Beruflich Dokumente

Kultur Dokumente

Investigation of The Plastification Behavior of Polymers in High-Speed Twin Screw Extruders

Hochgeladen von

Reza Mansourieh0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

250 Ansichten4 SeitenThis document summarizes an investigation into the initial melting processes of polymers in high-speed twin screw extruders. Experiments were conducted using a test stand that allowed high-speed visualization of a cross-section of the plasticization zone. The experiments showed that plastic energy dissipation during compression and deformation of polymer granules in the intermeshing zone of the screws is the primary mechanism for melting. A parametric study examined the effects of process parameters like screw speed, temperature, screw configuration, and material type on initial melting.

Originalbeschreibung:

A test stand to observe movement and deformation of thermoplastic polymers in a cross section of the plastification zone of a co-rotating twin screw extruder is presented. Multiple experiments to examine the initial melting processes in dependence of different process parameters such as rotational speed, temperature, kneading disk configuration, polymeric material, granule size and filling degree were conducted. The focus thereby was the visualization of underlying effects by high-speed imaging. This allowed gaining insights into the basic energy dissipation mechanisms and the most significant process parameters for the initial melting process

Originaltitel

INVESTIGATION OF THE PLASTIFICATION BEHAVIOR OF POLYMERS IN HIGH-SPEED TWIN SCREW EXTRUDERS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document summarizes an investigation into the initial melting processes of polymers in high-speed twin screw extruders. Experiments were conducted using a test stand that allowed high-speed visualization of a cross-section of the plasticization zone. The experiments showed that plastic energy dissipation during compression and deformation of polymer granules in the intermeshing zone of the screws is the primary mechanism for melting. A parametric study examined the effects of process parameters like screw speed, temperature, screw configuration, and material type on initial melting.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

250 Ansichten4 SeitenInvestigation of The Plastification Behavior of Polymers in High-Speed Twin Screw Extruders

Hochgeladen von

Reza MansouriehThis document summarizes an investigation into the initial melting processes of polymers in high-speed twin screw extruders. Experiments were conducted using a test stand that allowed high-speed visualization of a cross-section of the plasticization zone. The experiments showed that plastic energy dissipation during compression and deformation of polymer granules in the intermeshing zone of the screws is the primary mechanism for melting. A parametric study examined the effects of process parameters like screw speed, temperature, screw configuration, and material type on initial melting.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Proceedings of the Polymer Processing Society 28th Annual Meeting ~ PPS-28 ~ December 11-15, 2012, Pattaya (Thailand)

INVESTIGATION OF THE PLASTIFICATION BEHAVIOR OF POLYMERS

IN HIGH-SPEED TWIN SCREW EXTRUDERS

G. Spohr

1

, A. Knieper

2

, C. Beinert

3

*

1

Mechanical and Process Engineering, Technical University Darmstadt, Germany GuntramSpohr@gmail.com

2

Dutch Polymer Institute (DPI), PO Box 902, 5600 AX Eindhoven, the Netherlands

Alexander.Knieper@lbf.fraunhofer.de

3

Polymer Processing, Div. Plastics, Fraunhofer-Institute LBF, Germany Christian.Beinert@lbf.fraunhofer.de;

Abstract - A test stand to observe movement and deformation of thermoplastic polymers in a cross section of the

plastification zone of a co-rotating twin screw extruder is presented. Multiple experiments to examine the initial melting

processes in dependence of different process parameters such as rotational speed, temperature, kneading disk

configuration, polymeric material, granule size and filling degree were conducted. The focus thereby was the

visualization of underlying effects by high-speed imaging. This allowed gaining insights into the basic energy

dissipation mechanisms and the most significant process parameters for the initial melting process.

Keywords: Twin-screw extruder, plastic energy dissipation, initial melting, visualization

Introduction

Research Objective

Since up to 80% of the energy input in a co-TSE

extruder takes place in the plastification zone [1], the

optimization of the plastification process offers the

highest potential for an increase of the economic

efficiency by energy savings, improvement of material

properties and increase of throughput.

The objective of this work is therefore studying the

process of initial melting by experimental

investigations in the plastification zone of a high-speed

co-TSE. Here the responsible mechanisms for energy

input into the polymer are friction, heat transfer, plastic

and viscous deformation [1]. The mechanisms are

thereby coupled and change throughout the

plastification zone. They are also dependent onto

multiple parameters such as rotational speed,

temperature, kneading disk configuration, material

properties, granule geometry, filling degree, local

pressure, residence time, etc. The differentiation of the

four heating mechanisms is therefore difficult.

In order to have a basis for the development of new

melting models which are suitable for high-speed co-

TSE a visualization of the plastification zone was

conducted. Because the effects especially in a cross

section of the plastification zone have never been

observed, a test-stand that allowed looking at the side

faces of two kneading blocks was designed and built.

High-speed imaging of deformation, movement and

melting of the granules in the cross section of the

plastification zone led to further insights into

underlying effects.

State of the art

First models to describe plastification in extruders were

based on models for single screw extruders [2], [3], [4].

The models are based on the assumption of continuous

solid melting (CSM) which postulates a solid bed of

granules surrounded by a pool of melt. These models

are based on a continuous channel for material flow at

low rpm. Thus they do not describe the melting

processes adequately in twin screw extruders.

Therefore dispersed solid melting models (DSM) were

developed [5], [6], [7]. They assume that granules are

dispersed in melt. The melting of solids is thereby

related to the dissipation of energy in the melt and

conduction of energy from melt to solids. These

models describe the melting process in twin screw

extruders much better and are nowadays mainly used in

commercial extruder software.

The main problem with the DSM models is that the

initial melting is neglected in all these models. They

are only valid for granules surrounded by a polymer

melt matrix. Since at least 25% (for spherical

geometries) of the material must be melted for granules

to be embedded in melt, all energy dissipation

mechanisms up to this point are neglected. But because

plastic energy dissipation is the primary energy

dissipation mechanism for initial melting it plays a

significant role. It cannot be neglected for complete

modeling of the melting process. Thought examination

of plastic energy dissipation in polymers was already

conducted by [8], [9], [10], [11], [12], [13], melting

models still lack accuracy. In order to expand the

knowledge of the underlying mechanisms and process

parameters, experimental investigations on co-TSE

extruders are necessary. This will allow generating

melting models that integrate the initial melting.

Experimental

Experimental Setup

For the experiments a Coperion ZSK32 high-speed co-

TSE was used. The overall length of the extruder was

reduced to an L/D ratio of 21. The shafts protruded the

extruder for approximately 70mm. The partial length of

shaft inside the extruder was equipped with conveying

elements; onto the screw tip kneading disks were

mounted. This allowed positioning the first

O-05-166

Proceedings of the Polymer Processing Society 28th Annual Meeting ~ PPS-28 ~ December 11-15, 2012, Pattaya (Thailand)

compression zone and thus the plastification zone in

our test stand as seen in Fig. 1 and Fig. 3.

Figure 1 Screw and extruder configuration

The test stand allowed positioning of a window 1/10th

of a millimeter away from the side faces of the last

kneading disks and thus allowed observation of the

processes in the plastification zone.

Design of the Test Stand

The test stand (Fig. 2) consists out of three different

parts:

The first part is the "granule removal plate" (green). It

is directly mounted onto the endplate (blue) of the

extruder. It is necessary for running the extruder

continuously, without filling of the "plastification

zone". An opening allows exiting of granules out of the

extruder. By inserting the slider (grey) into the test

stand the experiment is started.

The second part, the "plastification zone plate"

(orange), allows positioning the last kneading disk pair

in plane with the raise (in the middle). Also sliding

rails (red) were welded onto the "plastification zone"

The third part is the "sledge", in which a window is

mounted. The sledge (and thus the window) slides on

the rails (red). With screws (blue) the pressure of the

window onto the raise on the "plastification zone plate"

can be adjusted. This is done by tightening or

loosening springs (not shown) which are mounted onto

the screws (blue). At a predefined pressure inside the

plastification zone the sledge thus moves away from

the "plastification zone plate", allowing granules to exit

the extruder at the end. This prevents brakeage of the

window. For window material a 10mm polycarbonate

plate was used. It was cut to fit into the sledge. Two

holes were milled into the windows to allow the shafts

to protrude the window. The windows were designed

as wear and tear parts.

Figure 2 Cad model of test stand

This setup made it possible to observe movement,

deformation and melting of granules in a cross section

of the plastification zone. The experiments were

recorded by high-speed imaging with 3000 fps. This

allowed recording of around 5 seconds. In this

timespan the observation of the kneading disks from

completely empty to completely filled and partly

melted was possible. A window thereby inhibited any

movement of granules out of the extruder until a

predefined pressure was exceeded. It therefore acted as

"back"-conveying elements.

Figure 3 Test setup (left) and schematic of window

position at the screw tip (right)

A parametric study of the initial melting with variation

of process parameters such as rotational speed,

temperature, kneading disk configuration, polymeric

material, granule size and filling degree inside the

melting zone was conducted.

Results and Discussion

Plastic Energy Dissipation in the Intermeshing Zone

It was shown that the energy required for melting is

primarily dissipated during one heavy, plastic

deformation in the intermeshing zone. Granules get

trapped between the active flanks and the upper or

lower wedge, the intermeshing zone. The granules are

thereby compressed into the void volume (~ 40% of

bulk volume) and the compressed bulk is deformed

(Fig. 4).

Both mechanisms lead to plastic deformation and thus

plastic energy dissipation in approximately 0.005

seconds (@ 1200rpm). High strain rates of the material

occur. Furthermore a hydrostatic stress is existent

because granules are enclosed on all sides while

compression and deformation take place.

Figure 4 Compression of polypropylene granules in

the intermeshing zone

Compression in Front of Active Flank

Compression in front of the active flank (Fig. 5) can be

observed during the experiments. Friction of granules

on the cylinder wall compresses material in front of the

active flank. Energy dissipation due to friction on the

extruder wall was thereby not observed to heat material

significantly. Heating only occurs due to "compression

into the void volume".

Figure 5 Compression of polyamide granules in front

of the active flank

Influence of Granule Size

Granule size has the biggest influence onto heating and

melting of polymer material. Small granules thereby

heat up slower than large granules. Reason for this is

Proceedings of the Polymer Processing Society 28th Annual Meeting ~ PPS-28 ~ December 11-15, 2012, Pattaya (Thailand)

that small granules show an increased tendency to

evade compression and deformation by flowing out of

the intermeshing zone (Fig. 6).

Figure 6 Small granules at low filling degrees

Large granules by contrast tend to get caught between

the kneading disks and the wedge even at low filling

degrees (Fig. 7). Granules that get caught thereby stop

any further movement of other granules through the

intermeshing zone. The amount of material that is

caught in the intermeshing zone is thus higher.

Therefore the material has to undergo heavier

deformation and heats up much faster.

Figure 7 Large granules at low filling degrees

This dependence of plastic energy dissipation onto

granule geometry is a significant scale-up problem for

initial melting. A melting process that is optimized for

one extruder size, may not work for another.

Influence of Filling Degree / Pressure

The second important influence onto melting behavior

of granules is the filling degree inside the plastification

zone. It is observable that flow of (small) granules

through the intermeshing zone decreases with

increasing filling degree: Because all space is already

filled by material, granules cannot evade compression

and deformation. Additionally the melting degree

increase with increasing amount of material used for

experimentation (Fig. 8). While at low filling degrees

and small granule sizes no plastic energy dissipation is

present, it increases rapidly at highest filling degrees.

Figure 8 Small granules at highest filling degrees

Only 10 to 14 compression and deformation cycles in a

fully filled plastification zone are then needed to

dissipate enough energy to partially melt all granules.

This equals 5 to 7 rotations.

With increasing amount of material used during

experimentation the pressure inside the plastification

zone as well as the melting degree increased. It

therefore seems reasonable that the hydrostatic stress,

which increases the compressive strength, is relevant

for increasing the amount of dissipated energy.

Influence of Rotational Speed on Granules

Experiments with two different rotational speeds (120

rpm & 1200rpm) were conducted. No dependence of

plastic and frictional energy dissipation onto the

rotational speed could be observed for granules. So

although the compressive strength increases at high

strain rates, no significant change of the amount of

energy that was dissipated per rotation resulted.

The experiments were also conducted with white PA12

powder (diameter: 80-120m) mixed with soot

coagulates. Here a significant change of effects in

dependence of the rotational speeds took place:

At lower rpm (120rpm) the soot coagulates were not

destroyed. No significant amount of plastic or frictional

energy was dissipated (Fig. 9).

Figure 9 Polyamide Powder mixed with soot

coagulates at 120rpm

At 1200rpm however some coagulates were already

ground in the conveying section (Fig. 10). High

relative speeds of the screws lead to frictional

destruction. In the plastification zone itself the powder

turned black within only few rotations and the powder

melted together. Plastic energy dissipation was not

observed and is known to decrease with decreasing

particle size. Therefore only friction remains as main

energy dissipation mechanism.

Figure 10 Polyamide Powder mixed with soot

coagulates at 1200rpm

Melting

It can be observed that the bulk of granules does not

heat up evenly; but that a heated (transparent) partial

quantity of granules is transported in front of the active

flank of the kneading disk (similar to the continuous

melting model of [4]). The energy is only dissipated

during the compression and deformation cycles in front

of the active flanks. The partial quantity of heated

granules grows with each rotation until all material is

transparent (Fig. 11).

Figure 11 Melting inside a fully filled kneading zone

with small PP granules

Melting of the bulk of granules starts in front of the

active flanks (highlighted in Fig. 11 on the right).

During around 10 to 14 compression / deformation

cycles (around 5-7 rotations) enough energy is

dissipated for melting.

Proceedings of the Polymer Processing Society 28th Annual Meeting ~ PPS-28 ~ December 11-15, 2012, Pattaya (Thailand)

Furthermore it is observable that, the granules are

embedded in a molten polymer matrix. In contrast to

the side faces of the kneading disks one can

distinctively see granules and melt (Fig. 12).

Figure 12 Melting behavior of small PP granules at

1200rpm and heated extruder wall (120C)

The partially melted mass thereby behaves at first like

granular material. The bulk of granules is pushed in

front of the active flank, it does not flow around the

kneading disks.

After few further rotations the material starts to flow

around the kneading disks.

Due to plastic and viscous energy dissipation the

melting degree increases: The viscosity of the melt-

granules mixture decreases and the mixture starts to

behave like a liquid. The bulk (granular material) does

not exist anymore. From this point on the melting

behavior stands in very good comparison with the

dispersed melting models (DSM).

Because material can flow around the kneading disks,

material can also flow out of the intermeshing zone

during the compression cycles. This results in receding

plastic energy dissipation. Therefore all further energy

can only be dissipated by viscous energy dissipation in

the melt or by heat transfer from heated extruder wall.

Conclusions

It was shown that most energy is dissipated by plastic

energy dissipation during one heavy deformation in the

intermeshing zone. Here granules get trapped between

the wedge and the two kneading disks and have to

undergo compression as well as deformation. It was

confirmed that plastic energy dissipation is the

dominant mechanism for initial melting. The other

energy dissipation mechanisms (friction, heat transfer)

play only a secondary role for initial melting; viscous

energy dissipation can only occur when melt is present.

The rate of energy dissipation was thereby primarily

dependent from the granule size. Large granules were

compressed and deformed heavily and thus heated

quickly, whereas small granules evaded compression

and deformation by flowing out of the intermeshing

zone. Significant heating of small granules occurred

thereby only at highest filling degrees, which lead to

higher hydrostatic stresses.

The rotational speed of the extruder did not have an

observable effect onto the amount of plastic energy

dissipation per rotation. Frictional energy dissipation

increased due to higher relative speeds, but was

thereby only significant for very small particle sizes

(powder) and at high rpm.

The experiments allowed observation of filling of the

plastification zone. The following plastic energy

dissipation led to the initial melting. Observation of

change from granular behavior to liquid behavior was

possible. Therefore the complete initial melting process

was visualized up to the point where the DSM models

describe the further melting process.

Acknowledgements

This work is part of the Research Program of the Dutch

Polymer Institute (DPI), Eindhoven, the Netherlands,

project nr. #671.

The support from the Dutch Polymer Institute, Bayer

Material Science, Bayer Technology Services and

DSM is gratefully acknowledged.

References

1. B. Qian; C. Gogos, Adv. Polym. Techn. 2000, 4,

287.

2. H. Hermann; U. Burkhardt, Kunststoffe 1978, 68,

19.

3. H. Potente; J. Ansahl; B. Klarholz, Intern. Polym.

Proc. 1994, 1, 11.

4. Z. Tadmor, Polym. Eng. Sci. 1966, 3, 185

5. H. Potente, International Polymer Processing,

2001, XVI.

6. P. Bleiman; M. Bulters; P. Elemans; H. Slot in

SPE ANTEC 2002, 456

7. A. Thuemen, PhD Thesis, University Paderborn,

2008.

8. L. Zhu; K. A. Narh, Simulation, 2006, 8, 543.

9. D. Rittel, Mechanics of Materials, 1999, 31, 131.

10. D. Chenouf, AIF-Project, 2007, IGF 13751.

11. L. Zhu; X. Geng, Adv. Polym. Techn. 2002, 3, 188.

12. J. R. A. Pearson, Polymer Engineering and

Science, 1978, 3, 222

13. S. Hei; C. Beinert, Investigation of the

plastification behaviour of polymers in high-speed

co-rotating twin screw extruders, German Institute

for Polymers, Dept. of Plastic Processing

Das könnte Ihnen auch gefallen

- Extrusion ProcessDokument35 SeitenExtrusion ProcessNam NguyenNoch keine Bewertungen

- Polymer Extrusion Experimental Report: April 2018Dokument9 SeitenPolymer Extrusion Experimental Report: April 2018Mehmet Sarı100% (1)

- Extrusion Simulation and Experimental Validation To Optimize Precision Die DesignDokument5 SeitenExtrusion Simulation and Experimental Validation To Optimize Precision Die DesignFethi Arslan KılınçNoch keine Bewertungen

- Mechanical Characterization of Talc Particle Filled ThermoplasticsDokument14 SeitenMechanical Characterization of Talc Particle Filled ThermoplasticsideepujNoch keine Bewertungen

- Waseem IntrDokument9 SeitenWaseem IntrDarshan R GorpadeNoch keine Bewertungen

- TS Extruder GuideDokument11 SeitenTS Extruder GuideKhaulla AwanNoch keine Bewertungen

- Investigation of Wet Ceramic Extrusion PDFDokument16 SeitenInvestigation of Wet Ceramic Extrusion PDFHector RamírezNoch keine Bewertungen

- Diesel Effect Problem Solving During Injection MouldingDokument6 SeitenDiesel Effect Problem Solving During Injection MouldingJohn WayneNoch keine Bewertungen

- Parameter PETDokument9 SeitenParameter PETRahul yadavNoch keine Bewertungen

- Tham KhaoDokument12 SeitenTham KhaoTuan DoNoch keine Bewertungen

- Injection MoldingDokument5 SeitenInjection MoldingRodrigo AndradeNoch keine Bewertungen

- Plastic Processes - FINALDokument48 SeitenPlastic Processes - FINALswap dNoch keine Bewertungen

- Experiment 4Dokument9 SeitenExperiment 4Kelvin LimNoch keine Bewertungen

- Polymers: Ffects of The Processing Parameters On The ShearDokument16 SeitenPolymers: Ffects of The Processing Parameters On The Shearnana jangNoch keine Bewertungen

- Formation of Tungsten Carbide Coatings With Different Thermal Spray GunsDokument5 SeitenFormation of Tungsten Carbide Coatings With Different Thermal Spray GunssajeelaqdasNoch keine Bewertungen

- Residual Stress Development During The Composite Patch Bonding Process: Measurement and ModelingDokument12 SeitenResidual Stress Development During The Composite Patch Bonding Process: Measurement and ModelingIris SousaNoch keine Bewertungen

- An Introduction To The Design, Manufacture and Application of Plastic OpticsDokument10 SeitenAn Introduction To The Design, Manufacture and Application of Plastic OpticsScribe.coNoch keine Bewertungen

- M.F Hot Drape FormingbDokument28 SeitenM.F Hot Drape FormingbKassahun FerdaNoch keine Bewertungen

- The Influence of Cure Pressure On Microstructure, Temperature Field and Mechanical Properties of Advanced Polymer-Matrix Composite LaminatesDokument6 SeitenThe Influence of Cure Pressure On Microstructure, Temperature Field and Mechanical Properties of Advanced Polymer-Matrix Composite LaminatesAbd BaghadNoch keine Bewertungen

- Design of Injection Mould Tool For Rubber Seal Used in Water HeaterDokument7 SeitenDesign of Injection Mould Tool For Rubber Seal Used in Water HeaterAgonafirNoch keine Bewertungen

- Com Moulding ThermoplasticsDokument9 SeitenCom Moulding ThermoplasticsAngel LagrañaNoch keine Bewertungen

- 30 Polyester Films Vol. 11Dokument12 Seiten30 Polyester Films Vol. 11ichsan hakimNoch keine Bewertungen

- Fabrication of Gear Type Injection Moulding AchineDokument29 SeitenFabrication of Gear Type Injection Moulding AchineAnonymous ITnkbIEF75% (4)

- Plastics and CompositesDokument23 SeitenPlastics and CompositesAamir RashidNoch keine Bewertungen

- Compression Molding Is A Method ofDokument4 SeitenCompression Molding Is A Method ofsathishpantaloonNoch keine Bewertungen

- Jem1853 PDFDokument12 SeitenJem1853 PDFNikhil AherNoch keine Bewertungen

- Optimizing Plastic Extrusion Process Via Grey Wolf Optimizer Algorithm and Regression AnalysisDokument8 SeitenOptimizing Plastic Extrusion Process Via Grey Wolf Optimizer Algorithm and Regression Analysissubramanya1982Noch keine Bewertungen

- Processing of Plastics PDFDokument61 SeitenProcessing of Plastics PDFCh Talha0% (1)

- 10 1 1 193 1767Dokument4 Seiten10 1 1 193 1767Jaime A. PascualNoch keine Bewertungen

- Fundamentals of Twin-Screw Extrusion Polymer Melting: Common Pitfalls and How To Avoid ThemDokument6 SeitenFundamentals of Twin-Screw Extrusion Polymer Melting: Common Pitfalls and How To Avoid ThemPrasanth VeeraNoch keine Bewertungen

- Development of Unconventional Forming MethodsDokument8 SeitenDevelopment of Unconventional Forming MethodshemanththulasiNoch keine Bewertungen

- AIMCAL 3M-McclureDokument13 SeitenAIMCAL 3M-McclureLAB9 MEXICONoch keine Bewertungen

- Issues Related To Processability During The Manufacture of Thermoplastic Composites Using On-Line Consolidation TechniquesDokument17 SeitenIssues Related To Processability During The Manufacture of Thermoplastic Composites Using On-Line Consolidation Techniquesduchm-tfaNoch keine Bewertungen

- Proceduri de Productie A Materialelor Compozite Metalice Prin Topire Si PresaDokument4 SeitenProceduri de Productie A Materialelor Compozite Metalice Prin Topire Si PresaMircea GhitulescuNoch keine Bewertungen

- IJRTI1706014Dokument5 SeitenIJRTI1706014kouam mbida stephane durelNoch keine Bewertungen

- Thermoforming of Glass Fibre Reinforced Polypropylene: A Study On The Influence of Different Process ParametersDokument7 SeitenThermoforming of Glass Fibre Reinforced Polypropylene: A Study On The Influence of Different Process Parametershalil yıldırımNoch keine Bewertungen

- ARBURG-Examples of Multi Component Mould Designs GB PDFDokument40 SeitenARBURG-Examples of Multi Component Mould Designs GB PDFkfaravNoch keine Bewertungen

- 11 - Coating and LaminationDokument8 Seiten11 - Coating and LaminationIlton EduardoNoch keine Bewertungen

- Filling Stage - Compression - Injection MouldingDokument17 SeitenFilling Stage - Compression - Injection Mouldinghello hiNoch keine Bewertungen

- Injection Moulding Lab ReportDokument27 SeitenInjection Moulding Lab ReportErnie Yana IINoch keine Bewertungen

- JEM1853Dokument12 SeitenJEM1853Harsh SolankiNoch keine Bewertungen

- Polymer Processing HandoutDokument68 SeitenPolymer Processing HandoutibraheemNoch keine Bewertungen

- Effects of Polymer Melt Compressibility On Mold Filling in Micro Injection MoldingDokument10 SeitenEffects of Polymer Melt Compressibility On Mold Filling in Micro Injection MoldingOakmeNoch keine Bewertungen

- Interacademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.Von EverandInteracademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.Noch keine Bewertungen

- Accepted Manuscript: Composites: Part ADokument17 SeitenAccepted Manuscript: Composites: Part AMarko PopovićNoch keine Bewertungen

- Wocke Auc2008Dokument16 SeitenWocke Auc2008klomps_jrNoch keine Bewertungen

- Comparison of The Processing of Epoxy Resins in Pultrusion With Open Bath Impregnation and Closed-Injection PultrusionDokument11 SeitenComparison of The Processing of Epoxy Resins in Pultrusion With Open Bath Impregnation and Closed-Injection PultrusionfahadNoch keine Bewertungen

- TrosDokument14 SeitenTrosyeabsira getachewNoch keine Bewertungen

- Novel Concepts For The Design of Moulds and Equipment For ExpandedDokument8 SeitenNovel Concepts For The Design of Moulds and Equipment For ExpandedJOSE GNoch keine Bewertungen

- Polymers: Modeling of Flexible Polyurethane Foam Shrinkage For Bra Cup Moulding Process ControlDokument13 SeitenPolymers: Modeling of Flexible Polyurethane Foam Shrinkage For Bra Cup Moulding Process ControlMansi ChaudhariNoch keine Bewertungen

- 8 Adopting FullDokument16 Seiten8 Adopting FullTJPRC PublicationsNoch keine Bewertungen

- Screw Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyDokument7 SeitenScrew Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyPaulo Canedo da SilvaNoch keine Bewertungen

- Compression Moulding Process - An Overview Ijariie11168Dokument10 SeitenCompression Moulding Process - An Overview Ijariie11168ARUN KUMAR KoterimadathilNoch keine Bewertungen

- AERO2289 Tensiles LabFinalDokument23 SeitenAERO2289 Tensiles LabFinalShanaka JayasekaraNoch keine Bewertungen

- Doctor Blade TechniqueDokument4 SeitenDoctor Blade Techniquearunbalaji86Noch keine Bewertungen

- 10.0000@Www - Fujipress.jp@generic 29FA4A78D074Dokument2 Seiten10.0000@Www - Fujipress.jp@generic 29FA4A78D074binukumar100Noch keine Bewertungen

- Kast Et Al-2015-Polymer Engineering ScienceDokument8 SeitenKast Et Al-2015-Polymer Engineering ScienceSy Nguyen VietNoch keine Bewertungen

- Design of A Micro Injection Moulding Machine For Thermosetting Moulding MaterialsDokument3 SeitenDesign of A Micro Injection Moulding Machine For Thermosetting Moulding Materialsregil01Noch keine Bewertungen

- GemDokument135 SeitenGemZelia GregoriouNoch keine Bewertungen

- Curriculum Vitae: Personal InformationDokument3 SeitenCurriculum Vitae: Personal InformationMira ChenNoch keine Bewertungen

- Athena 60 Installation Manual EN 2022.07.03Dokument30 SeitenAthena 60 Installation Manual EN 2022.07.03joaquin.cadondonNoch keine Bewertungen

- Kofax Cross Product Compatibility MatrixDokument93 SeitenKofax Cross Product Compatibility MatrixArsh RashaNoch keine Bewertungen

- SET UP Computer ServerDokument3 SeitenSET UP Computer ServerRicHArdNoch keine Bewertungen

- StatisticsAllTopicsDokument315 SeitenStatisticsAllTopicsHoda HosnyNoch keine Bewertungen

- A Professional Ethical Analysis - Mumleyr 022817 0344cst 1Dokument40 SeitenA Professional Ethical Analysis - Mumleyr 022817 0344cst 1Syed Aquib AbbasNoch keine Bewertungen

- Lesson 73 Creating Problems Involving The Volume of A Rectangular PrismDokument17 SeitenLesson 73 Creating Problems Involving The Volume of A Rectangular PrismJessy James CardinalNoch keine Bewertungen

- Gastric Emptying PresentationDokument8 SeitenGastric Emptying Presentationrahul2kNoch keine Bewertungen

- Sayyid DynastyDokument19 SeitenSayyid DynastyAdnanNoch keine Bewertungen

- Dummies Guide To Writing A SonnetDokument1 SeiteDummies Guide To Writing A Sonnetritafstone2387100% (2)

- 2019 09 20 New Balance Harvard Business CaseDokument7 Seiten2019 09 20 New Balance Harvard Business CaseFrans AdamNoch keine Bewertungen

- Magnetic Effect of Current 1Dokument11 SeitenMagnetic Effect of Current 1Radhika GargNoch keine Bewertungen

- Curriculum Vitae Mukhammad Fitrah Malik FINAL 2Dokument1 SeiteCurriculum Vitae Mukhammad Fitrah Malik FINAL 2Bill Divend SihombingNoch keine Bewertungen

- 37 Sample Resolutions Very Useful, Indian Companies Act, 1956Dokument38 Seiten37 Sample Resolutions Very Useful, Indian Companies Act, 1956CA Vaibhav Maheshwari70% (23)

- Organizational Behavior (Perception & Individual Decision Making)Dokument23 SeitenOrganizational Behavior (Perception & Individual Decision Making)Irfan ur RehmanNoch keine Bewertungen

- 2017 - The Science and Technology of Flexible PackagingDokument1 Seite2017 - The Science and Technology of Flexible PackagingDaryl ChianNoch keine Bewertungen

- De Luyen Thi Vao Lop 10 Mon Tieng Anh Nam Hoc 2019Dokument106 SeitenDe Luyen Thi Vao Lop 10 Mon Tieng Anh Nam Hoc 2019Mai PhanNoch keine Bewertungen

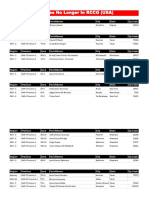

- Churches That Have Left RCCG 0722 PDFDokument2 SeitenChurches That Have Left RCCG 0722 PDFKadiri JohnNoch keine Bewertungen

- Final ReflectionDokument4 SeitenFinal Reflectionapi-314231777Noch keine Bewertungen

- Xavier High SchoolDokument1 SeiteXavier High SchoolHelen BennettNoch keine Bewertungen

- Irregular Verbs-1Dokument1 SeiteIrregular Verbs-1timas2Noch keine Bewertungen

- Mooting ExampleDokument35 SeitenMooting Exampleluziro tenNoch keine Bewertungen

- Introduction To Philosophy of The Human Person: Presented By: Mr. Melvin J. Reyes, LPTDokument27 SeitenIntroduction To Philosophy of The Human Person: Presented By: Mr. Melvin J. Reyes, LPTMelvin J. Reyes100% (2)

- Standard - Bronze Age - World History Human Legacy TextbookDokument11 SeitenStandard - Bronze Age - World History Human Legacy TextbookChris ChiangNoch keine Bewertungen

- Impact Grammar Book Foundation Unit 1Dokument3 SeitenImpact Grammar Book Foundation Unit 1Domingo Juan de LeónNoch keine Bewertungen

- Engineeringinterviewquestions Com Virtual Reality Interview Questions Answers PDFDokument5 SeitenEngineeringinterviewquestions Com Virtual Reality Interview Questions Answers PDFKalyani KalyaniNoch keine Bewertungen

- Order of Magnitude-2017Dokument6 SeitenOrder of Magnitude-2017anon_865386332Noch keine Bewertungen

- Effect of Added Sodium Sulphate On Colour Strength and Dye Fixation of Digital Printed Cellulosic FabricsDokument21 SeitenEffect of Added Sodium Sulphate On Colour Strength and Dye Fixation of Digital Printed Cellulosic FabricsSumaiya AltafNoch keine Bewertungen

- Transfer Pricing 8Dokument34 SeitenTransfer Pricing 8nigam_miniNoch keine Bewertungen