Beruflich Dokumente

Kultur Dokumente

1900/55 Fan Monitor: Operation Manual

Hochgeladen von

nabil160874Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1900/55 Fan Monitor: Operation Manual

Hochgeladen von

nabil160874Copyright:

Verfügbare Formate

Part Number 190155-01

Rev. J (01/08)

Bently Nevada Asset Condition Monitoring

Operation Manual

1900/55 Fan Monitor

1900/55 Fan Monitor Operation Manual

ii

Copyright 1995 Bently Nevada LLC

All rights reserved.

The information contained in this document is subject to change without notice.

The following are trademarks of General Electric Company in the United States and other

countries:

Bently Nevada, Sealtite, Velomitor

Contact Information

The following contact information is provided for those times when you cannot contact

your local representative:

Mailing Address 1631 Bently Parkway South

Minden, Nevada USA 89423

USA

Telephone 1.775.782.3611

1.800.227.5514

Fax 1.775.215.2873

Internet www.ge-energy.com/bently

iii

Additional Information

Product Disposal Statement

Customers and third parties, who are not member states of the European Union, who are

in control of the product at the end of its life or at the end of its use, are solely

responsible for the proper disposal of the product. No person, firm, corporation,

association or agency that is in control of product shall dispose of it in a manner that is

in violation of any applicable federal, state, local or international law. Bently Nevada LLC

is not responsible for the disposal of the product at the end of its life or at the end of its

use.

Label Symbols

Bently Nevada, LLC has attempted to identify areas of risk created by improper

installation and/or operation of this product. Read all instructions before installing or

operating this product. Pay particular attention to those areas designated by the

following label symbols.

This symbol denotes electrical ground when making power connections

to the device.

This symbol is an indication that high voltages may be present.

1900/55 Fan Monitor Operation Manual

iv

Contents

1. Monitor Overview...........................................................................................1

1.1. Front Panel Description.................................................................................................................. 3

1.2. Rear Panel Description.................................................................................................................... 6

1.3. Display.................................................................................................................................................... 7

2. Installation.......................................................................................................9

2.1 Weatherproof Enclosure Installation .....................................................................................10

2.2 Mounting Frame Installation......................................................................................................12

2.3 Remote Buffered Output Connections ..................................................................................14

2.4 Velomitor Transducer Connections.........................................................................................16

2.5 Relay Connections ..........................................................................................................................18

2.6 Power Connections ........................................................................................................................20

2.7 Powering Up the Monitor.............................................................................................................21

3. Program Mode...............................................................................................23

Relay Settings..............................................................................................................................................23

3.1. Entering PROGRAM Mode............................................................................................................24

3.2. Language............................................................................................................................................24

3.3. Point ID.................................................................................................................................................26

3.4. Setpoints..............................................................................................................................................28

3.5. Relay Settings....................................................................................................................................30

3.6. Danger Relay Bypass.....................................................................................................................33

3.7. Channel Activity ...............................................................................................................................35

3.8. Units ......................................................................................................................................................36

3.9. LCD Scan Time..................................................................................................................................37

3.10. Self-test................................................................................................................................................38

3.11. To exit PROGRAM Mode................................................................................................................39

3.12. Viewing and Recording Programmed Values.....................................................................39

4. Normal Mode.................................................................................................41

4.1. Velocity Display................................................................................................................................41

4.2. Buttons.................................................................................................................................................43

4.3. OK...........................................................................................................................................................44

4.4. Alert .......................................................................................................................................................45

4.5. Danger..................................................................................................................................................46

4.6. Bypass..................................................................................................................................................47

4.7. Connectors and Contacts............................................................................................................47

v

5. Maintenance and Troubleshooting.......................................................... 49

5.1 Calibration Check............................................................................................................................49

5.2 Troubleshooting...............................................................................................................................50

6. Specifications ............................................................................................... 57

6.1 Environmental...................................................................................................................................57

6.2 Electrical ..............................................................................................................................................58

6.3 Relays ...................................................................................................................................................59

6.4 Displays................................................................................................................................................60

6.5 Physical ................................................................................................................................................60

6.6 Ordering Information.....................................................................................................................60

7. Accessories ................................................................................................... 61

7.1 Velomitor CT Transducer .............................................................................................................61

7.1.1 Option Descriptions...................................................................................................................61

7.2 Velomitor Transducer....................................................................................................................62

7.2.1 Option Descriptions...................................................................................................................62

7.3 Velomitor XA Transducer .............................................................................................................62

7.3.1 Option Descriptions...................................................................................................................62

7.4 Weatherproof Enclosure..............................................................................................................63

7.5 Bulk Cable...........................................................................................................................................63

7.6 Conduit and Cable Fittings..........................................................................................................63

7.7 Fuses.....................................................................................................................................................64

7.8 1900/55 Fan Monitor Manual ....................................................................................................64

7.9 Optional 4 to 20 mA Communication Card .........................................................................64

7.10 Optional TM2000 Communication Card ...............................................................................64

Section 1 - Monitor Overview

1

1. Monitor Overview

The 1900/55 Fan Monitor is a four-channel monitor intended for low frequency

vibration monitoring on fan gear boxes. Although the monitor accepts input from

any Velomitor

transducer, the 190501 Velomitor

CT transducer must be used

for low frequency applications. This transducer will give you a response from 1.5

to 1000 Hz 3 dB which will give the needed response for monitoring fan speeds

of 90 RPM or greater.

All programmable options of the monitor can be set through the front panel

controls without using switches or jumpers. The programmable options include

relay time delays, latching or nonlatching relays, de-energized or energized

relays, danger relay bypass, LCD scan time, measurement units, and point ID.

The monitor can be ordered with a communication card or one can be added to

the monitor in the future. A communication card allows the monitor to send

current vibration levels to a plant computer or to some other system. This

vibration information can be trended so that changes in vibration over time can

be analyzed.

Application Alert

The 1900/55 should NOT be used for monitoring Reciprocating

Compressors. For machine protection parameters measured

with Velomitor sensors a sudden mechanical impact can

over-range the sensor output. The monitor is designed with

Timed OK Channel Defeat. When an over-range signal

exceeds the OK Limits the monitor may not annunciate an

alarm. This may result in a missed alarm and temporary loss

of machine protection.

On Reciprocating Compressors mechanical impacts will occur.

The 1900/55 Monitor doesnt have an option to disable Timed

OK Channel Defeat and should not be used for monitoring in

this application.

1900/55 Fan Monitor Operation Manual

2

Section 1 - Monitor Overview

3

1.1. Front Panel Description

This section describes the controls and features on the front panel of the monitor.

Refer to the front panel drawing on the preceding page.

1

LCD Display A 2 line by 16 character dot matrix display to show vibration

information in normal mode and configuration settings in program mode.

2

Status Lights Indicates the status of all four channels.

Light

Meaning

OK

All monitor channels and transducers are operating

correctly

Alert

The alert setpoint of one or more channels has been

exceeded

Danger

The danger setpoint of one or more channels has been

exceeded

Bypass

One or more channel is bypassed. When flashing, the

monitor is in program mode

1900/55 Fan Monitor Operation Manual

4

3

Pushbuttons Used to configure the monitor in program mode and control

the display in normal mode.

Mode Pushbutton

Normal

Program

Menu

Display current configuration

settings in Normal Mode

Menu Display.

Set configuration

settings

Stop/Resume

Stop or resume the scan

function

Not used

Up/Left and

Down/Right

Select a channel for display

Change program

options or with Shift

button move cursor in

Point ID menu

Select

Not used

Select a program

option

Reset/Shift

Reset latched relays and

lights

Not used

4 Mode Switch Change the operating mode to normal or program

5

Buffered Output Access the transducer signal from the front panel for

diagnostic

purposes. This connector is multiplexed so that the channel shown on

the display is available on this connector.

6

Channel Settings A region of the front panel label that can be written on

with a grease pencil or a transparency pen to record the point ID and

setpoints for each channel.

Section 1 - Monitor Overview

5

1

4

2

3

6

5

1900/55 Fan Monitor Operation Manual

6

1.2. Rear Panel Description

This section describes the features on the rear panel of the monitor. Refer to the rear

panel drawing on the preceding page.

1

Relay Terminals Connect cables to the relays and relay bypass terminals.

The

monitor has an OK relay, an Alert relay that is common to all four channels, four

independent Danger relays, and two terminals for relay bypass. Relay bypass is used to

hold the alert and danger relays in their current state.

2

Power Terminals Connect the power source into the monitor.

3

Fuse Holder The monitor is fuse protected with a 250 V 200 mA fuse for 120

VAC power or a 250 V 100 mA fuse for 240 VAC power.

The fuse is accessible through the

side of the monitor by unscrewing the fuse holder cap.

4 Communication The monitor can be used with various communication

card

Card

options. Communication cards allow you to send vibration information to

a plant computer or another computer to trend or analyze vibration data.

5

Transducer Connect the four Velomitor

transducers and the remote

Terminals

reset to the monitor. The remote reset connections allow a

momentary closed switch to be wired to the monitor so that it can be reset from

a remote location without opening the weatherproof enclosure to get to the reset

button.

6 Remote Buffered Connect diagnostic and portable instrumentation to the

Output Terminals

transducer signal.

Section 1 - Monitor Overview

7

1.3. Display

This section describes the regions on the LCD display in normal mode.

(For LCD indicators: = On, = Off, |||| = Flashing.)

1

Channel Number The first 3 characters indicate the channel number.

2

Point ID A 12 character field to identify the transducer location.

3

Vibration The current level of vibration for the channel shown.

4

Units The display can show the vibration in metric or English units.

5

OK Indicators Shows the status for the channel being displayed.

OK Indicator

Meaning

The channel and transducer are operating correctly.

A problem exists with the monitor channel or its transducer wiring.

||||

The channel is now OK, but was previously NOT OK .

1900/55 Fan Monitor Operation Manual

8

6 Alert Indicator Indicates if the channel is in Alert.

Alert Indicator

Meaning

The vibration for this channel has exceeded the alert setpoint.

The vibration for this channel is less than the alert setpoint.

||||

Vibration exceeded the alert setpoint, but is now below it.

7

Danger Indicator Indicates if the channel is in Danger.

Danger Indicator

Meaning

The vibration for this channel has exceeded the danger setpoint.

The vibration for this channel is less than the danger setpoint.

||||

Vibration exceeded the danger setpoint, but is now below it.

8 Bypass Indicator Indicates if the channel is in Bypass.

Bypass Indicator

Meaning

The channel is bypassed.

The channel is operating normally.

The channel is bypassed by the user or because the channel is currently NOT OK.

Bypassing the channel inhibits the relays from changing state if the vibration level

exceeds either setpoint.

Section 2 - Installation

9

2. Installation

The 1900/55 Monitor is designed for easy installation. The terminal strips for the

relays, transducers, and remote buffered outputs are removable to make

connecting the cabling easier. The monitor has many mounting options. It can

be mounted in a JIC standard 14" x 12" Type 4X enclosure, into a panel or

bulkhead, or in its mounting frame outside of a weatherproof enclosure. When

mounted in a weatherproof enclosure, the front panel hinges open to allow

access to the connections and to the communication card slot on the back of the

monitor.

CAUTION

Wiring and servicing must be

performed by qualified

personnel.

Conduit entry

valid on both

sides and

both ends

1900/55 Fan Monitor Operation Manual

10

STEPS 3 & 4

2.1 Weatherproof Enclosure Installation

Bently Nevada offers a JIC standard 14" x 12" (0.39 m x 0.36 m) Type 4X

nonmetallic weatherproof enclosure (part number 190101-01) that has been

designed specifically for the 1900/55 Fan Monitor. This housing is designed to

make the monitor tool-accessable" only. When mounting the monitor outdoors,

a weatherproof enclosure is required. When mounting the monitor indoors, use

this enclosure if you must protect the monitor or limit access to unauthorized

users.

Step 1 Find a suitable location for mounting the weatherproof enclosure.

Step 2 Punch conduit holes in the weatherproof enclosure. Pay particular

attention to where the conduit holes must be located (see figure on preceding

page). Conduit holes in the housing must not exceed the size needed for a

standard 1 inch conduit hub.

Section 2 - Installation

11

Step 3 Mount the enclosure at your chosen location.

Step 4 Install conduit and connect conduit with conduit hubs to the

weatherproof enclosure.

Step 5 Pull all the needed cables for your installation through the conduit into

the housing.

STEP 1

1900/55 Fan Monitor Operation Manual

12

STEP 2

2.2 Mounting Frame Installation

The mounting frame mounts directly in the weatherproof enclosure and its

mounting hole pattern meets the JIC standard footprint for weatherproof

enclosures. The mounting frame allows the front panel of the monitor to hinge

open for easy access to the terminal strips and to the communication card on the

rear panel.

Step 1 Place mounting frame in the weatherproof enclosure and

mount it with four 10-32 screws.

Step 2 Screw front panel of monitor onto mounting frame hinges.

At this time do not screw monitor front panel shut.

Section 2 - Installation

13

STEP 1 STEP 2

STEP 3 STEP 4

1900/55 Fan Monitor Operation Manual

14

2.3 Remote Buffered Output Connections

The remote buffered output terminal strip lets you connect to the analog

transducer signal for each channel. This terminal strip can either be used for

short term connections when doing machinery diagnostics or for permanent

connections with the cable routed to another location. Sending the buffered

outputs to another location may be preferable in instances where access to the

signal is desired but the monitor is mounted in an area that is not easily

accessible.

Step 1 Strip the insulation from the conductors for the remote

buffered output signals.

Step 2 Pull the remote buffered output terminal strip from the

monitor.

Step 3 Connect the wires for the remote buffered output into the

terminal strip. The voltage range at these connections is 0

to 20 volts. The wiring should be specified to handle these

voltages. Also, the total wiring capacitance should not

exceed 0.08 F for each output.

Step 4 Insert the terminal strip in the remote buffered output

connector of the monitor.

STEP 1 STEP 2

Section 2 - Installation

15

STEP 3 STEP 4

1900/55 Fan Monitor Operation Manual

16

2.4 Velomitor Transducer Connections

The Velomitor

transducers connect to the monitor through a removable terminal

strip. For measurements from 1.5 to 1000 Hz 3 dB use a 190501 Velomitor

CT

transducer. For vibration measurements from 4.5 to 3400 Hz 3 dB use the

330500 Velomitor

transducer or the 330525 Velomitor

XA transducer.

Step 1 Strip the outer insulation jacket off the transducer cable.

Pull the shield back and twist into shield conductor or attach

with solder a small length of wire to be used as a shield

conductor. Strip the inner conductor insulation from the

inner conductors.

Step 2 Pull the Velomitor

transducer terminal strip from the

monitor.

Step 3 Connect the wires for the Velomitor

transducers into the

terminal strip as shown in the figure. Connection A refers

to pin A of the transducer. Connection B refers to pin B

of the transducer. Connect the shield conductor to the

shield terminal on the terminal strip. The voltage range at

these connections is 0 to 20 volts. The wiring should be

specified to handle these voltages.

Step 4 Insert the terminal strip in the Velomitor

transducer

connector of the monitor.

Section 2 - Installation

17

2.5 STEP 1 2.5 STEP 2

2.5 STEP 3 2.5 STEP 4

1900/55 Fan Monitor Operation Manual

18

2.5 Relay Connections

The relay terminals let you connect six relays to shutdown circuitry or to alarm

annunciators such as a light. The six relays consist of an OK relay, a single alert

relay that is common to all four channels, and four independent danger relays for

each channel. Each relay has normally open and normally closed contacts, and

they can each be configured as latching or nonlatching relays. All the relays,

except the OK relay, can be configured as normally de-energized or normally

energized (see the table below for information on relay behavior for normally

energized and de-energized relays). The OK relay is always normally energized so

that a loss of power will cause the relay to change states to indicate a loss of

protection. Refer to the Program Mode chapter for more information on

configuring the relays.

Alarm State

Normally Energized

Normally De-energized

No Power

(shelf state)

With Power

No alarm

With Power

In alarm

The relays must be used in an application for which they were designed. The load

connected to the relays must not exceed the following specifications.

Minimum contact load: 100 mA at 12 Vac or 12 Vdc

Maximum contact load: 8 A 300 Vac or 28 Vdc 224 W or 2000 VA

Section 2 - Installation

19

CAUTION

When the BASEEFA option is ordered the

relays are limited to 5 A and 30 VAC or 30

VDC.

The relay terminal strip also has connections for relay bypass on terminals 1 and

2. Use this terminal strip to connect a switch across terminals 1 and 2 so that a

relay bypass signal can be sent to the monitor. This switch will inhibit relay

operation as long as it is held closed. Common uses for relay bypass are:

to inhibit the relays when the machinery being monitored has high vibration, or

when speed changes last longer than the maximum relay time delay of 15

seconds.

to inhibit the relays while the vibration data is trended in order to

determine correct alert and danger setpoint values for each channel.

to keep the monitors relays from going into their alarm states while the

machine is maintained or tested.

Step 1 Strip the insulation from the conductors in the relay cable.

Step 2 Pull relay terminal strip from the monitor.

Step 3 Connect the wires from the relay cable into the terminal strip. The

wiring should be specified to handle the above mentioned voltages.

Step 4 Replace the terminal strip in the relay connector of the monitor.

1900/55 Fan Monitor Operation Manual

20

2.6 Power Connections

The 1900/55 Fan Monitor can be powered by either 120 Vac or 240 Vac,

depending on which option was ordered.

CAUTION

Damage to the monitor may result

if incorrect power

is applied.

Section 2 - Installation

21

Step 1 Strip the insulation from the conductors in the power cable.

Step 2 Crimp ring or spade lugs on the power cable.

Step 3 Attach the power cable to the power terminal strip on the monitor.

The power cable used must be specified to handle the voltage levels.

An external 20 amp circuit breaker which conforms to local electrical codes is

recommended when connecting power to the monitor.

2.7 Powering Up the Monitor

Route the cables so that they are out of the way of the monitor and will not get

pinched or cut when the monitor closes. Leave enough slack in the cables so that

the monitor can be opened. Screw the monitor closed. Turn the power source to

the monitor on. The monitor should complete its power up self-test, the OK light

will flash, if the OK relay is configured as nonlatching, and all four channels should

be on. If any channels transducer was not connected, then the OK light will be off

until that channel is turned off. See the configuration chapter for information on

configuring each channel. Press the Reset button to stop the OK light from

flashing.

Section 3 - Program Mode

23

3. Program Mode

The 1900/55 Fan Monitor has two modes of operation: PROGRAM and NORMAL.

This chapter shows how to use the PROGRAM mode to configure the monitor.

The menu in PROGRAM mode is organized to contain primary menus and

secondary menus. The primary menus are:

Language

Point ID

Setpoints

Relay Settings

Danger Relay Bypass

Channel Activity

Units

LCD Scan Time

Self-Test

and possibly additional menus if a communication card is present.

While in NORMAL mode, you may view the programmed values but may not

change them. To enter NORMAL MENU mode (programmed values viewing

mode), press the Menu button on the front panel. To exit NORMAL MENU mode,

press the Stop / Resume button.

The selected value is marked with an asterisk (*) to the left of the value.

1900/55 Fan Monitor Operation Manual

24

3.1. Entering PROGRAM Mode

To enter PROGRAM mode, set the Mode switch to PROGRAM. The programmed

values will be saved when you turn the Mode switch back to NORMAL position.

Application Alert

Do not leave the monitor in PROGRAM mode.

The monitor is NOT protecting your machinery

while in PROGRAM mode.

3.2. Language

This menu lets you program the language that is used in the display. The

following table provides translations so that if the monitor accidentally gets

programmed in a language that you do not understand you can find the

language menu and program it for the desired language.

Options:

English

French

German

Spanish

Section 3 - Program Mode

25

Translation Table:

Language

Used:

English

French

German

Spanish

Language

Langage

Sprache

Lenguaje

English

Anglais

Englisch

Ingles

French

Francais

Franzoesisch

Frances

German

Allemand

Deutsch

Aleman

Term:

Spanish

Espagnol

Spanisch

Espanol

1900/55 Fan Monitor Operation Manual

26

3.3. Point ID

Use Point ID (Point Identification) to identify where the transducer attached to that

particular channel is mounted. It is only a label, therefore, it is not crucial for the

operation of the monitor.

Changes to Point ID are saved automatically whether the Select button is pressed

or not. This is different from other program parameters.

Section 3 - Program Mode

27

1900/55 Fan Monitor Operation Manual

28

3.4. Setpoints

There is an Alert and Danger setpoint for each channel. Each setpoint can be

programmed independently.

Adjust the setpoints within the ranges and at the increments shown in the

following table. Setpoints will be set at the default value if the channel setpoints

are not programmed.

Default Values

Units

Minimum

Maximum

Increment

Alert

Danger

in/s pk

0.10

2.00

0.10

0.50

1.00

in/s rms

0.10

1.50

0.10

0.50

1.00

mm/s pk

2.0

50.0

1.0

12.0

25.0

mm/s rms

2.0

35.0

1.0

12.0

25.0

Since setpoint values have units, choose the correct unit before you program the

setpoints. If you change units after you adjust the setpoints, the monitor

automatically converts the setpoints. After you change units, verify that the

converted setpoints are what you intend them to be.

Section 3 - Program Mode

29

1900/55 Fan Monitor Operation Manual

30

3.5. Relay Settings

The 1900/55 Fan Monitor has 6 relays: OK relay, Alert relay, and a Danger relay for

each channel.

The labels on the monitor are for the factory default of normally de-energized

relays. When configured as normally energized relay, then the normally open

(NO) and normally closed (NC) contacts are reversed.

Alarm State

Normally Energized

Normally De-energized

No Power

No alarm

(shelf state)

With Power

No alarm

With Power

In alarm

The alarm state for each type relay is not OK for the OK relay, Alert for the Alert

relay, and Danger for the Danger relay.

When the relay is configured for latching, the behavior of the relay is as follows: if

the relay goes into alarm and then the alarm condition goes away, the relay will

stay in the alarm state until the Reset button is pressed or the remote Reset

contacts are closed.

Section 3 - Program Mode

31

Relay

Option

Selection

Factory Default

latching OK relay

Latching

nonlatching

nonlatching

energized Normally energized

de-energized

de-energized

latching Latching

nonlatching

latching

Alert relay

Time delay

5 to 15 seconds

5 seconds

energized Normally energized

de-energized

de-energized

latching Latching

nonlatching

latching

Danger relay

Time delay

5 to 15 seconds

5 seconds

1900/55 Fan Monitor Operation Manual

32

Section 3 - Program Mode

33

3.6. Danger Relay Bypass

When the Danger relay is bypassed, and a danger condition exists, the display

and LED indicators will operate normally, but the danger relay will not go into an

alarm state.

Bypassing the danger relay is useful in the following situations:

--when you test or perform maintenance on your machine

--when you trend the vibration of a machine to determine appropriate

levels for the alert and danger setpoints.

The factory default for Danger Relay Bypass is not bypassed.

1900/55 Fan Monitor Operation Manual

34

Section 3 - Program Mode

35

3.7. Channel Activity

Each channel may be programmed ON or OFF. If a channel is programmed off,

the channel is not monitored and does not vote for the OK relay or the alert relay.

The parameters of channels that are turned off can still be programmed. Turn off

any channel that has no transducer attached so that the OK status of the monitor

will be valid for the remaining channels that are in use.

The factory default for channel activity is ON.

1900/55 Fan Monitor Operation Manual

36

3.8. Units

Use the Units menu for displaying velocity values and the setpoints. If you

change the units, check that the setpoints are within the maximum and minimum

values (see Setpoints section above).

Options:

in/s pk

in/s rms

mm/s pk

mm/s rms

The factory default is in/s pk.

Section 3 - Program Mode

37

3.9. LCD Scan Time

LCD Scan Time is used to determine how long each channel is displayed on the

front panel.

Data collection and monitoring continues for all four channels regardless of

which channel is being displayed. The front panel buffered output connector will

have the signal of the channel currently displayed.

Options:

1 to 20 seconds, in 1 second increments.

The factory default is 5 seconds.

1900/55 Fan Monitor Operation Manual

38

3.10. Self-test

Self-Test has 2 secondary menus:

Engage relays during test?

Begin Self Test?

Engage relays determines whether you want the relays to change state while the

self-test is run. If you select Yes, all the relays will be turned on and tested and

then turned off and tested again. The option always starts with No so that

relays will not be engaged during self-test. Only if you change the option to Yes

will the relays be engaged.

The next option is to Begin Self Test. Answering Yes to this option will begin the

self-test function. If you answer No then the self-test will not start and

programming can continue.

To run a Self-Test:

Set the Mode switch to PROGRAM

Press the arrow button until "SELF TEST menu is displayed on the front

panel

Press the Select button to move to the Engage relays secondary menu

and select the option you want. (We recommended that you engage

relays during the test, but ensure that engaging the relays on and off does

not cause a problem.)

Press the Menu button to move to the Begin Self-Test secondary menu,

choose yes, and press the Select button. The self-test will begin.

During self-test, the display will show TEST IN PROGRESS, all lights will be off, and

then all display segments and lights will come on. Any errors found during self-

test will be displayed once the monitor is returned to NORMAL mode. Any errors

that existed prior to performing a self-test will still be in the error list. All errors

should be cleared prior to running a self-test.

Section 3 - Program Mode

39

3.11. To exit PROGRAM Mode

When the Mode switch is set to NORMAL all the changes made in Program mode

will be in effect and vibration monitoring for all active channels will begin.

3.12. Viewing and Recording Programmed Values

While the Mode switch is in NORMAL position, you may view the programmed

values, but you may not change them. To view programmed values press the

Menu button on the front panel.

While viewing programmed values the functional buttons are Menu, Select, and

Stop/Resume. To move from one menu to another, press Menu or Select. To

return to velocity display, press Stop/Resume. Both the arrow buttons and

combination of Shift + Menu are not functional. A program record sheet is

provided to record the programmed options for your records. Copies of the sheet

can be made to record program changes or programs for other units in the plant.

1900/55 Fan Monitor Operation Manual

40

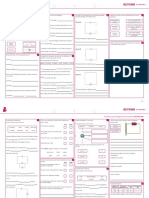

0.10 to 2.00 in/s pk incr.:0.10 in/s

0.10 to 1.50 in/s rms

2.0 to 50.0 mm/s pk incr.:1.0 mm/s

2.0 to 35.0 mm/s rms

(1 to 20 sec incr.:1

sec)

(Zero: -8 to +8)

(Span: -28 to

+28)

(5 to 15 sec incr.:1 sec)

1900/55 Program Record Sheet

Date: ___________________________

Plant location: ___________________________________________________

Part number: 1900/55- ________ - ________ - ________ - ________

Serial number: ________________________________________

Language: ___________________

Point ID: CH1 __________________________

CH2 __________________________

CH3 __________________________

CH4 __________________________

Setpoints: Alert Danger

CH1 _________________ ___________________

CH2 _________________ ___________________

CH3 _________________ ___________________

CH4 _________________ ___________________

Relay Settings:

OK ____ latching (Y/N)

Alert ____ energized (Y/N) ____ latching (Y/N) time delay ______ sec

Danger

CH1 ____ bypass (Y/N) ____ energized (Y/N) ____ latching (Y/N) time delay ______ sec

CH2 ____ bypass (Y/N) ____ energized (Y/N) ____ latching (Y/N) time delay ______ sec

CH3 ____ bypass (Y/N) ____ energized (Y/N) ____ latching (Y/N) time delay ______ sec

CH4 ____ bypass (Y/N) ____ energized (Y/N) ____ latching (Y/N) time delay ______ sec

Channel Activity (On/Off): CH1 _______ Units (check): in/s pk ____ rms ____

CH2 _______ mm/s pk ____ rms ____

CH3 _______

CH4 _______

LCD scan time: _______ sec

4 to 20 mA Comm Card

Date: __________________________

Zero Span Zero Span

Counts: CH1 __________ __________ CH3 __________ __________

CH2 __________ __________ CH4 __________ __________

Section 4 - Normal Mode

41

4. Normal Mode

In NORMAL mode, the 1900/55 Monitor monitors the vibration on all active

channels and displays data using the display, bars, and lights. This chapter

shows how the monitor displays vibration and channel status and explains how

to use the buttons on the front panel to control how this data is displayed. The

chapter also describes how the connectors, relays, and contacts work.

The display shows the vibration level on each of those channels. The display

either scans through the active channels or displays a specific channel. The

display also gives the OK, Alert, Danger and Bypass status for the displayed

channel.

The monitor votes among all active channels and uses the lights to display the

results of the voting. The lights display the status of the overall monitor

regardless of which channel is being displayed.

During NORMAL mode operation the current configuration of the monitor can be

viewed. See Program Mode chapter for viewing programmed values.

The front panel buffered output connection can be used to collect and analyze

transducer signals. The signal on the front panel buffered output is the signal for

the channel shown on the display.

Latched relays and latched / flashing Alert and Danger lights can be reset by

pressing the Reset button or closing the remote Reset contacts.

4.1. Velocity Display

The velocity display shows the following data for a particular channel:

channel number

point ID

vibration level (in the appropriate units)

channel status (OK, alert, danger, bypass)

To program point ID and the units, see Program Mode chapter.

1900/55 Fan Monitor Operation Manual

42

Display Description

Vibration Display

Description

velocity value

The measured value for velocity in the programmed

engineering units.

"channel off"

The channel is inactive. (See Program Mode chapter, Channel

Activity section for information about inactive channels.)

"overrange"

The measured value for velocity exceeds the maximum

velocity value. (See the following table.)

Valid Ranges for Velocity

Valid Velocity Range Units

minimum

maximum

in/s pk

in/s rms

mm/s pk

mm/s rms

0.00

0.00

0.0

0.0

2.00

1.50

50.0

35.0

Normally the Velocity display will scan from one channel to another. To stop at a

particular channel, press Stop / Resume button. To resume scanning, hold down

the Stop / Resume button again until the channel changes. To stop scanning and

step from one channel to another, press the Up Arrow / Down Arrow buttons. The

scan time is controlled by LCD Scan Time (see Program Mode chapter)

Section 4 - Normal Mode

43

4.2. Buttons

The following table lists the functions of the 6 buttons on the front panel.

Display Mode Button

Velocity Display

Error Display

Normal Menu Mode

Menu

Enter Normal Menu

mode (to view

programmed values)

or Error Display (to

view stored errors).

Move to the next

stored error.

Move from one primary

menu to another or

from one secondary

menu to another.

Stop/Resume

Stop scanning if the

monitor is scanning.

Resume scanning if

the monitor is not

scanning.

Return to Velocity

Display without erasing

errors.

Return to Velocity

display.

Up Arrow

Stop scanning and

move up one channel.

NOT USED

NOT USED

Down Arrow

Stop scanning and

move down one

channel.

NOT USED

NOT USED

Select

NOT USED

NOT USED

Display a secondary

menu.

Reset

Reset latched /

flashing alarms for the

channels, lights and

relays.

Reset latched / flashing

alarms for the

channels, lights and

relays.

Reset latched / flashing

alarms for the

channels, lights and

relays.

To resume scanning channels, press and hold the Stop/Resume button until the

channel display changes.

For menu structure, see Program Mode chapter.

To clear stored errors, see Maintenance and Troubleshooting chapter.

1900/55 Fan Monitor Operation Manual

44

4.3. OK

OK is displayed using three indicators: bars, light, and relay. The following table

shows how these indicators display the OK status.

OK Relay

Setting

OK Bar in

Display

OK

Light

OK

Relay

Explanation

latching or

nonlatching

at least one

channel's OK

bar is off.

off

alarm

state

the channel with the OK bar off is

not OK. Check the transducer

installation.

latching

off

alarm

state

nonlatching

at least one

channel's OK

bar is flashing.

flashing

nonalar

m state

a flashing OK bar means that the

channel has gone not OK since

the last reset, but is OK now. To

reset flashing bars / lights or

latched lights / relays, press the

Reset button or short the

remote Reset contacts.

latching or

nonlatching

all OK bars are

on.

on

nonalar

m state

all channels are OK.

NOTE

When a channel goes not OK, it takes 15

seconds after the channel goes back to

OK for the OK bar, OK light, and OK relay

to come back on.

If the OK relay is configured as latching and the channel goes not OK,

the OK light and OK relay stay in its not OK state until the Reset button is

pressed or the remote Reset contacts are closed and the not OK condition has

cleared.

when the bypass light is on alarming for that channel(s) is disabled

if the NOT OK channel(s) returns OK for a full 15 seconds the bypass light will go

off and alarming will be enabled. Resetting will unlatch the OK relay and the OK

light will come back on.

Section 4 - Normal Mode

45

4.4. Alert

Alert is displayed using three indicators: bars, light, and relay. The following table

shows how these indicators display the alert status.

Alarm

Setting

Alert Bar in

Display

Light

Relay

Explanation

latching or

nonlatching

at least one of

the alert bars is

on.

on

alarm

state

the channel with the alert bar on

is in alert.

latching

on

alarm

state

nonlatching

at least one of

the alert bars is

flashing.

flashing

nonalar

m state

flashing bar means that the

channel has gone into alert since

the last reset, but is not in alert

now. To reset flashing bars /

lights, or latched lights / relays

press the Reset button or short

the remote Reset contacts.

latching or

nonlatching

all alert bars are

off.

off

nonalar

m state

all channels are not in alert.

1900/55 Fan Monitor Operation Manual

46

4.5. Danger

Danger is displayed by using three indicators: bars, light, and relays. There are

four danger relays, one for each channel. The following table shows how these

indicators display the danger status.

Alarm

Setting

Danger Bar in

Display

Light

Relay

Explanation

latching or

nonlatching

at least one of

the danger bars

is on.

on

alarm

state

the channel with the danger bar

on is in danger.

latching

at least one of

the danger bars

is on

on

alarm

state

When the relay is configured for

latching, the bar, light, and relay

do not flash. To reset latched

lights / relays press the Reset

button or short the remote Reset

contacts.

nonlatching

at least one of

the danger bars

is flashing.

flashing

nonalar

m state

flashing bar means that the

channel has gone into danger

since the last reset, but is not in

danger now. To reset flashing

bars / lights, or latched lights /

relays press the Reset button or

short the remote Reset contacts.

latching or

nonlatching

all danger bars

are off.

off

nonalar

m state

all channels are not in danger.

NOTE

If Danger Relay Bypass is configured as

on for a particular channel, the danger

light may come on but the danger relay

will not go into alarm state.

Section 4 - Normal Mode

47

4.6. Bypass

Bypass light comes on when:

At least one of the channels is configured for Danger Relay Bypass (see

Program Mode chapter, Danger Relay Bypass section).

At least one of the channels is not OK (therefore that channel is

bypassed).

The Relay Bypass contacts are shorted.

A self-test is in progress.

Bypass light is flashing when:

The monitor is in PROGRAM mode.

4.7. Connectors and Contacts

Buffered Outputs:

The BNC connector on the front panel provides the buffered signal of the transducer of

the displayed channel.

The remote buffered output connector on the back of the monitor provides continuous

buffered outputs for all four channels.

Relay Bypass Contacts:

When the Relay Bypass contacts are shorted, alert and danger relays will go to their non-

alarm states. All channels will go not OK and the OK relay will go to its not OK state.

Remote Reset Contacts:

When the Remote Reset contacts are shorted, latched and flashing lights and

relays will be reset if the alarm condition is no longer present. This contact has

the same effect as pressing the Reset button on the front panel.

Section 5 - Maintenance and Troubleshooting

49

5. Maintenance and Troubleshooting

Although the 1900/55 Fan Monitor is a low maintenance instrument, we

recommend that you inspect the monitor every three to six months to verify that

the monitor is in good working order. Inspect the following items:

The monitor is powered up, the OK light is on and the display has a valid vibration

reading.

The electrical connections to the monitor are in good condition and have no

corrosion or loose wires.

The weatherproof enclosure is still properly sealed and does not contain any

moisture.

If the monitor is mounted in a weatherproof housing it should not require any

cleaning. However, if the monitor or weatherproof housing is in need of cleaning,

a damp cloth or mild detergent can be used. Do not use solvents or abrasive

cleaners on the monitor or weatherproof housing.

CAUTION

Wiring and servicing must be

performed by qualified personnel.

5.1 Calibration Check

Connect function generator, multimeter, 4000 ohm resistor, and 10 UF capacitor

as shown below for the channel of interest at the Velomitor

transducer input

connections. Adjust function generator sinewave to 63.66 Hz with 0 Vdc offset.

Convert the input voltages below to rms units before using the voltmeter to set

the function generator signal amplitude. The corresponding channel display will

indicate the velocity. If the display is incorrect, check the troubleshooting section

that follows for further assistance.

1 in/sec peak = 200 mV pk-pk

1 mm/sec peak = 7.874 mV pk-pk

1 in/sec rms = 282.8 mV pk-pk

1 mm/sec rms = 11.13 mV pk-pk

1900/55 Fan Monitor Operation Manual

50

5.2 Troubleshooting

The purpose of this section is to help you identify potential problems with your setup.

This section is not intended to instruct you on repairing the monitor. If after using the

troubleshooting guide you feel that the monitor is not operating properly then you should

contact your local Bently Nevada representative.

Application Alert

Do not leave the monitor in PROGRAM mode.

The monitor is NOT protecting your machinery

while in PROGRAM mode.

Consider the above application alert before proceeding on to the troubleshooting

table below.

Section 5 - Maintenance and Troubleshooting

51

Problem

Possible Solution

Monitor does not power

up.

Verify that the power to the monitor is on and meets the

monitor specifications (see Specification appendix).

Check the fuse in the monitor. The fuse is located near the

power terminal strip. The monitor's back cover does not need

to be removed in order to gain access to the fuse. Replace

with part number 01700067 or 01700068 depending on the

power option.

The monitor is on but

the OK light does not

turn on.

The monitor will not turn on the OK light until 15 seconds after

it has completed its self-test and all active channels are OK.

Turn off all channels that are not used (see Program Mode

chapter).

If the OK relay is configured as latching the OK light will not

turn on until the Reset button is pressed.

The OK light will not turn on if the display shows any channel

to be NOT OK. Check the transducer and cabling on those

channels that say NOT OK for proper connection (see

Installation chapter or transducer manual).

OK light is flashing.

If the OK relay is configured as nonlatching the monitor will

flash the OK light anytime it is powered down and then

restarted. Pressing the Reset button will stop the flashing.

When a channel goes NOT OK and then returns to OK status

the OK light will flash. The display will indicate which channel

this occurred on by flashing the OK bar for that channel.

Check the transducer and cable on that channel (see

Installation chapter or transducer manual). Pressing the Reset

button will stop the flashing.

Bypass light is flashing.

The monitor is in PROGRAM mode. Return the monitor to

NORMAL mode (see PROGRAM mode chapter).

Cannot change

programmed values.

Not in PROGRAM mode. Move the Mode switch to PROGRAM

position.

ROM Error

RAM Error

These are non-recoverable errors. The monitor is not

providing machine protection. Contact your local Bently

Nevada representative.

1900/55 Fan Monitor Operation Manual

52

Problem

Possible Solution

EEPROM Error

CONFIG Register

Error

EEPROM Setpoint

Error

EEPROM Relay

Setting Error

EEPROM Dgr Relay

Bypass Error

EEPROM Channel

Activity Error

EEPROM Units

Error

The monitor has detected an error in the configuration stored

in the EEPROM.

Go into program mode (see PROGRAM MODE chapter) and

confirm that all configurations are correct. Correct as needed.

Return to normal mode and clear the error (see the procedure

at the end of this section). If the error returns after clearing it

contact your local Bently Nevada representative.

V+ Error

V- Error

Vxdcr Error

The monitor has detected an error with one of its supply

voltages.

If the error is flashing alternately with the channel display then

the monitor has detected an error in the past but is no longer

present. Check to see that the line voltage to the monitor is

within monitor specifications (see Specifications appendix).

Line voltage fluctuations outside the monitor specifications will

cause this problem. Clear the errors (see the procedure at the

end of this section). If the error reappears contact your local

Bently Nevada representative.

If the error flashes continuously and is the only thing on the

display then the error is currently present. The OK light will be

off and the BYPASS light will be on. The monitor is not

providing machine protection. Check to see that the line

voltage to the monitor is within monitor specifications (see

Specifications appendix). If the line voltage meets the monitor

specifications then contact your local Bently Nevada

Section 5 - Maintenance and Troubleshooting

53

Problem

Possible Solution

representative. If the line voltage does not meet the monitor

specifications then the monitor will not work.

Alert Relay

Failed

OK Relay

Failed

SPI Error

A/D Error

The monitor has detected an internal error.

You need to clear the error (see the procedure at the end of

this section). Run self-test (see Program Mode chapter). If the

error reappears after clearing it contact your local Bently

Nevada representative.

If the error does not reappear after clearing it then run self-

test (see Program Mode chapter). When the error involves a

relay you must answer "yes" to "Engage relays during test?".

Application Alert

If you answer yes to "Engage relays during test?"

question, all relays will open and close. Ensure

that this will not cause problems to your machine.

If after running self-test the error reappears contact your local

Bently Nevada representative. The monitor has to be returned

to normal mode in order to view errors.

1900/55 Fan Monitor Operation Manual

54

Problem

Possible Solution

Danger 1 Relay

Failed

Danger 2 Relay

Failed

Danger 3 Relay

Failed

Danger 4 Relay

Failed

The monitor has detected a problem with one or more of

the danger relays.

You need to clear the error (see the procedure below) and

run self-test (see Program Mode chapter).

If the error reappears after clearing it contact your local

Bently Nevada representative.

If the error does not reappear after clearing it then run

self-test (see Program Mode chapter). To test the relays

you must answer "yes" to engage relays during test

question.

Application Alert

If you answer yes to "Engage relays during test?" question,

Ch 1 Span Adjust

Error

Ch 2 Span Adjust

Error

Ch 3 Span Adjust

Error

Ch 4 Span Adjust

Error

The monitor encountered a problem while trying to span adjust

during its self-test.

The monitor will not be able to protect any machine connected to a

channel that has encountered this error, even if the error has been

cleared.

You must clear the error and run self-test again (see Program Mode

chapter). Do not clear the error unless you are prepared to run self-

test. If you are not prepared to run self-test contact your local Bently

Nevada representative.

Clear the error (see the procedure below this table). Run self-test

(see Program Mode chapter). If after running the self-test the error

reappears contact your local Bently Nevada representative.

Ch 1: WARNING

High Span Adjust

Ch 2: WARNING

High Span Adjust

Ch 3: WARNING

High Span Adjust

The monitor encountered a problem while trying

to span adjust during its self-test.

The monitor is still able to provide protection if this error is

encountered but it is highly recommended that self-test be run

again. Clear the error (see the procedure below this table).

Next run self-test (see Program Mode chapter). If after running

self-test the error reappears contact your local Bently Nevada

representative.

Section 5 - Maintenance and Troubleshooting

55

Clearing Stored Error Codes

1. Start viewing the error list by pressing the Menu button.

2. Continue pressing the Menu button to display each error, until the display reads

"End Error List".

3. Press and hold the Shift button and then press the Select button until the

display reads "LANGUAGE".

4. Press the Resume button to return to a normal vibration display.

Replacing the Fuse

The back cover of the monitor does not need to be removed to replace the fuse.

Replace with part number 01700067 for 240 VAC power supply voltage or

01700068 for 120 VAC power supply voltage.

Section 6 - Specifications

57

6. Specifications

Parameters are specified at 25 C (77F) unless otherwise indicated.

Application Alert

Operation outside the specified

limits will result in false readings

or loss of machine monitoring.

6.1 Environmental

Operating Temperature: -20 to 70 C (-4 to 158 F)

Storage Temperature: -30 to 90 C (-22 to 194 F)

Maximum Relative Humidity: 95 % noncondensing

ESD: EN61000-4-2, Level 4 (8 / 15 kV), criteria B

RFI: EN55022, Radiated Emissions, Class A

EN55022, Conducted Emissions, Class A

ENV50140, Radiated Immunity, Level 3 (10 V/m), criteria A

ENV50141, Conducted Immunity, Level 3 (10 V), criteria A

EMI: EN61000-4-4, EFT, Level 3 (2 / 1 kV), criteria B

EN61000-4-5, Surge Immunity, Level 2 (1 / 0.5 kV), criteria B

EN61000-4-8, Power Frequency, Level 4 (30 A), criteria A

Shock: The monitor will withstand a 3-foot drop to a vinyl covered concrete floor.

1900/55 Fan Monitor Operation Manual

58

6.2 Electrical

120 V Option

Voltage: 90 to 125 Vac

Current: < 0.20 A

Frequency: 50 to 63 Hz

240 V Option

Voltage: 180 to 250 Vac

Current: < 0.10 A

Frequency: 50 to 63 Hz

Input

Transducer input: 3.94 mV/(mm/s) pk (100 mV/(in/s) pk) with a 12

Vdc bias

Frequency response

Monitor: 1 to 3000 Hz (-3 dB)

Monitor with Velomitor CT: 1.5 to 1000 Hz (-3 dB)

Impedance: 1 M in parallel with 3300 pF

Maximum input velocity: 50 mm/s pk, 35 mm/s rms,

2 in/s pk, 1.5 in/s rms

Accuracy

Monitor: 5 % + 5 counts at 100 Hz

Monitor with Velomitor CT: 10 % + 5 counts at 100 Hz

Relay Bypass: A short between Relay Bypass pins A and B

will keep alert and danger relays from changing states.

Remote Reset: A short between Remote Reset pins A

and B will clear a "Not OK" , an "Alert" or a "Danger" condition that is no longer

present.

Section 6 - Specifications

59

Buffered output

One dedicated output for each channel on terminal strip and one multiplexed

output on front panel (BNC connector).

Frequency response

Monitor: 0.17 to 5300 Hz (-3 dB)

Monitor with Velomitor CT: 1.5 to 1000 Hz (-3 dB)

Output scale factor: 19.7 mV/(mm/s) (3.94 mV/(mm/s) input),

500 mV/(in/s) (100 mV/(in/s) input)

Maximum velocity: 203 mm/s pk (8 in/s pk)

Output impedance: 300

Phase: 0 at 100 Hz

Maximum capacitive load: 0.08 F

Transducer Power

Current sources: 3.43 mA dc 0.1 mA (to power transducers)

6.3 Relays

Type: 1 form C SPDT

Case: Epoxy sealed

Contact Ratings

Maximum power: 224 W or 2000 VA

Maximum current: 8 A

5 A (BASEEFA option)

Maximum voltage: 28 Vdc or 300 Vac

30 Vdc or 30 Vac (BASEEFA option)

Minimum load: 12 V, 100 mA

Dielectric Strength (at sea level): 4000 V rms contact to coil

Life Expectancy (minimum)

Mechanical: 10 million operations

Electrical: 10

5

operations at rated load

Insulation Resistance: 1000 M minimum at 20C, 500 Vdc,

50 % relative humidity

1900/55 Fan Monitor Operation Manual

60

6.4 Displays

Liquid Crystal Display: 2 lines by 16 characters

Indicators

OK: Green light on indicates an OK condition.

Alert: Yellow light on indicates a vibration level higher than the alert

setpoint.

Danger: Red light on indicates a vibration level higher than the danger

setpoint.

Bypass: Red light on indicates a channel is bypassed.

6.5 Physical

Height: 337 mm (13.25 in)

Width: 295 mm (11.62 in)

Depth: 130 mm (5.13 in)

Weight: 3.18 kg (7 lbs)

6.6 Ordering Information

A B C D

1900/55-X-X-X-X

Option Descriptions

A - XX Power Supply Option D - XX Hazardous area

approvals

0 1 120 Vac Power Supply 0 0 No approvals

0 2 240 Vac Power Supply 0 1 CSA NRTL/C Approvals

0 2 BASEEFA Zone 2 Approvals

B - XX Communication Option

0 0 No communication

0 1 4 to 20 mA output

0 2 TM2000 Communication Card

C - XX Language Option

0 1 English

0 2 French

0 3 German

0 4 Spanish

Section 7 - Accessories

61

7. Accessories

The following list of items may be used with the 1900/55 Fan Monitor. For

transducer accessories, refer to the particular transducer's data sheet and

manual.

7.1 Velomitor CT Transducer

System Frequency Response using a Velomitor CT Transducer:

3.0 Hz to 900 Hz 1 dB

1.5 Hz to 1.0 kHz 3 dB

7.1.1 Option Descriptions

A B C

190501- XX XX - XX

A X X Mounting Hardware Option

0 0 No Stud

0 1 Stud 3/8-24 to 3/8-24

0 2 Stud 3/8-24 to 1/2-20

0 3 Adhesive Stud 3/8-24

0 4 Stud M6x1 with 3/8-24 Adapter

0 5 Adhesive Stud M6x1 with 3/8-24 Adapter

0 6 Stud 3/8-24 to 1/4-28

0 7 Plate Stud 3/8-24 to 3/8-24

0 8 Plate Stud 3/8-24 to 1/2-20

0 9 Plate Stud 3/8-24 to 1/4 NPT

1 0 Plate Stud M6x1 to M6x1 with 3/8-24 Adapter

1 1 Plate Stud 3/8-24 to 1/4-28

1 2 Plate Stud 3/8-24 to M8x1

1 3 Quick Disconnect Stud

* Contact your Bently Nevada representative for additional mounting options.

B X X Integral Cable Option

1 0 10 Meters

C X X Agency Approvals

0 0 No Approvals

0 1 CSA NRTL/C Approvals

0 2 LCIE

0 3 BASEEFA ZONE 2

125389-01 Velomitor CT Operation Manual

1900/55 Fan Monitor Operation Manual

62

7.2 Velomitor Transducer

System Frequency Response using a Velomitor Transducer:

4.5 Hz to 3.4 kHz 3 dB

A B

330500- XX - XX

7.2.1 Option Descriptions

A X X Mounting Thread Adapter Option

0 1 1/2-20 UNF

0 2 M8 X 1

0 3 1/4-28 UNF

0 4 1/4-20 UNC

0 5 1/4-18 NPT

If a housing is required, the Mounting Thread Adapter Option -01 for 1/2-20 UNF threads

is used with our 21128 Velocity Transducer Housing.

B X X Agency Approval Option

0 0 Not required

0 1 CSA NRTL/C

0 2 SIRA

100076-01 Velomitor Manual

7.3 Velomitor XA Transducer

System Frequency Response using a Velomitor XA Transducer:

4.5 Hz to 3.4 kHz 3 dB

A

330525- X X

7.3.1 Option Descriptions

A X X Approvals

0 0 None required

0 1 CSA NRTL/C

0 2 CENELEC Approval

107316-01 Velomitor XA Manual

Section 7 - Accessories

63

7.4 Weatherproof Enclosure

190101-01 Monitor Type 4X housing.

This housing is used when the monitor is mounted locally on the fan deck,

or when mounted in other outdoor locations.

106769 Junction Box / Terminal Housing.

This housing is for terminating transducer signal cable outside the fan

stack. This junction box is provided with terminal strips and optional

fittings.

7.5 Bulk Cable

02173006 Bulk Cable

2 conductor twisted, shielded 18 AWG (1.0 mm) cable without connectors or

terminal lugs. Specify number of feet.

7.6 Conduit and Cable Fittings

Based on installation requirements, conduit and cable fittings are available to

order for use with a weatherproof enclosure.

Sealtite Flexible Conduit

A

14847- X X 1/2 inch conduit assembly

14848- X X 3/4 inch conduit assembly

Option Description

A X X Conduit length option in feet

Order in increments of 1.0 foot (0.3 meters)

Minimum Length: 1 foot (0.3 meters)

Maximum Length: 99 feet (30 meters)

Fittings

03813103 3/4 inch NPT chrome plated zinc conduit hub fitting

03813106 1-1/4 inch NPT chrome plated zinc conduit hub fitting

26650-01 3/4 inch to 1/2 inch NPT reducer

26650-03 1-1/4 inch to 1 inch NPT reducer

03839240 1/4 inch NPT cable seal; 0.200 to 0.265 inch diameter (5.0 to 6.7 mm) for

use in sealing transducer cable entry to weatherproof enclosure. One

required per each cable entry to housing.

1900/55 Fan Monitor Operation Manual

64

7.7 Fuses

The fuse is used on the 1900/55 Fan Monitor to protect the electronics from

damage due to large voltages or currents appearing on the power supply input of

the monitor. The fuse required by the monitor is dependent on the type of power

supply.

01700068 200 mA fuse for 120 VAC supply

01700067 100 mA fuse for 240 VAC supply

7.8 1900/55 Fan Monitor Manual

Spare manuals may be useful to allow other engineers or technicians involved in

the installation, operation or maintenance of the 1900/55 Fan Monitor to have

their own copy.

190155-01 1900/55 Fan Monitor Manual

7.9 Optional 4 to 20 mA Communication Card

A

190201- X X

Option Descriptions

A X X Language Option

0 1 English

0 2 French

0 3 German

0 4 Spanish

If no communication card is desired, a blank cover is available.

129454-01 1900/55 blank communication card cover

7.10 Optional TM2000 Communication Card

A

190202- X X

Option Descriptions

A X X Language Option

0 1 English

0 2 French

0 3 German

0 4 Spanish

If no communication card is desired, a blank cover is available.

129454-01 1900/55 blank communication card cover

Das könnte Ihnen auch gefallen

- Supervisory control and data acquisition Third EditionVon EverandSupervisory control and data acquisition Third EditionNoch keine Bewertungen

- 0076J1 (330500)Dokument47 Seiten0076J1 (330500)susealiNoch keine Bewertungen

- Silver Magflow MetersDokument10 SeitenSilver Magflow Metersgreggles69Noch keine Bewertungen

- Cfgpro01 PDFDokument10 SeitenCfgpro01 PDFSalvador FayssalNoch keine Bewertungen

- Manual en Inglés - AVV701PRO - CompletoDokument59 SeitenManual en Inglés - AVV701PRO - Completojavier perezNoch keine Bewertungen

- 2008CoxPaper - The Benefits of Online DGA Tap Changer MonitoringDokument6 Seiten2008CoxPaper - The Benefits of Online DGA Tap Changer Monitoringlbk50Noch keine Bewertungen

- Gep 974GDokument43 SeitenGep 974GalbrodzNoch keine Bewertungen

- Opal Generator Annunciator - Turbine V1 - Rev CDokument35 SeitenOpal Generator Annunciator - Turbine V1 - Rev CRaj ChavanNoch keine Bewertungen

- Smart Grid Handbook Cybersecurity of SCADA Within SubstationsDokument17 SeitenSmart Grid Handbook Cybersecurity of SCADA Within Substationssehili ammarNoch keine Bewertungen

- CSI 4500 Datasheet PDFDokument16 SeitenCSI 4500 Datasheet PDFwretchNoch keine Bewertungen

- 1KGT210278R0001 Software Package Utilities Rtu500Dokument1 Seite1KGT210278R0001 Software Package Utilities Rtu500Lim NguyenNoch keine Bewertungen

- User'S Manual: Dynamic Signal Analyzer For Vibration Analysis and MonitoringDokument34 SeitenUser'S Manual: Dynamic Signal Analyzer For Vibration Analysis and Monitoringrodruren01Noch keine Bewertungen

- Stancor OilMinder BrochureDokument2 SeitenStancor OilMinder BrochureusarelaNoch keine Bewertungen

- Alarm Acknowledgment in The RTAC HMI - AG2014-35 - 20200807Dokument12 SeitenAlarm Acknowledgment in The RTAC HMI - AG2014-35 - 20200807teodorojrNoch keine Bewertungen

- Atv312 Installation Manual en Bbv46391 01Dokument32 SeitenAtv312 Installation Manual en Bbv46391 01Nikola LordanNoch keine Bewertungen

- 150 Um011 - en PDokument306 Seiten150 Um011 - en PaldocristianNoch keine Bewertungen

- 02 The Wind Turbine-0001Dokument16 Seiten02 The Wind Turbine-0001vodasanket100% (1)

- Siemens Modbus and Ion TechnologyDokument21 SeitenSiemens Modbus and Ion TechnologyGabriel SilvaNoch keine Bewertungen

- Man VLF Sinus 51 Eng 2Dokument33 SeitenMan VLF Sinus 51 Eng 2Lê Nguyên TríNoch keine Bewertungen

- Service Failure Analysis of D C Motor Co PDFDokument6 SeitenService Failure Analysis of D C Motor Co PDFOmar QatawnehNoch keine Bewertungen

- 3500 44 Aeroderivative Monitor 129774 01 Rev D PDFDokument87 Seiten3500 44 Aeroderivative Monitor 129774 01 Rev D PDFlancasaNoch keine Bewertungen

- Fast Fault Detection For Power Distribution SystemsDokument118 SeitenFast Fault Detection For Power Distribution SystemsBurak SurekNoch keine Bewertungen

- Alpha PlusTM42 2182CDokument172 SeitenAlpha PlusTM42 2182CVictor Hugo PerezNoch keine Bewertungen

- Heavy Duty Rectifier Broschuere Chlor 020 FINALDokument6 SeitenHeavy Duty Rectifier Broschuere Chlor 020 FINALdwijanuarpribadiNoch keine Bewertungen

- Liquid Level Controller - Water Level Controller - Level Controller - GIC IndiaDokument5 SeitenLiquid Level Controller - Water Level Controller - Level Controller - GIC IndiaPrasadPurohitNoch keine Bewertungen

- Insulation Monitoring Relays (Vigilohm) - BrochureDokument8 SeitenInsulation Monitoring Relays (Vigilohm) - BrochureNuengruthai WeerawattanaNoch keine Bewertungen

- Key Aspects in Developing A Wind Power ProjectDokument6 SeitenKey Aspects in Developing A Wind Power ProjectrafathhereNoch keine Bewertungen

- Manual Simocode Pro pcs7 Library v83 en-USDokument258 SeitenManual Simocode Pro pcs7 Library v83 en-USValentin ZheliazkovNoch keine Bewertungen

- Configuring ABTCP DAServer To Communicate With AB PLC5 Using SuiteLink ProtocolDokument8 SeitenConfiguring ABTCP DAServer To Communicate With AB PLC5 Using SuiteLink ProtocolPratish MalviyaNoch keine Bewertungen

- Current Carying Capacity of CopperDokument2 SeitenCurrent Carying Capacity of Coppereng_hosNoch keine Bewertungen

- EIT Instrumentation Automation Process Control BrochureDokument3 SeitenEIT Instrumentation Automation Process Control BrochureMuhammad ImranNoch keine Bewertungen

- Ultratev Plus Operating Manual: Product Code: Utp2Dokument86 SeitenUltratev Plus Operating Manual: Product Code: Utp2Hiếu Phan ThànhNoch keine Bewertungen

- Substation AutomationDokument12 SeitenSubstation AutomationSujan DebnathNoch keine Bewertungen

- Drive ExecutiveDokument4 SeitenDrive ExecutiveAlejandro HernandezNoch keine Bewertungen

- Manual Fuente AlimentacionDokument63 SeitenManual Fuente AlimentacionautofacilNoch keine Bewertungen

- GW Type 7 Controller ManualDokument53 SeitenGW Type 7 Controller Manualstudent_ujjwol3163100% (1)

- Principles and Applications of Variable Frequency DrivesDokument33 SeitenPrinciples and Applications of Variable Frequency Drivesqwerty_conanNoch keine Bewertungen

- Design and Construction of A Microcontroller Based Single-Phased Automatic ChangeoverDokument39 SeitenDesign and Construction of A Microcontroller Based Single-Phased Automatic ChangeoverMitesh GandhiNoch keine Bewertungen

- SIM7022 Series - Low Power Mode - Application Note - V1.01Dokument16 SeitenSIM7022 Series - Low Power Mode - Application Note - V1.01Spider hate bugsNoch keine Bewertungen

- Translation of Original Operating InstructionsDokument29 SeitenTranslation of Original Operating InstructionsAhmed HeikalNoch keine Bewertungen

- Corona ProbeDokument2 SeitenCorona ProbeLuis MendozaNoch keine Bewertungen

- ATV312 Installation Manual 090306Dokument33 SeitenATV312 Installation Manual 090306Marcela ElenaNoch keine Bewertungen

- Moxa Product Selection GuideDokument87 SeitenMoxa Product Selection GuidemigrozzNoch keine Bewertungen

- Complex Short Circuit MVA Method For Power PDFDokument4 SeitenComplex Short Circuit MVA Method For Power PDFluisNoch keine Bewertungen

- 3BDD015188 en G Freelance DCS Product CatalogDokument164 Seiten3BDD015188 en G Freelance DCS Product Catalogckati100% (1)

- TM ViewDokument25 SeitenTM ViewOscar Felipe C.Noch keine Bewertungen

- Inverter Duty MotorDokument6 SeitenInverter Duty Motorseshubabu_999Noch keine Bewertungen

- Leine Linde Rotary EncodersDokument16 SeitenLeine Linde Rotary EncodersDeepak JainNoch keine Bewertungen

- Rect Um 0618 en Rv003phDokument80 SeitenRect Um 0618 en Rv003phnikhom_dk1565Noch keine Bewertungen

- Nes 5100Dokument114 SeitenNes 5100QuangNoch keine Bewertungen

- 9.-Soluciones Industriales para El Oil& GasDokument22 Seiten9.-Soluciones Industriales para El Oil& GasBertín Cruz LópezNoch keine Bewertungen

- Role of SCADA in Hydro Power PlantDokument6 SeitenRole of SCADA in Hydro Power PlantIndin HasanNoch keine Bewertungen

- Descriptive Bulletin 242-32Dokument25 SeitenDescriptive Bulletin 242-32mashan98Noch keine Bewertungen

- Coherent Wireless Power Charging and Data Transfer for Electric VehiclesVon EverandCoherent Wireless Power Charging and Data Transfer for Electric VehiclesNoch keine Bewertungen

- Advanced Metering Infrastructure (AMI) Third EditionVon EverandAdvanced Metering Infrastructure (AMI) Third EditionNoch keine Bewertungen

- 109T7219 - E - Network Topology PDFDokument12 Seiten109T7219 - E - Network Topology PDFnabil160874Noch keine Bewertungen

- 109T7219 - E - Network Topology PDFDokument12 Seiten109T7219 - E - Network Topology PDFnabil160874100% (1)

- Customer Course CatalogDokument102 SeitenCustomer Course Catalognabil160874Noch keine Bewertungen

- AbreviationDokument2 SeitenAbreviationnabil160874Noch keine Bewertungen