Beruflich Dokumente

Kultur Dokumente

Lean Roadmap

Hochgeladen von

Ahmed MagedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lean Roadmap

Hochgeladen von

Ahmed MagedCopyright:

Verfügbare Formate

Lean Six Sigma Project Flow: Adapting Lean to DMAIC

Tool/Resource

CTQ Drilldown, Problem Statement, Project

Scope, Project Financial Savings, Pre-

Assessment (Min/Max Analysis)

Stakeholder Analysis (ARMI), Buy-

In/Sponsorship (CAP model)

High-level Process Map, SIPOC

Project Charter, Project Storyboard

OUTPUTS:

Takt Time, First Time Yield (FTY), Rolled

Throughput Yield (RTY)

IPO-FAT Model

Detailed Process Map, Value Stream Map

(VSM)

Measurement System Analysis (MSA)

OUTPUTS:

7 Deadly Wastes, VA & NVA steps, Work-in-

Process (WIP), Spaghetti Diagram

5S Program

Push vs. Pull, Batch Processing vs. One-Piece

Flow

Six Sigma Hypothesis Testing

OUTPUTS:

Question Levels 1 to 2

D

e

f

i

n

e

Do you fully understand the severity and scope of the problem?

Can you clearly define the problem and its potential impact to the organization?

Do you have a team that agrees with the project focus?

Do you understand the high-level process related to the problem?

Do you have a method for communicating the project information?

Project Storyboard, Charter, CTQ Drilldown, ARMI, SIPOC, High-Level Process Map, and Benefits Pre-Assessment.

M

e

a

s

u

r

e

Do you understand the flow and capability for the current process?

Do you know what time/cost metric reflects the output described by the problem

statement?

Have you identified all potential input>process>output opportunities according to the

flow, accuracy and timeliness perspectives?

Have you mapped out the flow of the As-Is process including sub-processes leading to

(inputs) and coming from (outputs) the target process?

Do you know if your process maps and collected data are accurate, repeatable and

reproducible?

Updated Project Storyboard, As-Is Process Map, As-Is Value Stream Map (VSM).

A

n

a

l

y

z

e

Do you know what are the non-value-added or wasteful steps in the process?

Have you reviewed the process map(s) to identify all Non-Value-Added (NVA) & Value-

Added (VA) steps?

Have you identified any steps in the process where 5S is not used?

If enough data is available, have you applied statistical tools to measure the input, flow

and output of sub-processes that could reveal additional areas of waste?

Updated Project Storyboard, identification of all VA and NVA process steps.

Have you identified any push flows or batch processing in the process?

OUTPUTS:

Detailed Process Map, Value Stream Map

(VSM)

Impact Matrix (PICK chart), FMEA

Pilot/Implementation Plan, Pilot Duration,

Scorecard, MSA

OUTPUTS:

FMEA, Pilot/Implementation Plan, Scorecard,

MSA

5S Program, Kanban System, Poke-Yoke

Control Charts

SOPs, Control Plan

Project Closure, Sponsorship

OUTPUTS:

Updated Project Storyboard, identification of all VA and NVA process steps.

I

m

p

r

o

v

e

Do you have a new streamlined process design that will resolve the process problem?

Have you mapped out the flow of a new To-Be process including sub-processes leading

to (inputs) and coming from (outputs) the target process?

Do you know the level of rewards (value) and risk expected from the new To-Be

process?

Did you pilot the new To-Be process and get successful results?

Updated Project Storyboard, To-Be Process Map or VSM, data/charts (e.g., scorecard) validating success of the pilot.

C

o

n

t

r

o

l

Does the new process resolve the original problem and will it be sustained?

Did you implement the new To-Be process?

Are the improvements successfully meeting expected results (sustained and in control)?

Did you fully transfer control and responsibility of the improvements to the process

owner?

Does the team (including the Sponsor & Champion) agree the project is complete?

Updated final project storyboard, control plan, SOP, agreement from entire team that the project is complete.

Did you optimize the new To-Be process with controls and visual queues?

Copyright 2011 by Matthew J. Hansen. All Rights Reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted by any means (electronic, mechanical,

photocopying, recording or otherwise) without prior written permission by the author and/or publisher.

Created by Matt Hansen, Lean Six Sigma Master Black Belt (Lean Six Sigma Project Flow v4.xls) 6/18/2012

Das könnte Ihnen auch gefallen

- Value Stream Mapping Software A Complete Guide - 2020 EditionVon EverandValue Stream Mapping Software A Complete Guide - 2020 EditionNoch keine Bewertungen

- LSS Improve Tollgate TemplatesDokument41 SeitenLSS Improve Tollgate TemplatesCarlos Oliver Montejano100% (1)

- Six Sigma WorksheetsDokument67 SeitenSix Sigma WorksheetsPuneet SharmaNoch keine Bewertungen

- Six Sigma Template KitDokument69 SeitenSix Sigma Template KitSilvio SchiessNoch keine Bewertungen

- Operational Excellence: Engineering and Manufacturing SolutionsDokument3 SeitenOperational Excellence: Engineering and Manufacturing Solutionsvuppalavhr254_189902Noch keine Bewertungen

- Yellow BeltDokument11 SeitenYellow BeltRoberto BismarckNoch keine Bewertungen

- V Buehler Lean Assessment TemplateDokument23 SeitenV Buehler Lean Assessment TemplateAntonio Fernández V.100% (1)

- Lean Six Sigma: Step by StepDokument1 SeiteLean Six Sigma: Step by StepgoleansixsigmaNoch keine Bewertungen

- Lean Excellence SEA Outline v3Dokument31 SeitenLean Excellence SEA Outline v3Yogesh GuptaNoch keine Bewertungen

- DMAIC TemplateDokument39 SeitenDMAIC Templateunknown139Noch keine Bewertungen

- Mahindra Black Belt Project Template - NewDokument66 SeitenMahindra Black Belt Project Template - NewSharma MaheshNoch keine Bewertungen

- Black Belt Tollgate Checklist BBv1.1Dokument12 SeitenBlack Belt Tollgate Checklist BBv1.1Kristof MCNoch keine Bewertungen

- Kaizen Event Workshop Aug.03Dokument19 SeitenKaizen Event Workshop Aug.03Gunawan tNoch keine Bewertungen

- DMAIC Project Plan TemplateDokument6 SeitenDMAIC Project Plan TemplatedeepakhsdNoch keine Bewertungen

- Applying Lean Thinking: Systems and Value StreamsVon EverandApplying Lean Thinking: Systems and Value StreamsBewertung: 4 von 5 Sternen4/5 (5)

- Design for Six SIGMA Complete Self-Assessment GuideVon EverandDesign for Six SIGMA Complete Self-Assessment GuideBewertung: 1 von 5 Sternen1/5 (1)

- Six Sigma Yellow Belt Project Charter TemplateDokument6 SeitenSix Sigma Yellow Belt Project Charter TemplateMANOJ KUMAR MECNoch keine Bewertungen

- Jon Jaggers Kanban 1s Board GameDokument46 SeitenJon Jaggers Kanban 1s Board Gamejon5083100% (2)

- Lean Manufacturing Training - Course OutlineDokument5 SeitenLean Manufacturing Training - Course OutlineMani SelvanNoch keine Bewertungen

- Six Sigma Statistics With Minitab 1697612881Dokument136 SeitenSix Sigma Statistics With Minitab 1697612881hajar iraamaneNoch keine Bewertungen

- 4a Quiz StraightenDokument2 Seiten4a Quiz StraightenJose Ortega0% (1)

- Lean Office AssessmentDokument10 SeitenLean Office Assessmentanthony2069100% (1)

- 5S Audit Checklist and Report 1663039107Dokument2 Seiten5S Audit Checklist and Report 1663039107Ashish R. SinghNoch keine Bewertungen

- YAMAZUMIDokument16 SeitenYAMAZUMImagudeeshNoch keine Bewertungen

- LSSGB Lesson0 Course OverviewDokument16 SeitenLSSGB Lesson0 Course OverviewNax ScNoch keine Bewertungen

- Oo Oo Oo Oo: DepartmentDokument3 SeitenOo Oo Oo Oo: Departmentsigmasundar100% (1)

- SMED single minute exchange of die A Complete Guide - 2019 EditionVon EverandSMED single minute exchange of die A Complete Guide - 2019 EditionNoch keine Bewertungen

- Agile Airplane GameDokument5 SeitenAgile Airplane GameKarthik SundarNoch keine Bewertungen

- Disciplined Agile Delivery A Complete Guide - 2019 EditionVon EverandDisciplined Agile Delivery A Complete Guide - 2019 EditionNoch keine Bewertungen

- Ford DFSSDokument8 SeitenFord DFSSiangardiner.iow5796100% (1)

- Value Stream Mapping A Complete Guide - 2020 EditionVon EverandValue Stream Mapping A Complete Guide - 2020 EditionNoch keine Bewertungen

- Quiz Answers Standard WorkDokument4 SeitenQuiz Answers Standard WorkJose OrtegaNoch keine Bewertungen

- A Set-Up Reduction Tool For Continuous ImprovementDokument31 SeitenA Set-Up Reduction Tool For Continuous ImprovementPriyang ShahNoch keine Bewertungen

- Industrial Solutions, Inc: Lean Assessment ScorecardDokument5 SeitenIndustrial Solutions, Inc: Lean Assessment ScorecardsigmasundarNoch keine Bewertungen

- VSMDokument13 SeitenVSMnavingaikwad100% (1)

- Kaizen Case StudyDokument44 SeitenKaizen Case StudyTanmoy ChakrabortyNoch keine Bewertungen

- Applying PDCA A3 Thinking and Problem SolvingDokument23 SeitenApplying PDCA A3 Thinking and Problem SolvingAndrei Timofeev100% (2)

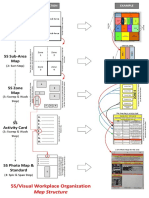

- 5S Map Structure Handout 20160108Dokument2 Seiten5S Map Structure Handout 20160108Ramesh Babu100% (1)

- Definitive Guide To Integrative Improvement TRACC 516Dokument116 SeitenDefinitive Guide To Integrative Improvement TRACC 516Eusebio NavarroNoch keine Bewertungen

- Lean IT Foundation Publication v1.0 PDFDokument14 SeitenLean IT Foundation Publication v1.0 PDFracringandhiNoch keine Bewertungen

- Sales Process Engineering A Complete Guide - 2020 EditionVon EverandSales Process Engineering A Complete Guide - 2020 EditionNoch keine Bewertungen

- Gemba Overview - Sheena Butts - IIESHS - WEBINAR v1Dokument35 SeitenGemba Overview - Sheena Butts - IIESHS - WEBINAR v1Bryan OrdialesNoch keine Bewertungen

- Lean Diagnostic ToolDokument5 SeitenLean Diagnostic Tooltruongngv100% (1)

- Lean - LeanEvent FacilitationGuide Jan2016Dokument34 SeitenLean - LeanEvent FacilitationGuide Jan2016share2gainNoch keine Bewertungen

- Value Stream Mapping A Complete Guide - 2021 EditionVon EverandValue Stream Mapping A Complete Guide - 2021 EditionNoch keine Bewertungen

- Lean SIx Sigma Yellow Belt Capstone Project InstructionsDokument1 SeiteLean SIx Sigma Yellow Belt Capstone Project InstructionsSesha SriramNoch keine Bewertungen

- Standardized Work Combination FormDokument3 SeitenStandardized Work Combination FormisolongNoch keine Bewertungen

- A Strategy For Performance ExcellenceDokument31 SeitenA Strategy For Performance ExcellenceMahesh KumarNoch keine Bewertungen

- Directions For Using Letter of Recommendation FormDokument3 SeitenDirections For Using Letter of Recommendation FormAhmed MagedNoch keine Bewertungen

- Process and Product Development: Valve Tappet Cold Forging ProcessDokument22 SeitenProcess and Product Development: Valve Tappet Cold Forging ProcessAhmed MagedNoch keine Bewertungen

- 1 Week GRE Study GuideDokument3 Seiten1 Week GRE Study GuideAhmed MagedNoch keine Bewertungen

- 5 Lab Unit STMDokument18 Seiten5 Lab Unit STMAhmed Maged0% (1)

- All Cover Letters Web 2011Dokument18 SeitenAll Cover Letters Web 2011Ahmed Maged100% (1)

- Motion of A Freely Falling BodyDokument46 SeitenMotion of A Freely Falling BodyAhmed MagedNoch keine Bewertungen

- The Bounce of A Ball: Rod CrossDokument6 SeitenThe Bounce of A Ball: Rod CrossAhmed MagedNoch keine Bewertungen

- Communications and Media PolicyDokument11 SeitenCommunications and Media PolicyJacky PhanNoch keine Bewertungen

- Modulation Schemes Effect On RF Power Amplifier Nonlinearity and RFPA Linearization TechniquesDokument23 SeitenModulation Schemes Effect On RF Power Amplifier Nonlinearity and RFPA Linearization Techniquesparsi sarenNoch keine Bewertungen

- Javascript NotesDokument55 SeitenJavascript NotesJony nathNoch keine Bewertungen

- MTS & MTO SenariousDokument4 SeitenMTS & MTO SenariousKoustubha Khare100% (1)

- Base CodeDokument118 SeitenBase CodePatrick de Wit100% (1)

- Pengenalan Dan Pemanfaatan Marketplace E-Commerce Untuk Pelaku Ukm Wilayah CilegonDokument8 SeitenPengenalan Dan Pemanfaatan Marketplace E-Commerce Untuk Pelaku Ukm Wilayah CilegonPemetaanPendidikanNoch keine Bewertungen

- City PlanningDokument2 SeitenCity PlanningNidhi KalraNoch keine Bewertungen

- unclass-DISN CPGDokument181 Seitenunclass-DISN CPGjacquez.kainoaNoch keine Bewertungen

- Training ReportDokument30 SeitenTraining ReportManuka DilshanNoch keine Bewertungen

- Roland Vs 640 Mechanical DrawingDokument40 SeitenRoland Vs 640 Mechanical DrawingEdwardo RamirezNoch keine Bewertungen

- DHCP Presentation 01Dokument20 SeitenDHCP Presentation 01rhariharan_13Noch keine Bewertungen

- Plenty of Room - Nnano.2009.356Dokument1 SeitePlenty of Room - Nnano.2009.356Mario PgNoch keine Bewertungen

- T4S Post Amendment 15.09.2020Dokument130 SeitenT4S Post Amendment 15.09.2020kambanNoch keine Bewertungen

- Extio 2 Remote Peripheral Solutions Installation Kit Instruction EP-DPCX24Dokument98 SeitenExtio 2 Remote Peripheral Solutions Installation Kit Instruction EP-DPCX24akramhomriNoch keine Bewertungen

- Present Perfect PracticeDokument25 SeitenPresent Perfect PracticeManuel Tutacha ™100% (1)

- ABX00063 SchematicsDokument8 SeitenABX00063 SchematicsIoan TudosaNoch keine Bewertungen

- 10-Inch Daylight Radar: 1932 MARK-2Dokument2 Seiten10-Inch Daylight Radar: 1932 MARK-2Thien NguyenNoch keine Bewertungen

- Embedded Systems DiplomaDokument9 SeitenEmbedded Systems DiplomaKarim SamhyNoch keine Bewertungen

- Characteristics of Digital DataDokument6 SeitenCharacteristics of Digital DataArdi DiraNoch keine Bewertungen

- Assignment No.7 PDFDokument6 SeitenAssignment No.7 PDFAbdul HameedNoch keine Bewertungen

- Chapter 7 - CPU Structure and Function Ver 1Dokument43 SeitenChapter 7 - CPU Structure and Function Ver 1Nurhidayatul FadhilahNoch keine Bewertungen

- EVAMANv 875Dokument50 SeitenEVAMANv 875prajapativiren1992Noch keine Bewertungen

- Script Rotation V 1.8.1BETADokument122 SeitenScript Rotation V 1.8.1BETADuni AhmadNoch keine Bewertungen

- School Management System: A Synopsis Submitted in Partial Fulfillment of The Requirements For The Degree of inDokument12 SeitenSchool Management System: A Synopsis Submitted in Partial Fulfillment of The Requirements For The Degree of inankush rathorNoch keine Bewertungen

- DFC-90 Cirrus Config and Testing AVDFC-096Dokument15 SeitenDFC-90 Cirrus Config and Testing AVDFC-096Anderson RamalhoNoch keine Bewertungen

- Mandriva Linux One 2009: Starter GuideDokument10 SeitenMandriva Linux One 2009: Starter GuideDarren JayNoch keine Bewertungen

- Archimate 3.1 - Delegate PackDokument318 SeitenArchimate 3.1 - Delegate PackvinodNoch keine Bewertungen

- Basic Introduction To The UCCE Servers and ComponentsDokument24 SeitenBasic Introduction To The UCCE Servers and ComponentsDaksin SpNoch keine Bewertungen

- RF-JUR - 24/3 - CT: Mounting InstructionsDokument13 SeitenRF-JUR - 24/3 - CT: Mounting InstructionsLim BoraNoch keine Bewertungen

- 3m Filtrete Fap 04 SeriesDokument10 Seiten3m Filtrete Fap 04 SeriesJP anonymousNoch keine Bewertungen