Beruflich Dokumente

Kultur Dokumente

(84030095) Isdm192

Hochgeladen von

Amal AhmedOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(84030095) Isdm192

Hochgeladen von

Amal AhmedCopyright:

Verfügbare Formate

International Symposium

on Devices MEMS,

Intelligent Systems &

Communication

(ISDMISC) 2011

Proceeings pu!lis"e !y International #ournal o$

Computer %pplications& (I#C%)

Application

of PLC for Elevator

Control System

Saurabh Sharma T.Y.Ladakhi A.P.Tiwary Dr. B.B.Pradhan R.Phipo

n

Assistant Professor- Assistant Associate Professor Associat

e Professor- Professor !ech. "n##. Dept. Professo

r !ech. "n##. Dept. !ech. "n##.

Dept.

!ech. "n##. S!T$ !a%itar !ech.

"n##. S!T$ !a%itar S!T$ !a%itar De

pt.

Dept.

S!T$

!a%itar

S!T$

!a%itar

ABSTRACT

In this research paper an attempt has been made to integrate the

programmable logic controller (PLC) with elevator for

developing its control system. Thus, this paper describes the

application of programmable logic controller for elevator control

system. The PLC used for this proect is !" #$%&C with si'

inputs and four outputs. The programming language used is

ladder diagram.

Keywords

Programmable logic controller (PLC), "levator

1. INTRODUCTION

(ith the overall rapid development ta)ing place in all spheres,

the living standard of human being particularly in urban areas

has tremendously increased as such the high rise buildings are

constructed for malls, and housing purposes. Thus the

installation of elevators in these high rise buildings becomes an

integral part of the infrastructure for the movement of goods and

people. *o, the control system is essential in the smooth and safe

operation of the elevator. It guides the elevator in what order to

stop at floors, when to open or close the door etc. +,-./.

Programmable logic controller (PLC) is a digital computer used

for automation of industrial processes such as control of

machinery on factory assembly lines. &nli)e general-purpose

computers, the PLC is designed for multiple inputs and outputs

arrangements, e'tended temperature ranges, immunity to

electrical noise, and resistance to vibration and impact.

Programs to control machine operation are typically stored in

battery-bac)ed or non-volatile memory. $ PLC is an e'ample of

a real time system since output results must be produced in

response to input condition within a given period of time,

otherwise, unintended operation will result. PLCs are used in

many different machines such as pac)aging and semiconductor

and in various industries for monitoring and controlling.

PLC has many advantages over other control systems. It is

)nown for its fle'ibility, low cost, operational speed, reliability,

ease of programming, security, and it is easy in implementing

changes and correcting errors +0/.

PLC is divided into three parts namely the Central Processing

&nit (CP&), the input1output (I12) selection and the

programming device. The bloc) diagram of PLC can be seen in

fig.,.

The CP& reads input data from various sensing devices,

e'ecutes the stored user program from memory, and sends

appropriate output command to control devices. The I12 system

forms the interface by which field devices are connected to the

controller. The purpose of this interface is to condition the

various signals received from or sent to e'ternal field devices.

The programming device, or terminal, is used to enter the

desired program into the memory of the processor. This program

is entered using relay ladder logic. The program determines the

se3uence of operation and ultimate control of e3uipment or

machinery. +,/

#ig ,4 5loc) diagram representing the different parts of PLC.

2. APPLICATION OF PLC FOR

CONTROL SYSTEM

The wor)ing principle of PLC for elevator control system

functions in the similar manner as that the

elevator we use in our daily life. The motion of

the elevator that people normally use is

controlled by a stepper motor. It consists of a

pulley which helps

in upward and downward movement of the lift.

The position feedbac) is provided by the limit

switches.

The principle of this set up is6 whenever the

cabinet is called to any level, the motor either

runs in forward or reverse direction and then

stops at the level indicated. The indication of the

level or the position of the cabinet is given by

the limit switches which act as a sensor and

gives the signal indicating that the cabinet has

reached the re3uired position.

3. DEVELOPMENT OF ARD!ARE

AND SOFT!ARE FOR INTERFACIN"

PLC !IT ELEVATOR

PLCs may need to interact with people for

the purpose of

configuration, alarm reporting or everyday

control. $ 7uman- 8achine Interface (78I) is

employed for this purpose. 78Is are also

referred to as 88Is (8an 8achine Interface)

and !&Is (!raphical &ser Interface).$ simple

system may use buttons and

lights to interact with the user. Te't displays are available as

.

International Symposium on Devices MEMS, Intelligent Systems & Communication (ISDMISC) 2011

Proceeings pu!lis"e !y International #ournal o$ Computer %pplications& (I#C%)

well as graphical touch screens. 8ore comple'

systems use programming and monitoring

software installed on a computer, with the PLC

connected via a communication interface. +9/

3.1 #rdw#re

The different devices used for the development

of this set up consist of a !"-#anuc %ano

PLC, *tepper motor, voltage supply, push

buttons, switches and connecting wires. The

details

of each of the elements mentioned above

are given below4

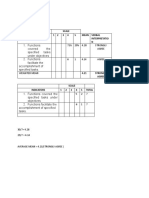

'(1(1 )E*+%,-C

P.C

Des$r%&'%o( S&e$%)%$#'%o(

(ei

ght

,:;

grams

8odule <imensions

7eight 4 =; mm

<epth 4 .> mm

(idth 4 >: mm

Typical *can ?ate ,.@ ms1A for 5oolean logic

Inp

uts

*i' @. B<C

positive1negative

logic input

2utp

uts

#our transistor outputs

2utput Power *upplies

C: B<C on pin > of

*erial

Port, ,;; m$ 8a'imum number of

slave

devices per ?*-

.=: networ)

= (can be increased

with a

repeater)

?eal-time

cloc)

accuracy(for

timer

C1-

;.:D

!eneral "lectric #anuc PLCs offer the

perfect solution for smaller pac)aging

machines, dispensing machines, and relay

replacement applications with 9 inputs and .

outputs. In spite of its small siEe, this versatile

controller provides powerful programming

features such as built-in-high-speed counter

functionality, support for floating-point function

bloc)s and subroutines, ability to assign

passwords and privilege levels, override

capability etc. It operates on C@.B <C nominal

input power and accept inputs from 9 positive or

negative logic inputs.

Table ,. *pecification of !"-#anuc %ano

PLC

decreasing tor3ue with increasing speed.

There are basically three types of stepping

motors6 variable reluctance, permanent magnet

and hybrid. They differ in terms of construction

based on the use of permanent magnets and1or

iron rotors with laminated steel stators. The

motor used for the development of the set-up is

permanent magnet type. The permanent magnet

motor, also referred to as a Fcanstac)F motor,

has, as the name implies, a permanent magnet

rotor. It is a relatively low speed, low tor3ue

device with large step angles of either .: or

G; degrees. Its simple construction and low cost

ma)e it an ideal choice for non-industrial

applications, such as a line printer print wheel

positioner.

.

0

International Symposium on Devices MEMS, Intelligent Systems & Communication (ISDMISC) 2011

Proceeings pu!lis"e !y International #ournal o$ Computer %pplications& (I#C%)

Fig 3(a): Internal arrangement of

Permanent Magnet Motor

&nli)e the other stepping motors, the P8 motor

rotor has no teeth and is designed to be

magnetiEed at a right angle to its a'is. #igure

0(a) shows a simple, G; degree P8 motor with

four phases ($-<) and fig 0(b) shows the

photographic views of P88. $pplying current

to each phase in se3uence will cause the rotor to

rotate by adusting to the changing magnetic

fields.

$lthough it operates at fairly low speed the P8 motor has a

Fig 2: GE-Fanuc Nano PLC

'(1(2 Stepper

Motor

The stepper motor is an electromagnetic device

that converts digital pulses into mechanical shaft

rotation. $dvantages of step motors are low

cost, high reliability, high tor3ue at low speeds

and a simple, rugged construction that operates

in almost any environment. The main

disadvantages in using a stepper motor is the

resonance effect often e'hibited at low

speeds and

.

International Symposium on Devices MEMS, Intelligent Systems & Communication (ISDMISC) 2011

Proceeings pu!lis"e !y International #ournal o$ Computer %pplications& (I#C%)

relatively high tor3ue characteristic. +@/

Fig 3(b): Permanent

Magnet Motor

3.2 So)'w#re

The software used for the development of the

set-up is the

HBersapro @.;@I. The programming language

used in this software is ladder diagram. The

ladder diagram language is

basically a symbolic set of instructions used

to create the

:

controller program. These ladder instructions are

arranged to obtain the desired control logic that

is to be entered into the memory of the PLC. +,/.

3.3 I('er)#$%(* o) PLC w%'+ E,e-#'or

PLC used in this set up is !" #$%&C with si'

inputs and four outputs. The photographic view

of interfacing of PLC with elevator is shown in

fig .. The inputs are connected to three limit

switches and three push buttons and the four

outputs are

connected to the stepper motor to generate a

pulse. PLC consists of an on delay timer which is

used to generate a pulse and also resets itself. $

bit se3uencer is also used in the program to

generate four pulses continuously in se3uence

which is also used

to change the direction of the motor. The program

also consists of thirteen mar)ers which are used

as an internal output because of the less number

of output ports. These mar)ers can be used in the

program as per the re3uirements.

#or storing the logic to PLC from the software,

firstly the PLC is to be selected and connected to

the port address that is to be used. $fter this, the

ladder program has to be created by using the

ladder options and then the program can be

stored to the PLC after the addressing has been

given.

Star

t

Sitc!

on t!e

Main"

Pre""

butto

n #

I"

cabinet

on t!e

$e"ire$

floor%

No

&e"

Fig 4: Interfacing PLC with

Elevator

Motor run"

in re'er"e$

con$ition

Limit

"itc!

on%

&e"

Motor

"to("

Motor $oe" not

run

%o

.. RESULTS AND DISCUSSION

$fter the interfacing of PLC with elevator

followed by thorough chec)ing for errors, the

trials of the setup were done and the said setup

successfully wor)ed as per the designed and

developed control system.

(hen push button for the first level is pressed

then the motor runs in reversed condition till the

cabinet reaches its re3uired position and actuates

the limit switch which enables the motor to stop

and if the cabinet is already in the re3uired

position then the motor wonJt get actuated.

$gain, when push button for the second level is

pressed then the motor runs either in forward or

reversed condition according to its position till

the cabinet reaches its re3uired position and

actuates the limit switch which enables the motor

to stop and if the cabinet is already in the

re3uired position then the motor will not get

actuated and subse3uently it wor)ed successfully

for other levels too.

$part from the ladder diagram we can also

use the bloc) diagram to control the elevator.

Sto

(

Fig 5: Flow Diagram of the whole

operation of the PLC based

controller for elevator.

/. CONCLUSION

In this paper, the authors have discussed the

application of a

Programmable Logic Controller for an "levator

Control *ystem. The authors successfully

designed and developed PLC based control

system for elevator.

The following conclusions have been drawn from

this research wor)4

(i) %ano PLCs can also be interfaced

with an elevator. (ii) 8ar)ers can be used

as an internal output.

(iii) The generation of ade3uate pulse by the

PLC based control system for developing

the re3uired tor3ue in the motor for the

movement of the elevator else elevator

will not function satisfactorily.

(i') It is observed that the PLC based

controller for elevator wor)s better than

the other control systems. the industries

and other business establishments will be

greatly benefitted from this type of control

systems. 7owever, before pressing this

type of control system for commercial use,

the indepth study, e'perimentation and

validation is re3uired.

9. ?"#"?"%C"*

+,/ Programmable Logic Controller &ser

8anual, B. I.

8icrosystems Pvt. Ltd.

+@/ $dvance micro system is available at

www.ams@;;;.com. +0/ Cheded, L. $l-8ulla,

8aKan, C ontrol of a four-level

elevator system using a programmable

logic controller, International Lournal of

"lectrical "ngineering "ducation,

@;;@

+./ Mang N., Ohu P., ,, Nu 7., <esign and

Practice of an

"levator Control *ystem 5ased

on PLC . +:/ Lac) 7.,

Programmable Logic Controller.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- FSLB ReadmeDokument7 SeitenFSLB ReadmeJoseIgnacioContreras100% (1)

- Mipi Unipro Specification v14000 PDFDokument397 SeitenMipi Unipro Specification v14000 PDFArnab GhoshNoch keine Bewertungen

- PXX 485 3Dokument79 SeitenPXX 485 3ABI RAJESH GANESHA RAJANoch keine Bewertungen

- Questionbank CPPDokument7 SeitenQuestionbank CPPHome AutomationNoch keine Bewertungen

- Simatic St80 STPC Complete English 2013Dokument676 SeitenSimatic St80 STPC Complete English 2013Galal Saif KariemNoch keine Bewertungen

- TLB Protocols CE-M Approved Manual enDokument88 SeitenTLB Protocols CE-M Approved Manual enAmine BenzNoch keine Bewertungen

- Sat - 30.Pdf - Smart Waste Management SystemDokument11 SeitenSat - 30.Pdf - Smart Waste Management SystemVj KumarNoch keine Bewertungen

- Mainframe Cost Optimization For DB2 For zOS Document PDFDokument14 SeitenMainframe Cost Optimization For DB2 For zOS Document PDFGabriel DNoch keine Bewertungen

- Chapter 5 - Ele232 - Feb11 (Compatibility Mode) PDFDokument7 SeitenChapter 5 - Ele232 - Feb11 (Compatibility Mode) PDFkavish malakaNoch keine Bewertungen

- MN67595 Eng PDFDokument27 SeitenMN67595 Eng PDF黃小虎Noch keine Bewertungen

- ARM7 Based Smart ATM Access SystemDokument3 SeitenARM7 Based Smart ATM Access SystemEditor IJRITCCNoch keine Bewertungen

- Database Management SystemDokument5 SeitenDatabase Management SystemGuruKPONoch keine Bewertungen

- Linear Control System: Presented by Imran Basha SyedDokument35 SeitenLinear Control System: Presented by Imran Basha SyedSyed Imran BashaNoch keine Bewertungen

- Cross-Platform Data SynchronizationDokument78 SeitenCross-Platform Data SynchronizationMakoto KondoNoch keine Bewertungen

- Ac Circuit Syllabus 2Dokument12 SeitenAc Circuit Syllabus 2ferdinandNoch keine Bewertungen

- Lecture2 Chapter4 - Design 4-Bit Ripple Carry Binary Adder-Subtractor CircuitDokument28 SeitenLecture2 Chapter4 - Design 4-Bit Ripple Carry Binary Adder-Subtractor CircuitRakhmeen GulNoch keine Bewertungen

- Double Smith Chart - Z & YDokument1 SeiteDouble Smith Chart - Z & YkgrhoadsNoch keine Bewertungen

- Assignment Automatic Drilling MachineDokument6 SeitenAssignment Automatic Drilling MachineSumit KambleNoch keine Bewertungen

- CPIN239 S05AssignDokument2 SeitenCPIN239 S05AssignJon0% (1)

- Azure Migration Readiness WhitepaperDokument17 SeitenAzure Migration Readiness Whitepapersanchetanparmar100% (2)

- DX DiagDokument9 SeitenDX Diagkosaj456Noch keine Bewertungen

- AOPEN Embedded PC BrochureDokument12 SeitenAOPEN Embedded PC BrochurepaulaNoch keine Bewertungen

- 13 TOUCHSCREEN CH 004 DS0013 Touch Screen Control of The LEDsDokument12 Seiten13 TOUCHSCREEN CH 004 DS0013 Touch Screen Control of The LEDsDante LeivaNoch keine Bewertungen

- Thesis SidelineDokument8 SeitenThesis SidelineChristian Aries LansanganNoch keine Bewertungen

- Bravia Update 11Dokument5 SeitenBravia Update 11ajaz123ahmedNoch keine Bewertungen

- SEN 2019 Winter Model Answer PaperDokument22 SeitenSEN 2019 Winter Model Answer Papermansilokhande3012Noch keine Bewertungen

- SX-1 V15 P2 ManualDokument16 SeitenSX-1 V15 P2 ManualAsmir JahićNoch keine Bewertungen

- An Nb-Iot-Based Smart Trash Can System For Improved Health in Smart CitiesDokument6 SeitenAn Nb-Iot-Based Smart Trash Can System For Improved Health in Smart CitiesShrivinayak DhotreNoch keine Bewertungen

- Command Line Interface PSS®E 35.3.1: September 2021Dokument368 SeitenCommand Line Interface PSS®E 35.3.1: September 2021Tin RabuzinNoch keine Bewertungen

- Selcopy User ManualDokument356 SeitenSelcopy User ManualSyed FaizNoch keine Bewertungen