Beruflich Dokumente

Kultur Dokumente

Tutorial 7 HT

Hochgeladen von

Sahil Goyal0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

207 Ansichten1 Seitesdfdads

Originaltitel

Tutorial+7+HT

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldensdfdads

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

207 Ansichten1 SeiteTutorial 7 HT

Hochgeladen von

Sahil Goyalsdfdads

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

THAPAR INSTITUTE UNIVERSITY, PATIALA

(Department of Chemical Engineering)

Tutorial Sheet 7 (Unsteady State Heat transfer)

Subject: Heat Transfer Semester: II

Course No.: UCH 402 Session: 2011 - 2012

Course-Coordinator: Dr. D. Gangacharyulu Date: February 13, 2012

1. A cylindrical ingot 10 cm diameter and 30 cm long passes through a heat treatment furnace,

which is 6 m in length. The ingot must reach 800

o

C before it comes out of the furnace. The

furnace gas is at 1250

o

C and ingot initial temperature is 90

o

C. What is the maximum speed

with which the ingot should move in the furnace to attain the required temperature? The

combined convective and radiative heat transfer coefficient is 100 W/(m

2

-K). The thermal

conductivity and the thermal diffusivity of the ingot steel are 40 W/(m-K) and 1.16x10

-5

m

2

/sec.

2. A 100 cm 100 cm copper slab of 10 cm thick has a uniform temperature of 400

o

C. Its

temperature is suddenly lowered to 100

o

C and maintained. Calculate the time required for the

plate to reach the temperature of 200

o

C. Take copper slab properties as, = 9000 kg/m

3

; Cp =

0.38 kJ/(kg-K); k = 370 W/(m-K); and h = 100 W/(m-K).

3. A vessel is filled with 0.0283m

3

of water initially at 288.8 K. The vessel, which is well stirred,

is suddenly immersed in a steam bath held at 377.6 K. The overall heat-transfer coefficient U

between the steam and water is 1136W/(m

2

-K) and the area is 0.372m

2

. Neglecting the heat

capacity of the walls and agitator, calculate the time in hours to heat the water to 338.7 K.

[Hint: Since the water is well stirred, its temperature is uniform.]

Das könnte Ihnen auch gefallen

- Solutions Manual to accompany Engineering Materials ScienceVon EverandSolutions Manual to accompany Engineering Materials ScienceBewertung: 4 von 5 Sternen4/5 (1)

- Additional Tutorial 3 Heat TransfeDokument6 SeitenAdditional Tutorial 3 Heat TransfeTeeWenSengNoch keine Bewertungen

- Heat and Mass TransferDokument1 SeiteHeat and Mass TransferlibbissujessyNoch keine Bewertungen

- Assignment Unsteady StateDokument2 SeitenAssignment Unsteady StateChirag JainNoch keine Bewertungen

- TRANSIENT HEAT TRANSFER CALCULATIONSDokument3 SeitenTRANSIENT HEAT TRANSFER CALCULATIONSSanith RenjalNoch keine Bewertungen

- HT Mod 3 and 4 Solved ProbsDokument46 SeitenHT Mod 3 and 4 Solved ProbsVishnu Prada A RNoch keine Bewertungen

- Sheet 5Dokument5 SeitenSheet 5Mohamed AbdulazimNoch keine Bewertungen

- MEL301 2014 Tutorial4 Draft Version 01 PDFDokument2 SeitenMEL301 2014 Tutorial4 Draft Version 01 PDFAkhil NekkantiNoch keine Bewertungen

- HT Homework 1Dokument2 SeitenHT Homework 1Nirmal PanghalNoch keine Bewertungen

- Heat Exchangers: Tutorial Sheet - 8Dokument2 SeitenHeat Exchangers: Tutorial Sheet - 8Mohammed MaazNoch keine Bewertungen

- Example 4.10-1. Radiation To A Metal TubeDokument7 SeitenExample 4.10-1. Radiation To A Metal TubeShane Patulot0% (2)

- Sheet 7Dokument1 SeiteSheet 7mkkNoch keine Bewertungen

- Assignment - Process Heat Transfer (CDB2023)Dokument4 SeitenAssignment - Process Heat Transfer (CDB2023)qrunchyNoch keine Bewertungen

- IPS College assignment on heat transfer and finsDokument2 SeitenIPS College assignment on heat transfer and finsFaraz KhanNoch keine Bewertungen

- Practice Problems For Quiz 2Dokument6 SeitenPractice Problems For Quiz 2divyanshuNoch keine Bewertungen

- Final HMT AssignmentsDokument7 SeitenFinal HMT Assignments544 vishwavijay PatilNoch keine Bewertungen

- HEAT TRANSFER TUTORIAL SHEET TITLEDokument5 SeitenHEAT TRANSFER TUTORIAL SHEET TITLEDhiraj DhimanNoch keine Bewertungen

- Rr310803 Heat TransferDokument8 SeitenRr310803 Heat TransferSaravanan MathiNoch keine Bewertungen

- 8S 2105 Mepc22 1Dokument2 Seiten8S 2105 Mepc22 1Challa YachendraNoch keine Bewertungen

- Tutorial 2 Temperature & Heat - Part 2Dokument4 SeitenTutorial 2 Temperature & Heat - Part 2Yixiang TanNoch keine Bewertungen

- HEAT TRANSFER 2011 JNTUH Question PaperDokument8 SeitenHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNoch keine Bewertungen

- 9A03505 Heat TransferDokument4 Seiten9A03505 Heat TransfersivabharathamurthyNoch keine Bewertungen

- HTDokument13 SeitenHTJhon MalabagNoch keine Bewertungen

- Heat Transfer HW ProblemsDokument1 SeiteHeat Transfer HW ProblemsSafaa Hameed Al NaseryNoch keine Bewertungen

- Heat Transfer - 012110043920 - 1Dokument8 SeitenHeat Transfer - 012110043920 - 1shweta_770587Noch keine Bewertungen

- Heat Transfer AssignmentDokument2 SeitenHeat Transfer Assignmentdodo123dodo0% (1)

- TRANSPORT PHENOMENA ASSIGNMENT HEAT TRANSFER PROBLEMSDokument2 SeitenTRANSPORT PHENOMENA ASSIGNMENT HEAT TRANSFER PROBLEMSNitish NehraNoch keine Bewertungen

- HT Notes For ESEDokument25 SeitenHT Notes For ESEM BhurleNoch keine Bewertungen

- Heat and Mass Transfer Practice Questions 1Dokument2 SeitenHeat and Mass Transfer Practice Questions 1Lucky 230503Noch keine Bewertungen

- HeatDokument7 SeitenHeatkevinjorgeramosNoch keine Bewertungen

- Tutorial - Transient ConductionDokument2 SeitenTutorial - Transient Conduction219016536Noch keine Bewertungen

- Soal KONDUKTIVITASDokument2 SeitenSoal KONDUKTIVITASSupriyantiNoch keine Bewertungen

- To UploadDokument2 SeitenTo Uploadsmg26thmayNoch keine Bewertungen

- SUB: Heat & Mass Transfer (EME 504) : Assignment-IDokument2 SeitenSUB: Heat & Mass Transfer (EME 504) : Assignment-IdearsaswatNoch keine Bewertungen

- Assignment 2Dokument3 SeitenAssignment 2Arjun AgarwalNoch keine Bewertungen

- 4.tutorial HMTDokument5 Seiten4.tutorial HMTdearsaswatNoch keine Bewertungen

- Phy103 Tutorial QuestionsDokument30 SeitenPhy103 Tutorial QuestionsGeorge nwatarali100% (1)

- Test-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oDokument2 SeitenTest-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oKrishnaJaiswal0% (1)

- 13_HT_ASSIGNMENT_01_2023_24_IISEM_89cc703321d8b909cfe132e1a7313704Dokument2 Seiten13_HT_ASSIGNMENT_01_2023_24_IISEM_89cc703321d8b909cfe132e1a7313704rakiravaishuNoch keine Bewertungen

- Heat Transfer Question Bank Part A ConductionDokument7 SeitenHeat Transfer Question Bank Part A ConductionR.MANIKANTHANoch keine Bewertungen

- Tutorial SheetDokument5 SeitenTutorial Sheetpradeep.kumarNoch keine Bewertungen

- Prob. Sheet Basic ConceptsDokument3 SeitenProb. Sheet Basic ConceptsAnonymous mXicTi8hBNoch keine Bewertungen

- Heat Transfer Lectures Chemical Engineering Department University of Technology, IraqDokument1 SeiteHeat Transfer Lectures Chemical Engineering Department University of Technology, IraqChemical EngineeringNoch keine Bewertungen

- Heat TransferDokument4 SeitenHeat TransferR B Yarasu100% (1)

- Thermodynamics Assignment SheetDokument3 SeitenThermodynamics Assignment SheetSatwikMohantyNoch keine Bewertungen

- Heat Transfer Calculations for Conduction, Convection and Radiation ProblemsDokument6 SeitenHeat Transfer Calculations for Conduction, Convection and Radiation Problemskevinjorgeramos100% (1)

- (An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaDokument2 Seiten(An Autonomous Institute Under VTU) Manandavadi Road, Mysore-570008, Karnataka, IndiaMohammed Maaz100% (1)

- Heat Transfer Equations and Critical Insulation RadiusDokument18 SeitenHeat Transfer Equations and Critical Insulation RadiusPon ShanmugakumarNoch keine Bewertungen

- Tutorial 3 HeatDokument1 SeiteTutorial 3 HeatBriana PalmerNoch keine Bewertungen

- Prob Set Heat and MassDokument15 SeitenProb Set Heat and MassCheng PasionNoch keine Bewertungen

- Heat Transfer Review ProblemsDokument1 SeiteHeat Transfer Review ProblemssayanNoch keine Bewertungen

- Assignment Chap 4Dokument1 SeiteAssignment Chap 4يزن اسامه احمد الغرايبهNoch keine Bewertungen

- Question Bank HTDokument12 SeitenQuestion Bank HTgreatrijuvanNoch keine Bewertungen

- Scientific American Supplement, No. 303, October 22, 1881Von EverandScientific American Supplement, No. 303, October 22, 1881Noch keine Bewertungen

- Advances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKVon EverandAdvances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKNoch keine Bewertungen

- Pay Fixation 1-1-06Dokument37 SeitenPay Fixation 1-1-06Sahil GoyalNoch keine Bewertungen

- Centrifugal PumpDokument5 SeitenCentrifugal PumpSandeep BuntyNoch keine Bewertungen

- National Curriculum Framework 2005 overviewDokument2 SeitenNational Curriculum Framework 2005 overviewSahil GoyalNoch keine Bewertungen

- SSC DigestDokument68 SeitenSSC DigestdassreerenjiniNoch keine Bewertungen

- Step 2Dokument1 SeiteStep 2Sahil GoyalNoch keine Bewertungen

- Thapar University: Patiala: Heads of Deptts/SchoolsDokument1 SeiteThapar University: Patiala: Heads of Deptts/SchoolsSushobhit ChoudharyNoch keine Bewertungen

- Index: © Fluent Inc., Mar-06 Index-1Dokument10 SeitenIndex: © Fluent Inc., Mar-06 Index-1Sahil GoyalNoch keine Bewertungen

- Samsung-Thapar - SL - Chem & CivilDokument2 SeitenSamsung-Thapar - SL - Chem & CivilSahil GoyalNoch keine Bewertungen

- 5 Natural Newtonian NewDokument7 Seiten5 Natural Newtonian NewSahil GoyalNoch keine Bewertungen

- Pumps TypesDokument6 SeitenPumps TypesYo MegalómanoNoch keine Bewertungen

- Gambit Turbo File FormatDokument22 SeitenGambit Turbo File FormatSahil GoyalNoch keine Bewertungen

- IndiaDokument28 SeitenIndiaSahil GoyalNoch keine Bewertungen

- GAMBIT Menu Commands GuideDokument125 SeitenGAMBIT Menu Commands GuideSahil GoyalNoch keine Bewertungen

- An Introduction To Vedic Mathematics: Course ContentDokument0 SeitenAn Introduction To Vedic Mathematics: Course ContentAmit ChaudhuriNoch keine Bewertungen

- A Computational Fluid Dynamics (CFD) Based Study To Predict The Flow and Combustion CharateristicDokument12 SeitenA Computational Fluid Dynamics (CFD) Based Study To Predict The Flow and Combustion CharateristicSahil GoyalNoch keine Bewertungen

- CFD 1 IntroDokument45 SeitenCFD 1 IntroSahil Goyal100% (1)

- Food Processing 5Dokument19 SeitenFood Processing 5Sahil GoyalNoch keine Bewertungen

- 2SDokument7 Seiten2SSahil GoyalNoch keine Bewertungen

- Food Processing 6Dokument32 SeitenFood Processing 6Sahil GoyalNoch keine Bewertungen

- Food Processing 6Dokument32 SeitenFood Processing 6Sahil GoyalNoch keine Bewertungen

- 0901 B 80380030 FC 9Dokument8 Seiten0901 B 80380030 FC 9Sahil GoyalNoch keine Bewertungen

- Cre NotesDokument56 SeitenCre Notesbhaskar5377Noch keine Bewertungen

- Heat Exchanger 1Dokument46 SeitenHeat Exchanger 1Sahil GoyalNoch keine Bewertungen

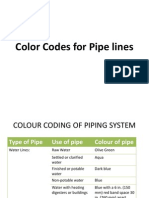

- Color Codes For Pipe LinesDokument24 SeitenColor Codes For Pipe Linesamantania12386% (14)