Beruflich Dokumente

Kultur Dokumente

Retaining Wall Counterfort PDF

Hochgeladen von

Silver Olguín CamachoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Retaining Wall Counterfort PDF

Hochgeladen von

Silver Olguín CamachoCopyright:

Verfügbare Formate

1

Summary Sheet

Session Number :

Date :

Subject Expert :

5

09.04.2007

Dr. M.C. Nataraja

Professor

Department of Civil Engineering,

Sri Jayachamarajendra College of

Engineering,

Mysore 570 006.

Phone:0821-2343521, 9880447742

E-mail: nataraja96@yahoo.com

2

Design and Detailing of Counterfort

Retaining wall

Dr. M.C. NATARAJA

3

When H exceeds about 6m,

Stem and heel thickness is more

More bending and more steel

Cantilever-T type-Uneconomical

Counterforts-Trapezoidal section

1.5m -3m c/c

Counterfort Retaining wall

CRW

CF

Base Slab

Stem

4

Parts of CRW

Same as that of Cantilever Retaining wall Plus

Counterfort

Stem

Toe

Heel

Base slab

Counterforts

Cross section Plan

5

The stem acts as a continuous slab

Soil pressure acts as the load on the

slab.

Earth pressure varies linearly over

the height

The slab deflects away from the

earth face between the counterforts

The bending moment in the stem is

maximum at the base and reduces

towards top.

But the thickness of the wall is kept

constant and only the area of steel

is reduced.

Design of Stem

BF

p=K

a

h

6

Maximum Bending moments for stem

Maximum +ve B.M= pl

2

/16

(occurring mid-way between counterforts)

and

Maximum -ve B.M= pl

2

/12

(occurring at inner face of counterforts)

Where l is the clear distance between the

counterforts

and p is the intensity of soil pressure

l

p

+

-

7

Design of Toe Slab

The base width=b =0.6 H to 0.7 H

The projection=1/3 to 1/4 of base width.

The toe slab is subjected to an upward

soil reaction and is designed as a

cantilever slab fixed at the front face of

the stem.

Reinforcement is provided on earth face

along the length of the toe slab.

In case the toe slab projection is large i.e.

> b/3, front counterforts are provided

above the toe slab and the slab is

designed as a continuous horizontal

slab spanning between the front

counterforts.

b

H

8

The heel slab is designed as a continuous slab

spanning over the counterforts and is

subjected to downward forces due to weight of

soil plus self weight of slab and an upward

force due to soil reaction.

Maximum +ve B.M= pl

2

/16

(mid-way between counterforts)

And

Maximum -ve B.M= pl

2

/12

(occurring at counterforts)

Design of Heel Slab

BF

9

Design of Counterforts

The counterforts are subjected to

outward reaction from the stem.

This produces tension along the

outer sloping face of the counterforts.

The inner face supporting the stem is

in compression. Thus counterforts

are designed as a T-beam of varying

depth.

The main steel provided along the

sloping face shall be anchored

properly at both ends.

The depth of the counterfort is

measured perpendicular to the

sloping side.

T C

d

10

Behaviour of Counterfort RW

-M

-M

TOE

COUNTERFORT

+M

+M

STEM

HEEL SLAB

Important points

Loads on Wall

Deflected shape

Nature of BMs

Position of steel

Counterfort details

11

PROBLEM

-Counterfort Retaining Wall

A R.C.C. retaining wall with counterforts is

required to support earth to a height of 7 m above

the ground level. The top surface of the backfill is

horizontal. The trial pit taken at the site indicates

that soil of bearing capacity 220 kN/m

2

is available

at a depth of 1.25 m below the ground level. The

weight of earth is 18 kN/m

3

and angle of repose is

30. The coefficient of friction between concrete

and soil is 0.58. Use concrete M20 and steel

grade Fe 415. Design the retaining wall.

12

Draw the following:

Cross section of wall near the counterfort

Cross section of wall between the counterforts

L/s of stem at the base cutting the counterforts

Given:

f

ck

= 20 N/mm

2

, f

y

= 415N/mm

2

, H = 7 m above G.L,

Depth of footing below G.L. = 1.25 m, = 18 kN/m

3

,

= 0.58, f

b

=SBC= 220 kN/m

2

13

a. Proportioning of Wall Components

Coefficient of active pressure = k

a

= 1/3

Coefficient of passive pressure= k

p

= 3

The height of the wall above the base

= H = 7 + 1.25 = 8.25 m.

Base width = 0.6 H to 0.7 H

(4.95 m to 5.78 m), Say b = 5.5 m

Toe projection = b/4 = 5.5/4 = say 1 .2 m

Assume thickness of vertical wall = 250 mm

Thickness of base slab = 450 mm

H

b=5.5 m

1.25 m

h

1

=

7 m

14

Spacing of counterforts

l = 3.5 (H/)

0.25

= 3.5 (8.25/18)

0.25

= 2.88 m

c/c spacing = 2.88 + 0.40 = 3.28 m say 3 m

Provide counterforts at 3 m c/c.

Assume width of counterfort = 400 mm

clear spacing provided = l = 3 - 0.4 = 2.6 m

l

15

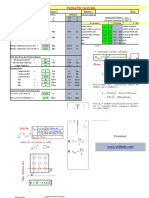

4.05m

h=7.8 m

d

250 mm

1.2 m

b=5.5 m

H=8.25 m h

1

=7 m

1.25m

CF: 3m c/c,

400 mm

T

Details of wall

16

Sr.

No.

Description of

loads

Loads in kN

Dist. of

e.g. from

T in m

Moment

about

T in kN-m

1

Weight of stem

W

1

25x0.25x1x7.8

= 48.75

1.2 + 0.25/2

=1.325

64.59

2

Weight of base

slab W

2

25x5.5x1x0.45

= 61.88

5.5/2 =2.75 170.17

3

Weight of earth

over heel slab W

3

18x4.05x1x7.8

= 568.62

1.45 +4.05/2

= 3.475

1975.95

Total W = 679.25

W

=2210.71

b. Check Stability of Wall

17

A B C D

H

8250

250 mm

1200 mm 4050 mm

450

D

f

= 1250

W

P

A

R

e X

b/2

T

W3

W1

W2

P

A

Pressure distribution

Cross section of wall-Stability analysis

b/3

k

a

H

H/3

h

1

= 7000

18

Stability of walls

Horizontal earth pressure on full height of wall

= P

h

= k

a

H

2

/2 =18 x 8.25

2

/(3 x 2) = 204.19 kN

Overturning moment = M

0

= P

h

x H/3 = 204.19 x 8.25/3 = 561.52 kN.m.

Factor of safety against overturning

= M / M

0

= 2210.71/561.52 = 3.94 > 1.55

safe.

19

Check for sliding

Total horizontal force tending to slide the wall

= P

h

= 204.19 kN

Resisting force = .W= 0.58 x 679.25

= 393.97 kN

Factor of safety against sliding

= .W/ P

h

= 393.97/204.19

= 1.93 > 1.55 .

.

. safe.

20

Check for pressure distribution at base

Let x be the distance of R from toe (T),

x = M / W= 2210.71 -561.52 /679.25 = 2.43 m

Eccentricity=e = b/2 - x = 5.5/2 - 2.43 = 0.32 < b/6 (0.91m)

Whole base is under compression.

Maximum pressure at toe

= p

A

= W / b ( 1+6e/b) = 679.25/5.5 ( 1+ 6*0.32/5.5)

= 166.61 kN/m

2

< f

b

(i.e. SBC= 220 kN/m

2

)

Minimum pressure at heel

= p

D

= 80.39 kN/m

2

compression.

21

Intensity of pressure at junction of stem with toe i.e. under

B

= p

B

= 80.39 + (166.61 - 80.39) x 4.3/5.5 = 147.8kN/m

2

Intensity of pressure at junction of stem with heel i.e. under

C

=P

c

= 80.39 + (166.61 - 80.39) x 4.05/5.5 = 143.9 kN/m

2

22

80.39

kN/m

2

166.61

kN/m

2

143.9 147.8 153.9

A B

C

D

H

8250

250 mm

1200 mm

5500 mm

4050 mm

450

1250

W

P

A

R

e X

b/2

T

23

b) Design of Toe slab

Max. BM

B

= psf x (moment due to soil pressure - moment

due to wt. of slab TB]

= 1.5 [147.8 x 1.2

2

/2 + (166.61 - 147.8) x 1.2 (2/3 x 1.2)

-(25x 1.2 x 0.45 x 1.2/2) =174.57 kN-m.

M

u

/bd

2

= 1.14 < 2.76, URS

24

To find steel

p

t

=0.34% <0.96%, A

st

=1326 mm

2

, # 16 @150

However, provide # 16 @110 from shear considerations.

Area provided =1827 mm

2

, p

t

=0.47%

Development length= 47 x 16=750 mm

Distribution steel = 0.12 x 1000 x 450/100 = 540 mm

2

Provide #12 mm at 200 mm c/c.

Area provided = 565 mm

2

b) Design of Toe slab- Contd.,

25

Check for Shear

Critical section for shear: At distance d (= 390 mm)

from the face of the toe

p

E

= 80.39 + (166.61 - 80.39) (4.3 + 0.39)/5.5

= 153.9kN/m

2

Net vertical shear

= (166.61 + 153.9) x 0.81/2 - (25 x 0.45 x 0.81)

=120.7 kN.

Net ultimate shear = V

u.max

= 1.5 x 120.7 =181.05

kN.

v

= 181.05x 1000/1000x390 =0.46 MPa

p

t

= 100 x 1827/ (1000 x 390) = 0.47 %

uc

= 0.36 + (0.48 - 0.36) x 0.22/0.25

= 0.47N/mm

2

>

v

safe

d

26

-M

-M

TOE

COUNTERFORT

+M

+M

STEM

HEEL SLAB

Counterfort RW

27

Continuous slab.

Consider 1 m wide strip near the outer edge D

The forces acting near the edge are

Downward wt. of soil=18x7.8xl= 140.4 kN/m

Downward wt. of heel slab = 25 x 0.45 x 1= 11.25 kN/m

Upward soil pressure 80.39 kN/m

2

= 80.39 x 1= 80.39 kN/m

Net down force at D= 140.4 + 11.25 - 80.39 = 71.26 kN/m

Also net down force at C = 140.4 + 11.25 - 143.9 = 7.75 kN/m

Negative Bending Moment for heel at junction of counterfort

M

u

= (psf) pl

2

/12 = 1.5 x 71.26 x 2.6

2

/12 = 60.2 kN-m (At the junction of CF)

(c) Design of Heel Slab

28

71.26

kN/m

7.75

kN/m

D C

Forces on heel slab

80.39

kN/m

2

166.61

kN/m

2

143.9 147.8 153.9

5500

mm

29

To find steel

M

u

/bd

2

=60.2x10

6

/(1000x390

2)=

0.39 < 2.76, URS

To find steel

p

t

=0.114% <0.12%GA (Min. steel), <0.96%(p

t,lim.

)

Provide 0.12% of GA

A

st

= 0.12x1000x450/100 = 540 mm

2

Provide # 12 mm @ 200 mm c/c,

Area provided = 565 mm

2

p

t

= 100 x 565/ (1000 x 390) = 0.14 %

30

Maximum shear = V

u,max

= 1.5 x 71.26 x 2.6/2 = 139 kN

For P

t

, = 0.14 % and M20 concrete,

uc

= 0.28 N/mm

2

v

= V

umax

/bd =0.36 N/mm

2

,

uc

<

v,

Unsafe, Hence shear steel is needed

Using #8 mm 2-legged stirrups,

Spacing=0.87x415x100/[(0.36-0.28)x1000]

= 452 mm < (0.75 x 390 = 290 mm or 300 mm )

Provide #8 mm 2-legged stirrups at 290 mm c/c.

Provide for 1m x 1m area as shown in figure

Check for shear (Heel slab)

31

A B

C

1200

mm

4050

mm

450

1250

R

e X

b/2

2600

3

0

0

0

4050

mm

C D

SFD

Net down force dia.

TOE

HEEL

139

71.28

kN/m

7.75

kN/m

x1

y1

Shear analysis and

Zone of shear steel

Area for

stirrups

32

Area of steel for +ve moment

(Heel slab)

Maximum +ve ultimate moment = psf x pl

2

/16

= 3/4 M

u

= 0.75 x 60.2= 45.15 kN-m.

M

u

/bd

2

=Very small and hence provide minimum steel.

A

st,min

= 540 mm

2

Provide # 12 mm bars at 200 mm c/c.

Area provided = 565 mm

2

> 540 mm

2

33

Check the force at junction of heel slab with stem

The intensity of downward force decreases due to

increases in upward soil reaction. Consider m width of

the slab at C

Net downward force= 18 x 7.8 +25 x 0.45 - 143.9 = 7.75

kN/m. Provide only minimum reinforcement.

Distribution steel

A

st

= 0.12 x 1000 x 450/100 = 540 mm

2

Using # 12 mm bars, spacing = 1000 x 113/468 = 241 mm.

Provide # 12 mm at 200 mm c/c.

Area provided = 565 mm

2

34

(d) Design of Stem (Vertical Slab).

Continuous slab spanning between the counterforts and

subjected to earth pressure.

The intensity of earth pressure

= p

h

= k

a

h =18 x 7.8/3=46.8 kN/m

2

Area of steel on earth side near counterforts :

Maximum -ve ultimate moment,

M

u

= 1.5 x p

h

l

2

/12 = 1.5 x 46.8 x 2.6

2

/12 = 39.54 kN.m.

Required d = (39.54 x 106/(2.76 x 1000)) = 119 mm

However provide total depth = 250 mm

M

u

/bd

2

= 39.54x10

6

/1000x390

2

=1.1 < 2.76, URS

35

To find steel: P

t

=0.34% <0.96%,

A

st

=646 mm

2,

#12 mm @ 170 mm c/c,

However provide #12 mm @ 110 mm c/c,

Area provided = 1027.27 mm

2,

P

t

= 0.54 %.

As the earth pressure decreases towards the top, the

spacing of the bars is increased with decrease in height.

Max.ult. shear = V

umax

= 1.5 x 46.8 x 2.6/2 = 91.26 kN

For P

t

, = 0.54 % and M20 concrete

uc

= 0.5 N/mm

2

v

= V

umax

/bd =91.28 x1000/(100X190)=0.48 N/mm

2

,

Shear steel is not needed and hence safe.

36

At any section at any depth h below the top, the total

horizontal earth pressure acting on the counterfort

= 1/2 k

a

y h

2

x c/c distance between counterfort

= 18 x h

2

x 3 x 1/6 = 9 h

2

B.M. at any depth h = 9h

2

xh/3 = 3h

3

B.M. at the base at C= 3 x 7.8

3

= 1423.7 kN.m.

Ultimate moment = M

u

= 1.5 x 1423.7 = 2135.60 kN.m.

Counterfort acts as a T-beam.

Even assuming rectangular section,

d =(2135.6 x 10

6

(2.76 x 400)) = 1390 mm

(e) Design of Counterfort

37

The effective depth is taken at right

angle to the reinforcement.

tan = 7.8/4.05 =1.93, = 62.5,

d = 4050 sin - eff. cover

= 3535 mm > > 1390 mm

M

u

/bd

2

=2135.6x10

6

/(400x3535

2

)

=0.427, p

t

=0.12%, A

st

=1696mm

2

Check for minimum steel

4.05m

h =7.8 m

d

38

A

st.min

= 0.85 bd/f

y

= 0.85 x 400 x 3535/415 = 2896 mm

2

Provided 4- # 22 mm + 4 - # 22 mm,

Area provided = 3041 mm

2

p

t

= 100 x 3041/(400 x 3535) = 0.21 %

The height h where half of the reinforcement can be

curtailed is approximately equal to H= 7.8=2.79 m

Curtail 4 bars at 2.79-L

dt

from top i.e, 2.79-1.03 =1.77m

from top.

39

Design of Horizontal Ties

The direct pull by the wall on counterfort for 1 m height at

base

= k

a

h x c/c distance =1/3x18 x 7.8 x 3 = 140.4 kN

Area of steel required to resist the direct pull

= 1.5 x 140.4 x 10

3

/(0.87 x 415) = 583 mm

2

per m height.

Using # 8 mm 2-legged stirrups, A

st

= 100 mm

2

spacing = 1000 x 100/583 = 170 mm c/c.

Provide # 8 at 170 mm c/c.

Since the horizontal pressure decreases with h, the

spacing of stirrups can be increased from 170 mm c/c to

450 mm c/c towards the top.

40

Design of Vertical Ties

The maximum pull will be exerted at the end of heel slab

where the net downward force = 71.26 kN/m.

Total downward force at D

= 71.26 x c/c distance bet. CFs = 71.28 x 3 = 213.78 kN.

Required A

st

= 1.5 x 213.78 x 10

3

/(0.87 x 415) = 888 mm

2

Using # 8 mm 2-legged stirrups , A

st

= 100 mm

2

spacing = 1000 x 100/888 = 110 mm c/c.

Provide # 8 mm 2-legged stirrups at 110 mm c/c.

Increase the spacing of vertical stirrups from 110 mm c/c to

450 mm c/c towards the end C

41

DRAWING AND DETAILING

COUNTERFORT RETAINING WALL

42

250 mm

1200 mm 4050 mm

450

1250

#16@120 #12@200 #12@200

#12@200

#12@200

8250 mm

7000

Cross section between counterforts

0-200mm

STEM COUNTERFORT

TOE HEEL

43

250 mm

1200 mm

450

1250

#16@120 #12@200

8 - # 22

#12@200

#8@170-450, HS

#8@110-450, VS

#12@

110-300

#12@200

#12@400

8-#22

1.77m

8250

Cross section through counterforts

44

Section through stem at the junction of Base slab.

Backfill

With straight bars

0.3l

0.25 l

Backfill

With cranked

bars

STEM

STRAIGHT

BARS

45

Cross section of heel slab

Backfill

Backfill

46

Examination Problems

July 2006

Single bay Fixed Portal Frame

Combined footing (Beam and slab type)

December 2006

T-shaped Cantilever Retaining wall

Combined footing (Type not mentioned)

47

Exam Problem (Dec. 2006)

Design a T shaped cantilever retaining wall to retain earth

embankment 3.2 m high above the ground level. The

unit weight of the earth is 18 kN/m2 and its angle of

repose is 30 degrees. The embankment is horizontal

at it top. The SBC of soil is 120 kN/m

2

and the co-

efficient of friction between soil and concrete is 0.5.

Use M20 concrete and Fe 415 steel. Draw the

following to a suitable scale:

1. Section of the retaining wall

2. Reinforcement details at the inner face of the stem.

60 Marks

Data: h

1

=3.2 m, =0.5, =18 kN/m

2

, =30, SBC= 120

kN/m

2

,

M20 Concrete and Fe 415 steel

Find H= h

1

+ D

f

48

Das könnte Ihnen auch gefallen

- Design and Detailing of Counterfort Retaining WallDokument48 SeitenDesign and Detailing of Counterfort Retaining WallSWADES RANJAN PAIRANoch keine Bewertungen

- Counter Fort Reatining WAll With HORZONTAL Bach FillDokument35 SeitenCounter Fort Reatining WAll With HORZONTAL Bach FillUlasi IfeanyiNoch keine Bewertungen

- KP Largeractangular Ground Water TankDokument28 SeitenKP Largeractangular Ground Water TankSakthivel VedachalamNoch keine Bewertungen

- Retaining WallDokument41 SeitenRetaining Wallp_ignatiusNoch keine Bewertungen

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Dokument2 SeitenAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- RCC Retaining Wall DesignDokument12 SeitenRCC Retaining Wall DesignifylasyNoch keine Bewertungen

- Design of Square Footing F2Dokument18 SeitenDesign of Square Footing F2Mohammed Sumer100% (1)

- 4.0 Design of PierDokument9 Seiten4.0 Design of PierDeepak Kr GuptaNoch keine Bewertungen

- Retaining Wall DesignDokument5 SeitenRetaining Wall DesignbharatNoch keine Bewertungen

- Design of BridgeDokument33 SeitenDesign of BridgeAnu PathakNoch keine Bewertungen

- Design of Pile CapDokument3 SeitenDesign of Pile CapHaris Lee100% (2)

- Basement Wall DesignDokument19 SeitenBasement Wall DesignwaikenNoch keine Bewertungen

- Design of INTZE Tank50000Glns Only DesignPDFDokument17 SeitenDesign of INTZE Tank50000Glns Only DesignPDFMike VictorNoch keine Bewertungen

- Wall Footing DesignDokument102 SeitenWall Footing DesignAUNGPSNoch keine Bewertungen

- Cantilever Retaining WallDokument5 SeitenCantilever Retaining WallAmit SinghNoch keine Bewertungen

- Design of two-way reinforced concrete slabDokument15 SeitenDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNoch keine Bewertungen

- Design of Cantilever Chajja SlabDokument4 SeitenDesign of Cantilever Chajja SlabMaheshNoch keine Bewertungen

- Wingwall Soil LoadsDokument4 SeitenWingwall Soil LoadsSharyn PolleyNoch keine Bewertungen

- Design of Raft FoundationDokument9 SeitenDesign of Raft FoundationAnonymous ciKyr0tNoch keine Bewertungen

- StaircaseDokument2 SeitenStaircaseMAGED MOHMMED AHMED QASEMNoch keine Bewertungen

- Staircase DesignDokument1 SeiteStaircase DesignJennifer PearsonNoch keine Bewertungen

- Pile Cap Design Calculations With CSI SAFEDokument6 SeitenPile Cap Design Calculations With CSI SAFEroshanNoch keine Bewertungen

- DESIGN AqueductDokument89 SeitenDESIGN AqueductmukhleshNoch keine Bewertungen

- Composite Slab Deck ACI318Dokument4 SeitenComposite Slab Deck ACI318jflttwNoch keine Bewertungen

- RCC51 Column Load Take-Down & DesignDokument8 SeitenRCC51 Column Load Take-Down & DesignirrezaNoch keine Bewertungen

- Retaining WallDokument8 SeitenRetaining WallChetanNoch keine Bewertungen

- Flat Slab 6 X 6 Ext PNLDokument5 SeitenFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- Corbel Excel Sheet WorksDokument5 SeitenCorbel Excel Sheet WorksIbrahim A.LNoch keine Bewertungen

- Isolated Sloped Footing SpreadsheetDokument283 SeitenIsolated Sloped Footing Spreadsheetarif_rubin100% (3)

- Manhole Design - AMRUT - Water Pressure & DryDokument13 SeitenManhole Design - AMRUT - Water Pressure & Drynavneet3bawaNoch keine Bewertungen

- Design of Combined Footing (CFDokument12 SeitenDesign of Combined Footing (CFp_ignatiusNoch keine Bewertungen

- Design of SyphonDokument7 SeitenDesign of SyphonraghurmiNoch keine Bewertungen

- Bucket DesignDokument6 SeitenBucket Designוויסאם חטארNoch keine Bewertungen

- RCC RampDokument4 SeitenRCC Ramphemantkle2uNoch keine Bewertungen

- Slab DesignDokument87 SeitenSlab Designshamen amarasekaraNoch keine Bewertungen

- Counter Fort Retaining WallsDokument11 SeitenCounter Fort Retaining WallsdsureshcivilNoch keine Bewertungen

- Design Gravity Retaining Wall SpreadsheetDokument32 SeitenDesign Gravity Retaining Wall SpreadsheetBudi Agung100% (1)

- Box Culvert Design and Analysis CalculationsDokument11 SeitenBox Culvert Design and Analysis CalculationscoreteamNoch keine Bewertungen

- Design of Cantilever Retaining WallDokument13 SeitenDesign of Cantilever Retaining WallHARSHARAN100% (1)

- Example 2 Simply Supported Beam - Flanged Section PDFDokument7 SeitenExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- 2way Slab DesignDokument10 Seiten2way Slab DesignHari Amudhan IlanchezhianNoch keine Bewertungen

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Dokument1 Seite16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNoch keine Bewertungen

- Isolated Trapezoidal Footing DesignDokument6 SeitenIsolated Trapezoidal Footing Designhemantkle2uNoch keine Bewertungen

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDokument3 SeitenDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeNoch keine Bewertungen

- Strap FootingDokument18 SeitenStrap Footinghemantkle2uNoch keine Bewertungen

- 3bow-String Girder - Design Construction Aspects PDFDokument12 Seiten3bow-String Girder - Design Construction Aspects PDFankur mundraNoch keine Bewertungen

- Design footing strap beam two columns axial loadsDokument26 SeitenDesign footing strap beam two columns axial loadskabutar_royal70450% (1)

- Design of WingwallDokument29 SeitenDesign of WingwallMar MartillanoNoch keine Bewertungen

- Design of Two Way Slab by IS 456Dokument8 SeitenDesign of Two Way Slab by IS 456Mohmmedhusain Fruitwala50% (2)

- Brick Wall Footing Design-1Dokument12 SeitenBrick Wall Footing Design-1mumarbsc7244Noch keine Bewertungen

- Design of T-BeamDokument6 SeitenDesign of T-BeamDineshNoch keine Bewertungen

- Counterfort Retaing Wall-OriginalDokument15 SeitenCounterfort Retaing Wall-OriginalHarish Kumar MahavarNoch keine Bewertungen

- Retain Wall Counter FortDokument48 SeitenRetain Wall Counter FortMarlon Martinez100% (1)

- Retaining WallDokument58 SeitenRetaining WallPradnya Sikachi100% (1)

- L Shaped Reatining WAll With HORZONTAL Bach FillDokument29 SeitenL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Design of Counterfort Retaining WallDokument14 SeitenDesign of Counterfort Retaining WallMonjit Gogoi100% (5)

- Reatining Wall With Sloping BackfillDokument16 SeitenReatining Wall With Sloping BackfillSana UllahNoch keine Bewertungen

- Retaining WallsDokument40 SeitenRetaining Wallssunleon31100% (1)

- RC Water Tank Design GuideDokument40 SeitenRC Water Tank Design GuideAdil MansuriNoch keine Bewertungen

- Design and Drawing of RC Structures: Dr. G.S.SureshDokument40 SeitenDesign and Drawing of RC Structures: Dr. G.S.SureshLeroy TuscanoNoch keine Bewertungen

- Wind Tunnel Testing Guide for Tall BuildingsDokument7 SeitenWind Tunnel Testing Guide for Tall BuildingsSilver Olguín CamachoNoch keine Bewertungen

- Influence Line Analysis of Bridges Using MATLABDokument14 SeitenInfluence Line Analysis of Bridges Using MATLABSilver Olguín CamachoNoch keine Bewertungen

- Arch BridgesDokument22 SeitenArch BridgesSilver Olguín CamachoNoch keine Bewertungen

- Suspension BridgesDokument32 SeitenSuspension BridgesSilver Olguín CamachoNoch keine Bewertungen

- StairsDokument21 SeitenStairstomnubiNoch keine Bewertungen

- Concrete Mix DesignDokument17 SeitenConcrete Mix DesignSilver Olguín CamachoNoch keine Bewertungen

- Vibration of The Millenium Bridge LondonDokument16 SeitenVibration of The Millenium Bridge LondonSilver Olguín CamachoNoch keine Bewertungen

- Hoja para CaracteresDokument3 SeitenHoja para CaracteresJaime FernandezNoch keine Bewertungen

- Foundations of Tensor Analysis For Students of Physics and Engineering With An Introduction To Theory of Relativity (Nasa)Dokument92 SeitenFoundations of Tensor Analysis For Students of Physics and Engineering With An Introduction To Theory of Relativity (Nasa)Silver Olguín CamachoNoch keine Bewertungen

- GD4107 05 TopographyDokument14 SeitenGD4107 05 TopographySilver Olguín CamachoNoch keine Bewertungen

- Report - Cu Cas 00 13Dokument18 SeitenReport - Cu Cas 00 13Silver Olguín CamachoNoch keine Bewertungen

- Agricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsDokument84 SeitenAgricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsRachel vNoch keine Bewertungen

- Main Research PaperDokument11 SeitenMain Research PaperBharat DedhiaNoch keine Bewertungen

- Java development user guide eclipse tutorialDokument322 SeitenJava development user guide eclipse tutorialVivek ParmarNoch keine Bewertungen

- India: Kerala Sustainable Urban Development Project (KSUDP)Dokument28 SeitenIndia: Kerala Sustainable Urban Development Project (KSUDP)ADBGADNoch keine Bewertungen

- Analytical Approach To Estimate Feeder AccommodatiDokument16 SeitenAnalytical Approach To Estimate Feeder AccommodatiCleberton ReizNoch keine Bewertungen

- Pre Job Hazard Analysis (PJHADokument2 SeitenPre Job Hazard Analysis (PJHAjumaliNoch keine Bewertungen

- Nursing Care Management of a Client with Multiple Medical ConditionsDokument25 SeitenNursing Care Management of a Client with Multiple Medical ConditionsDeannNoch keine Bewertungen

- Ujian Madrasah Kelas VIDokument6 SeitenUjian Madrasah Kelas VIrahniez faurizkaNoch keine Bewertungen

- BPL Millipacs 2mm Hardmetrics RarDokument3 SeitenBPL Millipacs 2mm Hardmetrics RarGunter BragaNoch keine Bewertungen

- Difference Between Text and Discourse: The Agent FactorDokument4 SeitenDifference Between Text and Discourse: The Agent FactorBenjamin Paner100% (1)

- Portfolio Artifact Entry Form - Ostp Standard 3Dokument1 SeitePortfolio Artifact Entry Form - Ostp Standard 3api-253007574Noch keine Bewertungen

- Guidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016Dokument76 SeitenGuidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016kofafa100% (1)

- To Introduce BgjgjgmyselfDokument2 SeitenTo Introduce Bgjgjgmyselflikith333Noch keine Bewertungen

- 20 Ua412s en 2.0 V1.16 EagDokument122 Seiten20 Ua412s en 2.0 V1.16 Eagxie samNoch keine Bewertungen

- Case Study Hotel The OrchidDokument5 SeitenCase Study Hotel The Orchidkkarankapoor100% (4)

- 2nd Pornhub Awards - WikipediaaDokument13 Seiten2nd Pornhub Awards - WikipediaaParam SinghNoch keine Bewertungen

- Towards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningDokument21 SeitenTowards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningTommy SiddiqNoch keine Bewertungen

- Lecture02 NoteDokument23 SeitenLecture02 NoteJibril JundiNoch keine Bewertungen

- Inventory Control Review of LiteratureDokument8 SeitenInventory Control Review of Literatureaehupavkg100% (1)

- 2023 Test Series-1Dokument2 Seiten2023 Test Series-1Touheed AhmadNoch keine Bewertungen

- Unit 3 Computer ScienceDokument3 SeitenUnit 3 Computer ScienceradNoch keine Bewertungen

- India Today 11-02-2019 PDFDokument85 SeitenIndia Today 11-02-2019 PDFGNoch keine Bewertungen

- Us Virgin Island WWWWDokument166 SeitenUs Virgin Island WWWWErickvannNoch keine Bewertungen

- 50 Years of Teaching PianoDokument122 Seiten50 Years of Teaching PianoMyklan100% (35)

- Change Management in British AirwaysDokument18 SeitenChange Management in British AirwaysFauzan Azhary WachidNoch keine Bewertungen

- The Berkeley Review: MCAT Chemistry Atomic Theory PracticeDokument37 SeitenThe Berkeley Review: MCAT Chemistry Atomic Theory Practicerenjade1516Noch keine Bewertungen

- SEO-Optimized Title for Python Code Output QuestionsDokument2 SeitenSEO-Optimized Title for Python Code Output QuestionsTaru GoelNoch keine Bewertungen

- Level 3 Repair PBA Parts LayoutDokument32 SeitenLevel 3 Repair PBA Parts LayoutabivecueNoch keine Bewertungen

- WSP Global EnvironmentDokument20 SeitenWSP Global EnvironmentOrcunNoch keine Bewertungen

- SCA ALKO Case Study ReportDokument4 SeitenSCA ALKO Case Study ReportRavidas KRNoch keine Bewertungen