Beruflich Dokumente

Kultur Dokumente

Molding Materails

Hochgeladen von

Aditya Koutharapu0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten35 Seitenmanufacturing technilogy

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenmanufacturing technilogy

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten35 SeitenMolding Materails

Hochgeladen von

Aditya Koutharapumanufacturing technilogy

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 35

Metal casting

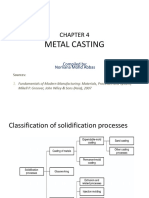

Classification of casting Processes

Casting processes can be classified into following FOUR categories: g p g g

1. Conventional Molding Processes Green Sand Molding

a) Green Sand Molding

b) Dry Sand Molding b) Dry Sand Molding

c) Flask less Molding

2. Chemical Sand Molding Processes

a) Shell Molding a) Shell Molding

b) Sodium Silicate Molding

c) Investment casting

d) No-Bake Molding

3. Permanent Mold Processes

a) Gravity Die casting

b) Low and High Pressure Die Casting

4. Special Casting Processes

a) Lost Wax

b) Ceramics Shell Molding

c) Evaporative Pattern Casting

d) Vacuum Sealed Molding

e) Centrifugal Casting

Pattern

Functions

Obtaining a shaped mold cavity for casting

Molding the gating system

Establishing the parting line

Making core prints

Establishing locating points

Minimizing the casting defects attributable to the

pattern p

Providing economy in molding.

Characteristics Wood Aluminium CastIron Polyurethane

Machinability E G F G Machinability E G F G

WearResistance P G E E

Strength P G E F Strength P G E F

Repairability E F G E

Corrosion E E P E Corrosion

Resistance

E E P E

E E ll t G G d F F i P P E - Excellent, G - Good, F - Fair, P - Poor

Patterns

Loose pattern Loose pattern

Match plate pattern

Cope and drag Pattern

Expendable patterns

1. Loose pattern

simplest least expensive type simplest, least expensive type

reusable pattern

also known as one-piece patterns or solid patterns

suited only for low-quantity production

generally used for experimental or prototypes

made either in one piece or in two pieces

gates and risers are cut by hand

2.Matchplatepattern

pattern is split and the two portions are fixed on the opposite sides of

a plate, called the match plate.

match plate confirms to the parting line of the mold match plate confirms to the parting line of the mold

size of the match plate corresponds to the size of the molding flask

used for moderate to high-volume production of small- and medium-

size castings size castings

considerable dimensional accuracy

3.CopeandDragpattern

cope and drag portions of a split pattern are mounted or integrally

cast on separate plates

used for high-volume production or for the production of large

castings

Pattern cost is higher than for match plate patterns

t t l ldi t ti b l total molding cost per casting may be lower

cope and drag impression is simultaneously made

PatternAllowances

Sh i k ll Shrinkageallowance

Machinefinishallowance

Draft allowance Draftallowance

Distortionallowance

Sh i k ll Shrinkage allowance

It is a correction for shrinkage of the metal

Shrinkage allowance is the amount the pattern be made larger than the Shrinkage allowance is the amount the pattern be made larger than the

casting to provide for contraction

Liquid shrinkage

Solidification shrinkage

Solid shrinkage

Pattern makers shrinkage rule is a special scale which is generally used in

foundries

Machinefinishallowance

The amount the dimensions on a casting is made oversize to Theamountthedimensionsonacastingismadeoversizeto

providestockformachining

Thisisinfluencedbythemetal,castingdesign,methodof

castingandcleaning

Draft allowance Draft allowance

Draftisthetaperallowedontheverticalfacesofapattern

foreasyremovalfrommold. y

Taperisgenerally1.5

o

providedforhandmolding

Machinedrawnpatternsrequires1

o

taper.

Distortion allowance

Largecasting(flatplates,domeorUshapedcasting)distortwhen

d d f f t tt producedfromaperfectpattern.

Totakecareofthisthepatternmaybeintentionallydistorted.

Sand molding

Drag half of mold made by hand. Drag is ready to be rolled over in

preparation for making the cope

Cope mold rammed up.

Procedure

Place the pattern on the molding board Place the pattern on the molding board.

The drag part of the molding flask is placed on the board

Dry facing sand or dust is sprinkled over the board and y g p

pattern to provide a non sticky layer.

Molding sand is then riddled in to cover the pattern with the

fi h h d i l l fill d fingers; then the drag is completely filled.

The sand is then compacted firmly in the drag by means of

hand rammers. The ramming must neither be too hard or hand rammers. The ramming must neither be too hard or

soft.

After the ramming is over, the excess sand is leveled off with

h b k k d a straight bar known as a strike rod.

With the help of vent rod, vent holes are made in the drag to

the full depth of the flask as well as to the pattern the full depth of the flask as well as to the pattern

to facilitate the removal of gases during pouring and

solidification.

Thefinisheddragflaskisnowrolledovertothebottomboard

exposing the pattern exposingthepattern.

Copehalfofthepatternisthenplacedoverthedragpattern

withthehelpoflocatingpins.Thecopeflaskonthe drag

is locatedaligningagainwiththehelpofpins

Thedrypartingsandissprinkled.

Asprue pinformakingthesprue passageislocatedatasmall p p g p p g

distancefromthepattern.Also,riserpin,ifrequired,is placed

atanappropriateplace.

Repeat the operations like filling ramming and venting Repeattheoperationslikefilling,rammingandventing.

Thesprue andriserpinsareremovedfirstandapouringbasin

isscoopedoutatthetoptopourtheliquidmetal.

h f h d d d d f Thenpatternfromthecopeanddragisremovedandfacing

sandintheformofpasteisappliedalloverthemoldcavity

andrunners.

Themoldisassembledandisreadyforpouring

Shell molding process Shell molding process

Advantages of shell molding

Much superior finish dimensional accuracy and consistency in Much superior finish, dimensional accuracy and consistency in

producing quality casting compared with even mechanized

green sand moulding. Shell molding process can accurately g g g p y

replicate even the fine pattern details and dimensions and

hence can be used for precision casting

Capital outlay on sand preparation plant is not essential.

Good utilization of space

Low sand to metal ratio Low sand to metal ratio

The mould is separated from the pattern without the need to

enlarge the cavity. g y

Only a small quantity of sand is used hence cheaper process.

Costly Zircon sand, which has better cooling characteristics

and lower thermal expansion than silica sand, can also be used

since the sand consumption is less.

Mould coating are unnecessary

Lightweight moulds are produced which are readily handled Lightweight moulds are produced which are readily handled

and have good storage characteristics

Skilled labor is not required q

Shells have excellent breakdown at the knockout stage

Lower cleaning at fettling costs

Disadvantages

The raw material are relatively expensive High cost of The raw material are relatively expensive. High cost of

pattern equipment and resin

Relative inflexibility in gating and risering as these have to y g g g

be provided in the shell itself.

The size and weight range of casting is limited

h i f hi h b The process generates noxious fumes which must be

effectively extract

Investmentcasting

InvestmentcastingProcess

1. Masterpattern

2 Mould making 2. Mouldmaking

3. Producingwaxpatterns

4. Waxpatternassembly

5. Investment

6. Dewax

7. Burnout&preheating

8. Pouring

9 Removal 9.Removal

Wax pattern

Finished Turbocharger Rotor

Investmentcasting

PLASTERMOULDING

The conventional plaster mould casting process.

The foamed plaster process.

The Antioch process The Antioch process

Conventional Plaster mold casting

Plaster of paris is mixed with water to produce a slurry.

Slurry is poured over a permanent pattern placed inside a moulding

box and allowed to set to form a rigid mold.

The pattern is stripped, and dried at an elevated temperature to

remove free and chemically combined water remove free and chemically combined water.

Molten metal is poured in to the mold and allowed to solidify.

The method produces a strong, dense, but inherently impermeable

mould..

Foam Plaster molding process

Plaster of paris is mixed with water to produce a slurry.

Air is incorporated in to the slurry during the mixing stage. p y g g g

The Slurry with air bubbles is poured on the permanent pattern

and allowed to set.

It is possible to produce a mould in which 50% of the volume

consists of air bubbles.

This increases the permeability from 1 or 2 units to between

15-30 units, as measured by the AFS permeability test.

The process provides the more economical use of the plaster The process provides the more economical use of the plaster.

However, the inherent strength of the mould is reduced and if

complex shapes are to be produced than flexible patterns complex shapes are to be produced than flexible patterns

traditionally rubber may be required.

Advantages of plaster molding

The ability to produce complex shapes The ability to produce complex shapes.

The ability to produce thin section castings.

The excellent replication of pattern detail.

The ability to produce castings which are dimensionally accurate.

The ability to produce castings with good surface finish.

The minimization of residual stresses and distortion in castings. g

Disadvantages

Poor productivity due to lengthy processing problems.

The need for multiple patterns to improve moulding productivity The need for multiple patterns to improve moulding productivity.

The requirement for close control production process.

The need for special procedure to overcome the problems of poor

mould permeability.

The possibility of impaired mechanical properties arising as a

result of slow cooling of the casting. g g

The mould materials are not reclaimable.

Permanent mold casting Permanentmoldcasting

LowpressurePermanentmold

(LPPM)process

Simplesplitpermanent

moldprocess

Truecentrifugalcasting

Semicentrifugalcasting

Highpressurediecasting

The dies prepared and assembled in the die casting machine.

Lubricant is sprayed on the mold cavity This is for easy

removal of the casting from the die as well as for controlling removal of the casting from the die as well as for controlling

the die temperature. The dies are then closed.

Molten metal is injected into the dies (till the mold cavity is

filled) under high pressure ( in the range 10 and 175 MPa).

The pressure injection leads to a quick filling of the die so

that the entire cavity fills before any part of the casting that the entire cavity fills before any part of the casting

solidifies The pressure is maintained until the casting

solidifies.

The dies are then opened and the shot solidified metal is

ejected by the ejector pins.

The casting is trimmed or sawed or ground to remove the The casting is trimmed or sawed or ground to remove the

scrap portion (like gate, runners, sprue, etc).

Ad t f hi h di ti Advantages of high pressure die casting

Excellent dimensional accuracy.

Smooth cast surfaces with Ra values in the range 12.5 m).

Thinner walls of the order of even 0.75 mm thick can be cast as

compared to sand and permanent mold casting. compared to sand and permanent mold casting.

Inserts such as threaded inserts, heating elements, high strength

bearing surfaces, etc. can be cast-in.

R d li i t d hi i ti Reduces or eliminates secondary machining operations.

Rapid production rates.

Due to pressure application, high solidification rate and absence of

gas defects, high strengths of the order of 400 MPa can be obtained

for castings.

Low fluidity metals can also be cast.. Low fluidity metals can also be cast..

Hot chamber die-casting

Initially the piston of the machine is retracted. This allows the molten metal y p

to flow and fill the cylinder up to the goose neck through the intake port ,

which allows the molten metal to fill the "gooseneck".

The externally powered piston then forces this metal out of the gooseneck

into the die and allow to solidify under pressure.

Cycle time is very fast (approximately 10-15cycles a minute).

Disadvantage

high-melting point metals cannot be

utilized.

Aluminium cannot be used because it

picks up some of the iron while in the

molten pool.

Used primarily for zinc, tin, and lead

based alloys

Hotchamberdiecasting

Coldchamberhighpressurediecasting

In cold chamber die casting the molten charge is ladled from a furnace In cold chamber die casting, the molten charge is ladled from a furnace

in to the shot sleeve of the machine. Normally more material than that

required for filling the cavity is taken. This is to supplement shrinkage

during solidification A hydraulically or pneumatically operated plunger during solidification. A hydraulically or pneumatically operated plunger

pushes the metal in to the die under a pressure of up to 70 MPa till

solidification is complete.

High volume cost-effective production with consistent quality

Eliminating costly post-casting operations. Hence reduced cost

Easily manufacture complex Net shaped parts with tight tolerances Easily manufacture complex Net shaped parts with tight tolerances

Lower tool cost and longer tool life

Lowest total acquisition cost

Cold Chamber diecasting ColdChamberdie casting

Continuouscastingprocess

Continuous casting process

Molten metal from the furnace is transferred in to ladle.

The ladle is transported to the top of the continuous casting machine.

Hot metal is transferred from ladle to a Tundish.

Molten metal from the tundish is fed continuously from the top into a

water cooled copper mold where it solidifies while in contact with the

mold (primary solidification). mold (primary solidification).

A thin shell of molten metal in contact with the mold solidifies.

Solidified metal is pulled out of the mold at a constant pull velocity.

The mold oscillation is provided to prevent the metal sticking to the mold The mold oscillation is provided to prevent the metal sticking to the mold.

The partially solidified metal is allowed to solidify while moving through a

series of water sprays.

The uninterrupted supply of the molten metal at the mold inlet and mold The uninterrupted supply of the molten metal at the mold inlet and mold

exit leads to a continuous production of slabs or billets.

After complete solidification , the strand passes through straightening

rolls and withdrawal rolls rolls and withdrawal rolls.

Finally, the strand is cut into predetermined lengths by mechanical

shears or by travelling oxyacetylene torches.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 3475331Dokument41 Seiten3475331Nguyen Trong TanNoch keine Bewertungen

- DefectsDokument51 SeitenDefectsCollege BoysNoch keine Bewertungen

- Casting ProcessesDokument64 SeitenCasting ProcessesShahzad ahamad100% (1)

- Lab ReportDokument16 SeitenLab ReportFgj Jhg100% (1)

- Continuous CastingDokument12 SeitenContinuous Castingরিপন মন্ডলNoch keine Bewertungen

- Manufacturing Process-I (Casting)Dokument25 SeitenManufacturing Process-I (Casting)Rahul Deb PalNoch keine Bewertungen

- NPTEL Web Course On Complex Analysis: A. SwaminathanDokument14 SeitenNPTEL Web Course On Complex Analysis: A. SwaminathanAditya KoutharapuNoch keine Bewertungen

- NPTEL Web Course On Complex Analysis: A. SwaminathanDokument27 SeitenNPTEL Web Course On Complex Analysis: A. SwaminathanAditya KoutharapuNoch keine Bewertungen

- NPTEL Web Course On Complex Analysis: A. SwaminathanDokument21 SeitenNPTEL Web Course On Complex Analysis: A. SwaminathanAditya KoutharapuNoch keine Bewertungen

- NPTEL Web Course On Complex Analysis: A. SwaminathanDokument16 SeitenNPTEL Web Course On Complex Analysis: A. SwaminathanAditya KoutharapuNoch keine Bewertungen

- NPTEL Web Course On Complex Analysis: A. SwaminathanDokument22 SeitenNPTEL Web Course On Complex Analysis: A. SwaminathanAditya KoutharapuNoch keine Bewertungen

- UIDAI Temporarily Suspends Airtel, Airtel Payments Bank's EKYC Licence - The HinduDokument3 SeitenUIDAI Temporarily Suspends Airtel, Airtel Payments Bank's EKYC Licence - The HinduAditya KoutharapuNoch keine Bewertungen

- Why Is Wassenaar Arrangement Important To India - The HinduDokument4 SeitenWhy Is Wassenaar Arrangement Important To India - The HinduAditya KoutharapuNoch keine Bewertungen

- Questionable Remedy - On The National Medical Commission Bill - The HinduDokument2 SeitenQuestionable Remedy - On The National Medical Commission Bill - The HinduAditya KoutharapuNoch keine Bewertungen

- The Rise and Fall of The WTO - The HinduDokument4 SeitenThe Rise and Fall of The WTO - The HinduAditya KoutharapuNoch keine Bewertungen

- Seeing Through A Glass Darkly - On Combating Terrorism - The HinduDokument5 SeitenSeeing Through A Glass Darkly - On Combating Terrorism - The HinduAditya KoutharapuNoch keine Bewertungen

- The Center of The Milky Way Is Teeming With Black Holes - The HinduDokument2 SeitenThe Center of The Milky Way Is Teeming With Black Holes - The HinduAditya KoutharapuNoch keine Bewertungen

- 230% Increase in Ceasefire Violations - GovtDokument2 Seiten230% Increase in Ceasefire Violations - GovtAditya KoutharapuNoch keine Bewertungen

- Pak. Diplomats Funded Unrest in J&K: NIA: But Chargesheet Doesn't Name AnyDokument2 SeitenPak. Diplomats Funded Unrest in J&K: NIA: But Chargesheet Doesn't Name AnyAditya KoutharapuNoch keine Bewertungen

- Casting ProcessesDokument40 SeitenCasting ProcessesreynierNoch keine Bewertungen

- MP Module 1Dokument13 SeitenMP Module 1Aryan RaiNoch keine Bewertungen

- Pattern Allowances 1 (2-14) - 1Dokument13 SeitenPattern Allowances 1 (2-14) - 1VDNoch keine Bewertungen

- Syllabus FTDokument2 SeitenSyllabus FTOrville SutariNoch keine Bewertungen

- Introduction To Casting ProcessesDokument11 SeitenIntroduction To Casting Processesuvsing100% (2)

- Casting DefectsDokument10 SeitenCasting DefectsshahazadNoch keine Bewertungen

- Unit 6 - Die CastingDokument86 SeitenUnit 6 - Die CastingNeo TarunNoch keine Bewertungen

- 3 1and3 2Dokument110 Seiten3 1and3 2MPRajNoch keine Bewertungen

- Chap6.1 - Casting-1Dokument31 SeitenChap6.1 - Casting-1Nex LeeNoch keine Bewertungen

- Sand MouldingDokument33 SeitenSand MouldingSuman DeyNoch keine Bewertungen

- MP-II COPYRIGHT PPT by SJYDokument177 SeitenMP-II COPYRIGHT PPT by SJYMohit GajaralwarNoch keine Bewertungen

- Metal-Casting Tomo 15Dokument8 SeitenMetal-Casting Tomo 15CamilaAndreaGrijalbaNoch keine Bewertungen

- Chapter 3 CastingDokument35 SeitenChapter 3 CastingShalin SharmaNoch keine Bewertungen

- Casting Slides 1-55Dokument55 SeitenCasting Slides 1-55Asjad khanNoch keine Bewertungen

- Metal Casting A Sand Casting Manual For The Small Foundry Volume 2 by Steve Chastain Stephen DchastainDokument10 SeitenMetal Casting A Sand Casting Manual For The Small Foundry Volume 2 by Steve Chastain Stephen Dchastainvictor manuel felixNoch keine Bewertungen

- Assignment For UNIT IDokument2 SeitenAssignment For UNIT IParamasivam VeerappanNoch keine Bewertungen

- Foundryman Vol II of II TheoryDokument106 SeitenFoundryman Vol II of II TheoryAkshay Kumar KNoch keine Bewertungen

- Foundry Manual - Part 3Dokument49 SeitenFoundry Manual - Part 3Khin Aung ShweNoch keine Bewertungen

- Ch08 HW QuestionsDokument2 SeitenCh08 HW QuestionsSirilak KlakwongNoch keine Bewertungen

- Previous Years Gate Questions On Casting 2007-2013 - Engineering Tutorials PDFDokument5 SeitenPrevious Years Gate Questions On Casting 2007-2013 - Engineering Tutorials PDFnallsrajj100% (1)

- Metal Casting: Compiled By: Norliana Mohd AbbasDokument34 SeitenMetal Casting: Compiled By: Norliana Mohd AbbasAziful AimanNoch keine Bewertungen

- Cold Shut and Misrun Defect in Al CastingDokument21 SeitenCold Shut and Misrun Defect in Al CastingRudi YansahNoch keine Bewertungen

- Casting AssignmentDokument2 SeitenCasting AssignmentAyush BaliNoch keine Bewertungen

- Casting NotesDokument36 SeitenCasting NotesAndrews ArunothayanNoch keine Bewertungen