Beruflich Dokumente

Kultur Dokumente

App. b1 - Hsse Epcc

Hochgeladen von

engmgsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

App. b1 - Hsse Epcc

Hochgeladen von

engmgsCopyright:

Verfügbare Formate

wv

OMV

MINIMU

REQUIR

FOR

CONT

M HSSE

EMENTS

EPCC

RACTS

Commissioning

Construction

Engineering

Procurement

OMV Group

EPCC Annex

Page 1 of 11

Table of Contents

1. INTRODUCTION ......................................................................................................................................... 2

1.1. Purpose ............................................................................................................................................ 2

1.2. Scope ............................................................................................................................................... 2

1.3. Application of this document ......................................................................................................... 2

1.4. OMV Expectations as defined in OMV HSSE Policy .................................................................... 2

2. OMV HSSE MANAGEMENT SYSTEM ...................................................................................................... 3

3. PLANNING AND PERFORMANCE MONITORING ................................................................................... 3

3.1. Predetermined HSSE Key Performance Indicators (HSSE KPIs) ................................................ 4

3.2 Key Contractor documents .............................................................................................................. 4

4. CONTRACTOR HSSE PLAN ....................................................................................................................... 4

A. Bridging Document ........................................................................................................................... 4

B. Standalone HSSE Plan ...................................................................................................................... 5

4.1. Leadership and Commitment ........................................................................................................ 5

4.2. Organization .................................................................................................................................... 5

4.3. People, Competency and Behavior ............................................................................................... 5

4.4. Risk Management ........................................................................................................................... 5

4.5. Engineering and Project Management.......................................................................................... 6

4.6. Operations and Performance Management ................................................................................. 6

4.7. Contracted Services ........................................................................................................................ 8

4.8. Planning and Cost Management ................................................................................................... 8

4.9. Incidents and Accidents ................................................................................................................. 8

4.10. Emergency and Crisis Control ..................................................................................................... 8

4.11. Stakeholder Dialog and Information Management ................................................................... 9

4.12. Audit and Review .......................................................................................................................... 9

5. TERMS AND DEFINITIONS ....................................................................................................................... 9

OMV Group

EPCC Annex

Page 2 of 11

1. INTRODUCTION

1.1. Purpose

The purpose of this document is to describe the performance and behavior expectations of OMV

Group companies from all contractors and subcontractors working for OMV Group involved in EPCC

activities and services.

While recognizing that there is considerable legislation and regulation already applicable to EPCC in

the locales in which OMV Group operates, there are significant differences in the implementation

and monitoring of this legislation between countries and even within countries.

1.2. Scope

This document intends to provide guidance on how to plan to safely execute contracted work as well

as emphasis compulsory processes or procedures. The document defines the minimum HSSE

requirements in the contracts towards Health, Safety, Security and Environment that the contractor

shall fulfill upon award of the contract in the provision of EPCC equipment and services.

This document does not replace the legal and regulatory requirements, nor does it prescribe how the

contractor shall manage their business. However, this document does describe the standards and

performance level against which the contractor shall be held accountable.

1.3. Application of this document

This document applies to all HSSE aspects of the contractors scope of work.

It is expected that contractor shall prepare a HSSE plan applicable for the engineering phase of their

work addressing how they shall demonstrate their provision of a safe working environment.

As contractor scope of work moves towards construction, a separate and independent

CONSTRUCTION HSSE plan shall be prepared and approved. In addition to the construction HSSE

plan other plans shall be required to address the major hazards created throughout construction, a

minimum being;

Transportation plan (See Road transportation annex for details of OMV Group

requirements)

Environmental Management plan

Community relations plan

As OMV Group has no contractual relationship with any subcontractor but as beneficiary of the work

is held accountable for the HSSE performance of all parties on the site, contractor shall ensure that

their subcontractors shall be held accountable to the HSSE performance and behavioral expectations

of contractor.

1.4. OMV Expectations as defined in OMV HSSE Policy

During the performance of the contract, contractors shall observe the latest valid version of OMV

HSSE Policy statement and supporting HSSE documentation as they were provided in writing or

electronically by OMV.

OMV Group

EPCC Annex

Page 3 of 11

2. OMV HSSE MANAGEMENT SYSTEM

O Ou ut tl li in ne e o of f O OM MV V H HS SS SE E M Ma an na ag ge em me en nt t S Sy ys st te em m

Management Element Description

1 LEADERSHIP AND

COMMITMENT

Management will provide visible and active leadership in

developing and maintaining a culture supportive of HSSE

matters

2 ORGANIZATION The organization and responsibilities for the management of

HSSE will be defined and documented

3 PEOPLE, COMPETENCY

AND BEHAVIOR

All people will be selected, trained and developed to carry out

their duties competently

4 RISK MANAGEMENT Hazards will be identified, the risks assessed and appropriate

controls implemented

5 ENGINEERING AND

PROJECT

MANAGEMENT

Facilities will be engineered to meet relevant codes of

practice and specifications, operational requirements, and

statutory regulations

6 OPERATIONS AND

PERFORMANCE

MANAGEMENT

All activities involving the exploration, development,

production, processing, transportation and distribution will

have relevant safe, secure and precautionary systems of work

defined and performance indicators established.

7 CONTRACTED

SERVICES

Supplies and contracted services will be controlled to ensure

they comply with company HSSE requirements.

8 PLANNING AND COST

MANAGEMENT

Objectives, targets and financial resources will be planned to

integrate HSSE in all business activities and avoid losses.

9 INCIDENTS AND

ACCIDENTS

Incidents and accidents will be fully reported and analyzed to

establish root causes and prevent recurrence

10 EMERGENCY AND

CRISIS CONTROL

Organizational arrangements, facilities and training will be

provided to effectively manage emergencies and crisis

situations

11 STAKEHOLDER DIALOG

AND INFORMATION

MANAGEMENT

Active dialogue with stakeholders and communities will

ensure confidence in the integrity of our activities. Accurate

and relevant documentation will be readily available for safe

working and to minimize undesirable effects

12 AUDIT AND REVIEW An independent audit and review system will be established

to assess the effectiveness of HSSE management and identify

areas for improvement

OMV Group

EPCC Annex

Page 4 of 11

3. PLANNING AND PERFORMANCE MONITORING

3.1. Predetermined HSSE Key Performance Indicators (HSSE KPIs)

In order to measure and monitor performance a set of Specific, Measurable, Achievable, Realistic

and Time bound (SMART) indicators shall be agreed and used for duration of the contract and will

form a major component of the assessment of contractor performance at the end of contract.

Contractor is encouraged to develop their own performance indicators to include in the assessment.

3.2 Key Contractor documents

The contractor shall prepare the following key HSSE documents covering their scope of work IN

ADDITION to the HSSE minimum requirements of the HSSE Annex (i.e. HSSE Plan)

Mobilization Plan

Construction site HSSE plan

Environmental Management Plan (Waste management, spill response, fluid and

chemical containment)

Transportation plan INCLUDING site traffic management plan

Community Relations plan

Commissioning plan ( including SIMOPS plan)

4. CONTRACTOR HSSE PLAN

The contractor shall develop an EPCC HSSE plan to ensure the health, safety and security of their

personnel, OMV Group personnel and third parties and to minimize their impact on the

environment and local communities. This EPCC HSSE plan shall be one of the following types a

Bridging document or a standalone EPCC HSSE plan based on the OMV Management System

structure and MAY be combined with the HSSE plan legally required but shall include the

requirements of the Minimum HSSE Requirements Annex as well as the EPCC requirements

described below.

A. Bridging Document

OMV Group expects our contractors to have a robust HSSE Management System in place and

demonstrably implemented in all Contractors work. In this event where contractor has such an active

management system then contractor has the option to present a Bridging Document that shall

address all activities for which contractor is responsible and accountable. This Bridging Document

shall include as a minimum:

Alignment of Contractor with OMV Group HSSE Policy

Alignment with the requirements of the 12 elements of the OMV HSSE Management

System intentions, expectations, objectives and metrics.

Contractor HSSE organization to support OMV Group HSSE objectives and

management system with respect to EPCC activities

Clear identification of roles and responsibilities in contractor organization.

Alignment of hazard identification and assessment with corresponding suitable and

appropriate preventive and mitigation actions including full accountability with

respect to EPCC

Clearly identify the health, security, safety, environmental and Community Relations

procedures and actions that contractor shall maintain with respect to EPCC

Inspection and audit process to demonstrate alignment with OMV Group 12

elements of HSSE Management System.

OMV Group

EPCC Annex

Page 5 of 11

B. Standalone HSSE Plan

This plan shall be developed by contractor as per the OMV HSSE Management System using the

template shown above of OMV expectations. Contractor, being the specialist in their field of EPCC

activities shall demonstrate competence of management of all activities to which contractor is

responsible and accountable in this plan and show alignment with OMV Group requirements.

*NB: The information provided below is for information purposes and represents a minimum

requirement contractor shall be required to provide a complete HSSE plan for ALL their

activities including sub contracted activities.

Contractor shall observe all OMV Group HSSE Management System documents provided to it in

writing or electronically by OMV and shall be expected to fully understand and implement the

necessary controls to ensure compliance.

Listed below is an example template of what shall be in the HSSE plan.

4.1. Leadership and Commitment

Visible and active leadership demonstrated throughout the period of work to support HSSE

in the execution of EPCC activities:

SEE MINIMUM HSSE REQUIREMENTS ANNEX

4.2. Organization

The contractors team shall be staffed with competent and motivated personnel working

towards well defined HSSE objectives:

SEE MINIMUM HSSE REQUIREMENTS ANNEX

4.3. People, Competency and Behavior

Contractor shall recruit and develop competent and motivated personnel to execute all work

safely:

SEE MINIMUM HSSE REQUIREMENTS ANNEX

4.4. Risk Management

The contractor shall demonstrate a robust risk management process so that all work hazards

and risks are identified and assessed with appropriate controls implemented to ensure a safe

work environment as well as the safe execution of work. It is recognized that many

engineering contracts do perceive HSSE hazards or risks due to their office environment.

However, this is not always the case as personnel may be required to make field, site or

facility visits. Therefore OMV Group expects the same management control to manage

hazards and risks:

The risk management program is appropriate for the risks in the execution of work

and shall comply with the legal requirements.

Contractor shall coordinate their risk assessments with other companies,

contractors and third parties with whom they interact.

Appropriate risk management tools are used for the level of risk of contractor work

Risk assessments are conducted for the normal routine activities AS WELL AS risk

assessments for the work environment experienced for the execution of work

Specific Job Safety Analysis (JSA) or risk assessments are completed for use by

personnel executing high risk activities

The contractor shall be able to demonstrate that risks are reduced to ALARP As

Low As Reasonably Practical

OMV Group

EPCC Annex

Page 6 of 11

Contractor shall demonstrate the completeness of these risk assessments by

formally documenting the following criteria:

Identification of all hazards

Identification of personnel exposed to these hazards or risks including

public, other contractors, client and third party and the range of potential

harm they may experience from each hazard.

Evaluation of the risk exposure to these personnel for each type of hazard or

risk considering the expected training and knowledge of these personnel

Prevention of risk through elimination completely or change or procedure to

significantly reduce exposure

Mitigation controls to reduce the consequences should the incident be

realized.

Identification of the remaining risk to indicate if controls are adequate to

reduce risk to as low as reasonably practicable (ALARP).

Mechanism by which actions will be checked to be in place and working as

planned.

4.5. Engineering and Project Management

Contractors shall ensure that the design software and equipment used is current and

compliant with the following:

Design codes, specifications and standards are identified and complied with to

meet current legal requirements

Contractor shall ensure software used is current, valid, correctly licensed and

applicable for the work being done.

Contractor shall ensure compliance with the OMV Group standard - Safety in

Design.

Contractor shall ensure that industry best practices and lessons learned are

incorporated into design to address the human interface particularly for the

management of alarms and warnings.

Contractor shall consider the operations and maintenance of their design over its

operating life and demonstrate that the human intervention required is easy and

safe with access for mechanical lifting equipment as necessary.

4.6. Operations and Performance Management

The contractor shall ensure that a safe, secure and precautionary system of work is in place

and maintained throughout the execution of their work:

The contractor shall ensure that a robust and efficient system is in place to manage

their workplace and that all hazards are identified and the risks reduced to

acceptable levels

Equipment is certified and checked fit for use prior to use (both before first use and

daily checks)

Equipment used for or with mechanical lifting equipment fitted shall be managed by

the contractor such that all hazards associated with this high risk lifting activity are

assessed and mitigated through a formal documented process. All lifts over 5 tons

shall require a specific lift plan. Routine lifts shall have a specific risk assessment

and to be reviewed prior to each lift. (Further detail is available in OMV Group

Regulations on Lifting and Manual Handling)

A robust and effective Permit to Work (PTW) shall be in place for high risk activities

and as legally required. Contractors shall comply with the requirements of the PTW

system. If OMV Group is not managing the PTW system, the contractor shall

OMV Group

EPCC Annex

Page 7 of 11

implement their own system. As a minimum the following shall be covered by the

Permit To Work system:

Mechanical lifting load over 5 ton weight

Working at height over 1.8 m

Working in excavations deeper than 0.7m

Working within 50m of an active hydrocarbon containing vessel

Hot work

Vessel entry

Personal Protective Equipment (PPE) shall be provided and maintained in good and

fit for purpose condition with appropriate testing and certification as required. The

contractor shall ensure that all their personnel (including visitors) have the

minimum PPE requirement of certified PPE overalls, boots, hard hat and glasses.

Additional PPE shall be provided as necessary and shall be appropriate for the work

being executed. (NOTE: minimum PPE requirements may change dependent on the

environment in which work is to be performed, such as Nomex comfort for use in

refineries.).

Contractors shall ensure that the minimum PPE (Boots, overalls, hard hat and

glasses) is worn at all sites when working on behalf of OMV Group companies. Sites

include proposed greenfield sites and brownfield sites where no apparent activity is

ongoing.

Contractors shall have in place a process to identify and manage the hazards and

risks associated with the execution of their work. Contractors shall use their

expertise and knowledge to demonstrate to OMV Group their professionalism and

competence in the implementation of this safe system of work.

Below is a non-exhaustive list of examples of activities (or hazards associated with

activities) that shall require specific management control by the contractor to

demonstrate that they have a safe work environment so that work can be performed

safely. The contractor shall have a plan or procedure in place where the hazards and risks

for the activities are identified, assessed and controlled for each OMV Group site.

Manual handling, stepping and lifting

Excavation work

Security of equipment

Working in hot/cold environments

Hazardous materials transport, security and storage

Waste management including hazardous and/or toxic waste loads

Lifting operations

Working with chemicals including cement/concrete

Working at height including on vehicles and vehicle loads

Warning barriers and signs,

NOTE: This list is provided for guidance purposes only; the contractor shall demonstrate their

own awareness of all the hazards and risks facing their workforce and document the

procedures and controls to reduce these to As Low As Reasonably Practicable (ALARP).

Contractor shall ensure they have spill prevention and spill control plan/procedure

in place to address all potential spills on site (including leaks form mechanical

equipment).

Contractor shall have in place a chemical management plan/procedure to address

the storage, transport and handling of chemicals used on site.

OMV Group

EPCC Annex

Page 8 of 11

Contractor shall ensure that they have a documented process in place to minimize

the generation of waste, the storage of waste with the correct and safe disposal of

their waste. Contractor shall ensure they maintain their worksite clear of waste

Contractor shall ensure full compliance with Safety Data Sheets (SDS) for their

hazardous materials.

4.7. Contracted Services

The contractor shall describe and be able to demonstrate how they shall manage their

subcontractors to meet the HSSE objectives and goals of the work:

Subcontracting process is managed in accordance with OMV Group requirements

A process is in place to monitor the HSSE performance of subcontractors

As OMV Group has no contractual relationship with any subcontractor but as beneficiary of

the work is held accountable for the HSSE performance of all parties on the site, contractor

shall ensure that their subcontractors shall be held accountable to the HSSE performance

and behavioral expectations of contractor.

4.8. Planning and Cost Management

Plans with objectives and targets shall be prepared, agreed and implemented to ensure that a

safe system of work is in place throughout the execution of the work:

The HSSE plan shall be reviewed at regular intervals to ensure it is still appropriate

and sufficient for the work, particularly at significant milestones of work

HSSE objectives/ targets/ milestones shall be identified at start of work and

performance against these objectives shall be documented and reported both to

OMV Group representative as well as to contractor personnel

HSSE Key Performance Indicators (HSSE KPIs) shall be identified before starting the

activities and shall be reported during the execution of work

A Quality monitoring program shall be in place to demonstrate compliance with

contractor Quality system and continuous improvement

Contractor shall ensure they have a plan in place to ensure the timely preparation of

documentation to support all permit applications

Regular meetings shall be held to review performance and incidents to ensure

lessons are captured with corrective actions implemented to prevent re-occurrence

4.9. Incidents and Accidents

All incidents and high potential incidents (HiPo = an incident where the actual consequence is

low (level 1-2) but could easily have been a higher consequence (level 3 and above) shall be

fully reported and investigated:

SEE MINIMUM HSSE REQUIREMENTS ANNEX

4.10. Emergency and Crisis Control

The contractor shall have plans in place to address and respond to all foreseeable

emergencies including natural disasters and to ensure their personnel are adequately trained

to respond to such emergencies:

Emergency response plan in place and drilled at appropriate frequency to address

foreseeable incidents and accidents

Integrated ER Plan when other parties are on the same site with clear identification

of person in charge either directly under OMV Group or lead contractor control.

Required emergency response material and equipment available, suitable in

required quantities and fit for purpose

OMV Group

EPCC Annex

Page 9 of 11

Contractor shall ensure they have a current, complete and robust INDEPENDENT

BACK UP system for all key information, data and communication - both paper

format and electronic format. (Independent means physically separate such that a

catastrophic event in the contractor office will not permanently destroy work

already completed).

Regulatory emergency response requirements compliance confirmed and

documented

4.11. Stakeholder Dialog and Information Management

To the extent that the contractor has been contracted with activities as regards Stakeholder

Dialogue and Information Management, it shall have a clear and unambiguous

communication process in place to distribute HSSE information to their workforce, third

parties and appropriate authorities:

A Community Relations plan shall be prepared and approved by OMV Group

representative as necessary which shall address the potential impact of the

contractors activities and describe how this impact shall be prevented or reduced.

When a Community Relations plan is required from contractor it shall address the

following:

Personnel transportation

Equipment and material transportation

Accommodation plan when necessary

Contractor shall observe any and all Community Relations plans in effect for the

area and activity in which they are involved were provided to it in writing or

electronically by OMV.

Regular formal documented HSSE meetings shall be held with the workforce with

appropriate subjects and issues discussed

HSSE specialists shall meet at regular intervals to report to OMV Group

representative on HSSE issues

HSSE related permits and compliance register shall be prepared and maintained for

the contractor scope of work

4.12. Audit and Review

The contractor shall have an independent audit program in place:

Audit schedule prepared and integrated into work schedule

Regular inspections and audits documented with tracking of actions showing the

responsible party and the expected closure date

5. TERMS AND DEFINITIONS

OMV Group: OMV Aktiengesellschaft, OMV Petrom S.A. and Petrol Ofisi and all their subsidiaries

Company: OMV Group companies

Contractor: A contractor is defined as an individual or organization performing work for OMV,

following verbal or written agreement. The term sub-contractor is used synonymously with

contractors.

Sub-contractor: A sub contractor is an individual or organization performing work for a contractor.

Shall: Indicates a compulsory instruction on the contractor that requires compliance. The contractor

shall maintain documentation to support compliance against such an instruction.

OMV Group

EPCC Annex

Page 10 of 11

ALARP: As Low As Reasonably Practicable. The concept of reducing risks to ALARP implies that

there is a trade-off between the costs of risk reduction and the benefits obtained. There should be a

transparent bias on the side of HSSE. (To meet this requirement the contractor/sub contractor must

demonstrate what efforts have been made to reduce the risk and what mechanism was used to

consider it to be acceptable).

Frequency: Number of occurrences of an event per unit time.

Hazard: Any unsafe act or unsafe conditions or object or physical effect with the potential to cause

harm. There is no immediate incident, but under slightly different circumstances, or if several things

were to happen at once, an incident could occur.

Hazid: A formal risk identification process, described in ISO 17776

Hazop: Hazard and operability study. Formal documented team based process to identify hazards

associated with operation of a module, unit or facility using a set of guidewords to direct the

potential consequences. Engineering documents (i.e. P&ID, single line diagram, etc.) are required as

input to the process

Harm: Physical injury or damage to the health of people, either directly or indirectly, as a result of

damage to property or to the environment.

HiPo (High potential) Incident: A high potential incident (HiPo) is any incident with actual severity

level 0 (near miss), 1, 2 or 3 that under slightly different circumstances could have become an

incident level 4 or 5.

HSSE: Health, Safety, Security and Environment

HSSE-MS: Health, Safety, Security and Environmental Management System. A management

system is a set of processes and practices that enable an organization to control and manage its

business activities. The HSSE MS is a process that applies a disciplined and systematic approach to

managing health, safety, security and environmental activities in OMV Group.

Incident: An unplanned event during working life, any deviation from the standard process that has

or could have (near miss) resulted in personal injuries/illness, damage to assets and equipment,

adverse environmental impact or unfavorable impact on the public and company reputation.

Incidents do not include degradation or failure of plant or equipment resulting solely from normal

wear and tear.

Vehicle incidents include all incidents to/from place of work, and all incidents during

work hours for both personal and company cars.

Occupational health incidents that occur on work sites or are a direct result of work

on OMV Group directed worksites.

Incidents that affect third parties due to work performed on OMV Group worksites.

Lost Time Injury (LTI): The sum of occupational injuries resulting in fatalities, permanent total

disabilities and lost workday cases, but excluding restricted work cases and medical treatment

cases.

Major incident: Incident with a severity of consequences that is equal or greater than level 3 using

the OMV Risk Matrix.

Near Miss: An incident which under slightly different circumstances could have had adverse

consequences.

OGP: International Association of Oil and Gas Producers.

Risk: Combination of the frequency of occurrence of harm and the severity of that harm.

OMV Group

EPCC Annex

Page 11 of 11

Restricted Work Injury (RWI): Any incident that results in an individual or individuals being unable to

return to their normal work the following day of the incident but are able to perform alternative light

duties. When the employee or contractor can resume his or her work with restriction after an

occupational injury, taking into consideration the legal framework.

Safety: Is a condition where either hazards or unacceptable/intolerable risks to people, environment

and/or assets are absent.

Third party: Third Parties are persons or organizations that are not employed by or contracted to a

company or contractor.

Work related activity: A work-related activity is an activity in a work environment, which is or ought

to be subject to management controls for company personnel as well as for contractors, including

attendance at courses, conferences and company-organized events, business travel, field visits or

any other activity or presence expected by the employer.

Workplace (work area/site): Facilities or the environment (as physical place, processes and

technology) where contractors and subcontractors are directed to work through contract by OMV

Group representatives.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Entrepreneurship by Hisrich, Shepherd, Peters Chapter 1 MCQs and QuestionsDokument6 SeitenEntrepreneurship by Hisrich, Shepherd, Peters Chapter 1 MCQs and QuestionsTooba100% (5)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Nebosh DiplomaDokument21 SeitenNebosh Diplomadaniel_amoako_2100% (3)

- HR offer letter for Systems Engineer role at InfosysDokument10 SeitenHR offer letter for Systems Engineer role at InfosysAtul SharmaNoch keine Bewertungen

- Practical Guide to Capturing Energy from Magnetic PulsesDokument6 SeitenPractical Guide to Capturing Energy from Magnetic Pulsestomcat0101Noch keine Bewertungen

- YountanksDokument114 SeitenYountanksengmgsNoch keine Bewertungen

- Short Notes On Harmonic Currents From HVDC ConvertersDokument7 SeitenShort Notes On Harmonic Currents From HVDC ConvertersengmgsNoch keine Bewertungen

- Element 5: Health & Safety Management System - Measuring, Audit & ReviewDokument34 SeitenElement 5: Health & Safety Management System - Measuring, Audit & ReviewengmgsNoch keine Bewertungen

- Baidu SecurityDokument1 SeiteBaidu SecurityengmgsNoch keine Bewertungen

- Rio o o BookDokument72 SeitenRio o o BookengmgsNoch keine Bewertungen

- SSG STARTERS GUIDE-Two PDFDokument21 SeitenSSG STARTERS GUIDE-Two PDFNabeel Dawod100% (1)

- Pandp 12Dokument556 SeitenPandp 12engmgsNoch keine Bewertungen

- Students' Expectations of University EducationDokument8 SeitenStudents' Expectations of University EducationMOHD DANIAL BIN MOHD JOHANNoch keine Bewertungen

- Book FliDokument104 SeitenBook FliengmgsNoch keine Bewertungen

- Element 1: Foundations in Health and SafetyDokument16 SeitenElement 1: Foundations in Health and SafetyengmgsNoch keine Bewertungen

- Book FiDokument12 SeitenBook FiengmgsNoch keine Bewertungen

- Books ofDokument42 SeitenBooks ofengmgsNoch keine Bewertungen

- FolbooyDokument1 SeiteFolbooyengmgsNoch keine Bewertungen

- FolboopyDokument1 SeiteFolboopyengmgsNoch keine Bewertungen

- Examiners' Report NEBOSH International General Certificate in Occupational Health and Safety (IGC1)Dokument10 SeitenExaminers' Report NEBOSH International General Certificate in Occupational Health and Safety (IGC1)engmgsNoch keine Bewertungen

- Igc3 Nebosh Guidance 2014 v.2Dokument21 SeitenIgc3 Nebosh Guidance 2014 v.2Cezar DumitriuNoch keine Bewertungen

- Examiners' Report NEBOSH International General Certificate in Occupational Health and Safety - IGC2Dokument12 SeitenExaminers' Report NEBOSH International General Certificate in Occupational Health and Safety - IGC2engmgsNoch keine Bewertungen

- Mar 1998Dokument15 SeitenMar 1998engmgsNoch keine Bewertungen

- Examiners Reports IGC2 - September 2009 IGC2 PDFDokument10 SeitenExaminers Reports IGC2 - September 2009 IGC2 PDFbharathost50% (2)

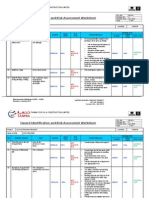

- RISK ASSESSMENT FOR GRIT BLASTINGDokument5 SeitenRISK ASSESSMENT FOR GRIT BLASTINGengmgsNoch keine Bewertungen

- RA - Arc WeldingDokument5 SeitenRA - Arc WeldingengmgsNoch keine Bewertungen

- JROGS Risk Assessment FormDokument8 SeitenJROGS Risk Assessment FormengmgsNoch keine Bewertungen

- Bitumen Emulsion Msds PDFDokument3 SeitenBitumen Emulsion Msds PDFengmgsNoch keine Bewertungen

- Tufguardrbe CGDokument2 SeitenTufguardrbe CGengmgsNoch keine Bewertungen

- 25 Phrases That Pay - Sales Strategy and CommunicationDokument9 Seiten25 Phrases That Pay - Sales Strategy and CommunicationRJNoch keine Bewertungen

- Isaca Cisa CoursewareDokument223 SeitenIsaca Cisa Coursewareer_bhargeshNoch keine Bewertungen

- Barilla-SpA CaseStudy Short Reaction PaperDokument3 SeitenBarilla-SpA CaseStudy Short Reaction Papersvk320Noch keine Bewertungen

- Solutions To All Assigned Practice Problems (W502)Dokument27 SeitenSolutions To All Assigned Practice Problems (W502)donjazonNoch keine Bewertungen

- The ArcSight Compliance Tool KitDokument24 SeitenThe ArcSight Compliance Tool Kitsrmv59Noch keine Bewertungen

- SAE1Dokument555 SeitenSAE1Aditya100% (1)

- Business Risk (D)Dokument5 SeitenBusiness Risk (D)Tchao AdrienNoch keine Bewertungen

- Stanford Antigua ComplaintDokument74 SeitenStanford Antigua ComplaintFOXBusiness.com100% (2)

- Pump and Dump - Print 1Dokument7 SeitenPump and Dump - Print 1Zahid FaridNoch keine Bewertungen

- DTC Agreement Between Cyprus and United StatesDokument30 SeitenDTC Agreement Between Cyprus and United StatesOECD: Organisation for Economic Co-operation and DevelopmentNoch keine Bewertungen

- Astro and CosmoDokument5 SeitenAstro and CosmoGerson SchafferNoch keine Bewertungen

- Marketing Strategy For Millennial of AlcoholDokument8 SeitenMarketing Strategy For Millennial of AlcoholKetan BedekarNoch keine Bewertungen

- Segmenting Global MarketsDokument12 SeitenSegmenting Global MarketsJenny YadvNoch keine Bewertungen

- Analyzing Risks and Controls in Information SystemsDokument42 SeitenAnalyzing Risks and Controls in Information SystemsHongNoch keine Bewertungen

- Solar Power Forecast: Weather. Impact On Your BusinessDokument2 SeitenSolar Power Forecast: Weather. Impact On Your BusinessCamilo DiazNoch keine Bewertungen

- كتاب النبي دانيال PDFDokument22 Seitenكتاب النبي دانيال PDFDemaa Naim75% (4)

- Transfer Pricing of Tivo and Airbag Division: RequiredDokument7 SeitenTransfer Pricing of Tivo and Airbag Division: RequiredajithsubramanianNoch keine Bewertungen

- SACCO Budgeting and Business Planning ManualDokument54 SeitenSACCO Budgeting and Business Planning ManualFred IlomoNoch keine Bewertungen

- The Product Manager and The ProductDokument24 SeitenThe Product Manager and The ProductRohitkumariluNoch keine Bewertungen

- Find stock prices for delisted companies in DatastreamDokument3 SeitenFind stock prices for delisted companies in Datastreamprofjblaze2Noch keine Bewertungen

- Tiong, Gilbert Charles - Financial Planning and ManagementDokument10 SeitenTiong, Gilbert Charles - Financial Planning and ManagementGilbert TiongNoch keine Bewertungen

- Leads Vs ReferralsDokument1 SeiteLeads Vs ReferralsDhanalakshmi chandramohanNoch keine Bewertungen

- DESIGNER BASKETS Vs Air Sea TransportDokument1 SeiteDESIGNER BASKETS Vs Air Sea TransportMarco CervantesNoch keine Bewertungen

- LA Chief Procurement OfficerDokument3 SeitenLA Chief Procurement OfficerJason ShuehNoch keine Bewertungen

- LS 4 Life and Career Skills!Dokument24 SeitenLS 4 Life and Career Skills!Markee JoyceNoch keine Bewertungen

- Building Productsspring 2010Dokument84 SeitenBuilding Productsspring 2010Adrian GhabbhalNoch keine Bewertungen

- Carriage and Insurance Paid To CIPDokument16 SeitenCarriage and Insurance Paid To CIParun arunNoch keine Bewertungen

- Small Industries Development Bank of India (Sidbi) : Growth, Development and Role in The Promotion of Entrepreneurship in Uttar Pradesh (U.P.)Dokument46 SeitenSmall Industries Development Bank of India (Sidbi) : Growth, Development and Role in The Promotion of Entrepreneurship in Uttar Pradesh (U.P.)Suhani jainNoch keine Bewertungen