Beruflich Dokumente

Kultur Dokumente

Nikko R. Nacion

Hochgeladen von

Ashraf Rios KhaterOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nikko R. Nacion

Hochgeladen von

Ashraf Rios KhaterCopyright:

Verfügbare Formate

Nikko R.

Nacion

PULTRUSION - The term pultrusion combines the words, "pull" and "extrusion". Extrusion is

the pushing of material, such as a billet of aluminum, through a shaped die. Whereas,

pultrusion, is the pulling of material, such as fiberglass and polymer resin, through a shaped

die.

1. The pultrusion process starts with racks or creels holding rolls of fiber mat or doffs of

fiber roving. Most often the reinforcement is fiberglass, but it can be carbon, aramid,

or a mixture.

2-3. This raw fiber is pulled off the racks and guided through a resin bath or resin

impregnation system. Resin can also be injected directly into the die in some

pultrusion systems. The raw resin is almost always a thermosetting resin, and is

sometimes combined with fillers, catalysts, and pigments. The fiber reinforcement

becomes fully impregnated (wetted-out) with the resin such that all the fiber filaments

are thoroughly saturated with the resin mixture.

4. As the resin rich fiber exits the resin impregnation system, the un-cured composite

material is guided through a series of tooling. This custom tooling helps arrange and

organize the fiber into the correct shape, while excess resin is squeezed out, also

known as debulking. This tooling is known as a pre-former. Often continuous

strand mat and surface veils are added in this step to increase structure and surface

finish.

5. Once the resin impregnated fiber is organized and removed of excess resin, the

composite will pass through a heated steel die. Precisely machined and often

chromed, the die is heated to a constant temperature, and may have several zones of

temperature through-out its length, which will cure the thermosetting resin. The

profile that exits the die is now a cured pultruded Fiber Reinforced Polymer (FRP).

6. This FRP profile is pinched and pulled by a gripper system. Either caterpillar tracks or

hydraulic clamps are used to pull the composite through the pultrusion die on a

continuous basis.

7. At the end of this pultrusion machine is a cut-off saw. The pultruded profiles are cut to

the specific length and stacked for delivery.

Nikko R. Nacion

Through the proper selection of resin and reinforcement, pultrusion offers the designer a

unique blend of performance properties.

High Strength-to-Weight Ratio

Corrosion Resistance

Dielectric Properties

Weatherability

Ease of Fabrication

Dimensional Stability

Heat Resistance

Custom and Unlimited Lengths

Applications

Applications for pultrusions are varied and include permanent and temporary structural

components for industrial plants, vandal-resistant indoor and outdoor public furniture.

Smaller scale applications include electrically insulated ladders, ski poles, fishing rods

and bicycle frames and many more.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Becoming An Effective Tutor - 3 Things You Need To KnowDokument1 SeiteBecoming An Effective Tutor - 3 Things You Need To KnowAshraf Rios KhaterNoch keine Bewertungen

- Five Most Sought-Out Type of TutorsDokument1 SeiteFive Most Sought-Out Type of TutorsAshraf Rios KhaterNoch keine Bewertungen

- Why Is Tutoring Important in The 21st CenturyDokument1 SeiteWhy Is Tutoring Important in The 21st CenturyAshraf Rios KhaterNoch keine Bewertungen

- Electromagnetic EnergyDokument2 SeitenElectromagnetic EnergyAshraf Rios KhaterNoch keine Bewertungen

- Importance of Having A Contract For Tutoring ServicesDokument1 SeiteImportance of Having A Contract For Tutoring ServicesAshraf Rios KhaterNoch keine Bewertungen

- Article 28 - Single Mother Help - How To Deal With FinancesDokument2 SeitenArticle 28 - Single Mother Help - How To Deal With FinancesAshraf Rios KhaterNoch keine Bewertungen

- The Benefits of Tutoring at A Centralized LocationDokument1 SeiteThe Benefits of Tutoring at A Centralized LocationAshraf Rios KhaterNoch keine Bewertungen

- Hiring Tutors 101 What To Look ForDokument1 SeiteHiring Tutors 101 What To Look ForAshraf Rios KhaterNoch keine Bewertungen

- How To Handle Difficult Clients - Should I Work With ThemDokument1 SeiteHow To Handle Difficult Clients - Should I Work With ThemAshraf Rios KhaterNoch keine Bewertungen

- Tackling Math Subjects - Tutoring Tips To ConsiderDokument1 SeiteTackling Math Subjects - Tutoring Tips To ConsiderAshraf Rios KhaterNoch keine Bewertungen

- Role of Beta-Alanine Supplementation On Muscle SummaryDokument1 SeiteRole of Beta-Alanine Supplementation On Muscle SummaryAshraf Rios KhaterNoch keine Bewertungen

- Opening The Gateway To The Egypt-The Gift of The Nile-Through HurghadaDokument3 SeitenOpening The Gateway To The Egypt-The Gift of The Nile-Through HurghadaAshraf Rios KhaterNoch keine Bewertungen

- Calculating Molecular WeightsDokument3 SeitenCalculating Molecular WeightsAshraf Rios KhaterNoch keine Bewertungen

- Article 30 - 4 Organizational Strategies For Increasing Your Business ProductivityDokument2 SeitenArticle 30 - 4 Organizational Strategies For Increasing Your Business ProductivityAshraf Rios KhaterNoch keine Bewertungen

- 2 LipidDokument48 Seiten2 LipidAshraf Rios KhaterNoch keine Bewertungen

- Characterizing PolymersDokument23 SeitenCharacterizing PolymersAshraf Rios KhaterNoch keine Bewertungen

- Impromptu!Dokument1 SeiteImpromptu!Ashraf Rios KhaterNoch keine Bewertungen

- Norick 30B 24continueDokument6 SeitenNorick 30B 24continueAshraf Rios KhaterNoch keine Bewertungen

- Problem Set 4. Energy BalancesDokument4 SeitenProblem Set 4. Energy BalancesAshraf Rios KhaterNoch keine Bewertungen

- Policies and Standards for the BSCHE program (April 23, 2008Dokument15 SeitenPolicies and Standards for the BSCHE program (April 23, 2008Ashraf Rios KhaterNoch keine Bewertungen

- Career Research Paper Name: - Overall GradeDokument2 SeitenCareer Research Paper Name: - Overall GradeAshraf Rios KhaterNoch keine Bewertungen

- An Eco-Friendly Tanning System For Leather ManufactureDokument8 SeitenAn Eco-Friendly Tanning System For Leather ManufactureAshraf Rios KhaterNoch keine Bewertungen

- 05 Periodic Table (4, D)Dokument7 Seiten05 Periodic Table (4, D)Ashraf Rios KhaterNoch keine Bewertungen

- Growing Your Local Section's Outreach To Area High Schools: American Chemical SocietyDokument35 SeitenGrowing Your Local Section's Outreach To Area High Schools: American Chemical SocietyAshraf Rios KhaterNoch keine Bewertungen

- Children in Poverty StoryDokument3 SeitenChildren in Poverty StoryAshraf Rios KhaterNoch keine Bewertungen

- Calculation and Definition of Particle SphericityDokument1 SeiteCalculation and Definition of Particle SphericityJay CruzatNoch keine Bewertungen

- 08 - Separable Differential Equations PDFDokument4 Seiten08 - Separable Differential Equations PDFAshraf Rios KhaterNoch keine Bewertungen

- 2355 Big M SupplementDokument1 Seite2355 Big M SupplementAshraf Rios KhaterNoch keine Bewertungen

- 4 3885 96Dokument5 Seiten4 3885 96Onesiforus Onie'dhimas AsmaraNoch keine Bewertungen

- VBEE WQI Data EXAMPLEDokument4 SeitenVBEE WQI Data EXAMPLEAshraf Rios KhaterNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Daftar Harga PT - Enseval Medika Prima 2003Dokument7 SeitenDaftar Harga PT - Enseval Medika Prima 2003umarNoch keine Bewertungen

- NDE RequestDokument2 SeitenNDE Requestkeymal9195Noch keine Bewertungen

- 14 Plastic ProcessingDokument20 Seiten14 Plastic Processingrkd2743Noch keine Bewertungen

- Fibre Reinforced Plastics PDFDokument2 SeitenFibre Reinforced Plastics PDFAprilNoch keine Bewertungen

- Conveyor Belts For Aluminum Extrusion: The Megadyne GroupDokument8 SeitenConveyor Belts For Aluminum Extrusion: The Megadyne GroupJuan Andrés Díaz RiveroNoch keine Bewertungen

- ARBURG ALLROUNDER 370A TD 526447 en GBDokument6 SeitenARBURG ALLROUNDER 370A TD 526447 en GBARRKAY DESIGN100% (1)

- Po 20161026Dokument33 SeitenPo 20161026MohamadMostafaviNoch keine Bewertungen

- Plastics Reference Standards GuideDokument4 SeitenPlastics Reference Standards GuideFred MundellNoch keine Bewertungen

- Polybenzoxazines: A Non-Halogen Thermoset Resin ChemistryDokument22 SeitenPolybenzoxazines: A Non-Halogen Thermoset Resin ChemistryantikaruNoch keine Bewertungen

- Plastic Injection Training ReportDokument31 SeitenPlastic Injection Training ReportsazmsNoch keine Bewertungen

- Everything You Need to Know About Synthetic RubberDokument10 SeitenEverything You Need to Know About Synthetic RubberSneha SahniNoch keine Bewertungen

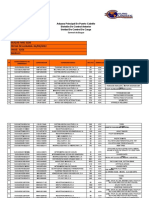

- Puerto Cabello Port Customs Control of MSC ELBE Cargo ManifestDokument19 SeitenPuerto Cabello Port Customs Control of MSC ELBE Cargo ManifestNathan Alexander MillánNoch keine Bewertungen

- Designing With Celanex, Vandar, Impet & Riteflex (ThermoDokument110 SeitenDesigning With Celanex, Vandar, Impet & Riteflex (ThermoAngel AmbNoch keine Bewertungen

- Plastic Product Design With NXDokument8 SeitenPlastic Product Design With NXTungdinh NguyenNoch keine Bewertungen

- Asme NM.3.1-18 PDFDokument470 SeitenAsme NM.3.1-18 PDFPablo DM100% (2)

- Preface 2014 Handbook of Thermoset PlasticsDokument3 SeitenPreface 2014 Handbook of Thermoset Plasticsaslı aslanNoch keine Bewertungen

- Experiment 3 (BFL)Dokument7 SeitenExperiment 3 (BFL)wajahat rasoolNoch keine Bewertungen

- Bond Polymers International BrochureDokument9 SeitenBond Polymers International Brochuregabriel oliveira monteiroNoch keine Bewertungen

- CETP charges chronical defaulters listDokument182 SeitenCETP charges chronical defaulters listdharmender singhNoch keine Bewertungen

- Closing The Carbon Loop in A Circular Plastics EconomyDokument37 SeitenClosing The Carbon Loop in A Circular Plastics Economynganssc.119dbpNoch keine Bewertungen

- Plastics, Wood Ad RubberDokument32 SeitenPlastics, Wood Ad RubberPaul KagunyaNoch keine Bewertungen

- PlasticDokument172 SeitenPlasticNGOC HUYNHNoch keine Bewertungen

- Fameg Pricelist2020 EURDokument99 SeitenFameg Pricelist2020 EURjganso0% (1)

- RUBBER COMPOUNDING: RAW MATERIALS AND APPLICATIONSDokument16 SeitenRUBBER COMPOUNDING: RAW MATERIALS AND APPLICATIONSMadan Saini100% (1)

- Niaounakis2015-Biopolymers DefinitionDokument90 SeitenNiaounakis2015-Biopolymers DefinitionBidan Roland FrédéricNoch keine Bewertungen

- Aramid FiberDokument5 SeitenAramid FiberRamesh Iyer100% (1)

- Mt1 Unit 5 NotesDokument11 SeitenMt1 Unit 5 NotesvelavansuNoch keine Bewertungen

- Hall Wise List of Exhibitiors Hiplex HyderabadDokument7 SeitenHall Wise List of Exhibitiors Hiplex HyderabadLakshay UniplarNoch keine Bewertungen

- Polymers CH 101 (Updated Version) FALL 22Dokument50 SeitenPolymers CH 101 (Updated Version) FALL 22Haider AliNoch keine Bewertungen

- Foundry Pouring LabDokument26 SeitenFoundry Pouring LabMuhd MuzafarNoch keine Bewertungen