Beruflich Dokumente

Kultur Dokumente

Module 3: Liquid Fossil Fuel (Petroleum) Lecture 22: Secondary Processing

Hochgeladen von

api-256504985Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Module 3: Liquid Fossil Fuel (Petroleum) Lecture 22: Secondary Processing

Hochgeladen von

api-256504985Copyright:

Verfügbare Formate

1|P a g e

IITKharagpurNPTELPhaseIIWebCourses

Module 3: Liquid Fossil Fuel (Petroleum)

Lecture 22: Secondary Processing

2|P a g e

IITKharagpurNPTELPhaseIIWebCourses

Keywords: FCC, RFCC, catalyst regeneration, feed atomisation

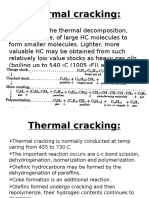

3.4.1.3 Catalytic cracking

Introduction

Catalytic cracking is the process where low-valued high boiling feedstocks are cracked into

value-added products by using a catalyst. Previously there were two types of catalytic cracking

practiced in the refinery, moving bed catalytic cracking and fluid bed catalytic cracking. But

eventually, fluid bed catalytic cracking proved to be advantageous and superior over moving bed

and hence the later one is no longer used in the refinery. Fluid Catalytic Cracking (FCC) and

Resid Fluid Catalytic Cracking (RFCC) are the two important cracking operations used in the

petroleum industry where high boiling gas oils (>350

0

C) and residues are converted into high

octane gasoline, light distillate oil and liquefied petroleum gas. FCC is a continuous process

where atomized feedstock is brought in contact with fluidized catalyst in a reactor. The heavy

feedstock is cracked to lighter products at temperature above 500

0

C and the catalyst is

deactivated. The products are separated from the catalyst and then the catalyst is sent to a

regenerator. In regenerator, the residual carbon on the surface of the catalyst powder is oxidized

at a high temperature (over 600

0

C) and regenerated. Regenerated catalyst is recycled to the

reactor.

In the early 1960s, M.G.Kellogg and Phillips Petroleum began the development of residual oil

cracking. It was clear that high carbon residue of these feedstocks would result in high coke yield

compared to gas oil unit at the same conversion. Moreover, these were contaminated with high

metal content such as nickel and vanadium, which resulted in deposition of metal on catalyst

which in turn increased the yield of light gases, especially hydrogen. Residual oil cracking got

3|P a g e

IITKharagpurNPTELPhaseIIWebCourses

significance when crude oil price was increased and availability of light crude was decreased, a

demand for producing light transportation fuel was grown high, at the end of 1970s. In response

to this pressure, two new residual oil cracking technologies- the UOP residual oil cracking

technology and the Total catalytic cracking technology were developed to compete with heavy

oil cracking. Both of these technologies cope with the problem of excess coke production by

using two stage regeneration. Depending on the level of contamination by metal and alphaltene,

the residual oil feeds may be deasphalted or hydrotreated.

The common feedstocks of modern catalytic cracking are: gas oils from different origin (such as,

atmospheric column, vacuum column, coker unit and thermal cracker), solvent deasphalted oil,

lube-oil extract and bottom product of hydrocracker fractionators. FCC catalysts are mainly high

silica to alumina Y-zeolites, ion exchanged by either rare-earth element or ammonium-ion. The

catalyst is a fine solid having particle diameter in the range of 60-70 m and at this size, the

catalyst particles are easily fluidized by hydrocarbon vapours in the riser reactor. The catalyst

particles are of high attrition resistance to prevent the fracture due to high speed vapour and

steam jets.

Process description

There are four major sections in the FCC plant: converter, flue gas train, main fractionator and

vapour recovery section. Converter can be subdivided into riser reactor, catalyst stripper and

regenerator. Fig. 1 shows the FCC converter. Cracking reaction occurs in the riser reactor. In this

part, preheated feedstock along with recycled feed is atomised at the bottom of the reactor. When

the atomised feed comes in contact with the hot catalyst powder, it vapourises and cracks into

smaller molecular weight compounds. The feed vapour carries the catalyst powder up to the riser

4|P a g e

IITKharagpurNPTELPhaseIIWebCourses

as a dilute suspension. With the progress of the reaction, coke is continuously deposited on the

catalyst powder and by this way, the catalyst loses it activity very soon. The feed atomizer is a

conical shaped piece consisting of a number of flat fan-shaped spray nozzles. These spray

nozzles atomize the feed in such a way that uniform coverage, to prevent bypassing of the

catalyst powder, and maximum penetration of the feed into the catalyst particle occur.

Fig. 1. Fluidised catalytic cracking unit

The catalyst after getting deactivated by the coke deposition is separated from the reaction

products by cyclone separators located in the disengager, at the end of the riser. The separation

of catalyst particle and reaction mixture stops the cracking reaction automatically. Product

vapours after separation flow through the disengager overhead line to the vapour recovery

section. In this section, product vapours are quenched and sent to the main fractionator. The

5|P a g e

IITKharagpurNPTELPhaseIIWebCourses

product vapours are not allowed to stay long in the disengager line, as at this place thermal

cracking of the products may occur to produce low valued gases. The spent catalyst after getting

separated from the products is sent to a two-stage steam stripper. Steam strips off the

hydrocarbon contamination of the catalyst particles from the surface and within. This way, steam

stripping minimizes the hydrocarbon carry over by the catalyst particles to the regenerator, which

in turn imparts the advantages of lower regeneration temperature and lesser probability of

catalyst deactivation due to sintering at high temperature. Hence, catalyst regeneration should be

done at such an environment which can retain the catalyst activity and selectivity to a maximum

possible extent.

After steam stripping, the coked catalyst particles are sent to regenerator where coke is removed

by oxidation with air at high temperature. Air is supplied by high volume air blower which

discharges air at low pressure. Air is passed counter-current to the catalyst. Spent catalyst is

charged at the top of the regenerator and distributed uniformly. Air is introduced from the

bottom. Combustion of coke produces mainly carbon dioxide, although some amount of carbon

monoxide can also be expected due to incomplete combustion. The carbon monoxide content of

flue gas is maintained below 200 ppm. The amount of coke deposition on the catalyst depends on

the type of feedstock charged to FCC. The lighter feed produces lesser coke while heavy feed

deposits higher amount of coke on catalyst. Moreover, the feed containing asphaltene and metals

is responsible to produce more coke. Asphaltene is a precursor of coke production and metals

catalyse dehydrogenation reaction of the feed compounds. Both of these aggravate the

production of extra coke on the catalyst surface. This situation occurs in RFCC unit.

After regeneration, the catalyst powders are cooled to the reactor temperature by the use of a

catalyst cooler. High pressure steam is generated here. The heat from the flue gas obtained from

6|P a g e

IITKharagpurNPTELPhaseIIWebCourses

the regenerator is recovered by a flue gas expander in the form of shaft work, i.e, mechanical

energy and also by generating superheated steam. After heat removal, the flue gas is sent to a

scrubbing unit and/or an electrostatic precipitator to remove SOx and particulate matter as per

environmental laws.

The product vapours obtained from the disengager is condensed and the condensed liquid is

separated into different cuts in the main fractionator. The products obtained from the fractionator

are wet gas and unstabilised gasoline as the top product, light cycle oil as middle product and a

heavy bottom product. The cycle oil is striped to remove light ends. Unstabilised gasoline is sent

to a debutanizer to remove C

4

cuts and thus the gasoline is stabilized.

The last unit of the whole operation is vapour recovery section, where C

2

to C

4

cuts are

recovered from wet gas and gasoline. C

3

and C

4

cuts are utilized as LPG components. Sometimes

a depropaniser is used to separate propane and propylene and a gasoline splitter is used to

separate light and heavy gasoline according to the requirement.

7|P a g e

IITKharagpurNPTELPhaseIIWebCourses

Reference

1. Modern petroleum technology, Downstream, ed. by Alan G, Lucas, Vol 2, 6

th

edition, IP, J ohn

Wiley & Sons Ltd., 2001.

2. Fluid Catalytic Cracking Technology and Operations, J oseph W. Wilson, Pennwell Books,

1997.

3. Fluid Catalytic Cracking Handbook, R. Sadeghbeigi, 3

rd

Edition, Elsevier, 2012.

Das könnte Ihnen auch gefallen

- Module 3: Liquid Fossil Fuel (Petroleum) Lecture 22: Secondary ProcessingDokument7 SeitenModule 3: Liquid Fossil Fuel (Petroleum) Lecture 22: Secondary Processingaditya kumarNoch keine Bewertungen

- m3l21 PDFDokument7 Seitenm3l21 PDFrenger20150303Noch keine Bewertungen

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsDokument6 SeitenAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaNoch keine Bewertungen

- FALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFDokument77 SeitenFALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFJateni GedaNoch keine Bewertungen

- Catalytic Cracking PDFDokument96 SeitenCatalytic Cracking PDFSri NivasNoch keine Bewertungen

- Catalytic Cracking3Dokument12 SeitenCatalytic Cracking3Abdurabu AL-MontaserNoch keine Bewertungen

- Cracking, Visbreaking, Coking and PropertiesDokument12 SeitenCracking, Visbreaking, Coking and Propertiesteyiv23540Noch keine Bewertungen

- CrackingDokument32 SeitenCrackingMuhammad HAmAd QureshiNoch keine Bewertungen

- Chapter-6 Catalytic CrackingDokument44 SeitenChapter-6 Catalytic CrackingVicky TuringNoch keine Bewertungen

- Catalytic Cracking: University of Zakho Faculty of Engineering Petroleum Eng. DepDokument9 SeitenCatalytic Cracking: University of Zakho Faculty of Engineering Petroleum Eng. DepSaMiHRNoch keine Bewertungen

- Introduction of Catalytic Reforming ProcessDokument10 SeitenIntroduction of Catalytic Reforming Processsagarchawla13100% (1)

- Fluid Catalytic CrackingDokument10 SeitenFluid Catalytic CrackingImran Hanif LubisNoch keine Bewertungen

- Fluid Catalytic Craking Unit (Fccu)Dokument6 SeitenFluid Catalytic Craking Unit (Fccu)Nitin VarshneyNoch keine Bewertungen

- FCC PosterDokument1 SeiteFCC PosterHai PhanNoch keine Bewertungen

- Thermal and Catalytic Convesion ProcessDokument54 SeitenThermal and Catalytic Convesion ProcessSaiPavanNoch keine Bewertungen

- Steam ReformingDokument5 SeitenSteam ReformingAshok S. PathakNoch keine Bewertungen

- Coking and Thermal ProcessesDokument8 SeitenCoking and Thermal ProcessesWulandariNoch keine Bewertungen

- Fluid Catalytic Cracking ProcessDokument3 SeitenFluid Catalytic Cracking ProcessMinh Tuấn PhạmNoch keine Bewertungen

- Fluid Catalytic CrackingDokument9 SeitenFluid Catalytic CrackingAntonitoNoch keine Bewertungen

- Fluid Catalytic CrackingDokument16 SeitenFluid Catalytic Crackingbubalazi100% (1)

- Unit 3Dokument11 SeitenUnit 3Shreyash UtekarNoch keine Bewertungen

- Module 4 (KTU)Dokument118 SeitenModule 4 (KTU)Aravind G100% (1)

- Chapter 2 Oil Refinery Plant - Conversion and TreatmentDokument52 SeitenChapter 2 Oil Refinery Plant - Conversion and Treatmenthafizulhakim02Noch keine Bewertungen

- CrackingDokument28 SeitenCrackingzaraNoch keine Bewertungen

- Cracking of Nephtha55555Dokument22 SeitenCracking of Nephtha55555Ankit YadavNoch keine Bewertungen

- HydrocrackingDokument33 SeitenHydrocrackingNikita SeleznevNoch keine Bewertungen

- Fluid Catalytic Cracking - Wikipedia PDFDokument9 SeitenFluid Catalytic Cracking - Wikipedia PDFSauptik DattaNoch keine Bewertungen

- Cracking 151114162534 Lva1 App6891Dokument33 SeitenCracking 151114162534 Lva1 App6891Truth SeekerNoch keine Bewertungen

- Thermal CrackingDokument4 SeitenThermal CrackingMuhammad TahirNoch keine Bewertungen

- FCC UnitDokument28 SeitenFCC UnitMohsin KhanNoch keine Bewertungen

- Bp-Uop Cyclar Process: Lubo ZhouDokument10 SeitenBp-Uop Cyclar Process: Lubo ZhouBharavi K SNoch keine Bewertungen

- 3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitDokument8 Seiten3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitAkankshya MishraNoch keine Bewertungen

- Cracking PDFDokument53 SeitenCracking PDFShabnam BanuNoch keine Bewertungen

- Introduction To Petroleum Technology - 3Dokument21 SeitenIntroduction To Petroleum Technology - 3Anish VazeNoch keine Bewertungen

- Petroleum Refining ProcessDokument11 SeitenPetroleum Refining ProcessRawsht MuradyNoch keine Bewertungen

- Simulation of Fluid Catalytic CrackerDokument62 SeitenSimulation of Fluid Catalytic CrackerAhmed Ali100% (1)

- Catalytic CrackingDokument120 SeitenCatalytic CrackingAlcides RodríguezNoch keine Bewertungen

- Modeling and Simulation of Fluidized Catalytic Cracking Riser Reactor Using Pseudo Reaction Kinetics: A ReviewDokument15 SeitenModeling and Simulation of Fluidized Catalytic Cracking Riser Reactor Using Pseudo Reaction Kinetics: A Reviewsalim salimNoch keine Bewertungen

- Advanced Petroleum Processing-Summary ProjectDokument76 SeitenAdvanced Petroleum Processing-Summary ProjectJohn WinstonNoch keine Bewertungen

- Delayed Coking LUMMUSDokument7 SeitenDelayed Coking LUMMUSEmad ElgebesyNoch keine Bewertungen

- 3 Coking ProcessesDokument26 Seiten3 Coking ProcessesFranklin RevillNoch keine Bewertungen

- UOP Fluidized Catalytic Cracking Process: Presented byDokument31 SeitenUOP Fluidized Catalytic Cracking Process: Presented byLaurensNoch keine Bewertungen

- Lecture5 - Fludized Catalytic Cracking (FCC)Dokument3 SeitenLecture5 - Fludized Catalytic Cracking (FCC)Bipradeep GhoshNoch keine Bewertungen

- Cracking:: Tanveer Ul HaqDokument5 SeitenCracking:: Tanveer Ul HaqNoraib AliNoch keine Bewertungen

- ChemEngineering - Fluid Catalytic CrackingDokument15 SeitenChemEngineering - Fluid Catalytic Crackingneha18_kambojNoch keine Bewertungen

- Petroleum: Chemistry and Technology OFDokument83 SeitenPetroleum: Chemistry and Technology OFMohamed MoüsaNoch keine Bewertungen

- Study Material On RefiningDokument20 SeitenStudy Material On RefiningRajat WadhwaniNoch keine Bewertungen

- Simulacion Robert - CristinaDokument8 SeitenSimulacion Robert - CristinaManuel Andres Rivera GuerreroNoch keine Bewertungen

- Petroleum Technology Two MarkDokument26 SeitenPetroleum Technology Two Markdhanagopal saiNoch keine Bewertungen

- Fluid Catalytic Cracking and HydrocrackingDokument31 SeitenFluid Catalytic Cracking and HydrocrackingIntanti Mulana PutriNoch keine Bewertungen

- What Is NaphthaDokument7 SeitenWhat Is Naphthamsabah bugtigNoch keine Bewertungen

- Module 3: Liquid Fossil Fuel (Petroleum) Lecture 20: Secondary ProcessingDokument8 SeitenModule 3: Liquid Fossil Fuel (Petroleum) Lecture 20: Secondary Processingapi-256504985Noch keine Bewertungen

- FCC Process Fundamentals & Technology EvolutionDokument42 SeitenFCC Process Fundamentals & Technology Evolutionranjith_asp0% (1)

- 1.introduction-1. Coke PlantDokument3 Seiten1.introduction-1. Coke PlantRohit KaleNoch keine Bewertungen

- Chemistry and Technology of PetroleumDokument83 SeitenChemistry and Technology of PetroleumManish TiwariNoch keine Bewertungen

- Deisel Hydrotreating UnitDokument9 SeitenDeisel Hydrotreating UnitRittu Paul100% (1)

- Coking and Thermal ProcessDokument26 SeitenCoking and Thermal Processkuldeep100% (3)

- Fluid Catalytic CrackingDokument16 SeitenFluid Catalytic CrackingArief Maulana IlhamNoch keine Bewertungen

- 19.-Pyrolysis FurnaceDokument5 Seiten19.-Pyrolysis FurnaceWilfredo PastranaNoch keine Bewertungen

- UntitledDokument27 SeitenUntitledapi-256504985Noch keine Bewertungen

- Lecture 4.4: Transfer Molding and Compression Molding Transfer MoldingDokument5 SeitenLecture 4.4: Transfer Molding and Compression Molding Transfer Moldingapi-256504985Noch keine Bewertungen

- Lecture 4.6: ThermoformingDokument4 SeitenLecture 4.6: Thermoformingapi-256504985Noch keine Bewertungen

- Module 7: Learning ObjectivesDokument1 SeiteModule 7: Learning Objectivesapi-256504985Noch keine Bewertungen

- Gopinath@acer Iitm Ernet inDokument3 SeitenGopinath@acer Iitm Ernet inapi-256504985Noch keine Bewertungen

- Traffic SignsDokument6 SeitenTraffic Signsapi-256504985Noch keine Bewertungen

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDokument32 SeitenAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985Noch keine Bewertungen

- Module 06: Integration and Placement of Equipment Lecture 42: Heat Integration of Evaporators Key Words: Evaporators, MEEDokument10 SeitenModule 06: Integration and Placement of Equipment Lecture 42: Heat Integration of Evaporators Key Words: Evaporators, MEEapi-256504985Noch keine Bewertungen

- Module 06 Lecture 43: Integration of Furnace Key Words:: StackDokument12 SeitenModule 06 Lecture 43: Integration of Furnace Key Words:: Stackapi-256504985Noch keine Bewertungen

- UntitledDokument1 SeiteUntitledapi-256504985Noch keine Bewertungen

- Module 06: Integration and Placement of Equipment Lecture 37: Integration of Gas Turbine With Process 1 Key WordDokument10 SeitenModule 06: Integration and Placement of Equipment Lecture 37: Integration of Gas Turbine With Process 1 Key Wordapi-256504985Noch keine Bewertungen

- Module 05 Lecture 35: Low Temperature Process Design Key Words: Refrigeration SystemDokument15 SeitenModule 05 Lecture 35: Low Temperature Process Design Key Words: Refrigeration Systemapi-256504985Noch keine Bewertungen

- Module 05 Lecture 32: HEN Optimization: Key Words: HEN, Loop Breaking, PDM, Utility PathDokument9 SeitenModule 05 Lecture 32: HEN Optimization: Key Words: HEN, Loop Breaking, PDM, Utility Pathapi-256504985Noch keine Bewertungen

- Sika Viscocrete - 20heDokument2 SeitenSika Viscocrete - 20heTARGET TRADE LINKSNoch keine Bewertungen

- MCH-Fluids Properties ExcercisesDokument2 SeitenMCH-Fluids Properties ExcercisesRafraf Ezdine100% (1)

- Safety Data Sheet TERMINATOR! Antibacterial CleanerDokument7 SeitenSafety Data Sheet TERMINATOR! Antibacterial CleanerIPKL RSBHAYANGKARA KEDIRINoch keine Bewertungen

- Synthesis of Isoamyl Acetate PDFDokument4 SeitenSynthesis of Isoamyl Acetate PDFJenny MorenoNoch keine Bewertungen

- Application Note - Trace Metals in Waters by GFAAS, in Accordance With U.S. EPA and Health Canada RequirementsDokument5 SeitenApplication Note - Trace Metals in Waters by GFAAS, in Accordance With U.S. EPA and Health Canada RequirementsNguyễnHoàngDanhNoch keine Bewertungen

- High-Temperature Tensile and Creep Data For Inconel 600Dokument13 SeitenHigh-Temperature Tensile and Creep Data For Inconel 600Gustavo Alonso Luévanos Arizmendi100% (1)

- Some Basic ConceptsDokument5 SeitenSome Basic ConceptsebooksufiNoch keine Bewertungen

- Primer Mixes Composition and Behaviour.: Marco MorinDokument15 SeitenPrimer Mixes Composition and Behaviour.: Marco Morin9976382Noch keine Bewertungen

- Commercial Production of Fullerenes and Carbon Nanotubes PDFDokument12 SeitenCommercial Production of Fullerenes and Carbon Nanotubes PDFLuis RamosNoch keine Bewertungen

- Ethyl Alcohol, 70%, in Water: Safety Data SheetDokument6 SeitenEthyl Alcohol, 70%, in Water: Safety Data SheetAmalia Desy SaputriNoch keine Bewertungen

- Hydration of CementDokument39 SeitenHydration of CementheminNoch keine Bewertungen

- Doc-20231126-Wa0008. 20231126 161647 0000Dokument13 SeitenDoc-20231126-Wa0008. 20231126 161647 0000chanchal.x04Noch keine Bewertungen

- Manfred Held - Liners For Shaped ChargesDokument7 SeitenManfred Held - Liners For Shaped ChargesGhoree23456Noch keine Bewertungen

- KVPY 2012 Stream SB SX Solved PaperDokument32 SeitenKVPY 2012 Stream SB SX Solved PaperdevkgunaNoch keine Bewertungen

- Montie Carlo S O S of La Itice Models For CromoleculesDokument52 SeitenMontie Carlo S O S of La Itice Models For CromoleculespovNoch keine Bewertungen

- Wormholes, Time Machines and The Weak Energy ConditionDokument4 SeitenWormholes, Time Machines and The Weak Energy ConditionkeyboardNoch keine Bewertungen

- RLC TransientDokument12 SeitenRLC TransientFlorenzo Miguel AclanNoch keine Bewertungen

- Argco Fig 403 - Mec TeeDokument3 SeitenArgco Fig 403 - Mec TeeFIRE RL SYSTEMSNoch keine Bewertungen

- Introduction To Flow Cytometry May 10 PDFDokument7 SeitenIntroduction To Flow Cytometry May 10 PDFSilviaGonzalezSierraNoch keine Bewertungen

- Ec 6702Dokument22 SeitenEc 6702Madhan ReddyNoch keine Bewertungen

- 4PH1 2P Que 20210304Dokument24 Seiten4PH1 2P Que 20210304Nuh Zaman Chistee100% (1)

- IS 10500: 2012 Table 2 General Parameters Concerning Substances Undesirable in Excessive AmountsDokument4 SeitenIS 10500: 2012 Table 2 General Parameters Concerning Substances Undesirable in Excessive AmountsMukunda DhakalNoch keine Bewertungen

- Powder Technology: Stephane Ngako, Ruben Mouangue, Sebastien Caillat, Alexis Kuitche, Ernest SaragbaDokument7 SeitenPowder Technology: Stephane Ngako, Ruben Mouangue, Sebastien Caillat, Alexis Kuitche, Ernest SaragbauvsarathiNoch keine Bewertungen

- Ketene Production and Utilization Experimental StudyDokument4 SeitenKetene Production and Utilization Experimental Studyspedhome1Noch keine Bewertungen

- Assignment # 2 ElectrolysisDokument4 SeitenAssignment # 2 ElectrolysisRashard AlexanderNoch keine Bewertungen

- Some Notes On SI vs. Cgs Units: by Jason HarlowDokument4 SeitenSome Notes On SI vs. Cgs Units: by Jason HarlowRoy VeseyNoch keine Bewertungen

- 8642 7.bteDokument7 Seiten8642 7.bteMuhammad Maiz GhauriNoch keine Bewertungen

- Bsi BS en 12091 - 2013Dokument14 SeitenBsi BS en 12091 - 2013alferedNoch keine Bewertungen

- Unit-4 Polymer ChemistryDokument35 SeitenUnit-4 Polymer ChemistryHermione GrangerNoch keine Bewertungen

- Ball Mill GrindingDokument78 SeitenBall Mill GrindingFran jimenezNoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItVon EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItBewertung: 4 von 5 Sternen4/5 (25)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionVon EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersVon EverandBulk Material Handling: Practical Guidance for Mechanical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionVon EverandThe Laws of Thermodynamics: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Aerodynamics for Engineering StudentsVon EverandAerodynamics for Engineering StudentsBewertung: 5 von 5 Sternen5/5 (5)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CVon EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNoch keine Bewertungen

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (51)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsVon EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNoch keine Bewertungen

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataVon EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataNoch keine Bewertungen

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Safety Theory and Control Technology of High-Speed Train OperationVon EverandSafety Theory and Control Technology of High-Speed Train OperationBewertung: 5 von 5 Sternen5/5 (2)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeVon EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeBewertung: 4 von 5 Sternen4/5 (9)

- Mechanical Vibrations and Condition MonitoringVon EverandMechanical Vibrations and Condition MonitoringBewertung: 5 von 5 Sternen5/5 (1)

- Piping Design for Industrial Facilities: Understanding Codes and StandardsVon EverandPiping Design for Industrial Facilities: Understanding Codes and StandardsBewertung: 4 von 5 Sternen4/5 (1)