Beruflich Dokumente

Kultur Dokumente

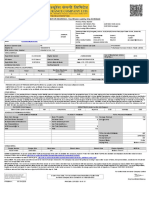

Dilo Test Equipment For Leak Detection in GIS

Hochgeladen von

Travis WoodOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dilo Test Equipment For Leak Detection in GIS

Hochgeladen von

Travis WoodCopyright:

Verfügbare Formate

DILO Armaturen und Anlagen GmbH in Babenhausen has developed a new SF

6

leakage test unit

that allows detection of even smallest leakages within a short period of time.

The SF

6

leakage test system developed by DILO allows an integral and fully automatic leak

measurement on gas-insulated medium- or high-voltage components and assemblies. The system's

core components are a vacuum test chamber with diffusion accelerator, a highly sensitive leak

measuring system and a vacuum pump for evacuation of the test chamber.

State-of-the-art control technology and a 17-inch (43-cm) TFT screen make system operation easy

and comfortable. All major system parameters are stored for further processing. Layout, size of

vacuum test chamber and the conveying system can be widely realized according to customer's

specifications. As a standard, the vacuum chamber is feasible with a volume of up to 4 m

3

allowing a

large component or several smaller GIS components to be checked in one process. Upon request,

however, larger chamber volumes can be configured, too.

The inert gas SF

6

(sulphur hexafluoride) is used in component testing. As the gas cannot be found in

ambient air, a highly precise and pure test result can be guaranteed.

The new leak test unit virtually does detective work for it is able to trace smallest SF

6

leakages.

Even leakage rates down to 1*10-9 mbar l/s can be easily detected. The system's detection limit is

as low as < 1 ppb, and test time is very short: As a rule, the test result is already indicated after 3 to

5 minutes, the total leakage rate being displayed on the screen in mbar l/s or other common

measurement units.

For the test, no high vacuum is needed. As a rule, an absolute test pressure of about 10 mbar to 20

mbar is fully sufficient. Upon start of operation, the leakage test system carries out a preliminary

leakage test, and only in case of a positive result, the final precision is test started. Pressure and

vacuum are permanently monitored during the process.

As SF

6

is used as quenching and insulating gas in the GIS assembly itself, it can stay in the test

object when the test is completed. Therefore, the SF

6

leak test method is a viable alternative to the

well-established helium leak test as no test gas needs to be recovered upon completion of the

process. Thus, with the SF

6

test method, the handling time per test object is shorter.

Before the test starts, the test object is evacuated from air outside the test installation and is

subsequently filled with SF

6

up to the desired final pressure. For preparatory handling of GIS

components before the SF

6

leak test starts, DILO delivers special SF

6

equipment allowing emission-

free gas handling of GIS assemblies manufactured in series. For highly challenging test objects,

such as medium voltage GIS components, the leak test system can be configured with recovery and

filling functions to be carried out inside the vacuum chamber. With this option, the admissible

pressure difference between chamber and internal pressure of the test object is permanently

monitored via system control.

Part of DILO's core business are SF

6

gas service carts for maintenance of gas-insulated switchgear

as well as measuring devices to determine SF

6

quality. Hermetically sealing valves and couplings

round off the specialist's product range.

Das könnte Ihnen auch gefallen

- Double Sampling-Wha It Means PDFDokument17 SeitenDouble Sampling-Wha It Means PDFTravis WoodNoch keine Bewertungen

- What SF6 Gas TestingDokument4 SeitenWhat SF6 Gas TestingAnonymous V1oLCBNoch keine Bewertungen

- Pressure TestingDokument30 SeitenPressure TestingKaushal Gandhi100% (1)

- NGL Fractionation Part 1 483KBDokument4 SeitenNGL Fractionation Part 1 483KBlutfi awnNoch keine Bewertungen

- Piping and Vessels Preparation For Commissioning - Part 2Dokument12 SeitenPiping and Vessels Preparation For Commissioning - Part 2MohamedNoch keine Bewertungen

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentVon EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentBewertung: 4.5 von 5 Sternen4.5/5 (3)

- WT Training ManualDokument429 SeitenWT Training Manualbilmard100% (4)

- Fretting Fatigue in Overhead ConductorsDokument16 SeitenFretting Fatigue in Overhead ConductorsTravis WoodNoch keine Bewertungen

- 400 Puzzles and Answers PDFDokument188 Seiten400 Puzzles and Answers PDFTravis WoodNoch keine Bewertungen

- ASM142 Helium Leak DetectorDokument11 SeitenASM142 Helium Leak DetectornasrpkNoch keine Bewertungen

- NDT Pressure TestingDokument23 SeitenNDT Pressure TestingRamu Nallathambi100% (2)

- CT Grounding To Avoid Nuisance TrippingDokument2 SeitenCT Grounding To Avoid Nuisance TrippingTravis WoodNoch keine Bewertungen

- Leak Testing MethodologiesDokument9 SeitenLeak Testing MethodologiesPin SantosNoch keine Bewertungen

- Vaccum Test MethodDokument4 SeitenVaccum Test MethodMahmud AlamNoch keine Bewertungen

- Deed of Assignment CorporateDokument4 SeitenDeed of Assignment CorporateEric JayNoch keine Bewertungen

- Dewpoint Measurement in SF6 Gas-Insulated SwitchgearDokument2 SeitenDewpoint Measurement in SF6 Gas-Insulated SwitchgearvladaukiNoch keine Bewertungen

- Leak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCDokument3 SeitenLeak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCMirza Safeer Ahmad100% (1)

- Pressure & Leak TestingDokument18 SeitenPressure & Leak TestingBilly KurniawanNoch keine Bewertungen

- PGCIL GIS Specification - Rev 4 (June-14)Dokument74 SeitenPGCIL GIS Specification - Rev 4 (June-14)Travis Wood100% (1)

- Basic Vibration Analysis Training-1Dokument193 SeitenBasic Vibration Analysis Training-1Sanjeevi Kumar SpNoch keine Bewertungen

- Aluminium Recycling ProcessDokument69 SeitenAluminium Recycling ProcessTravis Wood100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsVon EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNoch keine Bewertungen

- 3119-600series Rev2 0912 LRes PDFDokument8 Seiten3119-600series Rev2 0912 LRes PDFAlper Emrah SakalsızNoch keine Bewertungen

- 09 WA500-3 Shop ManualDokument1.335 Seiten09 WA500-3 Shop ManualCristhian Gutierrez Tamayo93% (14)

- Commissioninng Procedure For Clean Air Flow Test Rev.01 PDFDokument11 SeitenCommissioninng Procedure For Clean Air Flow Test Rev.01 PDFRAJKISHORE OJHA100% (1)

- Jet Venturi Fume ScrubbersDokument7 SeitenJet Venturi Fume ScrubbersihllhmNoch keine Bewertungen

- Mud Architecture: I J I R S E TDokument6 SeitenMud Architecture: I J I R S E TJazzNoch keine Bewertungen

- Transformer Factory Assembly Area LayoutDokument55 SeitenTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- Pipe and Vessel PurgingDokument4 SeitenPipe and Vessel PurgingAnonymous v5uipH100% (2)

- Aluminium Recycling Process PDFDokument69 SeitenAluminium Recycling Process PDFTravis WoodNoch keine Bewertungen

- 15 Reasons Why The Zerowaste SF6 Analyser Beats All Comers IndoDokument4 Seiten15 Reasons Why The Zerowaste SF6 Analyser Beats All Comers IndoferiNoch keine Bewertungen

- 15 Reasons Why The Zerowaste SF6 Analyser Beats All Comers.Dokument3 Seiten15 Reasons Why The Zerowaste SF6 Analyser Beats All Comers.Trần Danh VũNoch keine Bewertungen

- BR Gis en 0621Dokument6 SeitenBR Gis en 0621fumyzNoch keine Bewertungen

- 973-SF Analyzer: Laboratory Precision - Field ReadyDokument4 Seiten973-SF Analyzer: Laboratory Precision - Field ReadyEngr Irfan AkhtarNoch keine Bewertungen

- Intertek Confinement ASHRAE 110 1995Dokument31 SeitenIntertek Confinement ASHRAE 110 1995Linh NgoNoch keine Bewertungen

- BR Leak Detection Systems en 0913 2Dokument4 SeitenBR Leak Detection Systems en 0913 2Travis WoodNoch keine Bewertungen

- 973-SF Analyzer: Laboratory Precision - Field ReadyDokument4 Seiten973-SF Analyzer: Laboratory Precision - Field ReadymersiumNoch keine Bewertungen

- 8RY 800 001-SF6密度继电器说明书 (ABB)Dokument8 Seiten8RY 800 001-SF6密度继电器说明书 (ABB)Trần Văn HiếuNoch keine Bewertungen

- SF - An Excellent Insulating and Quenching Gas: Substantial Properties at A GlanceDokument16 SeitenSF - An Excellent Insulating and Quenching Gas: Substantial Properties at A GlancedennyyusufNoch keine Bewertungen

- CorrosionboxDokument4 SeitenCorrosionboxmankari.kamal.18022963Noch keine Bewertungen

- Leak Testing MethodologiesDokument9 SeitenLeak Testing MethodologiesElena-Cristina IonitaNoch keine Bewertungen

- Test Rigs Filter TestDokument4 SeitenTest Rigs Filter TestRajesh DwivediNoch keine Bewertungen

- SF6 Meas Tech.Dokument6 SeitenSF6 Meas Tech.sameerNoch keine Bewertungen

- Laboratory ControlDokument6 SeitenLaboratory Controlkumar123rajuNoch keine Bewertungen

- WJL 6000Dokument8 SeitenWJL 6000totoNoch keine Bewertungen

- HD 254 Foam Chamer Model-FCADokument6 SeitenHD 254 Foam Chamer Model-FCAktc8120Noch keine Bewertungen

- Enclosure Integrity - Commissioning and TestingDokument3 SeitenEnclosure Integrity - Commissioning and TestingSalim BakhshNoch keine Bewertungen

- Gorter r100 enDokument6 SeitenGorter r100 enManish SaraswatNoch keine Bewertungen

- DANI Gas ChromatographyDokument4 SeitenDANI Gas Chromatographyidhem1110Noch keine Bewertungen

- 2.5 Tracer Gas Leak TestingDokument10 Seiten2.5 Tracer Gas Leak TestingNguyễn ĐạtNoch keine Bewertungen

- Issac Pressure DecayDokument2 SeitenIssac Pressure DecaydcobbNoch keine Bewertungen

- Foam ChamberFCADokument6 SeitenFoam ChamberFCAarachman297988Noch keine Bewertungen

- Automotive - Vacuum Pressure Detection On GrippersDokument1 SeiteAutomotive - Vacuum Pressure Detection On GrippersBalluff SensorsNoch keine Bewertungen

- 5990 8243ENGasCleanFiltersDokument8 Seiten5990 8243ENGasCleanFilterskutts76Noch keine Bewertungen

- Day 04 Design of LPG System Part 04Dokument14 SeitenDay 04 Design of LPG System Part 04kmas1612Noch keine Bewertungen

- Epa Source Test MethodsDokument18 SeitenEpa Source Test MethodsMike ColeNoch keine Bewertungen

- Method Statement For Integrity TestDokument2 SeitenMethod Statement For Integrity TestmrNoch keine Bewertungen

- 142 EaDokument3 Seiten142 EaKenny RuizNoch keine Bewertungen

- 7 Steps To Selecting A Quality DesiccantDokument2 Seiten7 Steps To Selecting A Quality DesiccantMohammed AlShammasiNoch keine Bewertungen

- SF and A World First: ABB Launches The First-Ever SF Recycling CenterDokument4 SeitenSF and A World First: ABB Launches The First-Ever SF Recycling CenterAlexKvNoch keine Bewertungen

- App B SOP-10r0 PM10 Hi Vol Air SamplingDokument22 SeitenApp B SOP-10r0 PM10 Hi Vol Air SamplingJorge Kovach AlvaradoNoch keine Bewertungen

- Expt 14Dokument2 SeitenExpt 14cpt.ghostNoch keine Bewertungen

- Unit One This or That 1Dokument9 SeitenUnit One This or That 1sushantNoch keine Bewertungen

- Eagle Brochure 5Dokument3 SeitenEagle Brochure 5Adnan KhalidNoch keine Bewertungen

- Foam Chamber PDFDokument6 SeitenFoam Chamber PDFAinur RohmanNoch keine Bewertungen

- Leak Detection RefDokument62 SeitenLeak Detection Refaries26march100% (1)

- Power Transformer BrochureDokument4 SeitenPower Transformer Brochure3319826Noch keine Bewertungen

- Process Gas ChromatographRaphyDokument8 SeitenProcess Gas ChromatographRaphyoviemeNoch keine Bewertungen

- DILO SF6 Catalogue 2021 ENDokument214 SeitenDILO SF6 Catalogue 2021 ENBadraa BatorgilNoch keine Bewertungen

- AnalyserDokument14 SeitenAnalyserNaseer HydenNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryVon EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNoch keine Bewertungen

- KSEB Technical SPec PDFDokument279 SeitenKSEB Technical SPec PDFTravis WoodNoch keine Bewertungen

- Effect of Grading Ring On Voltage Distribution of ArrestorsDokument7 SeitenEffect of Grading Ring On Voltage Distribution of ArrestorsTravis WoodNoch keine Bewertungen

- Anandaram BaruaDokument1 SeiteAnandaram BaruaTravis WoodNoch keine Bewertungen

- Ehv Disconnectors For Smart GridDokument2 SeitenEhv Disconnectors For Smart GridTravis WoodNoch keine Bewertungen

- Unidirectional Corona RingDokument2 SeitenUnidirectional Corona RingTravis WoodNoch keine Bewertungen

- 1363 Bolts and Nut Standard PDFDokument7 Seiten1363 Bolts and Nut Standard PDFTravis WoodNoch keine Bewertungen

- ElectricalDokument34 SeitenElectricalTravis WoodNoch keine Bewertungen

- Spacer Damper IssuesDokument5 SeitenSpacer Damper IssuesTravis WoodNoch keine Bewertungen

- 3 Sec-III-Hardware Fittings & AccessoriesDokument49 Seiten3 Sec-III-Hardware Fittings & AccessoriesTravis WoodNoch keine Bewertungen

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDokument10 SeitenAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodNoch keine Bewertungen

- China Claim FinalDokument1 SeiteChina Claim FinalTravis WoodNoch keine Bewertungen

- CB Spec SvenskaDokument44 SeitenCB Spec SvenskaTravis WoodNoch keine Bewertungen

- Production - The Heart of Organization - TBDDokument14 SeitenProduction - The Heart of Organization - TBDSakshi G AwasthiNoch keine Bewertungen

- Mid Term Exam 1Dokument2 SeitenMid Term Exam 1Anh0% (1)

- M2 Economic LandscapeDokument18 SeitenM2 Economic LandscapePrincess SilenceNoch keine Bewertungen

- Vangood Quotation - Refrigerator Part - 2023.3.2Dokument5 SeitenVangood Quotation - Refrigerator Part - 2023.3.2Enmanuel Jossue Artigas VillaNoch keine Bewertungen

- Audit On ERP Implementation UN PWCDokument28 SeitenAudit On ERP Implementation UN PWCSamina InkandellaNoch keine Bewertungen

- Activity Description Predecessor Time (Days) Activity Description Predecessor ADokument4 SeitenActivity Description Predecessor Time (Days) Activity Description Predecessor AAlvin LuisaNoch keine Bewertungen

- Schmidt Family Sales Flyer English HighDokument6 SeitenSchmidt Family Sales Flyer English HighmdeenkNoch keine Bewertungen

- Health Insurance in Switzerland ETHDokument57 SeitenHealth Insurance in Switzerland ETHguzman87Noch keine Bewertungen

- Amare Yalew: Work Authorization: Green Card HolderDokument3 SeitenAmare Yalew: Work Authorization: Green Card HolderrecruiterkkNoch keine Bewertungen

- Material Safety Data Sheet (According To 91/155 EC)Dokument4 SeitenMaterial Safety Data Sheet (According To 91/155 EC)Jaymit PatelNoch keine Bewertungen

- Ishares Core S&P/TSX Capped Composite Index Etf: Key FactsDokument2 SeitenIshares Core S&P/TSX Capped Composite Index Etf: Key FactsChrisNoch keine Bewertungen

- Pneumatic Fly Ash Conveying0 PDFDokument1 SeitePneumatic Fly Ash Conveying0 PDFnjc6151Noch keine Bewertungen

- Innovations in Land AdministrationDokument66 SeitenInnovations in Land AdministrationSanjawe KbNoch keine Bewertungen

- 5 Deming Principles That Help Healthcare Process ImprovementDokument8 Seiten5 Deming Principles That Help Healthcare Process Improvementdewi estariNoch keine Bewertungen

- KSU OGE 23-24 AffidavitDokument1 SeiteKSU OGE 23-24 Affidavitsourav rorNoch keine Bewertungen

- Hayashi Q Econometica 82Dokument16 SeitenHayashi Q Econometica 82Franco VenesiaNoch keine Bewertungen

- Tivoli Performance ViewerDokument4 SeitenTivoli Performance ViewernaveedshakurNoch keine Bewertungen

- Year 9 - Justrice System Civil LawDokument12 SeitenYear 9 - Justrice System Civil Lawapi-301001591Noch keine Bewertungen

- Historical Development of AccountingDokument25 SeitenHistorical Development of AccountingstrifehartNoch keine Bewertungen

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDokument1 Seite18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaNoch keine Bewertungen

- Portrait of An INTJDokument2 SeitenPortrait of An INTJDelia VlasceanuNoch keine Bewertungen

- PCDokument4 SeitenPCHrithik AryaNoch keine Bewertungen

- 30 Creative Activities For KidsDokument4 Seiten30 Creative Activities For KidsLaloGomezNoch keine Bewertungen

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDokument1 SeiteMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNoch keine Bewertungen

- SND Kod Dt2Dokument12 SeitenSND Kod Dt2arturshenikNoch keine Bewertungen

- Environmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsDokument8 SeitenEnvironmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsAhmad Zubair Hj YahayaNoch keine Bewertungen

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDokument9 SeitenForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaNoch keine Bewertungen