Beruflich Dokumente

Kultur Dokumente

WCDE-00088-01 BMEIA Hydram Pump Design 100420

Hochgeladen von

Chandra Shekhar Chaurasiya0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

97 Ansichten5 SeitenBasic metal and engineering industries agency (BMEIA) is located in addis ababa, Ethiopia. The agency aspires to be a center of excellence for the Basic Metals and Engineering Industries sub-sector. A Hydram pump is used to supply water for rural communities, mainly for livestock and irrigation purposes.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenBasic metal and engineering industries agency (BMEIA) is located in addis ababa, Ethiopia. The agency aspires to be a center of excellence for the Basic Metals and Engineering Industries sub-sector. A Hydram pump is used to supply water for rural communities, mainly for livestock and irrigation purposes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

97 Ansichten5 SeitenWCDE-00088-01 BMEIA Hydram Pump Design 100420

Hochgeladen von

Chandra Shekhar ChaurasiyaBasic metal and engineering industries agency (BMEIA) is located in addis ababa, Ethiopia. The agency aspires to be a center of excellence for the Basic Metals and Engineering Industries sub-sector. A Hydram pump is used to supply water for rural communities, mainly for livestock and irrigation purposes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

BMEIA HYDRAM PUMP DESIGN

David Effa and Dr. Abiy Awoke

WCDE-00088-01

Revision 100126

David M. Effa of the Waterloo Cases in Design Engineering (WCDE) Group and Dr. Abiy Awoke of BMEIA prepared this design case study for

classroom use. The authors do not intend to illustrate either effective or ineffective handling of an engineering situation. The authors may have

disguised certain names and other identifying information to protect confidentiality.

The Waterloo Cases in Design Engineering Group prohibits any form of reproduction, storage or transmittal of this document without its written

permission. This material is not covered under authorization of CanCopy or any reproduction rights organization. To order copies or request

permission to reproduce materials contact Waterloo Cases in Design Engineering c/o Department of Mechanical Engineering, University of

Waterloo, Waterloo, Ontario, Canada, N2L 3G1 e-mail: design@mme.uwaterloo.ca website : www.design.uwaterloo.ca

Introduction

Basic Metal and Engineering Industries Agency (BMEIA) is located in Addis Ababa, Ethiopia. The agency

aspires to be a center of excellence for the Basic Metals and Engineering Industries sub-sector in research and

development activities. BMEIA has developed a range of products including machinery, plastic moulds, and

press tools as customized systems or research activities. In addition, the agency develops suitable technologies

for rural communities, in particular, products related to water supply systems. One such product is the

hydraulic ram (Hydram) pump, depicted in Figure 1. It is used to supply water for rural communities, mainly

for livestock and irrigation purposes. A Hydram pump is a unique device that uses the lower pressure head

(height) energy from a stream of water to pump a small volume of the water to a head located at a much

higher elevation. After discovering and refurbishing a station of hydram pumps in Ziway, BMEIA proposed to

supply water from the same stream to a small, nearby village (population of about 500 people) using a

Hydram pump. The Hydram pump components must be designed according to the results generated from a

site survey and an environmental assessment.

Figure 1 - Basic components of Hydram pump

2

BMEIA HYDRAM PUMP DESIGN

WCDE-00088-01

A simplified system arrangement for a Hydram pump installation is shown in Figure 2. These pumps use

the energy contained in water falling from a short height to lift a small portion of the driving water to a

much greater height. In this way, water from a spring or stream in a valley can be pumped to a village or

irrigation scheme on a hillside. The main and unique advantage of the Hydram pump is the continuous

supply of water it can provide to a target area without the need for an external energy source. It uses a

renewable energy source (a stream of water) and hence ensures low running costs, while imparting little or

no harm to the environment.

Figure 2- Basic structural system arrangement for Hydram pump

Hydram pump projects at BMEIA

Provision of adequate domestic water supplies to scattered rural populations is a major problem in many

developing countries. Fuel and maintenance costs to operate conventional pumping systems are becoming

prohibitive as the cost of fuel continues to rise. In recent years an increased interest in renewable energy

devices and an awareness of the technological needs of water supply and management markets in developing

countries have prompted a reappraisal of Hydram pump utility. Although a number of Hydram pumps have

been successfully installed in developing countries, the potential use of this technology far exceeds current

levels of implementation. The main reason for this is a general lack of local knowledge in the design and

manufacture of Hydram pumps. Hence, the widespread use of Hydram pumps can only occur if there is a local

manufacturer to deliver products quickly, and provide assistance with system design, installation, and after-

3

BMEIA HYDRAM PUMP DESIGN

WCDE-00088-01

sales service. BMEIA has taken the lead in developing and implementing this technology for rural community

water supply systems.

During a performance follow up of hand pumps developed and installed by BMEIA around Ziway, a city 250

km from the capital of Addis Ababa, a Hydram pump station installed about forty years ago was discovered.

The pumps are located in Adami-Tulu village, which is a part of Ziway city. Five Hydram pumps in this

station were used to supply water to a ranch located about 20 km away from the water source. At the Ziway

station, only one out of five pumps was operational when discovered. BMEIA engineers refurbished these

Hydram pumps back to operational status. The following maintenance was performed on the existing Hydram

pumps.

i. The drive pipes of the Hydram station were 4" galvanized steel pipe, and, due to long years of service,

were corroded and leaking at many points. The drive pipes were replaced by new galvanized steel

pipes. Flanged connections were added for ease of maintenance.

ii. The threaded parts of the Hydram main body were seized due to corrosion. This required re-threading

of the Hydram body to fix the valve parts securely.

iii. Due to the cyclic load endured during pump operation, the bolts, studs and nuts must be replaced

often throughout the service life of Hydram pumps. New studs were made out of stainless steel and

other parts were electro-galvanized for longer maintenance-free operation.

iv. The waste valve-retaining ring was broken due to repeated fatigue loading and corrosion. They were

replaced.

v. Rubber parts need to be replaced often during service life. For these Hydram pumps, all the delivery

and waste valve rubber parts were damaged due to wear. Due to the custom size, a new rubber mould

was designed and manufactured at BMEIA to make new rubber parts.

vi. Other parts such as the diversion canal gate, header pipes, and intake valves were re-designed and

manufactured.

New Hydram pump design requirements

After refurbishment of the old Hydram pump, BMEIA performed extensive research to improve overall

efficiency and minimize maintenance costs. The agency designed and manufactured improved Hydram pumps

in collaboration with World Vision and other organizations involved in water supply and management

systems. BMEIA investigated potential new sites and designed new Hydram pumps with different capacities

according to specifications derived from environmental assessment data. Figure 3 shows a new cast Hydram

air chamber and main body part designed and fabricated for a 120 litres/min. water supply requirement.

4

BMEIA HYDRAM PUMP DESIGN

WCDE-00088-01

Figure 3 - Hydram part components manufactured at BMEIA

BMEIA learned that another part of Adami-Tulu village needed an additional water supply and the Hydram

pump was selected to provide it. Therefore, a new Hydram pump was required to deliver water to the village

from the same stream used to supply water through existing Hydram pump installations. The new water

supply is for irrigation and drinking water, including livestock use. The pump needed to be designed to lift

water from a depth of 6 m (H) below the surface of the stream to a storage and treatment plant in the village,

as shown in Figure 4, with no external energy source. The available fall is based on previously existing

Hydram pump infrastructure, which was reused for the new Hydram pump system. Due to the existing hill

between the water source and the village, an overall delivery head (H

d

) of 25m must be overcome by the

pump system.

Figure 4 Schematic of Hydram pump system installation

In order to use the existing Hydram pump installation infrastructure, the new drive pipe requires a 4" inside

diameter to fit securely with existing parts. Furthermore, the pump was designed to deliver water at a rate of

80 litres per minute in order to supply sufficient water for the 500 village residents and their livestock.

5

BMEIA HYDRAM PUMP DESIGN

WCDE-00088-01

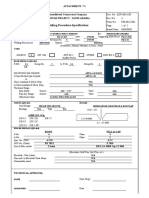

Following a full assessment of village needs and suitability of the water source, the following design

specifications were developed for the new Hydram pump design, Table 1.

Table 1 Design specification for new Hydram pump design obtained from environment assessment

Design Parameter Units Value

Head

Supply head (H) meters 6.2

Delivery head (H

d

) meters 25.5

Distances

Source Drive Tank: (L

sd

) meters 30

Drive tank - Hydram Pump: (L

dp

) meters 60

Hydram Pump Storage and Treatment: (L

ps

) meters 440

Storage and Treatment Village/ Tapstand: (L

sv

) meters 400-500

Water amounts

Water requirement (Q

s

) litres/min 80

Water source flow (Q) litres/min -

Pipe diameter

Drive pipe diameter (d) 4 Sch 40 4 inside

Structural dimensions

Drive tank meters 0.6 1 2

Treatment tank meters 1 1 1

Reservoir tank litres 2,000

The engineers at BMEIA designed, manufactured and implemented a hydram pump system to meet these

needs.

References

[1]. Basic Metal and engineering industry agency fliers, Vol. I, Rev 004, July 19, 2005.

[2]. Dr. Tessema, Abiy Awoke Hydraulic Ram Pump System Design and Application" ESME 5th Annual

Conference on Manufacturing and Process Industry, September 2000

[3]. Teferi Taye, "Hydraulic Ram Pump", Journal of the Ethiopian Society of Mechanical Engineers, Vol. II,

No. l, July 1998.

[4] Lorenz, H.: Theorie des hydraulischen Widders. Z. VDI Vol. 54 (1910) pp. 88/90.

[5] Krol, J.: The automatic hydraulic ram. Inst. Mechanical Engineering Proc. Vol. 165 (1951) No. 64, pp.

53/73.

[6] Kraemer, K.: Bemerkungen zum hydraulischen Widder. MPI for Str6mungsforschung G/3ttingen (BRD),

Report 118/1978.

[7] David, J.P. and Edward, H.W., 1985, Schaum's Outline of Theory and Problems of Fluid Mechanics and

Hydraulics, SI (Metric) Edition, McGraw-Hill Book Company, Singapore.

Das könnte Ihnen auch gefallen

- Install Hydraulic Ram Pump VillageDokument5 SeitenInstall Hydraulic Ram Pump VillageChandra Shekhar ChaurasiyaNoch keine Bewertungen

- HYDRAM PUMPS CHAPTER 1Dokument70 SeitenHYDRAM PUMPS CHAPTER 1Mburu NjorogeNoch keine Bewertungen

- Hydraulic RAM ApplicationDokument70 SeitenHydraulic RAM ApplicationApoorv SinghNoch keine Bewertungen

- Solar Water Pumping SystemDokument5 SeitenSolar Water Pumping Systemsalem BEN MOUSSA100% (1)

- Pedal Operated Centrifugal Water PumpDokument19 SeitenPedal Operated Centrifugal Water PumpNeelmani100% (3)

- Design and Fabrication of Rope Pump: Mohamed Abu Waseem RDokument5 SeitenDesign and Fabrication of Rope Pump: Mohamed Abu Waseem Rimma coverNoch keine Bewertungen

- Guide to Hydraulic RamsDokument22 SeitenGuide to Hydraulic RamsSameera LakmalNoch keine Bewertungen

- Hydraulic Ram PumpDokument9 SeitenHydraulic Ram PumpmastermindishereNoch keine Bewertungen

- Sumo Submersible Borehole Pumps PDFDokument2 SeitenSumo Submersible Borehole Pumps PDFDhanasekaran ArumugamNoch keine Bewertungen

- I RJ Mets 40300097618Dokument10 SeitenI RJ Mets 40300097618design gipfelNoch keine Bewertungen

- Hydraulic Ramp Pump (Hydram)Dokument41 SeitenHydraulic Ramp Pump (Hydram)danish9183% (18)

- Dewatering Plan For Underground PipingDokument7 SeitenDewatering Plan For Underground PipingAhmed Imran100% (1)

- Adityapur Phe Dbr-22mar13Dokument17 SeitenAdityapur Phe Dbr-22mar13Shiyam RajNoch keine Bewertungen

- Department of Mechanical Engineering Faculty of Engineering Coursework Report Session 2011/2012 Hydraulic Ram PumpDokument45 SeitenDepartment of Mechanical Engineering Faculty of Engineering Coursework Report Session 2011/2012 Hydraulic Ram PumpግሩምሠውአሰፋመላኩNoch keine Bewertungen

- Plumbing Design Course NotesDokument39 SeitenPlumbing Design Course NotesAli Hossain100% (1)

- Innovations and Technological Developments in Long Distance Water Transmission SystemDokument7 SeitenInnovations and Technological Developments in Long Distance Water Transmission SystemProphx BliziceNoch keine Bewertungen

- Solar Water PumpingDokument9 SeitenSolar Water PumpingsivaramanpsrNoch keine Bewertungen

- LRP Paper 11Dokument18 SeitenLRP Paper 11crististan1969Noch keine Bewertungen

- Unit 17Dokument50 SeitenUnit 17chidyamakuniNoch keine Bewertungen

- Course On: Wastewater Pumping Stations DesignDokument10 SeitenCourse On: Wastewater Pumping Stations DesignAQ UANoch keine Bewertungen

- Leading Pump Magazine Explores Water Sourcing Solutions for MiningDokument7 SeitenLeading Pump Magazine Explores Water Sourcing Solutions for MiningTamani MoyoNoch keine Bewertungen

- LeyteDokument12 SeitenLeyteimperialcaha01Noch keine Bewertungen

- Solar Water HeaterDokument2 SeitenSolar Water HeaterSandeep PandeyNoch keine Bewertungen

- Estimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemDokument13 SeitenEstimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemAnand M VNoch keine Bewertungen

- Design and Performance Evaluation of A Solar Water Pumping System: A Case StudyDokument8 SeitenDesign and Performance Evaluation of A Solar Water Pumping System: A Case StudyYves UmuhozaNoch keine Bewertungen

- Development of A Solar-Powered Slider-Crank Mechanism For Hand Pump in Rural AreasDokument9 SeitenDevelopment of A Solar-Powered Slider-Crank Mechanism For Hand Pump in Rural AreasPoonam KilaniyaNoch keine Bewertungen

- Rotodynamic Pumps Reduce Shear for Oil & GasDokument6 SeitenRotodynamic Pumps Reduce Shear for Oil & GasmariasofiarossiNoch keine Bewertungen

- Plumbing Design and Sewer Network for Residential TowersDokument14 SeitenPlumbing Design and Sewer Network for Residential TowersRK PROJECT CONSULTANTSNoch keine Bewertungen

- Energy Saving Water PumpDokument4 SeitenEnergy Saving Water PumpEnriv YasiladNoch keine Bewertungen

- GUO 2018 OptimalDesign PerformanceDokument15 SeitenGUO 2018 OptimalDesign PerformanceRodrigo FrancoNoch keine Bewertungen

- Solar Pumps Sizing and DesigningDokument27 SeitenSolar Pumps Sizing and DesigningAwadhesh RanjanNoch keine Bewertungen

- RJ STP BrochureDokument3 SeitenRJ STP Brochurefrancisb65Noch keine Bewertungen

- Design of Modern Hydraulic Tank Using Fluid Flow SimulationDokument12 SeitenDesign of Modern Hydraulic Tank Using Fluid Flow SimulationRNoch keine Bewertungen

- Fairbanks Nijhuis Municipal Pump ProductsDokument8 SeitenFairbanks Nijhuis Municipal Pump Productsdavalgonzalez100% (1)

- Sulzer Pumps Retrofit: Increasing The Efficiency of Pumps: Technical and Economic OptimizationDokument8 SeitenSulzer Pumps Retrofit: Increasing The Efficiency of Pumps: Technical and Economic OptimizationAri HeryadiNoch keine Bewertungen

- Layout of Water Distribution SystemDokument39 SeitenLayout of Water Distribution SystemIr Fik TNoch keine Bewertungen

- 6.04. Wüst MDokument8 Seiten6.04. Wüst MAnonymous NUn6MESxNoch keine Bewertungen

- Rain Water HarvestingDokument10 SeitenRain Water HarvestingBalaji's skye chalet 16 Sree Balaji ConstructiionsNoch keine Bewertungen

- Ar002Dokument28 SeitenAr002Pedro Tiago Batista CoelhoNoch keine Bewertungen

- Voith Pumped Storage PlantsDokument12 SeitenVoith Pumped Storage PlantsClaudio RodriguesNoch keine Bewertungen

- Wastewater Pump Station Design Problems and SolutionsDokument37 SeitenWastewater Pump Station Design Problems and Solutionssinduh100% (2)

- Pump Products: Hydraulic EngineeringDokument16 SeitenPump Products: Hydraulic EngineeringLászló Szabó100% (1)

- Design and Performance Evaluation of A Solar Water Pumping System: A Case StudyDokument8 SeitenDesign and Performance Evaluation of A Solar Water Pumping System: A Case Studymohamed bllaminNoch keine Bewertungen

- EPA Fact Sheet on In-Plant Wastewater Pump StationsDokument9 SeitenEPA Fact Sheet on In-Plant Wastewater Pump StationsAndrés BahamondeNoch keine Bewertungen

- Fabrication of Hydraulic Pipe Bending Machine PDFDokument2 SeitenFabrication of Hydraulic Pipe Bending Machine PDFAndrew100% (1)

- Voith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesDokument8 SeitenVoith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesAshutosh VashishthaNoch keine Bewertungen

- Custom Made Pumps: Napier - ReidDokument2 SeitenCustom Made Pumps: Napier - ReidLTE002Noch keine Bewertungen

- Prototype Model of Hydraulic Milling Machine CircuitDokument49 SeitenPrototype Model of Hydraulic Milling Machine CircuitRamjan ShidvankarNoch keine Bewertungen

- CVP NewDokument23 SeitenCVP NewBhaskar ReddyNoch keine Bewertungen

- Group No: 7' Group Members: Supervisor: Mafidur RahmanDokument20 SeitenGroup No: 7' Group Members: Supervisor: Mafidur RahmanmonotoshNoch keine Bewertungen

- Hydraulic Equipment & Machinery: Hydropower Engineering SystemsDokument4 SeitenHydraulic Equipment & Machinery: Hydropower Engineering Systemsbukit_guestNoch keine Bewertungen

- Catalogo Submersible Sewage PumpDokument80 SeitenCatalogo Submersible Sewage PumpDavid FergusonNoch keine Bewertungen

- Section 7Dokument4 SeitenSection 7Nassif Abi AbdallahNoch keine Bewertungen

- Welcome To My Presentation: Wednesday, Ma y 12, 2021Dokument30 SeitenWelcome To My Presentation: Wednesday, Ma y 12, 2021mulalem baheru67% (3)

- Department of Civil Engineering: Reticulation DesignDokument30 SeitenDepartment of Civil Engineering: Reticulation Designanon_307271108100% (1)

- Pumping Stations: Compiled By: Beat Stauffer (Seecon International GMBH), Dorothee Spuhler (Seecon International GMBH)Dokument4 SeitenPumping Stations: Compiled By: Beat Stauffer (Seecon International GMBH), Dorothee Spuhler (Seecon International GMBH)Kaniz PriyangkaNoch keine Bewertungen

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentVon EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Designing Rainwater Harvesting Systems: Integrating Rainwater into Building SystemsVon EverandDesigning Rainwater Harvesting Systems: Integrating Rainwater into Building SystemsNoch keine Bewertungen

- Improving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsVon EverandImproving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsNoch keine Bewertungen

- Legal AptitudeDokument4 SeitenLegal AptitudeChandra Shekhar ChaurasiyaNoch keine Bewertungen

- Informativeengli 020302 MBPDokument119 SeitenInformativeengli 020302 MBPChandra Shekhar ChaurasiyaNoch keine Bewertungen

- GrammarDokument23 SeitenGrammarhanoimuathu2013Noch keine Bewertungen

- WCDE-00088-02 BMEIA Hydram Pump Design 100420Dokument9 SeitenWCDE-00088-02 BMEIA Hydram Pump Design 100420Chandra Shekhar ChaurasiyaNoch keine Bewertungen

- English Grammer 19Dokument62 SeitenEnglish Grammer 19Chandra Shekhar ChaurasiyaNoch keine Bewertungen

- Grammerarmeniane00awgerich PDFDokument160 SeitenGrammerarmeniane00awgerich PDFrarajvcNoch keine Bewertungen

- Session 1 Dinesh Adjikari Centre For Rural Technology, Nepal - Hydram - 0Dokument11 SeitenSession 1 Dinesh Adjikari Centre For Rural Technology, Nepal - Hydram - 0Chandra Shekhar ChaurasiyaNoch keine Bewertungen

- Ram PumpsDokument20 SeitenRam PumpsChandra Shekhar ChaurasiyaNoch keine Bewertungen

- Pumps for Small-Scale Irrigation GuideDokument37 SeitenPumps for Small-Scale Irrigation GuideChandra Shekhar ChaurasiyaNoch keine Bewertungen

- Blowoff ExplanationDokument5 SeitenBlowoff ExplanationPablo SanciminoNoch keine Bewertungen

- Resistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooDokument6 SeitenResistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooTJPRC PublicationsNoch keine Bewertungen

- SGL PT Brochure Graphite Block Heat ExchangersDokument16 SeitenSGL PT Brochure Graphite Block Heat ExchangersdardocapoNoch keine Bewertungen

- B8 PPT Composites MT14 20nov14Dokument86 SeitenB8 PPT Composites MT14 20nov14Rasagya MishraNoch keine Bewertungen

- Get TRDocDokument238 SeitenGet TRDocShev PanushkinNoch keine Bewertungen

- AGTE Theory 1 Chapter 1Dokument41 SeitenAGTE Theory 1 Chapter 1Abush NigussieNoch keine Bewertungen

- Ejercicios de ConfiabilidadDokument3 SeitenEjercicios de ConfiabilidadIvan Jose HerreraNoch keine Bewertungen

- Science 8 q1 w3Dokument12 SeitenScience 8 q1 w3Je-ann AcuNoch keine Bewertungen

- 2018 1 X Y HamadaDokument28 Seiten2018 1 X Y HamadaGaurav Kumar ThakurNoch keine Bewertungen

- Exploded View of The Suntour Duro DJ E Suspension ForkDokument1 SeiteExploded View of The Suntour Duro DJ E Suspension Forksdjanus0% (1)

- Questions Old 2066 & 2068 NTC Level - 7 (Elx & Comm)Dokument5 SeitenQuestions Old 2066 & 2068 NTC Level - 7 (Elx & Comm)Prashant McFc AdhikaryNoch keine Bewertungen

- Me-1 To 10 Gf-PodiumDokument10 SeitenMe-1 To 10 Gf-PodiumKristina OrmacidoNoch keine Bewertungen

- CDI 6: Fire Behavior and Arson Investigation ExamDokument3 SeitenCDI 6: Fire Behavior and Arson Investigation ExamRyan PelayreNoch keine Bewertungen

- Ipc Autosaw en Web 0115Dokument2 SeitenIpc Autosaw en Web 0115Jose Miguel Gonzalez VirviescasNoch keine Bewertungen

- Syngas Gas Train Schematic and Spare Parts ListDokument4 SeitenSyngas Gas Train Schematic and Spare Parts ListShamshuddin TanekhanNoch keine Bewertungen

- Honda PCX150 Service Manual PDFDokument436 SeitenHonda PCX150 Service Manual PDFjuanchoakorn71% (7)

- Esquema Elétrico NGD 9.3 PDFDokument2 SeitenEsquema Elétrico NGD 9.3 PDFluiskovalchukNoch keine Bewertungen

- Consolidated Contractors Welding Procedure SpecificationDokument3 SeitenConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- Catalogo Repuestos YBR125DX 2008 ColombiaDokument58 SeitenCatalogo Repuestos YBR125DX 2008 ColombiaadrielairaldoNoch keine Bewertungen

- Postgrad Courses PDFDokument36 SeitenPostgrad Courses PDFShah Wali UllahNoch keine Bewertungen

- Split Case LRDokument8 SeitenSplit Case LRmartin.rubenNoch keine Bewertungen

- Tofd & Pe ReportDokument1 SeiteTofd & Pe ReportLuong Ho VuNoch keine Bewertungen

- Softdough & Cookies Manufacturing ProcessesDokument32 SeitenSoftdough & Cookies Manufacturing ProcessesPhạm Hữu PhướcNoch keine Bewertungen

- Hydraulic Design of IntakeDokument4 SeitenHydraulic Design of IntakeGokul100% (1)

- Diamondchaincoctalogo PDFDokument151 SeitenDiamondchaincoctalogo PDFFranco Matias TemporinNoch keine Bewertungen

- Interlock, Protection & Permissive of BFPDokument15 SeitenInterlock, Protection & Permissive of BFPShweta Srivastava100% (2)

- Is Schrodinger EquationDokument3 SeitenIs Schrodinger EquationSpirosKoutandosNoch keine Bewertungen

- 3 Phase TMDokument39 Seiten3 Phase TMHari Kishan Nimmu0% (1)

- Pipe Stress AnalysisDokument7 SeitenPipe Stress AnalysisTushar NaikNoch keine Bewertungen