Beruflich Dokumente

Kultur Dokumente

105-s29 Control of Flexural Cracking in Reinforced Concrete

Hochgeladen von

Thomas CroweCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

105-s29 Control of Flexural Cracking in Reinforced Concrete

Hochgeladen von

Thomas CroweCopyright:

Verfügbare Formate

ACI Structural Journal/May-June 2008 301

ACI Structural Journal, V. 105, No. 3, May-June 2008.

MS No. S-2006-346 received August 21, 2006, and reviewed under Institute publication

policies. Copyright 2008, American Concrete Institute. All rights reserved, including the

making of copies unless permission is obtained from the copyright proprietors. Pertinent

discussion including authors closure, if any, will be published in the March-April

2009 ACI Structural Journal if the discussion is received by November 1, 2008.

TECHNICAL PAPER ACI STRUCTURAL JOURNAL

Excessive cracking is one of the common causes of damage in

concrete structures and results in huge annual cost to the construction

industry. Most of the current design approaches for crack control

are empirical and based on observed crack widths in laboratory

specimens tested under short-term loads. Most approaches fail to

adequately model the increase in crack width that occurs with time

due to shrinkage. In this paper, an alternative design method for

flexural crack control that overcomes many of the limitations of the

current code approaches is proposed. The proposed method takes

into account the time-dependent development of cracking and the

increase in crack widths with time due to shrinkage. The crack

width calculation procedure has been shown to provide good

agreement with the measured spacing and width of cracks in a

variety of slabs and beams tested in the laboratory under sustained

service loads.

Keywords: crack control; creep; flexural cracking; reinforced concrete;

serviceability; shrinkage.

INTRODUCTION

Current design procedures to control cracking in concrete

structures using conventional steel reinforcement are overly

simplistic and often fail to adequately account for the

gradual increase in crack widths with time due to shrinkage.

The bonded reinforcement in every reinforced concrete

beam or slab provides restraint to shrinkage, with the

concrete compressing the reinforcement as it shrinks and the

reinforcement imposing an equal and opposite tensile force

on the concrete at the level of the steel. This internal

restraining tensile force is often significant enough to cause

time-dependent cracking. In addition, the connections of a

concrete member to other parts of the structure or to the

foundations also provide restraint to shrinkage. The tensile

restraining force that develops rapidly with time at the

restrained ends of the member usually leads to cracking, often

within days of the commencement of drying. In a restrained

flexural member, shrinkage also causes a gradual widening of

flexural cracks and a gradual build-up of tension in the

uncracked regions that may lead to time-dependent cracking.

Cracks occur at discrete locations in a concrete member,

often under the day-to-day service loads. The width of a

crack depends on the quantity, orientation, and distribution

of the reinforcing steel crossing the crack. It also depends on

the deformation characteristics of the concrete and the bond

between the concrete and the reinforcement bars at, and in

the vicinity of, the crack. A local breakdown in bond at each

crack complicates the modeling, as does the time-dependent

change in the bond characteristics caused by drying

shrinkage and tensile creep. Great variability exists in observed

crack spacing and crack widths and accurate predictions of

behavior are possible only at the statistical level.

Most of the current design approaches for crack control

specified in building codes are empirical

1-3

and are based on

observed crack widths in laboratory specimens tested under

short-term loads. These approaches also specify certain

detailing requirements, including maximum limits on both

the center-to-center spacing of bars and on the distance from

the side or soffit of the member to the nearest longitudinal

bar. These limits do not generally depend on any of the

factors that affect the size and location of cracks. The codes

of practice

1-3

also specify a minimum quantity of tensile

reinforcement in those regions of the member where

cracking is likely under service loads and maximum limits

are placed on the tensile steel stress on a cracked section

depending on either the bar diameter or the bar spacing.

2,3

The existing code approaches,

1-3

however, fail to adequately

account for the increase in crack width that occurs with time

due to shrinkage.

This paper outlines a design method for flexural crack

control that overcomes many of the limitations of the current

code approaches. The proposed method is based on a

recently developed procedure

4

for the calculation of the

maximum final crack spacing and crack width in a beam or

slab and takes into account the time-dependent development

of cracking and the increase in crack widths with time due to

shrinkage. The crack width calculation procedure has been

shown to provide good agreement with the measured spacing

and width of cracks in a variety of slabs and beams tested in

the laboratory under sustained service loads.

RESEARCH SIGNIFICANCE

Excessive cracking resulting from either restrained

deformation or external loads (or both) is one of the most

common causes of damage in concrete structures and results

in huge annual cost to the construction industry. Current

design procedures to control cracking using conventional

steel reinforcement

1-3,5

do not adequately account for the

gradual increase in crack widths with time due to the effects

of shrinkage.

6

This paper provides a rational method for

designers to control flexural cracking in reinforced concrete

beams and slabs and thereby improve the serviceability of

concrete structures.

FLEXURAL CRACKING MODEL

Recently, Gilbert

4

proposed a model for predicting the

maximum final crack width, w*, in reinforced concrete flexural

members based on the Tension Chord Model of Marti et al.

7

The model was shown to provide good agreement with the

measured final spacing and width of cracks in a range of

reinforced concrete beams and slabs tested in the laboratory

under sustained service loads for periods in excess of 400 days.

6

The notation associated with the model is shown in Fig. 1.

Title no. 105-S29

Control of Flexural Cracking in Reinforced Concrete

by R. Ian Gilbert

ACI Structural Journal/May-June 2008 302

In the following, Gilberts model is used to develop a

simple procedure to ensure that the final maximum flexural

crack width in a beam or slab is less than a selected

maximum design crack width, w

max

.

Consider a segment of a singly reinforced beam of rectan-

gular section subjected to an in-service bending moment M

s

greater than the cracking moment M

cr

. The spacing between

the primary cracks is s, as shown in Fig. 1(a). A typical cross

section between the cracks is shown in Fig. 1(b) and a cross

section at a primary crack is shown in Fig. 1(c). The cracked

beam is idealized as a compression chord of depth c and

width b and a cracked tension chord consisting of the tensile

reinforcement of area A

s

surrounded by an area of tensile

concrete A

ct

as shown in Fig. 1(d). The centroids of A

s

and

A

ct

are assumed to coincide at a depth d below the top fiber

of the section.

For the sections containing a primary crack (Fig. 1(c)),

A

ct

= 0 and the depth c and the second moment of area about

the centroidal axis, I

cr

, may be determined from a cracked

section analysis. Away from the crack, the area of the

concrete in the tension chord of Fig. 1(d) (A

ct

) is assumed to

carry a uniform tensile stress

ct

that develops due to the

bond stress

b

that exists between the tensile steel and the

surrounding concrete.

For the tension chord, the area of concrete between the

cracks, A

ct

, may be taken as

A

ct

= 0.5(h c)b

*

(1)

where b

*

is the width of the section at the level of the

centroid of the tensile steel (that is, at the depth d). At each

crack in the tension chord of Fig. 1(d),

st1

= T/A

s

,

c

= 0, and

(2)

As distance z from the crack increases, the stress in the

steel reduces due to the bond shear stress

b

between the steel

and the surrounding tensile concrete. For reinforced concrete

under service loads, where

st1

is less than the yield stress f

y

,

Marti et al.

7

assumed a rigid-plastic bond shear stress-slip

relationship, with

b

= 2f

ct

at all values of slip and where f

ct

is the direct tensile strength of concrete. In reality, the

magnitude of

b

is affected by steel stress, concrete cover,

bar spacing, transverse reinforcement (stirrups), lateral

pressure, degree of compaction, and size of bar deformations.

In addition,

b

is likely to be reduced with time by tensile

creep and shrinkage. Experimental observations by Gilbert

and Nejadi

6

and others indicate that

b

reduces as the stress

in the reinforcement increases and, consequently, the tensile

stresses in the concrete between the cracks reduces (that is,

tension stiffening reduces with increasing steel stress).

Gilbert

4

proposed that

b

=

1

2

f

ct

, where

1

depends on

the steel stress at the crack (and varies from 3.0 at low stress

levels to 1.0 at high stress levels); and where

2

= 1.0 for

short-term calculations and

2

= 0.5 for long-term calculations.

These values of

1

and

2

where calibrated to provide

agreement with the results of a detailed experimental study

of cracking in reinforced concrete beams and slabs under

both short-term and long-term sustained loads.

6

To avoid the

discontinuities in

1

, it is herein assumed that

1

is independent

of steel stress and equal to 2.0 (as proposed by Marti et al.

7

).

That is, for short-term calculations, the bond stress

b

= 2.0f

ct

and, for long-term calculations in the determination of the

final maximum crack width,

b

= 1.0f

ct

.

An elevation of the tension chord is shown in Fig. 2(a) and

the stress variations in concrete and steel in the tension chord

are illustrated in Fig. 2(b) and (c), respectively. Following

the approach of Marti et al.,

7

the concrete and steel tensile

stresses in Fig. 2(b) and (c), where 0 < z s/2, may be

expressed as

(3)

where

tc

is the reinforcement ratio of the tension chord

(= A

s

/A

ct

) and d

b

is the reinforcing bar diameter. Midway

between cracks, at z = s/2, the stresses are

T

nM

s

d c ( )

I

cr

---------------------------A

s

=

stx

T

A

s

-----

4

b

z

d

b

---------- - and

cx

4

b

tc

z

d

b

------------------ = =

R. Ian Gilbert is a Professor of civil engineering and an ARC Australian Professorial

Fellow in the School of Civil and Environmental Engineering at the University of New

South Wales, Sydney, Australia. His research interests include serviceability and the

time-dependent behavior of concrete structures.

Fig. 1Cracked reinforced concrete beam and idealized

tension chord model.

1

Fig. 2Tension chordactions and stresses.

7

ACI Structural Journal/May-June 2008 303

(4)

The maximum crack spacing immediately after loading

s = s

max

occurs when

c2

= f

ct

, and from Eq. (4)

(5)

where

b

= 2.0f

ct

. The minimum spacing is half the

maximum value, that is, s

min

= s

max

/2.

The instantaneous crack width w

i

is the difference between

the elongation of the tensile steel over the length s and the

elongation of the concrete between the cracks and is given by

(6)

Under sustained load, additional cracks occur between

widely spaced cracks (usually when 0.67s

max

< s s

max

).

The additional cracks are probably due to the combined

effect of tensile creep rupture and shrinkage. As a consequence,

the number of cracks increases and the maximum crack

spacing reduces with time. The final maximum crack

spacing s

*

is only approximately 2/3 of that given by Eq. (5),

but the final minimum crack spacing remains approximately

1/2 of the value given by Eq. (5).

As previously mentioned, experimental observations indicate

that

b

decreases with time, probably as a result of shrinkage-

induced slip and tensile creep. Hence, the stress in the tensile

concrete between the cracks gradually reduces. Further,

although creep and shrinkage will cause a small increase in

the resultant tensile force T in the real beam and a slight

reduction in the internal lever arm,

8

this effect is relatively

small and is ignored in the tension chord model presented

herein. The final crack width is the elongation of the steel

over the distance between the cracks minus the extension of

the concrete caused by

cx

plus the shortening of the

concrete between the cracks due to shrinkage. For a final

maximum crack spacing of s*, the final maximum crack

width is

(7)

where

sh

is the shrinkage strain in the tensile concrete (ve);

n = E

s

/E

e

; E

e

is the effective modulus given by E

e

= E

c

/(1 +

cc

);

E

c

and E

s

are the elastic modulus of the concrete and the

elastic modulus of steel, respectively; and

cc

is the creep

coefficient of the concrete.

A good estimate of the final maximum crack width is

given by Eq. (7), if s* is the maximum crack spacing after all

time-dependent cracking has taken place, that is, s* =

0.67s

max

. If s

max

is given by Eq. (5), s* may be taken as

(8)

By rearranging Eq. (7), the steel stress on a cracked section

corresponding to a particular crack width w* is given by

st2

T

A

s

-----

2

b

s

d

b

---------- - and

c2

2

b

tc

s

d

b

------------------ = =

s

max

f

ct

d

b

2

b

tc

--------------- =

w

i

s

E

s

-----

T

A

s

-----

b

s

d

b

------- 1 n

tc

+ ( ) =

w*

s*

E

s

-----

T

A

s

-----

b

s*

d

b

----------- 1 n

tc

+ ( )

sh

E

s

=

s*

d

b

6.0

tc

-------------- =

(9)

By substituting Eq. (1) and (8) into Eq. (9) and selecting a

maximum desired crack width in a particular structure w*,

the maximum permissible tensile steel stress can be obtained.

COMPARISON WITH TEST DATA

A total of 12 simply-supported beams and one-way slabs

were subjected to constant sustained service loads for a

period of 400 days by Gilbert and Nejadi.

6

Full details of the

test program and test results are available elsewhere.

6

Each

specimen was prismatic, with a rectangular cross section

(b = 250 mm [9.8 in.] and d = 300 mm [11.8 in.] for the six

beams and b = 400 mm [15.8 in.] and d = 130 mm [5.1 in.]

for the six one-way slabs) and a span of 3500 mm (138 in.),

and was carefully monitored throughout the test to record the

time-dependent deformation, together with the gradual

development of cracking and the gradual increase in crack

widths with time. The parameters varied in the tests were the

shape of the section b/d, the number of reinforcing bars, the

spacing between bars s

b

, the concrete cover c

t

, and the

sustained load level.

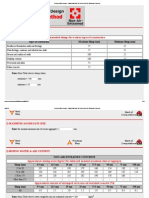

Details of the 12 specimens are provided in Table 1. All

specimens were cast from the same batch of concrete and all

the tests commenced when the specimens were 14 days old.

The measured elastic modulus, compressive strength, and

tensile strength of the concrete at the age of first loading

were E

c

= 22,820 MPa (3310 ksi), f

c

= 18.3 MPa (2650 psi),

and f

ct

= 2.00 MPa (290 psi) and the measured creep coefficient

and shrinkage strain associated with the 400-day period of

sustained loading were

cc

= 1.71 and

sh

= 0.000825.

The measured and predicted final maximum crack widths

are compared in Table 2. The mean value of predicted-to-

measured final maximum crack widths (w*/w

max

) is 1.54 and

the coefficient of variation is 21.4%. Considering the

variability of cracking in concrete and the requirement for

conservatism in design-oriented equations such as Eq. (7), the

agreement with test data is considered to be entirely satisfactory.

MAXIMUM STEEL STRESS FOR CRACK CONTROL

The model outlined in the previous section is herein used

to examine the effects of various parameters on the

maximum tensile stress permitted in the main longitudinal

f

st

w*E

s

s*

-------------

b

s*

d

b

----------- + 1 n

tc

+ ( )

sh

+ E

s

=

Table 1Details of test specimens

6

Beam

d

b

, mm

No. of bars

A

s

, mm

2

c

t

, mm

s, mm

f

st

, MPa

B1-a 16 2 400 40 150 227

B1-b 16 2 400 40 150 155

B2-a 16 2 400 25 180 226

B2-b 16 2 400 25 180 153

B3-a 16 3 600 25 90 214

B3-b 16 3 600 25 90 129

Slab

d

b

, mm

No. of bars

A

s

, mm

2

c

t

, mm

s, mm

f

st

, MPa

S1-a 12 2 226 25 308 252

S1-b 12 2 226 25 308 195

S2-a 12 3 339 25 154 247

S2-b 12 3 339 25 154 171

S3-a 12 4 452 25 103 216

S3-b 12 4 452 25 103 159

Note: 1 MPa = 145 psi; 1 mm = 0.0394 in.

304 ACI Structural Journal/May-June 2008

tensile reinforcement if the maximum crack width is to be

limited to a preselected value w*. The maximum permitted

steel stress is determined using Eq. (9).

Crack control in reinforced concrete slab

Consider a one-way reinforced concrete slab of thickness

h containing a single layer of longitudinal tensile bars of

diameter d

b

at a bar spacing s

b

. The clear cover to the

reinforcement from the tension face is c

t

. The area of

tensile reinforcement per unit width of the slab is A

s

and it

is located at an effective depth of d (= h c

t

d

b

/2) from the

compressive face of the slab. The characteristic compressive

strength of the concrete is f

c

. Unless noted otherwise, the slab

dimensions and material properties are taken as h = 200 mm

(8 in.); d

b

= 12 mm (0.5 in.); c

t

= 20 mm (0.79 in.); w* =

0.35 mm (0.0138 in.); f

c

= 32 MPa (4640 psi); E

c

= 28,600 MPa

(4140 ksi);

cc

= 2.5;

sh

= 0.0006; f

ct

= 2.04 MPa (296 psi);

and E

s

= 200 GPa (29,000 ksi).

In Fig. 3, the effect of bar diameter on the maximum

permissible steel stress is shown. For a given bar spacing, an

increase in bar diameter results in an increase in A

s

and an

increase in the maximum steel stress required to produce a

crack width of 0.35 mm (0.0138 in.). Of course, under a

particular in-service sustained moment, an increase in bar

diameter results in an increase in A

s

and a reduction in

crack width.

The effect of varying the slab thickness on the maximum

permissible steel stress for a slab containing 12 mm (0.5 in.)

diameter tensile bars is shown in Fig. 4. The slab depth has a

marked influence on the maximum steel stress required to

produce a maximum particular crack width, with the

maximum steel stress increasing as the slab depth decreases.

Figure 5 shows the effect of changing the bar diameter, but

at the same time adjusting the bar spacing so that the area of

tensile reinforcement remains constant. For a given reinforce-

ment ratio (A

s

/bd), if the bar diameter is reduced (that is,

smaller diameter bars at closer centers are used), the

maximum steel stress required to limit the maximum final

crack width increases. In this case, the slab thickness was

200 mm (8 in.) and the maximum final crack width was 0.35 mm

(0.0138 in.). Of course, under a particular in-service

sustained moment, using smaller diameter bars at closer

centers will result in a reduction in crack width.

Table 2Measured

6

and predicted maximum

crack widths at 400 days

Beam

Maximum steel

stress f

st

, MPa

Maximum crack width, mm

Ratio

w*/w

max

Measured

w

max

Predicted w*

(Eq. (7))

B1-a 226 0.38 0.383 1.01

B1-b 154 0.18 0.304 1.69

B2-a 225 0.36 0.382 1.06

B2-b 153 0.18 0.303 1.68

B3-a 213 0.28 0.239 0.85

B3-b 128 0.13 0.180 1.39

Slab

Maximum steel

stress f

st

, MPa

Maximum crack width, mm

Ratio

w*/w

max

Measured

w

max

Predicted

w* (Eq. (7))

S1-a 252 0.25 0.412 1.65

S1-b 195 0.20 0.347 1.73

S2-a 247 0.23 0.272 1.18

S2-b 171 0.18 0.216 1.20

S3-a 216 0.20 0.183 0.92

S3-b 159 0.15 0.154 1.03

Note: Mean (w*/w

max

) = 1.54; and coefficient of variation (w*/w

max

) = 21.4. 1 MPa =

145 psi; 1 mm = 0.0394 in.

Fig. 3Effect of bar diameter on maximum permissible

steel stress.

Fig. 4Effect of section depth on maximum permissible

steel stress.

ACI Structural Journal/May-June 2008 305

For a slab containing 12 mm (0.5 in.) diameter bars, the

effect of varying the maximum desired crack width w* is

shown in Fig. 6. As the permissible crack width increases,

the maximum permissible tensile steel stress also increases.

For exposure classifications where crack widths have no

influence on durability, the selection of a maximum desired

final crack width w* of 0.30 to 0.35 mm (0.012 to 0.014 in.)

will generally be acceptable from the point of view of

aesthetics and the cracks will not detract from the appearance of

the structure. Where the crack will not be visible and

aesthetics is not important, a wider crack may be acceptable

perhaps up to 0.55 mm (0.022 in.). Where durability is an

issue, the maximum desired final crack may be as low as

0.15 mm (0.006 in.) in aggressive environments but not

greater than 0.3 mm (0.012 in.).

The effect of variations in the final shrinkage strain on the

maximum permissible steel stress is shown in Fig. 7 for a

200 mm (8 in.) thick slab containing 12 mm (0.5 in.) diameter

bars. As expected, as the final shrinkage strain increases, the

maximum permitted tensile steel stress decreases. Of course,

under particular in-service conditions, an increase in the

final shrinkage strain results in wider cracks.

The effect of varying the concrete strength on the

maximum permissible tensile steel stress is shown in Fig. 8

for a 200 mm (8 in.) thick slab containing 12 mm (0.5 in.)

diameter bars. It is assumed herein that the concrete strength

only affects the tensile strength, the elastic modulus, and

the creep coefficient. In all cases, the final shrinkage was

sh

= 0.0006. Clearly, the concrete strength does not

significantly affect the maximum tensile steel stress required

for crack control.

Design example

Consider a 150 mm (5.91 in.) thick, simply-supported one-

way slab located inside a building. With appropriate regard for

durability, the concrete strength is selected to be f

c

= 32 MPa

(4640 psi) and the cover to the tensile reinforcement is taken

to be 20 mm (0.79 in.). The final shrinkage strain is taken to

Fig. 5Effect of bar diameter and reinforcement ratio (A

s

/ b

d

)

on maximum steel stress.

Fig. 7Effect of final shrinkage strain on maximum

permissible steel stress.

Fig. 6Effect of maximum final crack width on maximum

steel stress.

306 ACI Structural Journal/May-June 2008

be

sh

= 0.0006. Other relevant material properties are E

c

=

28,600 MPa (4140 ksi); n = E

s

/E

c

= 7.00;

cc

= 2.5; f

ct

=

2.04 MPa (296 psi); and E

s

= 200 GPa (29,000 ksi). The

effective modulus is therefore E

e

= E

c

/(1 +

cc

) = 8170 MPa

(1180 ksi) and the effective modular ratio n = E

s

/E

e

= 24.5.

The tensile face of the slab is to be exposed and the maximum

final crack width is to be limited to w* = 0.3 mm (0.0118 in.).

After completing the design for strength and deflection

control, the required minimum area of tensile steel is 650 mm

2

/m

(0.307 in.

2

/ft). Under the full service loads, the maximum in-

service sustained moment at midspan is 20.0 kNm (14.7 kipft).

The designer must select the bar diameter and bar spacing so

that the requirements for crack control are also satisfied.

Case 1Use 10 mm (0.394 in.) bars at 120 mm (4.72 in.)

centers, that is, A

s

= 655 mm

2

/m (0.309 in.

2

/ft) at d = 125 mm

(4.92 in.).

Referring to Fig. 1, elastic analysis of the cracked section

gives c = 29.6 mm (1.16 in.) and I

cr

= 50.3 10

6

mm

4

(121.0 in.

4

). The maximum in-service tensile steel stress on

the fully-cracked section at midspan is calculated using

Eq. (2) and is

st

= T/A

s

= 7.00 20 10

6

(125 29.6)/

50.3 10

6

= 265 MPa (38.4 ksi).

The area of concrete in the tension chord is obtained using

Eq. (1) and is A

ct

= 60,200 mm

2

(93.3 in.

2

). The reinforcement

ratio of the tension chord is

tc

= A

s

/A

ct

= 0.0109. With the

final bond stress taken as

b

= 1.0f

ct

= 2.04 MPa (296 psi) and

the maximum final crack spacing obtained from Eq. (8) as

s* = 10/(6.0 0.0109) = 153 mm (6.04 in.), the maximum

permissible steel stress required for crack control is obtained

using Eq. (9).

f

st

0.3 200 000 ,

153

----------------------------------

2.04 153

10

------------------------- 1 24.5 0.0109 + ( ) + =

0.0006 200,000 = 310 MPa (45.0 ksi)

The actual stress at the crack

st

= 265 MPa (38.4 ksi) is

less than f

st

= 310 MPa (45.0 ksi) and, therefore, cracking is

easily controlled.

Case 2Use 12 mm (0.472 in.) bars at 170 mm (6.69 in.)

centers, that is, A

s

= 665 mm

2

/m (0.314 in.

2

/ft) at d = 124 mm

(4.88 in.).

For this section, c = 29.6 mm (1.17 in.) and I

cr

= 50.1

10

6

mm

4

(121 in.

4

). The maximum in-service tensile steel

stress on the fully-cracked section at midspan is

st

= T/A

s

=

263 MPa (38.1 ksi). The area of concrete in the tension chord

is A

ct

= 60,200 mm

2

(93.3 in.

2

). The reinforcement ratio of

the tension chord is

tc

= A

s

/A

ct

= 0.0111. With

b

= 1.0 f

ct

=

2.04 MPa (296 psi) and s* = 12/(6.0 0.0111) = 181 mm

(7.13 in.), the maximum permissible steel stress required for

crack control (obtained using Eq. (9)) is f

st

= 251 MPa

(36.4 ksi), which is just less than the actual maximum stress

at the crack

st

= 263 MPa (38.1 ksi). Therefore, the final

maximum crack width may just exceed the desired

maximum of 0.3 mm (0.012 in).

Case 3Use 16 mm (0.630 in.) bars at 300 mm (11.8 in.)

centers, that is, A

s

= 670 mm

2

/m (0.317 in.

2

/ft) at d = 122 mm

(4.80 in.).

For this section, c = 29.5 mm (1.16 in.) and I

cr

= 48.7

10

6

mm

4

(117.0 in.

4

). The maximum in-service tensile steel

stress on the fully-cracked section at midspan is

st

= T/A

s

=

266 MPa (38.6 ksi). The area of concrete in the tension

chord is A

ct

= 60,270 mm

2

(93.42 in.

2

) and the reinforcement

ratio of the tension chord is

tc

= A

s

/A

ct

= 0.0111. With

b

=

1.0f

ct

= 2.04 MPa (296 psi) and s* = 16/(6.0 0.0111) =

240 mm (9.45 in.), the maximum permissible steel stress

required for crack control is f

st

= 169 MPa (24.5 ksi) (Eq. (9)),

which is much less than the actual steel stress due to the

sustained moment of

st

= 266 MPa (38.6 ksi). Therefore,

crack control is not adequate and the maximum final crack

width will exceed 0.3 mm (0.012 in.).

By contrast, the procedures for crack control specified by

ACI 318-05,

1

Eurocode 2,

2

AS3600,

3

and Gergely and Lutz

5

all suggest that cracking is adequately controlled in all three

of the aforementioned cases. Each of these methods does not

adequately account for the time-dependent increase in crack

widths due to shrinkage. It is not surprising that excessively

wide cracks are a common serviceability problem in many

reinforced concrete structures throughout the world.

CONCLUDING REMARKS

The procedure outlined previously provides a simple and

reliable approach to crack control and has been proposed for

inclusion in the next edition of the Australian Standard for

Concrete Structures, AS3600. In the design for crack

control at the serviceability limit state, the designer must

select the maximum desired final crack width in the structure

and then ensure that the tensile steel stress on the cracked

section under the sustained service load is less than the

maximum value f

st

given by Eq. (9). The approach has been

shown to provide good agreement with measured final crack

widths in beam and slab specimens under sustained service

loads for a period of 400 days.

Sensible detailing should always be specified for crack

control. For example, the distance from the side or soffit of a

beam to the center of the nearest longitudinal bar should not

exceed approximately 100 mm (4.0 in.) and the center-to-

Fig. 8Effect of concrete strength on maximum permissible

steel stress.

ACI Structural Journal/May-June 2008 307

center spacing of bars near a tension face of a beam or slab

should not exceed approximately 300 mm (12 in.).

4

For exposure classifications where crack widths have no

influence on durability, the selection of a maximum desired

final crack width w* of 0.3 to 0.35 mm (0.012 to 0.014 in.)

will generally be acceptable from the point of view of

aesthetics and the cracks will not detract from the appearance of

the structure. Where the crack will not be visible and

aesthetics is not important, a wider crack may be acceptable

perhaps 0.5 to 0.6 mm (0.02 to 0.025 in.). Where durability

is an issue, the maximum desired final crack may be as low

as 0.15 mm (0.006 in.) in aggressive environments but not

greater than 0.3 mm (0.012 in.).

ACKNOWLEDGMENTS

The support of the Australian Research Council through an ARC

Discovery Grant and an ARC Australian Professorial Fellowship is

gratefully acknowledged.

NOTATION

A

ct

= area of concrete in tension chord, mm

2

(in.

2

)

A

s

= area of tensile reinforcement, mm

2

(in.

2

)

b = width of compression chord, mm (in.)

b* width of section at level of centroid of tensile reinforcement,

mm (in.)

c = depth of compression chord or compression zone, mm (in.)

c

t

= clear cover to tensile reinforcement, mm (in.)

d = effective depth to centroid of tensile reinforcement, mm (in.)

d

b

= bar diameter, mm (in.)

E

c

= elastic modulus of concrete, MPa (ksi)

E

e

= effective modulus of concrete, MPa (ksi)

E

s

= elastic modulus of steel reinforcement, MPa (ksi)

f

c

= characteristic compressive (cylinder) strength of concrete,

MPa (psi)

f

ct

= direct tensile strength of concrete

f

st

= stress in tensile steel at crack, MPa (ksi)

f

y

= yield stress of steel reinforcement, MPa (ksi)

h = overall depth or thickness of beam or slab, mm (in.)

I

cr

= second moment of area of cracked transformed section, mm

4

(in.

4

)

M

cr

= cracking moment, kNm (kipft)

M

s

= in-service bending moment, kNm (kipft)

n = modular ratio (E

s

/E

c

)

n = effective modular ratio (E

s

/E

e

)

s = crack spacing, mm (in.)

s* = final crack spacing, mm (in.)

s

b

= center-to-center spacing between bars, mm (in.)

T = total tensile force in tension chord, kN (kips)

w* = maximum final crack width, mm (in.)

w

i

= maximum initial crack spacing (at first loading), mm (in.)

z = distance along tension chord, mm (in.)

sh

= shrinkage strain of concrete

cc

= creep coefficient of concrete

tc

= reinforcement ratio of tension chord (A

st

/A

ct

)

c

= stress in concrete, MPa (psi)

c2

= tensile stress in concrete in tension chord midway between cracks,

MPa (psi)

ct

= uniform average tensile stress in concrete in tension chord,

MPa (psi)

st1

= stress in reinforcement in tension chord at crack, MPa (ksi)

st 2

= stress in reinforcement in tension chord midway between cracks,

MPa (ksi)

b

= average bond stress, MPa (psi)

REFERENCES

1. ACI Committee 318, Building Code Requirements for Structural

Concrete (ACI 318-05) and Commentary (318R-05), American Concrete

Institute, Farmington Hills, MI, 2005, 430 pp.

2. BS EN 1992-1-1:2004, Eurocode 2: Design of Concrete Structures

Part 1-1: General Rules and Rules for Buildings, European Committee for

Standardization, CEN, Brussels, 2004, 224 pp.

3. Standards Australia Committee BD-002, Australian Standard for

Concrete Structures (AS3600-2001), Standards Australia, Sydney,

Australia, 2001, 176 pp.

4. Gilbert, R. I., Cracking and Crack Control in Reinforced Concrete

Structures Subjected to Long-Term Loads and Shrinkage, 18th Australian

Conference on the Mechanics of Structures & Materials (ASMSM18), V. 2,

A. J. Deeks and H. Hao, eds., the Netherlands, 2004, pp. 803-809.

5. Gergely, P., and Lutz, L. A., Maximum Crack Width in Reinforced

Concrete Flexural Members, Causes, Mechanism, and Control of

Cracking in Concrete, SP-20, American Concrete Institute, Farmington

Hills, MI, 1968, 244 pp.

6. Gilbert, R. I., and Nejadi, S., An Experimental Study of Flexural

Cracking in Reinforced Concrete Members under Sustained Loads,

UNICIV Report No. R-435, School of Civil and Environmental Engineering,

University of New South Wales, Sydney, Australia, 2004, 59 pp.

7. Marti, P.; Alvarez, M.; Kaufmann, W.; and Sigrist, V., Tension Chord

Model for Structural Concrete, Structural Engineering International, Apr.

1998, pp. 287-298.

8. Gilbert, R. I., Time Effects in Concrete Structures, Elsevier Science

Publishers, Amsterdam, the Netherlands, 1988, 321 pp.

Das könnte Ihnen auch gefallen

- Concret Mix Design (M10 To M100)Dokument65 SeitenConcret Mix Design (M10 To M100)Rajesh Kollipara93% (14)

- Concrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFDokument10 SeitenConcrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFThomas CroweNoch keine Bewertungen

- MIDAS Civil Analysis ManualDokument316 SeitenMIDAS Civil Analysis Manualmadepao75% (4)

- Truss DesignDokument111 SeitenTruss DesignSuhas NatuNoch keine Bewertungen

- Installation Guidance For Precast Concrete Headwalls PD81Dokument7 SeitenInstallation Guidance For Precast Concrete Headwalls PD81sosi2020Noch keine Bewertungen

- MacomberV-Beam-Catalog-1968 - Open Web Steel JoistsDokument12 SeitenMacomberV-Beam-Catalog-1968 - Open Web Steel JoistsFredCreads100% (1)

- Determination of Pipe and Bedding Combinations For Drainage WorksDokument26 SeitenDetermination of Pipe and Bedding Combinations For Drainage WorksFitriansyah Adi PutraNoch keine Bewertungen

- March 2010 Detailing Corner - Wide Beam Stirrup ConfigurationsDokument3 SeitenMarch 2010 Detailing Corner - Wide Beam Stirrup Configurationslattmdy100% (1)

- Finite Element Modeling of Concrete Beams Prestressed With External TendonsDokument8 SeitenFinite Element Modeling of Concrete Beams Prestressed With External TendonsviniciusltNoch keine Bewertungen

- Sand FM DetailsDokument1 SeiteSand FM DetailsV Venkata Narayana100% (1)

- Bca Eurocodes Traffic Loading and Design AssumptionsDokument2 SeitenBca Eurocodes Traffic Loading and Design AssumptionsFreddie KooNoch keine Bewertungen

- Concrete Pipes and Portal Culverts HandbookDokument52 SeitenConcrete Pipes and Portal Culverts HandbookKenya Ayallew Asmare100% (3)

- Rigid PavementDokument48 SeitenRigid PavementashoknrNoch keine Bewertungen

- RCC Box Culvert - Methodology and Designs Including Computer MethodDokument31 SeitenRCC Box Culvert - Methodology and Designs Including Computer Methodmohan1441Noch keine Bewertungen

- Chhatrapati Shivaji International AirportDokument3 SeitenChhatrapati Shivaji International AirportRiddhi PatelNoch keine Bewertungen

- 2013 Soil Heave Due To Pile DrivingDokument20 Seiten2013 Soil Heave Due To Pile DrivingWilliam ChongNoch keine Bewertungen

- Young's ModuleDokument12 SeitenYoung's Modulelazy catNoch keine Bewertungen

- MiTek Structural Fixings On-Site Guide 2012 PDFDokument124 SeitenMiTek Structural Fixings On-Site Guide 2012 PDFragulan1983Noch keine Bewertungen

- Aashto - LRFD of Steel Beam Bridges Fatigue and FractureDokument56 SeitenAashto - LRFD of Steel Beam Bridges Fatigue and Fractureg401992100% (1)

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 20-Feb-2013 101Dokument12 SeitenSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 20-Feb-2013 101Thomas Crowe0% (1)

- Crack Width Calc - BS 8110Dokument1 SeiteCrack Width Calc - BS 8110Thomas Crowe100% (2)

- EC2 - How To Design Concrete StructuresDokument117 SeitenEC2 - How To Design Concrete StructuresThomas Crowe100% (2)

- GR L Weap 2010 Whats New 2010Dokument6 SeitenGR L Weap 2010 Whats New 2010Nguyen Quoc VuNoch keine Bewertungen

- Design Calculation - G+1 Accommodation Block Building-R0Dokument41 SeitenDesign Calculation - G+1 Accommodation Block Building-R0meetsaf83Noch keine Bewertungen

- Design of Truss BridgeDokument18 SeitenDesign of Truss BridgeBCE 2074 B Teacher100% (3)

- Load Bearing Bahaviour of Cast in Shear Dowels PDFDokument7 SeitenLoad Bearing Bahaviour of Cast in Shear Dowels PDFToan PhamNoch keine Bewertungen

- Seismic Design of BridgesDokument20 SeitenSeismic Design of BridgesIon PusculitaNoch keine Bewertungen

- Lecture Plate Girder Intro DSS 2Dokument37 SeitenLecture Plate Girder Intro DSS 2Amarendra KojjaNoch keine Bewertungen

- Design of Box Culvert (AASHTO)Dokument12 SeitenDesign of Box Culvert (AASHTO)Sudhir Reddy Nallamilli77% (26)

- RCC42 Post Tensioned Analysis & DesignDokument8 SeitenRCC42 Post Tensioned Analysis & DesignCarlos Valverde PortillaNoch keine Bewertungen

- Precast Concrete PilesDokument1 SeitePrecast Concrete PilesRazeenNoch keine Bewertungen

- Beaudrain PVD Vacuum Systemsolf Bangkok ClayCase Studyofthe Suvarnabhumi Airport ProjectDokument17 SeitenBeaudrain PVD Vacuum Systemsolf Bangkok ClayCase Studyofthe Suvarnabhumi Airport ProjectAdarsh ChatraNoch keine Bewertungen

- Vertical DrainDokument15 SeitenVertical DrainSyahbani EkaNoch keine Bewertungen

- Ultimate Punching Shear Strength Analysis of Slab-Column ConnectionsDokument13 SeitenUltimate Punching Shear Strength Analysis of Slab-Column ConnectionssamannikNoch keine Bewertungen

- Question BankDokument21 SeitenQuestion BankmoinNoch keine Bewertungen

- Calculation of P-Y Curve: Soft ClayDokument2 SeitenCalculation of P-Y Curve: Soft ClayLeung FanNoch keine Bewertungen

- Autogenous Self-Healing of ConcreteDokument23 SeitenAutogenous Self-Healing of Concreteanon_650335530Noch keine Bewertungen

- Gannon - Primary Firm Secant Pile Concrete Specification - April 2016Dokument11 SeitenGannon - Primary Firm Secant Pile Concrete Specification - April 2016muhammad ismailNoch keine Bewertungen

- A New Formula To Calculate Crack Spacing For Concrete PlatesDokument11 SeitenA New Formula To Calculate Crack Spacing For Concrete PlatesphamminhquangNoch keine Bewertungen

- Sika Concrete - Handbook 2012Dokument260 SeitenSika Concrete - Handbook 2012Adina Si Razvan MelekNoch keine Bewertungen

- Design Principles For Roof Steel TrussDokument17 SeitenDesign Principles For Roof Steel TrussNasir AhmedNoch keine Bewertungen

- 134 - As Struck Finishes PDFDokument2 Seiten134 - As Struck Finishes PDFJonathan KeoughNoch keine Bewertungen

- CH 14Dokument161 SeitenCH 14Priyanka CholletiNoch keine Bewertungen

- Laterally Loaded Piles in CLAYDokument12 SeitenLaterally Loaded Piles in CLAYdr100% (1)

- Crack Width Evaluation For Flexural RC MembersDokument10 SeitenCrack Width Evaluation For Flexural RC MembersAly AnisNoch keine Bewertungen

- Tata Welded Joints in Tubular SteelwowrkDokument94 SeitenTata Welded Joints in Tubular SteelwowrkyeelingsNoch keine Bewertungen

- Time Effects On Bearing Capacity of Driven PilesDokument4 SeitenTime Effects On Bearing Capacity of Driven Pilessmw100% (1)

- 013 - Strut and Tie Method (2014 11 09)Dokument58 Seiten013 - Strut and Tie Method (2014 11 09)Hui Jie LeeNoch keine Bewertungen

- Preliminary Steel Composite Bridge Design ExampleDokument11 SeitenPreliminary Steel Composite Bridge Design Examplemamad66Noch keine Bewertungen

- Advanced Crack Width Analysis of Reinforced Concrete Beams Under Repeated LoadsDokument10 SeitenAdvanced Crack Width Analysis of Reinforced Concrete Beams Under Repeated Loadsuhu_plus6482Noch keine Bewertungen

- 1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringDokument8 Seiten1985-Review of Cracking of Partially Prestressed Concrete Member Canadian Journal of Civil EngineeringChan Dara KoemNoch keine Bewertungen

- 14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilDokument6 Seiten14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilWondwosen BelayNoch keine Bewertungen

- Hyperbolic Method For Settlement in Clays With Vertical DrainsDokument7 SeitenHyperbolic Method For Settlement in Clays With Vertical DrainsMark MengNoch keine Bewertungen

- USBR - Design of Embankement DamDokument2 SeitenUSBR - Design of Embankement Dampggopal_85Noch keine Bewertungen

- 12 Plaxis Bulletin-With ShotcreteDokument24 Seiten12 Plaxis Bulletin-With ShotcreteGEOMAHESHNoch keine Bewertungen

- dESIGN OF D REGIONS STRUT AND TIE PDFDokument54 SeitendESIGN OF D REGIONS STRUT AND TIE PDFconsultor9010Noch keine Bewertungen

- Base Concrete Placement: 1. SubgradeDokument1 SeiteBase Concrete Placement: 1. Subgradeapuhapuh_153349Noch keine Bewertungen

- NCCI: Initial Sizing of Fin Plate Connections. SN016a-EN-EUDokument8 SeitenNCCI: Initial Sizing of Fin Plate Connections. SN016a-EN-EUCatalin234Noch keine Bewertungen

- Shaft Capacity of Driven Pipe Piles in ClayDokument7 SeitenShaft Capacity of Driven Pipe Piles in Clayinigo38Noch keine Bewertungen

- Structural Use of Bamboo. Part 4: Element Design Equations: SynopsisDokument4 SeitenStructural Use of Bamboo. Part 4: Element Design Equations: SynopsisVictor OmotoriogunNoch keine Bewertungen

- Concrete Bridge Design and Construction Series: No. 11: Specialist Concrete BridgesDokument6 SeitenConcrete Bridge Design and Construction Series: No. 11: Specialist Concrete BridgesJianhua WuNoch keine Bewertungen

- ERSS-Lecture 2 (ChiewSP 5mar20)Dokument30 SeitenERSS-Lecture 2 (ChiewSP 5mar20)sunilarunaNoch keine Bewertungen

- Design Considerations For Offshore Piles PDFDokument1 SeiteDesign Considerations For Offshore Piles PDFarkadjyothiprakashNoch keine Bewertungen

- New Formula For Creep of Concrete in Fib Model Code 2010Dokument8 SeitenNew Formula For Creep of Concrete in Fib Model Code 2010RamchandraNoch keine Bewertungen

- Pile - Chapter 6Dokument16 SeitenPile - Chapter 6SudharsananPRSNoch keine Bewertungen

- Grundfos and Wind TurbinesDokument32 SeitenGrundfos and Wind TurbinesingrbarrosNoch keine Bewertungen

- 1999-Performance Comparison of Bored and Excavated Piles in The Layered Soils of Bangkok PDFDokument10 Seiten1999-Performance Comparison of Bored and Excavated Piles in The Layered Soils of Bangkok PDFDavid Aponte RojasNoch keine Bewertungen

- Chun Wo - Technical Note 005Dokument3 SeitenChun Wo - Technical Note 005Paul KwongNoch keine Bewertungen

- Lateral Earth Pressure in Expansive Clay SoilsDokument14 SeitenLateral Earth Pressure in Expansive Clay SoilsSamad Arabi100% (1)

- L2. Closure To Effect of Bentonite Slurry Pressure On Interface Friction of Pipe Jacking by Mucahit Namli and Erol GulerDokument4 SeitenL2. Closure To Effect of Bentonite Slurry Pressure On Interface Friction of Pipe Jacking by Mucahit Namli and Erol GulerAna Maria Garcia EscandonNoch keine Bewertungen

- Responsibility For Controlling Slab CurlingDokument1 SeiteResponsibility For Controlling Slab CurlingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- TCC61 Basement WallDokument3 SeitenTCC61 Basement WallMario Sajulga Dela CuadraNoch keine Bewertungen

- Performance of Multi-Propped Deep Excavation in Kenny Hill Formation, 2013 PDFDokument8 SeitenPerformance of Multi-Propped Deep Excavation in Kenny Hill Formation, 2013 PDFfreezefreezeNoch keine Bewertungen

- Masterthesis Tawvancorven 2015Dokument238 SeitenMasterthesis Tawvancorven 2015RavitejaNoch keine Bewertungen

- Post - Installed Rebar DesignDokument2 SeitenPost - Installed Rebar DesignAsyraf ZailudinNoch keine Bewertungen

- Development of Column Interaction Curves For Higher Grades of ConcreteDokument22 SeitenDevelopment of Column Interaction Curves For Higher Grades of Concreteyedida v r aviswanadhNoch keine Bewertungen

- Lecture 4Dokument28 SeitenLecture 4Mong100% (1)

- Vertical Extensions Technical Challenges and Carbon ImpactDokument4 SeitenVertical Extensions Technical Challenges and Carbon ImpactMyo Min ThuNoch keine Bewertungen

- Crack - Width of Flexural RC Members-ICJ-Nov05Dokument6 SeitenCrack - Width of Flexural RC Members-ICJ-Nov05Munish BansalNoch keine Bewertungen

- Cracking and DeflectionsDokument19 SeitenCracking and DeflectionsVelammal SomasundaramNoch keine Bewertungen

- 2003 ISHPC Paper - Flexural Crack Control in Concrete Structures PDFDokument24 Seiten2003 ISHPC Paper - Flexural Crack Control in Concrete Structures PDFaomareltayebNoch keine Bewertungen

- Pull-Out Test For Studying Bond Strength inDokument14 SeitenPull-Out Test For Studying Bond Strength inحسام رسميNoch keine Bewertungen

- The Implications of The Change To Eurocodes For Bridge Design PDFDokument12 SeitenThe Implications of The Change To Eurocodes For Bridge Design PDFThomas CroweNoch keine Bewertungen

- CIP 5 Plastic Shrinkage Cracking PDFDokument2 SeitenCIP 5 Plastic Shrinkage Cracking PDFSwëêt Rãsçäl SëlvåNoch keine Bewertungen

- Fixed Deposit SampleDokument14 SeitenFixed Deposit SampleThomas CroweNoch keine Bewertungen

- STD Technical ExpertsDokument21 SeitenSTD Technical ExpertsNermin MustafiNoch keine Bewertungen

- Retrofit & Replicate: Project BriefingDokument8 SeitenRetrofit & Replicate: Project BriefingThomas CroweNoch keine Bewertungen

- Fixed Deposit SampleDokument14 SeitenFixed Deposit SampleThomas CroweNoch keine Bewertungen

- Cracking and DeflectionsDokument21 SeitenCracking and DeflectionsDeepakRavindraPrasadNoch keine Bewertungen

- Electric Wharf Bridge Jd311Dokument10 SeitenElectric Wharf Bridge Jd311Thomas CroweNoch keine Bewertungen

- Evaporation RateDokument162 SeitenEvaporation RateThomas CroweNoch keine Bewertungen

- Direct Comparison Between Tensile Strength and Flexural Strength of Ceramic/Metal Brazing Joint PDFDokument5 SeitenDirect Comparison Between Tensile Strength and Flexural Strength of Ceramic/Metal Brazing Joint PDFPunya SureshNoch keine Bewertungen

- Guidelines For Lifting DesignDokument42 SeitenGuidelines For Lifting Designthanzawtun1Noch keine Bewertungen

- Bridge Deck BehaviourDokument167 SeitenBridge Deck BehaviourThomas CroweNoch keine Bewertungen

- In Torque Technology: Leading The WorldDokument2 SeitenIn Torque Technology: Leading The WorldThomas CroweNoch keine Bewertungen

- Tetron Disc BearingsDokument9 SeitenTetron Disc BearingsThomas CroweNoch keine Bewertungen

- Instruction Manual: For High Strength Friction Grip BoltingDokument13 SeitenInstruction Manual: For High Strength Friction Grip BoltingThomas CroweNoch keine Bewertungen

- Steel Concrete Composite BridgesDokument169 SeitenSteel Concrete Composite BridgesThomas CroweNoch keine Bewertungen

- Behavior of Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic LoadsDokument12 SeitenBehavior of Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic LoadsAbdelhamid ElgasaierNoch keine Bewertungen

- Beam TheoryDokument61 SeitenBeam Theorysaleemm_2Noch keine Bewertungen

- Design Analysis 1Dokument13 SeitenDesign Analysis 1Katy PerryNoch keine Bewertungen

- Paper Dome Challenge 2018 - FInalDokument8 SeitenPaper Dome Challenge 2018 - FInalshehan madusankaNoch keine Bewertungen

- Plant Layout Assignment 2Dokument16 SeitenPlant Layout Assignment 2ashpikaNoch keine Bewertungen

- Retrofitting Arch Bridges PragueDokument13 SeitenRetrofitting Arch Bridges PragueTamaduianu IoanNoch keine Bewertungen

- ASCE 7-16 Live Load CDokument6 SeitenASCE 7-16 Live Load CNgoc TonNoch keine Bewertungen

- Dss McqsDokument44 SeitenDss McqsRavpreet Karanbir AhluwaliaNoch keine Bewertungen

- Karamba 1 1 0 ManualDokument127 SeitenKaramba 1 1 0 ManualLuca ValzanoNoch keine Bewertungen

- 02DHIET - ARC 313 - Option - Advanced Structural Systems & Building Tech I - Lecture 1-2 PDFDokument10 Seiten02DHIET - ARC 313 - Option - Advanced Structural Systems & Building Tech I - Lecture 1-2 PDFOmerta SpiritNoch keine Bewertungen

- Double Corbel PDFDokument5 SeitenDouble Corbel PDFSushil Dhungana100% (1)

- Chapter4 PDFDokument26 SeitenChapter4 PDFvaibhav dahiwalkarNoch keine Bewertungen

- Gen 7001Dokument21 SeitenGen 7001Meshoo ZakyNoch keine Bewertungen

- A Case Study On The Structural Assessment of FireDokument8 SeitenA Case Study On The Structural Assessment of FireHarshsav SethiNoch keine Bewertungen

- Planning, Analysis, Designing & Estimation of High Rise BuildingDokument34 SeitenPlanning, Analysis, Designing & Estimation of High Rise BuildingZweli KhathwayoNoch keine Bewertungen

- RoofDokument99 SeitenRoofshingkeong100% (1)

- ENGM032 Steel and Composite Bridge Design. Unit 5 Ultimate Load Method of Design For Plate Girders. Study Time 15 HoursDokument18 SeitenENGM032 Steel and Composite Bridge Design. Unit 5 Ultimate Load Method of Design For Plate Girders. Study Time 15 Hoursmocker1987Noch keine Bewertungen

- ASS PRES NaeemDokument123 SeitenASS PRES NaeemAbdullah Al NomanNoch keine Bewertungen

- AENG252Dokument83 SeitenAENG252inpursuitofhappynessNoch keine Bewertungen