Beruflich Dokumente

Kultur Dokumente

Viorel Badescu 2

Hochgeladen von

Asmaa RamadanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Viorel Badescu 2

Hochgeladen von

Asmaa RamadanCopyright:

Verfügbare Formate

Optimal control of solar

energy systems

Viorel Badescu

Candida Oancea Institute

Polytechnic University of Bucharest

Contents

1. Optimal operation - systems with water

storage tanks

2. Sizing solar collectors

3. Optimal operation - maximum exergy

extraction

4. Sizing solar collection area

5. Conclusions

2. Sizing solar collectors

The optimum fin geometry in flat-plate solar

collector systems.

The width and thickness of fins is optimized

by minimizing the cost per unit useful heat flux.

The proposed procedure allows computation of

the necessary collection surface area.

A rather involved but still simple flat-plate solar

collector model is used

V Badescu, Optimum fin geometry in flat plate solar collector systems,

Energy Conversion and Management, 47 (2006) 2397-2413

Preliminaries

The main objective:

reduce the parameters of the design process which are

influenced by the changing cost conditions to the

smaller possible number

Fins with

constant and

variable thickness are studied

Preliminaries

Two different objective functions are considered.

In case of fins with constant thickness

the cost per unit useful heat is minimized

when fins of variable thickness were considered

the material cost per unit fin length was minimized

to find the optimum fin thickness variation.

Subsequently, the cost per unit useful heat allowed

to obtain the optimum fin width.

Preliminaries

Computations are

performed on a hourly

basis

The temperature is

interpolated linearly

between neighboring

measured data

Uniform fin thickness

standard Hottel-Whillier-Bliss Eq.

the time averaged useful heat flux provided

per unit collection area:

the time averaged solar energy conversion

efficiency

( )

* * * * *

0

* *

"

a fi R L R u

T T F U F G q = q

' ' '

0

T U G q

u

= q

G

T U

G

q

u

' '

'

0

= q q

Uniform fin thickness

Uniform fin thickness

The collector cost per unit length for a single

tube is given by:

the cost per unit useful heat flux is given by

reduced cost parameters are defined by

A new cost function may be defined as

u

Wq

C

J

v

F

v

A

c

c

a

c

c

a

2 1

,

( )

v A F

c d W W c c C o + +

( )

u v

Wq

d W a W a

c

J

J

o + +

=

2 1

'

Optimization

the minimum value of J may be found by

solving the equations

0 / ' / ' = c c = c c o J W J

Results depend on

the meteorological features

of the site,

the solar collector design,

the solar collector economics

(through the reduced cost

parameters

the operation regime

(through the average

temperature difference ).

Among these factors

the average temperature

difference only may be at

users choice.

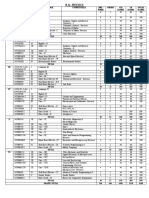

Results

The optimum distance between

tube centers decreases by

increasing the difference of

temperature (Fig. a).

This is reasonable since higher

operating temperatures,

associated to a rather constant

heat transfer rate in the tubes,

require a smaller collection

surface per tube

The optimum fin thickness is

relatively the same,

whatever the operation

temperature and meteorological

factors (Fig. b).

Important result

A remarkable early result states that

for an optimum fin.

In fact, the optimum product

is rather constant, especially at higher

operation temperatures.

2

4 a W = o

o W

Optimized shape of the collection

surface area

Optimized shape of the collection

surface area

Time averaged energy balance for the collection area

the width of the collection surface area is given by

The tube length is

( )

u c i f out f p

q A T T c m =

, ,

m A m

c

/ '

tube tube

m m n / =

W n l

tube

=

l m m l A L

c

/ ' / = =

Results

(a) Width of the

collection surface area

as a function of the

distance x from fluid

inlet and

(b) the distance

necessary to increase

by one degree Celsius

the working fluid

temperature

as a function of the

temperature difference

Variable fin thickness

The useful heat flux

provided by an

elemental collector area

of unit length and width

is given by:

( ) ( ) | | { } ' ' " '

* * * *

0

*

dx T x T U G x dq

a L

= q

Variable fin thickness

The useful heat flux per unit collection

surface area

After integration over time

( ) | | { } ' ' "

2

2 /

0

* * * *

0

* *

}

=

}

=

W

a L u

dx T x T U G

W

dq q q

( ) | | { } ' '

0

dx T x T U G dq

a

= q

( ) | | { } ' '

2

2 /

0

0

}

=

W

a u

dx T x T U G

W

q q

Variable fin thickness

The cost per unit collection area is given by

A constant temperature of the tube on

direction x is assumed here

( )

|

.

|

\

|

}

+ + =

2 /

2 /

' ' 2

1

W

d

v A F

dx x c W c c

W

C o

( )

s s

s s =

=

2 / ' 2 / for variable

2 / ' 0 for ) constant (

'

W x d

d x T

x T

b

Variable fin thickness

The objective (cost) function is defined

the solution satisfies the heat flow equations

The solution satisfies the boundary conditions

( )

( )

( ) | | ( ) | | { }

( )

}

+

}

|

.

|

\

|

+

+

=

2 /

0

0 0

2 /

0

1 2

2

2

1

'

d W

a a b

d W

u v

dx T x T U G

W

T T U G

W

d

dx x

d W

W a a

W

q

C

c

J

q q

o

( ) x k

q

dx

dT

p

o

= ( ) | | { }

a

T x T G

dx

dq

=

0

q

( )

b

T x T = = 0

0

2

=

|

.

|

\

|

=

d W

x q

Optimal control problem

Pontryagin theory is used.

The Hamiltonian is defined:

The adjoint variables satisfy the equations

( )

( ) | | ( ) | | { }

( )

( )

( ) | | { } { }

a

b

d W

a a b

T x T G

x k

q

dx T x T U G

W

T T U G

W

d

x

d W

W a a

W

H

+

+

}

+

|

.

|

\

|

+

+

0 2

1

2 /

0

0 0

1 2

2

2

q

o

q q

o

( )

( ) | | ( ) | | { }

( )

2

2 /

0

0 0

1 2

2

1

2

2

)

`

}

+

|

.

|

\

|

+

+

+ =

c

c

=

d W

a a b

dx T x T U G

W

T T U G

W

d

x

d W

W a a

U

W

d W

W

U

T

H

dx

d

q q

o

( ) x k q

H

dx

d

p

o

1 2

=

c

c

=

Optimal control problem

The boundary conditions are:

The Hamiltonian is a maximum for

Then, the optimum control is

0

2

1

=

|

.

|

\

|

=

d W

x

( ) 0 0

2

= = x

0 / = c c o H

( )

( ) ( )

( ) | | ( ) | | { }

( )

2

1

2 /

0

0 0

1

2

2

)

)

`

}

+ =

d W

a a b

p

opt

dx T x T U G

W

T T U G

W

d

k

x x Wq

x q q

o

Optimal control problem

To find the optimum width value the following

equation should be solved

0 / ' = c c W J

Previous results

Fins of variable thickness

the minimum amount of material as an objective function.

constant value for the heat loss coefficient and

operation temperature and meteorological factors

neglected.

Results

A circular shape requires the least material

but a triangular shape requires almost the same material.

In practice an absorber fin having a step-change in local

thickness may be adopted

for compatibility with existing manufacturing methods.

Previous results

Four different shapes of fins:

(a) straight rectangular fins,

(b) fins with a step-change in local thickness;

(c) straight triangular fins and

(d) straight fins of inverse parabolic profile.

the minimum amount of material was the objective

function

The model does not take account of the thermal

operation regime

The inverse parabolic profile save the larger amount

of material

when the ratio of material amount reduction to

reduction in collector efficiency is calculated, design (b)

has the highest value

Results

(a)

(b)

The optimum shape is very

close to an isosceles triangle

The fin is longer for the cold

season as compared to the

warm season (Fig. a).

This allows a larger quantity of solar

energy to be collected and transferred

when the insolation is smaller.

At larger operating

temperatures the fin is much

shorter and thicker for the warm

season as compared to the cold

season (Fig. b).

This way the amount of solar energy

collected and transformed in thermal

energy is easier transferred to the fluid

in the tube

.

C T T

a

= 20

C T T

a

= 40

Results

The optimum distance

between the tubes

increases by increasing

the inlet fluid

temperature

The distance is larger in

the cold season than in

the warm season

Results

The width of the

collection area

increases when the

inlet fluid

temperature

increases

the width is larger

for the cold season

Conclusions

The optimum fin cross-section is very close to an

isosceles triangle.

The fin width is shorter and the seasonal

influence is weaker at lower operation

temperatures.

Fin width and thickness at base depend on

season.

The optimum distance between the tubes

increases by increasing the inlet fluid

temperature

and it is larger in the cold season than in the

warm season.

End of part 2/4

Thank you!

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Astm C1363Dokument43 SeitenAstm C1363Asmaa RamadanNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- 10Dokument7 Seiten10Asmaa RamadanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Development of Standard Data Records For Computerization of Thermal Transmission Test Data For Thermal InsulationDokument10 SeitenDevelopment of Standard Data Records For Computerization of Thermal Transmission Test Data For Thermal InsulationAsmaa RamadanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Selecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationDokument3 SeitenSelecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationAsmaa RamadanNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- 6Dokument7 Seiten6Asmaa RamadanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 6Dokument7 Seiten6Asmaa RamadanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 9Dokument35 Seiten9Asmaa RamadanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- C1045-07 (Reapproved 2013)Dokument13 SeitenC1045-07 (Reapproved 2013)Asmaa RamadanNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 11Dokument21 Seiten11Asmaa RamadanNoch keine Bewertungen

- 9Dokument35 Seiten9Asmaa RamadanNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 2.5 Control Volume Form of ..Dokument7 Seiten2.5 Control Volume Form of ..Paijo TejoNoch keine Bewertungen

- Supercharging of Internal Combustion Engines - Additional Chapter 12-Springer Berlin Heidelberg (1981)Dokument40 SeitenSupercharging of Internal Combustion Engines - Additional Chapter 12-Springer Berlin Heidelberg (1981)Raul PandaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 10Dokument7 Seiten10Asmaa RamadanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 7Dokument11 Seiten7Asmaa RamadanNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- 11Dokument21 Seiten11Asmaa RamadanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 2.5 Control Volume Form of ..Dokument7 Seiten2.5 Control Volume Form of ..Paijo TejoNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Danfoss VLT 2800 Page 29 31Dokument34 SeitenDanfoss VLT 2800 Page 29 31Asmaa RamadanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- 7Dokument11 Seiten7Asmaa RamadanNoch keine Bewertungen

- Borneo Science Special EditionDokument6 SeitenBorneo Science Special EditionAsmaa RamadanNoch keine Bewertungen

- 7805Dokument25 Seiten7805DraKo BaracunataNoch keine Bewertungen

- Jindal Power Limited Draft Red Herring Prospectus PDFDokument523 SeitenJindal Power Limited Draft Red Herring Prospectus PDFAsmaa RamadanNoch keine Bewertungen

- Internal Combustion Engines290963208 PDFDokument2 SeitenInternal Combustion Engines290963208 PDFAsmaa RamadanNoch keine Bewertungen

- Gill 2017Dokument23 SeitenGill 2017Asmaa RamadanNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- A Review of Absorption RefrigerationDokument30 SeitenA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- Water Desalination Lecture 6 - NEWDokument63 SeitenWater Desalination Lecture 6 - NEWAsmaa RamadanNoch keine Bewertungen

- A Review of Absorption RefrigerationDokument30 SeitenA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- Market StatisticsDokument45 SeitenMarket StatisticsfrancismazingaNoch keine Bewertungen

- Thermodynamic Analysis of Vapor Absorption Refrigeration System and Calculation of COPDokument8 SeitenThermodynamic Analysis of Vapor Absorption Refrigeration System and Calculation of COPEver Ospino MeloNoch keine Bewertungen

- Combined Refrigeration Cycle For Thermal Power Plant Using Low Grade Waste SteamDokument4 SeitenCombined Refrigeration Cycle For Thermal Power Plant Using Low Grade Waste SteamAsmaa RamadanNoch keine Bewertungen

- 23Dokument4 Seiten23leynatmarNoch keine Bewertungen

- Nuri - Fractional Reserve Banking As Economic Parasitism - A Scientific, Mathematical and Historical Expose, Critique and Manifesto (2002)Dokument62 SeitenNuri - Fractional Reserve Banking As Economic Parasitism - A Scientific, Mathematical and Historical Expose, Critique and Manifesto (2002)Indianhoshi HoshiNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Cambridge IGCSE: PHYSICS 0625/31Dokument16 SeitenCambridge IGCSE: PHYSICS 0625/31Susan GeorgeNoch keine Bewertungen

- Engineering Research Paper PDFDokument7 SeitenEngineering Research Paper PDFafnhekkghifrbm100% (1)

- 201011091651430.logmatic 4121-4122-4126Dokument88 Seiten201011091651430.logmatic 4121-4122-4126SnrNoch keine Bewertungen

- Newton's Law of Cooling & Its ApplicationsDokument13 SeitenNewton's Law of Cooling & Its ApplicationsDr Srinivasan Nenmeli -K100% (5)

- Thermoking Training Manual 50390Dokument375 SeitenThermoking Training Manual 50390carmaNoch keine Bewertungen

- Ihte Que BankDokument2 SeitenIhte Que BankNikunj PatelNoch keine Bewertungen

- Free and Forced ConvectionDokument7 SeitenFree and Forced ConvectionRenewable Energy Engi50% (2)

- SM CHDokument492 SeitenSM CHsandwichnachosNoch keine Bewertungen

- A Seminar Report OnDokument20 SeitenA Seminar Report Onadarsh_m00675% (4)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Fluidization Bed Column Lab ManualDokument10 SeitenFluidization Bed Column Lab ManualAshish VermaNoch keine Bewertungen

- Lab Session 9, Experiment 8: Calorimetry, Heat of ReactionDokument3 SeitenLab Session 9, Experiment 8: Calorimetry, Heat of ReactionFruitiliciousNoch keine Bewertungen

- Chapter - 6 - Pengantar KonveksiDokument46 SeitenChapter - 6 - Pengantar KonveksiAldy GustaNoch keine Bewertungen

- 640i 780i Instruction ManualDokument125 Seiten640i 780i Instruction ManualJorge JulianNoch keine Bewertungen

- Building Util Summary NotesDokument18 SeitenBuilding Util Summary NotesJohn Gil SuarezNoch keine Bewertungen

- Boiler System - GEADokument8 SeitenBoiler System - GEAKhoaNguyenNoch keine Bewertungen

- 4 Chapter Four Chemical Reaction and CombustionDokument90 Seiten4 Chapter Four Chemical Reaction and CombustionMohamed AbdelaalNoch keine Bewertungen

- Is - 12802 - 1989Dokument16 SeitenIs - 12802 - 1989sangita ghaisasNoch keine Bewertungen

- Physics Lesson Plan 57 Determination of Thermal ConductivityDokument5 SeitenPhysics Lesson Plan 57 Determination of Thermal Conductivityelty TanNoch keine Bewertungen

- Intro To MechanicalDokument25 SeitenIntro To MechanicalRondell SinananNoch keine Bewertungen

- Diffraction PhysicsDokument71 SeitenDiffraction PhysicsRishabh SinghNoch keine Bewertungen

- Latent HeatDokument32 SeitenLatent HeatAbhijit Kar Gupta100% (11)

- Paper 1 - July 2022Dokument8 SeitenPaper 1 - July 2022Ravi ShankarNoch keine Bewertungen

- Design of LPG Refrigeration System: June 2021Dokument47 SeitenDesign of LPG Refrigeration System: June 2021Fatima Nasir R:29Noch keine Bewertungen

- SCI NK Compressor 150Dokument48 SeitenSCI NK Compressor 150Ramon SanhuezaNoch keine Bewertungen

- University of Calicut: General and Academic Branch - I J' SectionDokument197 SeitenUniversity of Calicut: General and Academic Branch - I J' SectionSreeja SunderNoch keine Bewertungen

- Printronix T8000 - Administrator ManualDokument327 SeitenPrintronix T8000 - Administrator ManualJonathan LongNoch keine Bewertungen

- SSC Thermal EngineeringDokument47 SeitenSSC Thermal EngineeringSteph Dela MujerNoch keine Bewertungen

- Cambridge O Level: Physics 5054/11Dokument16 SeitenCambridge O Level: Physics 5054/11Jack KowmanNoch keine Bewertungen

- PACKET - Thermochemistry PracticeDokument7 SeitenPACKET - Thermochemistry PracticefkjsljNoch keine Bewertungen