Beruflich Dokumente

Kultur Dokumente

Piping Reinstatement: Inspection Test Report Form No

Hochgeladen von

FranciscoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Piping Reinstatement: Inspection Test Report Form No

Hochgeladen von

FranciscoCopyright:

Verfügbare Formate

Project No:

Name:

Client:

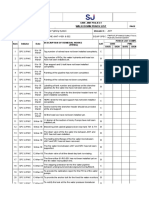

INSPECTION TEST REPORT

PIPING REINSTATEMENT

A Mechanical Completion

FORM NO:

P-05A

Project Phase:

Scope Owner :

ITR Item:

Tag No: Other Tag No:

Description:

System:

Sub-System:

Location:

Drawing No: Rev:

Form: ITR Rev.: Page 1 of 2 Printed:

ITR Instructions:

This ITR shall be read in conjunction with

(i) Mechanical Completion / Commissioning / Hand Over Management Manual.

ITR Acti vities:

Activity No:

Inspection Activity

Complete

Yes No N/A

1 Check that all pipework has been flushed and hydrostatic testing has been satisfactorily completed and recorded, drained, vented and dried.

2 Check that the flange alignment is correct and that the correct bolts and gaskets are installed at all mechanical joints to the correct torque setting,

bolts have been lubricated.

3 Visually check that pipe compound on screwed connections is to specifications.

4 Check that all temporary vents and drains have been removed.

5 Check that all process blinds, spectacle blinds, and spacers have been correctly installed as indicated on the P&ID.

6 Verify blanks, Vents and Drain plugs are correct materials pressure rating and installed correctly.

7 For fire fighting pipe system ensures the following devices are reinstated; Sprinkler heads / rosettes / nozzles are reinstated.

8 For fire fighting pipe system ensures the following devices are reinstated; Hoses and Hose couplings reinstated.

9 For fire fighting pipe system ensures the following devices are reinstated; Monitors and hydrants reinstated.

10 For fire fighting pipe system ensures the following devices are reinstated; Discharge agent heads reinstated.

11 For fire fighting pipe systems ensure the following devices are reinstated; Foam monitors reinstated.

12 Check that all temporary pipe spools have been removed and all control valves and internals have been re-instated in the correct flow position.

13 Ensure that all check valve internals have been re-instated and the valve has been installed in the correct flow direction, and any "jack open"

devices have been removed.

14 Where dissimilar metal(s) spec breaks are located are identified on P&ID's, Confirm material grades are correct and correct isolation kits are

installed.

15 Ensure valve key interlock has been installed, interlocking function verified & Key handed over to commissioning.

16 Check that all relief valves have been correctly installed.

17 Check that all gauges have been correctly installed.

18 Check that all pump suction strainers have been correctly installed.

19 Check that all chain wheels and extended spindles to specified valves are installed.

20 Ensure that the valve spindles are lubricated

21 Check that all pipes, including supports, have been installed as per design.

Note for Special piping item:

22 Ensure for Corrosion coupon / Erosion probes Fitting (body) and plug is installed and verified.

23 Verify the space for corrosion coupon retrieval is adequate

24 Confirm baseline weight survey done & report available in MDR.

25 Take Photographic evidence conforming corrosion coupons has been installed properly.

26 Installation of other (Chemical Injection Quill,etc) Special Piping Parts (SPP) completed.

27 Take photographic evidence confirming a chemical injection quills component has been installed.

Pyrenees Dry Dock

TR.003 - Piping

DTM DebottIenecking - SwiveI Tie in SAS LeveI

DTM DebottIenecking - SwiveI Tie in SAS LeveI

0 - 25-Sep-2013 03-Oct-2013 19:47:53 PM

ptcid:[27C4C8D203FB]

Project No:

Name:

Client:

INSPECTION TEST REPORT

PIPING REINSTATEMENT

A Mechanical Completion

FORM NO:

P-05A

Project Phase:

Scope Owner :

ITR Item:

Tag No: Other Tag No:

Description:

System:

Sub-System:

Location:

Drawing No: Rev:

Form: ITR Rev.: Page 2 of 2 Printed:

28 Take photographic evidence confirming Orifice Plate has been installed properly & handled is stamped with design data.

29 Check all exposed spectacle blinds have clean faces and wrapped in denso tape to prevent corrosion.

30 Painting and Coating completed as per specifications and undamaged. Piping service color coding (Band) and flow direction marks completed.

31 Insulation completed as per specifications and undamaged.

32 Check all exposed RTJ, RF, Clamp / HUB Joints have clean faces and are wrapped in Denso tape to prevent Damage /corrosion.

33 Red line drawings / Final AFC drawings attached.

Punchlist Raised (In above, any item marked No should be recorded as Punchlist item below)

No Yes

Item

No

Description of Punch Item Punchlist

Type Code

Category

(A/B)

Action By

Inspector Comments:

ITR Signatures:

VENDOR / CONTRACTOR MODEC QA/QC CERT.AUTH (IF APPL) PT INPUT

Print Name:

Signature:

Title:

Date:

Pyrenees Dry Dock

TR.003 - Piping

DTM DebottIenecking - SwiveI Tie in SAS LeveI

DTM DebottIenecking - SwiveI Tie in SAS LeveI

0 - 25-Sep-2013 03-Oct-2013 19:47:53 PM

ptcid:[27C4C8D203FB]

Das könnte Ihnen auch gefallen

- Flang ManegmentDokument12 SeitenFlang ManegmentYasser Abd El Fattah100% (1)

- ChecksheetDokument423 SeitenChecksheetAbdul Hakam Mohamed Yusof100% (2)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Dokument24 SeitenItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Piping Fabrication Installation QCP On SiteDokument1 SeitePiping Fabrication Installation QCP On SiteTarun PatelNoch keine Bewertungen

- Petronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - ADokument5 SeitenPetronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - AAbang Shahrin Abang IdinNoch keine Bewertungen

- 033-Itp For Piping Installation Ag and Ug PDFDokument13 Seiten033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- Ag Test Package FormatDokument25 SeitenAg Test Package FormatoparoystNoch keine Bewertungen

- ITP For Piping SystemsDokument6 SeitenITP For Piping SystemsP SHANKAR BABU100% (16)

- Fit Up Report Format-1Dokument1 SeiteFit Up Report Format-1BalkishanDyavanapellyNoch keine Bewertungen

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- Itp For Carbon Steel PipeDokument9 SeitenItp For Carbon Steel PipehamedpdmsNoch keine Bewertungen

- Pressure Test & Test Pack ManagementDokument43 SeitenPressure Test & Test Pack ManagementStanley Alex100% (4)

- ITP For HDPEDokument2 SeitenITP For HDPEAshraf Mohammed75% (4)

- Piping Field Inspection ChecklistDokument2 SeitenPiping Field Inspection Checklistanwarhas0583% (6)

- Piping Release Report (Spool For Paint)Dokument2 SeitenPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Itp For Piping QPDokument4 SeitenItp For Piping QPRejoy baby100% (2)

- Itp For Piping Fabrication and Erection CorrectionDokument4 SeitenItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- Piping Field Inspection Checklist DikonversiDokument3 SeitenPiping Field Inspection Checklist DikonversiJo Francesc100% (2)

- MS-M-063 Rev. 1 - Air Fin Cooler InstallationDokument6 SeitenMS-M-063 Rev. 1 - Air Fin Cooler InstallationwalitedisonNoch keine Bewertungen

- Flange Management Register PDFDokument1 SeiteFlange Management Register PDFsudeesh kumar100% (1)

- Daily Welding Progress ReportDokument1 SeiteDaily Welding Progress ReportManoj KumarNoch keine Bewertungen

- Equipment Erection, Static and RotaryDokument8 SeitenEquipment Erection, Static and RotaryHamada ELaraby60% (5)

- Attachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7Dokument66 SeitenAttachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7indusampath100% (2)

- Sadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingDokument1 SeiteSadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingSiddiqui Abdul KhaliqNoch keine Bewertungen

- JIMT Fire Fighting System Pre Commissioning Punch List (Piping)Dokument9 SeitenJIMT Fire Fighting System Pre Commissioning Punch List (Piping)Gomathyselvi100% (1)

- TOC Mechanical Complation DossierDokument3 SeitenTOC Mechanical Complation DossierMiftah Masrur0% (1)

- Flange Management Register: Dr. Concrete Building Material General Contracting & Trading FZEDokument1 SeiteFlange Management Register: Dr. Concrete Building Material General Contracting & Trading FZEsudeesh kumar100% (1)

- Bolted Flanged Joints New Methods Practices ProceedingsDokument2 SeitenBolted Flanged Joints New Methods Practices ProceedingsMladen ČorokaloNoch keine Bewertungen

- Hydrotest Test PacksDokument1 SeiteHydrotest Test Packsswaraj4u50% (2)

- Method Statement For Field LaminationDokument13 SeitenMethod Statement For Field Laminationkais rguigui0% (1)

- Inspection and Test Plan - PipingDokument15 SeitenInspection and Test Plan - PipingFerdie OS100% (5)

- ITP Installation of Static EquipmentDokument3 SeitenITP Installation of Static EquipmentAwais Tariq90% (10)

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDokument36 SeitenDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823Noch keine Bewertungen

- Check List For Installation of Local Instruments.Dokument1 SeiteCheck List For Installation of Local Instruments.Jaya SeelanNoch keine Bewertungen

- Report No. TA-V-1456Dokument2 SeitenReport No. TA-V-1456u04ajf3Noch keine Bewertungen

- Piping NDT Request Quality Control and Inspection FormDokument1 SeitePiping NDT Request Quality Control and Inspection FormEdison WalitNoch keine Bewertungen

- Procedure For Piping Hydrostatic Pressure Test - 15124-MS-M-006 Rev-1Dokument17 SeitenProcedure For Piping Hydrostatic Pressure Test - 15124-MS-M-006 Rev-1Midhun K Chandrabose100% (3)

- QC Dossier For Mechanical Completion: IndexDokument3 SeitenQC Dossier For Mechanical Completion: IndexJoel Alcantara80% (5)

- Qcf301 Hydrotest Package - (Piping) - SampleDokument1 SeiteQcf301 Hydrotest Package - (Piping) - Sampleminhnn75% (4)

- 3 - Hdpe - Itp Pipe WeldingDokument2 Seiten3 - Hdpe - Itp Pipe WeldingAttiq Ahmad Choudhry89% (9)

- Fabrication Erection and Installation Procedure For PipingDokument60 SeitenFabrication Erection and Installation Procedure For Pipinghasan_676489616Noch keine Bewertungen

- 0.hydro Test Package Index - 1Dokument13 Seiten0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNoch keine Bewertungen

- F-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistDokument1 SeiteF-Qa-03a Material - Receiving - Storage and Handling Inspection ChecklistHilal mohamedNoch keine Bewertungen

- ITP For Site Installation of Pipe Rev 1 15.07.10Dokument4 SeitenITP For Site Installation of Pipe Rev 1 15.07.10Rejoy babyNoch keine Bewertungen

- Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDokument4 SeitenItp For Hvac (Heating Ventilation and Air Conditioning) System InstallationAhmed HassanNoch keine Bewertungen

- 048-Itp For Installation of Hvac Unit PDFDokument8 Seiten048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- Air Blowing ProcedureDokument5 SeitenAir Blowing ProcedureArslan NisarNoch keine Bewertungen

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Dokument28 SeitenField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNoch keine Bewertungen

- Itp PaintingDokument14 SeitenItp PaintingNamta George100% (4)

- Zee-Method Statement For Construction Steel Platform ErectionDokument8 SeitenZee-Method Statement For Construction Steel Platform Erectionzeeshansheikh7Noch keine Bewertungen

- R057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor PackageDokument10 SeitenR057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor Packagedharwin100% (1)

- Flange Joint Assembly ChecklistDokument2 SeitenFlange Joint Assembly ChecklistRonald Alejandro Bustos Soto100% (1)

- SP-2092 - GRP Specification Qualification and ManufacturingDokument47 SeitenSP-2092 - GRP Specification Qualification and Manufacturingchandana kumar100% (2)

- RTR Pipe Hydrotest ProcedureDokument13 SeitenRTR Pipe Hydrotest ProcedureMohammad Rizwan0% (1)

- Piping Above Ground Installation Work ProcedureDokument38 SeitenPiping Above Ground Installation Work Proceduremanoj thakkar100% (1)

- MOS For Fabrication and InstallationDokument21 SeitenMOS For Fabrication and InstallationDo Van HUNG100% (3)

- Itp Forabove Grade and Embedded Conduits Rev. 0Dokument6 SeitenItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Line History SheetDokument46 SeitenLine History SheetBhanu Pratap Choudhury33% (3)

- Tank Inspectiom ChecksheetDokument3 SeitenTank Inspectiom Checksheetyskushwah16100% (1)

- Petronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - A Piping Work Completion P01-ADokument21 SeitenPetronas Carigali Sdn. Bhd. Inspection Test Record (Itr) - A Piping Work Completion P01-AWael Chouchani100% (2)

- Vi35 San GuideDokument43 SeitenVi35 San Guideapi-3824328Noch keine Bewertungen

- BBRAUNDokument9 SeitenBBRAUNLuis RosasNoch keine Bewertungen

- 1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)Dokument84 Seiten1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)khanh phanNoch keine Bewertungen

- Lab 11 12 ECA HIGH AND LOW PASSDokument32 SeitenLab 11 12 ECA HIGH AND LOW PASSAmna EjazNoch keine Bewertungen

- MF 3854 WDDokument96 SeitenMF 3854 WDRizwanAli100% (1)

- Fandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekDokument2 SeitenFandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekCH1253Noch keine Bewertungen

- Luyện tâp Liên từ Online 1Dokument5 SeitenLuyện tâp Liên từ Online 1Sơn KhắcNoch keine Bewertungen

- Colebrook EquationDokument3 SeitenColebrook EquationMuhammad Ghufran KhanNoch keine Bewertungen

- TDS - Masterkure 106Dokument2 SeitenTDS - Masterkure 106Venkata RaoNoch keine Bewertungen

- West Zone: South-West Zone: South Zone: Central Zone: North Zone: North West Zone: East ZoneDokument6 SeitenWest Zone: South-West Zone: South Zone: Central Zone: North Zone: North West Zone: East ZoneKanupriyamNoch keine Bewertungen

- Filtration 2Dokument5 SeitenFiltration 2Ramon Dela CruzNoch keine Bewertungen

- 26-789 Eng Manual Pcd3Dokument133 Seiten26-789 Eng Manual Pcd3Antun KoricNoch keine Bewertungen

- NCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsDokument26 SeitenNCP81243 Dual Output 3 & 2 Phase Controller With Single Intel Proprietary Interface For Desktop and Notebook CPU ApplicationsAhmed Sherif CupoNoch keine Bewertungen

- Guidelines For Xii Plan: Ther Backward Classes (Obc)Dokument15 SeitenGuidelines For Xii Plan: Ther Backward Classes (Obc)SACHCHIDANAND PRASADNoch keine Bewertungen

- Cap 1Dokument10 SeitenCap 1Oscar Bello LemusNoch keine Bewertungen

- RRLDokument3 SeitenRRLNeil RosalesNoch keine Bewertungen

- Non Domestic Building Services Compliance GuideDokument76 SeitenNon Domestic Building Services Compliance GuideZoe MarinescuNoch keine Bewertungen

- List of The Registered UAE CompaniesDokument3 SeitenList of The Registered UAE Companiesirfan aminNoch keine Bewertungen

- Remuz TreeDokument608 SeitenRemuz TreeEdward JonesNoch keine Bewertungen

- Manual de Serviço PDFDokument394 SeitenManual de Serviço PDFMarcos Antonio de Souza JuniorNoch keine Bewertungen

- Sa 449Dokument8 SeitenSa 449Widya widya100% (1)

- Real Time Blood Type Determination by Gel Test Method On An Embedded SystemDokument4 SeitenReal Time Blood Type Determination by Gel Test Method On An Embedded Systemngocbienk56Noch keine Bewertungen

- Acord and IAADokument4 SeitenAcord and IAABHASKARA_20080% (1)

- Thrust StandDokument43 SeitenThrust StandABHIMANYU KHADGANoch keine Bewertungen

- Operating System ComponentsDokument59 SeitenOperating System ComponentsJikku VarUgheseNoch keine Bewertungen

- Timetable Victoria Chichester PDFDokument2 SeitenTimetable Victoria Chichester PDFLizzie CosterNoch keine Bewertungen

- Computer Science Ram PresentationDokument11 SeitenComputer Science Ram Presentationapi-268896185100% (3)

- SDLCDokument2 SeitenSDLCTahseef RezaNoch keine Bewertungen

- Trumpf TruSystem 7500 Service ManualDokument424 SeitenTrumpf TruSystem 7500 Service ManualVitor FilipeNoch keine Bewertungen

- REVIEWDokument12 SeitenREVIEWGoka Agbesi GokaNoch keine Bewertungen