONTENT

Mi Purvis

mpurvis@venturepublishing.ca

EDITOR

Shelley Williamson

swilliamson@venturepublishing.ca

EDITORIAL ADVISORS

Jeff Howard,

Michelle Loewen

ART DIRECTOR

Charles Burke

cburke@venturepublishing.ca

ASSOCIATE ART DIRECTOR

Andrea deBoer

ASSOCIATE ART DIRECTOR

Colin Spence

PRODUCTION COORDINATOR

Betty Feniak Smith

PRODUCTION TECHNICIANS

Brent Felzien,

Brandon Hoover

CIRCULATION COORDINATOR

Karen Reilly

circulation@venturepublishing.ca

ADVERTISING REPRESENTATIVE

Anita McGillis

amcgillis@venturepublishing.ca

CONTRIBUTING WRITERS

Robin Brunet, Caitlin Crawshaw, David DiCenzo,

Martin Dover, Lucy Haines, Robbie Jeffrey, Nomi LoPinto,

Christy Nich, Cory Schachtel

CONTRIBUTING PHOTOGRAPHERS AND ILLUSTRATORS

Tawna Brown, Amie Contact, Heff O'Reilley,

Aaron Pedersen, Joey Podlubny

Tracks & Treads is published to provide its readers with

relevant business, technology, product and service

information in a lively and engaging manner.

Tracks & Treads is published for

Finning Canada by

Venture Publishing Inc.

10259-105 Street

Edmonton, Alberta T5J 1E3

Phone: 780-990-0839

Fax: 780-425-4921

Contents 2014 by Finning Canada. No part of this publication

should be reproduced without written permission.

www.finning.ca

Tell us what you think

Tracks & Treads would love to hear from you. Tell us what you think

of the magazines stories, columns and look, so that we can improve

it and make it a more interesting read.

Send your comments to editor-in-chief Hilary Anaka by email at

hanaka@nning.ca or the old-fashioned way to: Hilary Anaka, Tracks & Treads,

Finning Canada, 16830 107 Avenue, Edmonton, Alberta T5P 4C3

PM #40020055

A CAREFUL READER:

Sidney Anderson, 87, of Richmond B.C., has an eagle eye. He called us

to let us know that a story in a recent issue of T&T referred to a pump

motor. It should have read pup motor, so named for its small size.

Sometimes they were called pony motors, Sid explained. He should

know. He was a eld service rep for Finning for 25 years, assigned to

major projects in Vancouver in the 1960s.

Well-spotted Sid, and thanks!

- Tracks & Treads Editor

Letters & Feedback

www.nning.ca 5 Summer 2014

T&T_Summer_14_p04-05.indd 5 2014-06-19 2:18 PM

www.nning.ca 6 Summer 2014 tracks & treads

By David DiCenzo

Caterpillar is getting into the movie

business. Short lms, to be exact.

Stack is the rst in a series of shorts in the

Built For It Trials, a collection showing what Cat

machines, and their capable operators, can do.

Stack features ve models (the 320E,

TH514C, 277D, M316D and 349E), run by

operators that total 121 years of experience, in

a real-life game of Jenga. The massive blocks

of wood weigh more than 600 pounds each

Jenga in Real Life

and are carefully arranged just like in the traditional game but only on a much

larger scale. And also like the real game, it comes to its inevitable conclusion when

the blocks all tumble down.

In total, the pieces of wood used in Stack weighed an astonishing eight tons.

They were rubbed down with about 72 cans worth of shufeboard wax to help

them slide into position better. And the operators, despite their extensive experi-

ence, admitted to being nervous before the game began.

It took about 28 hours to complete the game, but Stack is only a few minutes

long. Watch it at: www.cat.com/en_US/articles/customer-stories/the-

ultimate-challengeisoninstack.html

T&T_Summer_14_p06-11.indd 6 2014-06-20 10:27 AM

www.nning.ca 7 Summer 2014

NEW DIGS: Lethbridge Colleges future centre for trades and technology ofcially

broke ground on April 24. With some pointers from Lyndon Wincheruk of Finning,

Alberta Premier Dave Hancock helmed the 312EL to do groundbreaking honours.

The building is expected to usher in its rst students in the fall of 2017.

Welcome back, Broster!

Cody Broster hasnt forgotten his roots. The 30-year-old B.C. native

got his start at Finning back in 2004, after graduating from the College of

New Caledonia, where he studied both business and as a pre-apprentice

machinist. Ten years later, Broster is entrenched as the customer service

manager at Finnings Prince George branch. While meeting the needs of cus-

tomers in the region is top priority, he has also remained loyal to the school

that gave him the foundation for his career.

Brosters close relationship with CNC and the students learning their

trades there earned him the prestigious Presidents Industry Council Award

late last year.

It was really nice to receive this award, says Broster. I enjoy working

with the college and the partnership weve formed between Finning

and them. Its great to give back and see these kids coming through the

programs.

Broster is a member of the Presidents Council and has devoted time to

helping CNC since he left in 2004. He was instrumental in developing the

machinist program for levels one through four at the schools Prince

George campus.

Broster still does shop tours for students and talks with classes about

his experiences. But the award itself was given for his work maintaining a

partnership between Finning and CNC. He says he was happy to help CNC

through the purchase of some Cat equipment for the program, a 259 skid

steer, a 312 excavator and a D4K small dozer.

Broster has also contributed to the pipeline

between the school and Finning, where grads

have landed jobs leading to apprenticeships.

Broster says its gratifying to see young, energetic

workers get their start, but he understands this is

also critical to the future of the industry. Theres

a huge decit for tradespeople, especially in

Northern B.C., Broster explains. We wont

be able to meet the demands if we dont train

these kids.

Brosters history with the school and Finning

made him the perfect choice. Part of our

success, especially in trades training, is our ability

to collaborate with industry to ensure their needs

are being met and our students are receiving

the best, most relevant training possible, CNCs

executive director of external relations, Randall

Heidt, said at the award presentation. People

like Cody are invaluable to us and are excellent

corporate partners who really want to constantly

improve trades training in northern B.C.

T&T_Summer_14_p06-11.indd 7 2014-06-19 2:23 PM

www.nning.ca 8 Summer 2014 tracks & treads

Quality equipment and unmatched service

have been at the very root of Finnings success as

Western Canadas Caterpillar supplier. But those

customers in the market for an excavator will nd

that the best has gotten even better.

Finning has a new motto for those customers in

2014: Put Us to the Test.

The whole idea is that we want to put more

belief in the customer, says Garry Hadley,

Finnings excavator marketing manager based in

Edmonton. The new E series excavators are world

class. They are number one in the world. The way

to prove that is to put us to the test; take it out

and try it, says Hadley. The program, applicable

to select E series excavators, incorporates a huge

commitment to fuel consumption, a promise on

a machines delivery date and a try-before-you-

buy demo program thats already a big hit

with customers.

Finning guarantees that newly purchased

E series excavators (without special modications)

will be delivered within 14 days of the companys

receipt of a signed order and nance approval.

If not, a $2,000 parts and service credit will be

applied to the customers account.

Already boasting the most fuel-efcient

machines on the market, Hadley says Finning is

now also guaranteeing that annual fuel consump-

tion will not exceed the stated gure provided to

the customer at the time of delivery, covering a

one-year term. If the gure is exceeded, Finning

will issue a parts-and-service credit to the account

that represents the difference between what was

E Series Gets Tested

stated and the actual fuel consumed, based on a calculated rate of $1 per litre.

The fuel commitment has really caught their eye, Hadley says. Theyre

seeing an incredible number as to what their fuel efciency can be. It allows our

sales guys to go in with condence, knowing that we truly are world class in fuel

economy and efciency.

The demo component allows customers the opportunity to test run an

excavator and see rst-hand the many changes made to E series machines: cabs

redesigned for improved comfort; Isochronous engine speed control; increased

horsepower; electronic boom regeneration; T4 Interim Solution after-burner treat-

ment; and 2D grade control that is ideal for earthmoving contractors to improve

productivity and protability by using an angle sensor, dual axis sensor and laser

catcher to measure the relationship between the body, boom, stick and bucket.

Jim Thiessen describes Fox Creek, Alberta,

very matter-of-factly. Its in the middle of

nowhere, says Thiessen, purchasing manager at

Marnevic Construction.

Its true. Tucked along Highway 43, about 260

kilometres northwest of Edmonton, the small town

of about 2,000 people doesnt have much going

on around it. Thats why its so important for the

prominent members of the community to do

their part.

Marnevic Construction is one of them. Twice

a year, at a spring barbecue and at a special

Christmas event, Thiessen rafes and auctions off

merchandise graciously donated by any individuals,

employees and businesses willing to chip in. The

Fundraiser Puts Fox Creek on the Map

funds raised go to support causes like womens shelters or kids playground

construction. Whatever organization is in need at that time determines where

money is used.

We hit a record $3,683 raised from the Christmas event this past year,

Thiessen says. All of those funds were donated to the Fox Creek Minor Sports

Association.

Thiessen took over the fundraisers about eight years ago and has a knack

for it, getting major suppliers on board who gladly donate items some pretty

strange, albeit very useful. We get everything you could possibly imagine from

kitchen wares to clothing to tools, he says. One supplier donated a log splitter,

which was pretty neat. It surprises me a little every year.

To show its gratitude, Marnevic regularly takes out an ad in the newspaper

acknowledging contributors. All of the funds stay here in Fox Creek, Thiessen

says. Its really important in an isolated community like this because it shows

which businesses are willing to support the town.

T&T_Summer_14_p06-11.indd 8 2014-06-19 2:23 PM

www.nning.ca 9 Summer 2014

about hunger in the city. We wanted to make a difference.

The CBC Edmonton Turkey Drive Advisory Council was born. Hilary Anaka,

team lead of external relations at Finning (and Tracks & Treads editor) joined the

council. Piercey says that the HNIC package idea grew organically and quickly.

Mark Connollys brother Brendan is part owner at Ruths Chris, so the food was

covered. John Chwyl, in charge of marketing at Kingsway Mall, chipped in the

gift certicates. Richard Wong, vice-president of Chateau Lacombe, was keen

to offer a couple of rooms once the ball got rolling. Finally, Don Metz of Aquila

Productions instantly agreed to allow the winners behind-the-scenes access for

a full game-day experience at Rexall Place.

The whole package was sorted out in 48 hours, says Piercey.

Edmonton is home to the largest Habitat for Humanity afliate

in all of Canada. In 2013 alone, Habitat built 83 homes in Edmonton and

northern Alberta.

Thats a lot of product to move to sites, says Brenda Netter, of

HFHs Edmonton branch. Netter and her organization got a big boost

on that front for 2014. In need of some help, she reached out to the

Cat Rental Store and was able to secure a massive 10-foot by 30-foot

snowmobile trailer to borrow this year. Its a great asset to move

material and smaller landscaping equipment, Netter says. It helps us

be much more mobile in the delivery of our program. We put it to use

the day we got it.

Rhett Nickerson of the Cat Rental Store was also eager to oblige. We

happened to have a trailer that t the bill here in the Edmonton yard,

says Nickerson. Habitat for Humanity is a great organization. We have

the tools and we are happy to assist. Whenever an organization that

helps the community is in need, we absolutely want to help.

Hockey Night in Edmonton

For fans of the Edmonton Oilers, March 22,

2014, was a day to forget. The Oil not only lost

that edition of the Battle of Alberta to the hated

Calgary Flames but also got pummelled in an 8-1

thrashing that will take some time to shake off.

Regardless of the result, the Finning quartet

of Kurtis Lunn, Julie Fisher, Teddy and Lars Harpe

will have a very unique recollection of that night.

Lunn and his friends manufactured a winning

bid of $4,000 in an auction for a behind-the-

scenes Hockey Night in Canada (HNIC) package,

where they got to experience the game, and its

production, in a manner known to few. After

Finning equalled the bid, a total of $8,000 went

directly to the Edmonton Food Bank.

The HNIC package was impressive. CBCs Mark

Connolly hosted the foursome at Ruths Chris

Steak House for a pre-game meal. They also

enjoyed great seats for the Battle of Alberta, got a

VIP tour of the Rexall Place press box, CBC control

room and an up-close view of After Hours as

Scott Oake and Kelly Hrudey did their post-game

work. The group also enjoyed a two-night stay at

Edmontons Chateau Lacombe, and received gift

cards from Kingsway Mall. While it sounds like

a prize that was months in the making, it took a

mere two days.

CBC has an annual fundraiser for the Food

Bank, but last year we did something innovative,

says Judy Piercey, managing director of CBC. We

pulled together stakeholders, business, community

and civic leaders. We wanted to raise awareness

A Hand Up for Habitat

ICE TIME: From left, Julie Fisher and Kurtis Lunn are

joined by Lars Harpe, Teddy Harpe and CBC host

Scott Oake on their winning night at Rexall.

T&T_Summer_14_p06-11.indd 9 2014-06-20 10:27 AM

www.nning.ca 10 Summer 2014 tracks & treads

20,000

By the Numbers

-63 C

The year of completion for the Alaska Highway,

the main roadway connecting Alaska, Yukon,

and British Columbia

1942

3.5 million

The number of

square kilometres

comprising the

three northern

territories. The area

covers 40 per cent

of Canadas total

land mass

28

The number of

communities

in Nunavut

The percentage of

Canadians who live in

the northern territories

0.3

The population of the Northwest Territories remaining

after the division of the Northwest Territories into

Nunavut and Northwest Territories, in 1999

The vacancy rate in

Whitehorse.

1.4

The coldest recorded

temperature, in Snag,

Yukon (1947) The average price of a condominium in Iqaluit

$382,359

The number of years that people have lived in

Canadas North

T&T_Summer_14_p06-11.indd 10 2014-06-19 2:23 PM

would cause the track on that side to freewheel, resulting

in the machine turning to the right instead of to the left.

Te opposite eect would occur when travelling on level

or uphill grades.

After decades of tractor steering with the two-lever,

two-pedal system, Caterpillar introduced hand-lever

steering on its D8K tractor in 1974. Independent clutches

and brakes were still used, but the same lever activated

both. Partly pulling the lever would disengage the crawler

drive on one side; a further pull on the lever applied the

brake for a sharp turn. Both levers were worked by the

operators left hand, leaving his right hand to control

tractor implements, dozer or ripper.

In 1987, Caterpillar introduced its revolutionary

dierential steering system on its D8N tractor. Tis steering

method, now applied on all Caterpillars mid-size tractors

(D6T, D7E, D8T and D9T), is controlled by a single tiller-type

lever, and ensures power is divided equally to both tracks at

all times. Power is transmitted to the nal drives through

three planetaries. Te centre steering dierential can also

receive power through a bevel gear xed to its housing which

is rotated by a high-torque hydraulic motor. For straight-

ahead travel, this motor and the dierential housing are

stationary. When the operator moves the tiller lever to make a

turn, the hydraulic motor is actuated and the steering

dierential causes one track to slow down while the opposite

track speeds up an equal amount. Te tractor makes a

smooth turn without loss of power to either track.

Caterpillars small, nimble tractor line (D3K2, D4K2,

D5K2) now employs an electronic hydrostatic drive

system that allows turns under full power and a step-less

speed range. No dierential drive is needed, but as with

the mechanical system, steering and machine motions are

controlled by a single lever at the operators left hand.

However, Caterpillar continues to employ steering

clutches and brakes on its largest tractors (D10T and

D11T) as the most reliable steering type for that size of

tractor. Tese are electronically controlled by a pair of

short ngertip levers at the operators left hand console.

No matter which system is employed, the steering, speed

and direction of todays Caterpillar crawler tractors are

controlled by one hand a far cry from the array of heavy

multiple levers and pedals of yesterdays machines.

Most vehicles are steered with a steering wheel, and steering

to the left or to the right feels natural and automatic. Te same goes for

modern Caterpillar crawler tractors and, more recently, wheel loaders.

Steering these machines is just as simple, except it is performed entirely by

the operators left hand with a single joystick lever or, depending on the

model, short ngertip levers. Te same left-hand console also controls

speed and direction.

But steering of crawler

tractors wasnt always

that simple.

Until 1974, Caterpillar

tractors required two foot

pedals and two hand levers

to steer left or right. Te

system was very reliable and,

for the tractor operator,

became just as easy as using

a steering wheel. But the

controls were once not

power-assisted and gave the

operator quite a workout.

Left and right levers were

connected to clutches,

which disengaged the drive

to the respective left or right

crawler track, allowing it to

freewheel. As the track

slowed, it permitted the

tractor to make a gradual

turn in one direction. Te

right or left foot pedal

applied the brake to the

track for a sharp turn.

Te downside to this

system was that during a

turn, power to the inside

track was cut and the full

tractor power was applied

to the outside track.

Operators had to

remember that when going

downhill pulling the

left-hand clutch lever

Steering Trough

the Decades

Most vehicles are easy to steer, but that wasnt

always the case with crawler tractors

www.nning.ca 11 Summer 2014

BY KEITH HADDOCK

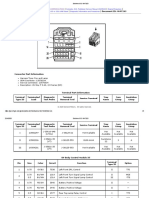

PROGRESS: Caterpillar introduced its revolutionary double

differential steering system on the D8N tractor in 1987. The

technology, now applied to all Cats mid-size tractors, is shown

in simplied form in the bottom sketch.

T&T_Summer_14_p06-11.indd 11 2014-06-19 2:23 PM

Tips

the material, fuel savings of up to 25 per cent can be achieved. Sliding material also

minimizes the wear and tear on the dozer.

Auto Carry is an optional feature for ensuring that your dozer maintains its opti-

mum pushing power, which relates to 10 to 15 per cent slippage. With sensors that

measure ground speed and track slippage, Auto Carry will guarantee there is no

undue wear and tear. Regardless of what part of the cycle the operator is in, Nunn

says, Auto Carry is going to optimize it, and it simply wont let you slip the tracks or

stall a torque convertor. Tese kinds of mistakes are costly, and they happen all too

often. Spinning tracks in a large dozer can chew up the undercarriage an expense

to be avoided at all costs.

Auto Rip is a new optional feature on large dozers that works best in consistent

materials. A lot like Auto Carry, the machine senses track slip, ground speed and

engine load, Nunn says. By letting the machine sense when the ripper needs to

be raised or lowered, the operator can focus on their surroundings. Auto Rip is

extremely ecient when ripping for scrapers or ripping in consistent soil types.

Far too often, operators dont position the shank for proper penetration at the be-

ginning of a cycle. Fortunately, Auto Ripper Stow takes the thought process out of it.

Te operator can pre-program the ripper to the position desired for the beginning

of the cycle. Te push of a button is all thats required, says Nunn, noting, Te

ripper will automatically raise and position the shank for initial penetration. When

the ripper is programmed to raise and shank out at the end of the cycle, it removes

all doubt as to where one will be when they return to the start position. Like the

Automatic Blade Assist, Auto Ripper Stow comes standard on all large dozers.

As an operator, you already know the power of your Cat machine, and you trust

it to deliver consistent, ecient work. With these automated features, you form

a partnership with your machine that not only makes evident your respect for

the bottom line but gives you command over your operation. Te work is always

changing this is how you stay in control.

To step up productivity, you may need to step aside and learn how to

make the most of Cat features

BY ROBBIE JEFFREY

Operation: Automation

As an operator, you are more than a master

of your machine. You know whats going on at all

times, what lies ahead, and how it all transpires. You

know that time is money and so is fuel, and that as an

operator, youre the rst and last line of defence against

redundancies and blunders. An operator doesnt just

operate a machine you guarantee that the entire

operation is a nely-tuned machine.

A dutiful operator keeps in mind a fundamental

goal: reduced cost per hour. Sometimes, the best way

to reduce this cost is to limit your interventions. Try

as you might, you cant do everything. Handing over

the reins to the automated features on your trusted

Cat machine frees you up to focus on other tasks that

streamline the operation.

Finnings Brad Nunn, application specialist for

Heavy Construction and Mining, steers you through

some of the automated features in Caterpillars large

track-type tractors. Proper use directly impacts an

owners bottom line, and that kind of reputation looks

good on an operator.

Automatic Blade Assist allows the operator to

preset the cut, carry and spread positions for the blade

pitch function on large tractors, Nunn explains. Tis

is done by setting the percentage of cylinder stroke for

each segment of the dozing cycle. Its crucial to load

the blade quickly, since this can use the most fuel dur-

ing the cycle. At the end of the cycle, the operator can

roll the blade forward to dump the material and not

have carry-back on the blade, and can cycle through

all the blade positions that he or she has preset for the

material being worked in.

Rolling the material takes a lot more energy than

sliding it, he continues. If the operator can load the

blade quickly and then pitch the blade back to carry

With these automated features,

you form a partnership with

your machine that not only

makes evident your respect for

the bottom line but gives you

command over your operation.

www.nning.ca 12 Summer 2014 tracks & treads

T&T_Summer_14_p12-13.indd 12 2014-06-20 10:28 AM

Bears are not uncommon, so Glacier Exploration also provides an awareness

course and bear spray to each employee. Moose are especially worrisome in the fall

and, of course, workers need to be aware of other animal dangers throughout the year.

To manage remote teams, good organizational and communication skills are very

much essential. Jud Overton, operations director for Finning in the oil sands, says its

important that you and your teams have a clear understanding of your customers

business and operational goals to allow in-depth planning for remote worksites.

Having a team with very high skills and the condence to make good decisions as

conditions can change quickly is a must. Remote worksites do not always have text-

book tooling or facilities, so workers have to make safety a top priority. As a manager,

you have to be able to coach, mentor and support your team when needed but if you

are managing from osite, this is sometimes very challenging. It has been my experi-

ence with employees that sign up for remote work that they truly enjoy the challenge

and personal accomplishment this work brings, says Overton.

Having the right team can make all the dierence, so its worth it to hire and make

sure employees are content with the work and the compensation package your com-

pany provides. Are your individual employees qualied, safety-conscious, ecient,

and well suited for remote work? Do they understand the goals and are they commit-

ted to help you accomplish them? If the answer is yes, then youve done your job, say

the experts. If not, its time to make the necessary improvements to change it into a

positive work environment for everyone.

BY CHRISTY NICH

Remote Control

Managing y-in workers is easier with advance planning,

and selective hiring and training

Youve been working in your industry for

years, know your job inside and out, but youve been

given a new challenge managing remote workers.

Where do you start?

One of the main concerns is hiring the right people

for the job. Every industry has its own standards and

qualications, so you have some choices on where to

begin based on your own companys requirements.

You can advertise via your company website (if you

have one), at any of the training institutions, or by word

of mouth. Maybe you require operators who have a

ticket to prove that they can handle heavy machinery,

or specialized professionals like plumbers or

pipetters. Tickets can be obtained by hands-on expe-

rience or through technical institutions, such as SAIT

Polytechnic or NAIT, which makes a campus recruiting

visit worth your while.

Potential employees may also require safety certica-

tion specic to your industry, like WHMIS or H2S Alive

training, as well as rst aid certication. Your company

may provide this or you may have a list of places where

new employees can obtain it.

Ten there are the personality traits that work best in

the eld. Mike Kennelly has been a seismic surveyor for

22 years and is currently working on the advance team as

a senior surveyor at Glacier Exploration Surveys Ltd. He

describes his work as contractors to look after the team

of other contractors while out in the eld. Hes been in

charge of sta and says the best personality types are not

typical of any other kind of day job. Employees need to

be diverse and exible since the working conditions are

extreme. You dont go home at the end of an eight-hour

day or on weekends, for that matter. In fact, you could

go months before you return home for a break.

Sta working remotely must be able to put up

with extreme climate changes. It gets cold out in the

bush and you cant go inside because its raining or

even pouring. Te ideal Glacier Exploration worker

needs to be physically t because he or she is scaling

steep hills or mountains, not hiking trails. Helicopters

take workers into and out of remote camps, so proper

heli-procedures also need to be followed. And because

workers are out in the wild, safety is the utmost concern.

As a manager, you have to be able to coach,

mentor and support your team when needed

but if you are managing from offsite, this is

sometimes very challenging.

www.nning.ca 13 Summer 2014

T&T_Summer_14_p12-13.indd 13 2014-06-20 10:29 AM

FULL SPEED

AHEAD

BY CAITLIN CRAWSHAW | PHOTOGRAPHY BY TAWNA BROWN

A

L

L

P

H

O

T

O

G

R

A

P

H

S

T

A

W

N

A

B

R

O

W

N

The Mackenzie Valley Highway will nally

connect Inuvik and Tuktoyaktuk all year long

www.nning.ca 14 Summer 2014 tracks & treads

T&T_Summer_14_p14-17.indd 14 2014-06-19 2:30 PM

n most places in Canada, summertime

is jokingly referred to as construction season,

since long, cold winters make outdoor roadwork

dicult. But in the North, its just the opposite:

the construction season cant start until mercury dips

well below zero.

You dont want to mess with the permafrost the

ground has to be frozen before you put a road on top

of it, explains Merven Gruben, vice-president and

co-owner of E. Grubens Transport Ltd. in Tuktoyaktuk.

You mess with that and you really screw up your foun-

dation and the base of the road.

Tats why the new Mackenzie Valley Highway pro-

ject broke ground in early January 2014, after a rib-

bon-cutting ceremony with Prime Minister Harper.

Te $300-million project will extend the Dempster Highway, which currently ends

in Inuvik, to the remote community of Tuktoyaktuk (known also as Tuk). Te

137-kilometre long, two-lane highway will be surfaced with gravel, allowing driv-

ers to reach speeds of up to 70 kilometres per hour more than twice as fast as the

ice road that the communities previously used during the wintertime.

Te highway expansion was long awaited by the community, explains Gruben,

whose company is building the road with Inuvik partner Northwind Industries.

During his six years as mayor of Tuk, he lobbied government agencies to have a

permanent road built an idea that was rst proposed in the 1960s.

Tis winter, the project nally ocially went ahead. Once E. Grubens Transport

Ltd. and Northwind Industries were awarded the contract, they had to move quickly

to gather the equipment theyd need to build the road before the ice road closure in

March. After examining bids from several of the biggest players in the market, they

picked Caterpillar iron. Tey have a proven record up here, says Gruben, noting

that the family-owned company has used Cat equipment since the 1970s.

I

www.nning.ca 15 Summer 2014

T&T_Summer_14_p14-17.indd 15 2014-06-19 2:30 PM

Te Coldest Journey

to bad weather, the U.S.-built equipment made its

way to Canadian Finning branches to be prepped for

shipping up North. Te vast majority of the machines

were prepared by Finnings Centre of Excellence

branch in Red Deer.

Once in Inuvik, Finning technicians faced an even

more challenging task, says Carter: Tey had to

assemble everything in -45Celsius. But for all of the

challenges, the equipment arrived on site before the

closure of the ice road. With the necessary equip-

ment, it was full-speed ahead until the end of the

winter season.

Slated for completion in 2018, the roadway will

be built in ts and starts. For the next three sea-

sons, the majority of the work will happen during

the coldest months of the year. Youre limited to

periods of time when the ground is frozen to haul

gravel, says Russell Newmark, CEO of E. Grubens

Transport Ltd. But while this is a big part of the

job, he stresses that some work can still be done in

summer months. At the moment, workers are com-

pacting and grading the road, adding signage, and

installing guardrails, for instance.

After the weather, the projects biggest challenge

will be labour. We need a lot of employees and were

trying to use all local people, says Kurt Wainman,

president and owner of Northwind Industries.

But he adds that the service contract was also

appealing, since Finning is the only heavy equipment

company with a location in the region. Tey wanted

a one-stop shop, says Finning sales rep Brendan

Carter. Cat customers in the area have access to

parts and technicians who can regularly service their

machinery an important consideration for northern

companies. Flying in parts from elsewhere is especial-

ly expensive so far north.

For the four-year project, E. Grubens Transport

Ltd. and Northwind Industries went with a compre-

hensive service package to protect their investment

of 63 pieces of equipment worth nearly $40 million,

including 30 articulated dump trucks (740Bs), six 349

excavators, three D10T tractors, and other equipment.

In the North, this was the largest single purchase of

Cat equipment ever, Carter says. Not in terms of the

money, but the number of machines.

Once the deal was signed, the real work began.

All the equipment had to be hauled up north from

Baltimore, Maryland, as well as Aurora, Illinois and

other locations in North America, before the ice road

closed. After being held up throughout the U.S. due

In the North, this was the largest single purchase

of Cat equipment ever, Brendan Carter says.

www.nning.ca 16 Summer 2014 tracks & treads

TIS THE SEASON: For the next three years, the majority of the road work

to the Mackenzie Valley Highway will have to be done during the winter.

T&T_Summer_14_p14-17.indd 16 2014-06-20 10:38 AM

Its been good, but its been a short season. Next

season will be ve or six months, so that will be a

bigger challenge. Tis year, about 140 workers were

involved in the roads construction, but this number

should jump to 240 in November and grow even

more next year.

Gruben has been anticipating the highway project

for years and says his company has been steadily hir-

ing and training workers in Tuk and neighbouring

northern communities for the last 15 to 20 years.

We have a lot of people with class-one and class-ve

driver training, mechanics, welders, a lot of appren-

tice training, he says.

While it may be more dicult in the short term

to deal with the labour crunch, the owners of both

companies agree that the long-term benets make

it worthwhile. For us, training locally will give us a

bigger pool of workers, says Wainman. Tis means

more skilled labour for future projects down the line.

Employing local people is also a good thing for the

community, he notes.

In fact, he thinks the highway has the potential to

create more opportunities for his company. We say,

Its a road to resources, Wainman explains, noting

that the highway will improve access to the oileld

and potentially encourage more economic activity

in the region. Theres a lot more hooked to the

road than the cost of groceries, he says.

Newmark agrees that the highway will transform

Tuk: Every aspect of life health care or recreation

improves when youre not isolated anymore. At the mo-

ment, getting to Inuvik to buy cheaper groceries or take

the kids swimming takes hours on the ice road. With a

permanent highway, families will be able to access

a wide range of services with just a 45-minute drive.

It opens up everything. For the community of Tuk,

its an incredible benet, he says.

And then there are the cost savings. Gruben points out

that a permanent road is a big investment, but its more

expensive for the community to build and maintain a new

ice road year after year. He would know: his company has

had the ice road contract for the last 20 years.

A permanent road will also be safer. Over the years,

Gruben has had some vehicles and the company's

loads fall through the ice. Te risk has become greater

because of warmer temperatures resulting from climate

change: Ive never gone through myself but Ive

gotten close. Ive had my foot on the battery box on a

couple of occasions, but never had to jump.

Every aspect of life health care or recreation

improves when youre not isolated anymore,

Russell Newmark says.

www.nning.ca 17 Summer 2014

RESOURCE ROAD: The new highway, when complete in 2018, will improve

access to the oileld and encourage more economic activity in the region.

T&T_Summer_14_p14-17.indd 17 2014-06-20 10:39 AM

STORY BY RICK OVERWATER

The seasonal highway between Tibbitt and Contwoyto lakes

is the worlds longest heavy-haul winter road

or many Canadians, winter is a four-letter word.

But for those who live in Canadas northernmost reaches,

the season has a denite upside: the opening of winter roads.

Each winter, many communities build temporary roadways

made of snow and ice to allow vehicles to safely cross over frozen

tundra and lakes, connecting remote areas to the goods and servic-

es in other regions. Its a more convenient and much less expensive

alternative to air travel.

BY CAITLIN CRAWSHAW

F

PASSAGE

NORTHWEST

But ice roads arent just important for the people who dwell in

Canadas northernmost reaches; they are critical for industry, as

well. About 65 kilometres northeast of Yellowknife, Northwest

Territories, lies the access point to an ice road that stretches from

Tibbitt Lake to Contwoyto Lake each winter. Tis is the only

on-land transportation route for the mining operations of Diavik

Diamond Mines, Dominion Diamond Corporation, and De Beers

Canada. Tis highway, which was rst constructed in the early

www.nning.ca 18 Summer 2014 tracks & treads

T&T_Summer_14_p18-19.indd 18 2014-06-19 2:32 PM

1980s, is considered the worlds longest heavy haul

winter road. In its early days, the road stretched from

outside Yellowknife to the north end of Contwoyto

Lake, a distance of up to 600 kilometres. Tese days,

the road is about 360 kilometres long, although this

distance varies with the weather conditions and needs

of industry.

Since 1998, Inuit majority-owned company Nuna

Logistics Limited has built and maintained the road

using Cat equipment. Each year, the road is open dur-

ing the months of February

and March, although

planning for the temporary

road begins much earlier

than that, explains Nuna

Logistics project manager

Tim Tattrie: In November

or December, we send a crew up to the south end of

the road by helicopter to do ice spot checks for us. Im

looking for them to give a ballpark gure of what ice

we have from Tibbitt to our south camp.

Once he has a sense of how well the ice is forming

along the route, Tattrie and his team look to help the

ice in areas where its a bit thin. Generally, this means

clearing snow from the ice, exposing it to the cold

air in order to increase thickness. Sometimes, water

trucks are used to ood areas to create ice. Tis is

particularly important for freezing a portage the

portion of the ice road that crosses over land. About

85 per cent of the road is built over frozen lakes and

15 per cent over rocky islands and tundra. We have to be very cognizant of the

tundra because it takes such a long time to recover, Tattrie explains. So we take

great care not to damage it.

Because the ice road is only available for about 60 days each winter, the mining

companies strategically plan to haul in as much equipment and fuel as they can.

In 2014, 7,480 loads carrying about 250,000 tonnes of commodity were transport-

ed along the Tibbitt to Contwoyto Winter Road. Because of this demand, and the

size of the loads, the road must thicken enough to bear the weight of the vehicles

travelling along its surface. Our target ice is usually 40 to 42 inches, says Tattrie.

Tat will put the heaviest loads up to the sites. Tat said, he recalls one instance

where they had to go a bit thicker about 44 inches to transport a large exca-

vator to a mine site. To ensure the road will be safe for all loads, Nuna Logistics is

supported by an engineering company to calculate the exact thickness of the ice

required, based on the conguration of the haul equipment that will be transport-

ed along the roads surface.

Every year, it takes about one month and 125 road builders and support per-

sonnel to build the road, install road signs, and grade the slipperier portions of

the route to ensure the highway is safe. But the opening of the road is just the

beginning for Nuna Logistics. Troughout the season, the company maintains the

roadway a service which involves a great deal of technology, engineering prowess

and people power.

A big part of this work involves monitoring the condition of the ice. In the past,

crews accomplished this by drilling into the ice to determine its thickness, but

now the industry standard is a technology called ground penetrating radar (GPR),

which transmits high-frequency radio waves through the ice sheet to determine

a minimum measurement. Almost every day, we get measurements o of the ice

and watch how the ice is growing, says Tattrie.

Its completely normal for the road to change over the course of the season, he

notes: Te ice sheet is a oating surface that bends and contracts throughout the

winter road season. When the temperature changes, the weak points in the ice

often shatter, and one piece of ice might go above another piece where it cracks,

forming a ridge line. Most of the time, these pressure ridges can be xed with the

aid of a grader, but if theyre too high say eight or nine feet tall the road must

be repositioned to allow vehicles to drive around them.

Wind is also a challenge since it sweeps snow across the ice. Tis both narrows

the road and causes the ice beneath it to thin (since snow has insulating proper-

ties). Te ice road is 130 to 150 feet wide for the most part, with the exception of

the portages, where its only 30 to 35 feet wide. Regular road clearing is required to

preserve both the width and integrity of the road.

In addition to supplying Cat machines for Nuna

Logistics for the road creation and maintenance,

Finning supplies plenty of equipment to the mining

companies that use the road. But unlike a traditional

highway, shipping along the ice road comes with some

limitations, says Dave Erwin, a sales representative with

Finning: I always tell people that by March 20, the road could close. To that end,

he aims to have all equipment ready to ship to the mining companies by March 1.

Te ice road also aects how Cat equipment is packaged for shipping. Erwin

explains that machines are stripped down to meet weight specications dictated

by ice road limitations.

In spite of all of the measures taken to keep the road in good working order,

there are times when Mother Nature doesnt co-operate. Sometimes, the wind

can pick up and it literally shuts the road down, says Tattrie. At times, well have

100 tractor trailers stuck in our centre camp, all along the road.

Last year, road operations were suspended for about 39 hours; other years, the

roads use was suspended for as many as 100 hours. Te downtime is expensive

for the client and users of the road, but its inevitable so far north. Once the wind

stops, we get the road open and the tractor trailers moving again, he says.

We have to be very cognizant of

the tundra because it takes such a

long time to recover. So we take

great care not to damage it.

LONG HAUL: These days the road spans 360 kilometres

and is only available for about 60 days a year.

www.nning.ca 19 Summer 2014

T&T_Summer_14_p18-19.indd 19 2014-06-19 2:32 PM

Finnings Yellowknife branch is increasing the reach

of its service to customers across the NWT BY ROBIN BRUNET

ay River, a community of 3,600 on the

south shore of Great Slave Lake, used to be

referred to as the hub of the North and

was Finnings base of operations in the Northwest

Territories. For decades, the branch was a crucial

supplier of equipment and parts to the nearby Pine

Point lead zinc mine, which operated between 1965

and 1988, and after that it was kept busy with the

diamond boom.

But the Northwest Territories is a place of dramat-

ic and fundamental change, and by the early 2000s,

many resource rms in the region had moved their

head oces to Yellowknife, the capital city of the

NWT. Hay River was still a parts and service hub;

H

but Finning representatives had to journey ve hours around the Slave to Yellowknife

and board a plane to remote locations in order to serve a growing number of isolated

customers. A way to serve customers in a more timely fashion was badly required.

Tat, in a nutshell, is what prompted Finning to open its Yellowknife branch in

2013. But building a new facility is one thing: it was quite another to nd a manag-

er who would make the most of it and also felt at home in 456,792 square miles of

sub-arctic and arctic landscape, populated by only 44,000 people.

Cut to Mitch Tompson, Finnings Calgary customer service manager. He and his

wife Rhonda had lived in that city for six years, and although they had friends and

enjoyed many aspects of the Prairies, living in a city the size of Calgary was getting to

them. It was the biggest city Id ever lived in, and as it grew so did the grind, he says.

So when Finning asked Tompson, 56, to shore up Yellowknife, he promptly

consulted with Rhonda; soon the couple was heading north. Getting used to near-24

hour daylight during summer and perpetual night in winter wasnt a problem: prior

www.nning.ca 20 Summer 2014 tracks & treads

T&T_Summer_14_p20-21.indd 20 2014-06-19 2:34 PM

BRANCHING OUT: The Yellowknife branch,

which opened in December 2013, is poised

to give Finning customers full service.

BY ROBIN BRUNET

to Calgary, Tompson had worked for Finning in Hay

River, rst as a service supervisor then as customer

service manager. Id been

there ve years and enjoyed

the community-oriented,

genuinely friendly people

up north, he says.

Although its been a

year since the Tompsons

unpacked their bags, the

Yellowknife branch is still

very much a work in pro-

gress. It ocially opened

in December of 2013 just

after the last parts and mechanical positions were lled;

some of the personnel are from Hay River and true to

the NWT spirit, they love their hometown so much they

return on weekends. Tey think Yellowknife is way too

big, says Tompson, with a laugh.

Te Yellowknife facility sits beside a lot that has been earmarked for a mechan-

ical shop. When were nally nished in a few years well be a fully-functioning

branch, servicing what we sell and supplying parts courtesy of daily deliveries from

Edmonton, says Tompson. Whats really exciting about the new branch is the

opportunity for growth: the resource sector is booming, and plans are underway for

entirely new industries to be launched here.

One example of a new industry is, surprisingly enough, logging, which would be

undertaken to supply a proposed pellet mill in Hay River. Even though nothing is

certain, were in the unlikely position of quoting forestry equipment up here, says

Tompson. Forestry will never be a huge component of the regional economy, but it

would certainly be unique.

Another potential new venture for the Yellowknife area would be Te Cat Rental

Store. If theres one thing were constantly asked, its when will you have rentals avail-

able? Tompson says. Overall in the territories theres a lack of rental outlets, so we

would be lling a big void.

Meanwhile, Finning is kept busy with its mining clients, including its largest,

Dominion Diamonds. Other important mining clients include the Diavik Diamond

Mine, about 300 kilometres north of Yellowknife. Te mine is typical of NWT ven-

tures in that transportation can be a challenge: its connected to Yellowknife by an ice

road, and one winter the road froze late and thawed early, meaning arrangements had

to be made to bring supplies in by air.

De Beers Canadas Snap Lake Mine is 350 kilometres northeast of Yellowknife, and

is another Finning customer. Its ice road makes the site accessible by land for six to

eight weeks per year (the mine itself is built under a lake and the deposit slopes from

the lakeshore at an almost horizontal angle).

But the Dominion Diamond Corporations Ekati Diamond Mine is by far the

branchs biggest mining customer, says Tompson. Te mine (named for the Tlicho

word meaning fat lake) is Canadas rst surface and underground diamond

mine. Like Diavik, the Ekati mine site is in the Lac de Gras region of the Northwest

Territories, about 300 kilometres northeast of Yellowknife.

Other clients include the City of Yellowknife, the Government of the Northwest

Territories, and northern construction rms, including those run by the business

arm of the Tlicho First Nation, and Nuna Logistics, an aboriginal majority-owned

company that maintains the ice road. (For more on the ice road and its importance,

turn to page 18). Meanwhile, Northwinds Industries and E. Grubens Transport, both

of which are heavily involved in the Inuvik to Tuktoyaktuk highway project, are also

key Finning customers through the Yellowknife branch.

All of these clients receive the fast service customers in urban areas take for grant-

ed. We nish ordering parts everyday at about seven, and the truck from Edmonton

arrives about 24 hours later at Hay River and Yellowknife, says Tompson, noting that

the Yellowknife branch consists of 14 people. Hay River still has six mechanics on the

payroll, as both branches continue to develop strategies

for how to serve all of Finnings NWT customers.

About the only equipment Finning doesnt sell in the

Territories much of the land is covered by Canadian

Shield are scrapers. Tey dont work well because its

all hard rock here, not the nice sand you get in Calgary,

says Tompson. Other than that, sales patterns are

pretty similar to other branches: graders, wheel loaders,

articulated trucks you name it.

As the Yellowknife branch gears up, Tompson and

his wife are entirely at home in one of the worlds last

frontiers. Yellowknife has all the amenities of a big city,

but theres no mistaking were a hub in a vast wilderness, he says. For some people

that would be troubling, but we spend as much of our spare time hiking, shing and

meeting people we knew years ago. Tats the great thing about the North: everyone is

far-ung geographically, but we all know each other. Its really fullling and it makes

for good business.

Thats the great thing

about the North, says Mitch

Thompson. We all know

each other. Its fullling and

it makes for good business.

www.nning.ca Summer 2014 21

T&T_Summer_14_p20-21.indd 21 2014-06-20 10:33 AM

Spot light

A piece of Caterpillar equipment on a

construction site requires brake servicing. Sounds

pretty innocuous right? No. Its a big deal, especially

if youre an equipment manager trying to get a job

done right, and on time. Unscheduled downtime on

a construction site means theres potential that the

entire project could go o schedule. Its an unwanted

scenario that Trevor Tetzla, product support

marketing program manager at Finning Canada, helps

customers avoid.

Now Tetzla and his team at Finning Canada have

a new solution in the arsenal of product support and

preventive and proactive maintenance: Cat Connect.

In Tetzlas example, Cat Connect would simply

send an automated text message to the projects

equipment manager alerting him of the brake overheat

before theres an outright brake failure, allowing the

equipment manager to assess the situation and take

corrective action. It could be a possible operator error

or a site condition that is impacting the machines

performance. Either way, the manager can tamp that

spark before it becomes a ame.

Of course the goal is proactive maintenance. Not

reactive. Te worst thing for a customer is if that

machine has unscheduled downtime, its costing

him money instead of making him money, Tetzla

explains. If we can be proactive and have a plan to

work with the customer, then his machine doesnt go

down, and his operating costs are reduced.

Te technology behind that convenient text message

has much broader implications. Cat Connect is

allowing Finning Canada to integrate cutting-edge

technologies into Caterpillar machines. It means that

Finning can provide the added service to its customers

when they need it most.

Cat Connect gives customers more control of the job

site, helping them monitor and enhance operations in

four key areas: equipment management, productivity,

safety and sustainability.

Using the data from technology-equipped machines,

customers receive new information and insight into

the inner workings of their equipment and operations.

Finning can tailor the right combination of Cat

Connect technologies and services for any jobsite. One

customer might want to ramp up production, while

another might want to improve safety. Finning can

make Cat Connect work for both.

Savvy customers know that technology is at the leading edge in the battle

against downtime

BY MARTIN DOVER

Time to Connect

As were talking to a customer, he might say, You know whats really

important to me? Productivity. Customers want to know how the equipment

helps hit payload targets more eciently, boost production with faster cycle

times, and possibly improve grade and compaction eciency, Tetzla says.

By combining equipment, technology and services, were able to say, Yes,

actually I have the ability to help you increase your productivity. Cat Connect

can, for example, make use of a precision grading system to provide onboard

information that helps new and experienced operators deliver improvements in

grading eciency specic to the task at hand.

Another customer, facing a new challenge presented by a job, might want to

maintain or improve safety. Cat Connect can precisely track equipment location,

speed and avoidance zones, and relay the information to a site supervisor,

equipment manager, and provide feedback to the operator.

Its a way to use technology to help build a culture of safety, Tetzla says of

the safety features. Caterpillar has recognized that technology is driving change

in the heavy equipment industry. And our customers look for ways to use this

technology to their advantage.

Take for example the introduction of telematics into equipment management.

In the last decade, telematics, or the use of wireless communications to

understand and manage machine operations, has become an increasingly

valuable tool on worksites. Telematics is the foundation for Cat EMSolutions

under the Cat Connect umbrella of services.

So if youre hearing that telematics will have a penetration equal to the

cellphone by 2020, which isnt that far away holy smokes that means that

every machine will be talking to something, data will be out there, Tetzla says.

We want to beon the forefront, using that data to help customers business, to

gain eciencies.

And we are interested in their businesses, and their successes, Tetzla says.

If our customers are successful, were successful.

Cat Connect can, for example, precisely track equipment

location, speed and avoidance zones, and relay the

information to a site supervisor or machine operator.

www.nning.ca 22 Summer 2014 tracks & treads

SERVICE

T&T_Summer_14_p22-23.indd 22 2014-06-19 2:35 PM

BY CHRISTY NICH / ILLUSTRATION BY HEFF O'REILLY

There are statistically 600 near misses for every

serious workplace incident, according to the risk

pyramid developed by Frank Bird in 1969, which was

based on an earlier work by H.W. Heinrich. Birds

study also showed that there are 30 incidents leading

to property damage and 10 minor injuries occurring at

work prior to every serious incident.

Heinrichs theory proposes that serious incidents

dont occur in isolation. He wrote that incidents are

usually of the same type and generally involve the same

people. Another study found that there are as many as

300,000 at-risk behaviours, which are dened as not

consistent with proper safety practices or training, or

resulting from misuse of machinery.

But a study by Behavioral Science Technology

(BST), a safety management consulting rm, shows

that minor injury numbers have steadily declined

over the past few years, yet the number of serious

incidents and fatalities have not. It suggests a new

paradigm, based on the notion that serious injuries

have dierent underlying

causes than minor

ones including missed

controls, procedural

ineciencies and badly

designed equipment.

Tese factors can create

high-risk situations that

can often lead to major incidents.

Identifying and addressing these high-risk situations

is the key to prevention of major incidents. A precursor

is any high-risk practice that has been overlooked and

not corrected. For example, a safety control that is

routinely ignored by a company could go for years with

very low lost-time injury rates until there is a serious

incident. Te focus needs to be on preventing those

high-risk situations, regardless of whether or not they

are reported. And while property damage incidents

account for billions of dollars being lost annually, they

are often misnamed as near misses, but they could have

just as easily resulted in personal injuries.

Analyzing your companys safety data to uncover

trends and the pattern of safety incidents and

For every serious workplace

incident, there are hundreds

more near misses

Close Calls

violations can help your serious recordable injury rate stay low. Such approaches

to safety can allow workers to see crucial safety red ags and highlight areas

requiring more attention.

According to Noel Hill, general manager of health and safety for Finning

Canada, its near misses that help identify problem areas in need of analysis and

correction. We treat all of our near misses as learning opportunities. We do

ourselves a favour and take the 15 minutes to ask What

happened here and how can we keep it from happening

again? Trough Finnings online reporting system,

all near misses are reported and the company can then

conduct trending to notice where patterns exist, Hill

says. Were also looking to see if there are trends in

certain kinds of injuries. Is somebody being struck by

something? Are we having falls? [After asking these

questions] we can categorize and pinpoint where we want to focus our eorts to

create greater awareness, he explains.

Being aware of potential dangers can go far in cutting down on near misses. You

can have a serious incident where the outcome is not catastrophic, but it has the

potential to be and I think thats really how we look at all of our incidents, says Hill,

pointing to Finnings Risk Assessment Matrix, which measures the severity of every

incident, big or small.

We treat all of our near misses as

learning opportunities, says Noel Hill.

We do ourselves a favour and ask

What happened here and how can we

keep it from happening again?

JOBSITE CHECKLIST

Some quick reminders to ensure an injury-free workplace:

Analyze the job before starting work

Identify the hazards

Follow manufacturers service guides

Educate yourself and staff to take necessary safety precautions

www.nning.ca 23 Summer 2014

1

10

100

1,000

10,000

100,000

Fatality

Disabling injuries

Recordable injuries

Incidents requiring rst aid

Near misses

Unsafe acts/conditions

T&T_Summer_14_p22-23.indd 23 2014-06-20 10:35 AM

From its inception during the Great Depression,

Finning Canadas forward-thinking approach was

clear, helping turn Earl Finnings original $50,000 loan

into a cutting edge, global company. While there are

few Finning-free places on the planet today, there are

always new ways to bring customers new products.

Over the last four years, Surrey branch sales manager

Dan Warrington has challenged his sta to up their

game when it comes to informing customers about new

products and technology. Late last year, once employees

had a grasp, they began promoting a more advanced,

on-board technology designed by SITECH, a Finning-

owned, independently-run construction technology

company. Trough SITECH, contractors learn how to

use technology that makes signicant improvements in

their project workow dramatically increasing their

production, improving their accuracy, and lowering

their operating costs.

But rst, the sta got some training of their own.

Te rst thing we did was bring in Ed Picher from

SITECH to give the sales team a run down on the

new technology, specically grade control, says

Warrington. We turned that into our business plan for

the year: dont sell to the customers, educate them, so

they can take advantage of these new tools.

As SITECHs technology sales and service rep since

2011, Picher and his team were used to receiving

the stereotypical IT guy treatment. Tis time was

dierent. In the past, whenever wed get invited to

speak at an event or a sales training, wed be relegated

to ve or 10 minutes. Tis time, we got three hours to

explain the technology, what they can do with it and

how it benets our customers.

Te sales team suciently educated, it was time

to roll it out to specic customers. Tis April, each

sales person brought select employees an owner, a

supervisor, operators or even a full crew from three

targeted companies to the very rst Surrey Technology

Day, held in the branchs operating engineers site. Each

of the ve machines two dozers, two excavators and a

packer had a Finning and SITECH member assigned

to it, to answer client questions as they gave them each

a go, in some cases for the rst time.

Its not about Finning, its about our customers,

says Alex Docherty, director of technology for Finning

Canada, who adds that its these new products

eciency that helps maintain Finnings status as an

When it comes to customer education, Finning's Surrey branch is leading the

company that leads

BY CORY SCHACHTEL

Higher Learning

Spot light

industry leader. Take the two-dimension grade controllers, he says, a system

that helps manage the up and down. Usually someone has to go into the trench

and take measurements to make sure they have the right depth and slope. With

the new system, you dont have to send anyone into the trench, because in the

cab you get a graphic representation of what youre trying to dig, including the

teeth of the bucket itself. And theres a line that represents where you should

be from an elevation perspective, which guides your cutting edge to the correct

elevation, achieving grade the rst time.

Participants also saw VisionLink demoed, an online application where

customers see where their machines are, how many hours are on them, their rate

of fuel burn and how much time theyve spent idling important data that gives

a fuller view of machine eciency and utilization.

Over two days, Finning and SITECH crews gave more than 60 custom-

ers from 18 companies rst-hand experience with the newest machines

and technology on the market. Some orders came pretty much on the

spot, others took longer. And while the immediate business is nice, Surrey

Technology Day the first of its kind in Western Canada had far-

reaching eects.

We already have requests from all the other regions. Southern Alberta, Fort

McMurray, Grande Prairie, Edmonton they all want to follow the Surrey

model, says Picher, noting a company doesnt reach Finnings level of success

without innovation, both in the product it sells and how it delivers.

Warrington agrees it was a success. Ive been in the business for 28 years, and

Ive got a great team, says Warrington. I pitched them my vision, and they ran

with it. Most importantly, the customers loved it.

We already have requests from all the other regions.

Southern Alberta, Fort McMurray, Grande Prairie, Edmonton

they all want to follow the Surrey model.

TECH

P

H

O

T

O

:

A

M

I

E

C

O

N

T

A

C

T