Beruflich Dokumente

Kultur Dokumente

114202-6464 Ijecs-Ijens

Hochgeladen von

Nick Cat0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

39 Ansichten6 Seitenupload IJECS

Originaltitel

114202-6464 IJECS-IJENS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenupload IJECS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

39 Ansichten6 Seiten114202-6464 Ijecs-Ijens

Hochgeladen von

Nick Catupload IJECS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 02 12

114202-6464 IJECS-IJENS April 2011 IJENS

I J E N S

Fuzzy Logic Controller for BLDC Permanent Magnet

Motor Drives

Tan Chee Siong, Baharuddin Ismail, Siti Fatimah Siraj, Mohd Fayzul Mohammed

School of Electrical System Engineering, Universiti Malaysia Perlis, Malaysia

terry_tcs_5510@yahoo.com, baha@unimap.edu.my

Abstract- This paper presents a fuzzy logic controller for

brushless direct current (BLDC) permanent magnet motor

drives. Initially a fuzzy logic controller is developed using

MATLAB Fuzzy-Logic Toolbox and then inserted into the

Simulink model. The dynamic characteristics of the brushless DC

motor such as speed, torque, current and voltage of the inverter

components are observed and analyzed using the developed

MATLAB model. In order to verify the effectiveness of the

controller, the simulation results are compared with

TMS320F2808 DSP experimental results. The simulation and

experimental results show that the brushless direct current motor

(BLDC) is successfully and efficiently controlled by the Fuzzy

logic controller.

I ndex Term Fuzzy logic controller, BLDC motor drives,

Digital Signal Processing

I. INTRODUCTION

Modern intelligent motion applications demand accurate speed

and position control. Many machine and control schemes have

been developed to improve the performance of BLDC motor

drives. Some simulation models based on state-space

equations, Fouries-transforms, d-q axis model and variable

sampling have been proposed for the analysis of BLDC motor

drives. Limitations of brushed DC motors overcome by BLDC

motors include lower efficiency and susceptibility of the

commutator assembly to mechanical wear and consequent

need for servicing, at the cost of potentially less rugged and

more complex and expensive control electronics. BLDC

motors offer better speed versus torque characteristics, high

dynamic response, high efficiency, long operating life,

noiseless operation and higher speed ranges [1]. Due to

their favorable electrical and mechanical properties, BLDC

motors are widely used in servo applications such as

automotive, aerospace, medical, instrumentation, actuation,

robotics, machine tools and industrial automation equipment.

Many machine design and control schemes have been

developed to improve the performance of BLDC motor

drives. The model of motor drive has to be known in order

to implement an effective control in simulation. Furthermore,

fuzzy logic controllers (FLCs) have been used to analyze

BLDC motor drives [2]. In this paper, a comprehensive

simulation model with a fuzzy logic controller is

presented. MATLAB/fuzzy logic toolbox is used to design

the FLC, which is integrated into simulations with

Simulink [3]. Besides, considering that the computational

time without affecting the accuracy of the results obtained is

very low, it can be said that the proposed method is promising

[4]. Previous studies and development of control schemes

have made a very good contribution to BLDC motor drives,

but the comprehensive approach has not been available for

modeling and analysis of fuzzy logic controlled BLDC motor

drives using TMS320F2808 hardware experimental set.

Several simulation and experimental results are shown to

ensure the validity and performance of the fuzzy logic BLDC

motor drive. .

.

II. SYSTEMS STRUCTURE

A. Permanent-Magnet BLDC Motor Structure

Fig. 1 illustrates the transverse section structure of a

brushless DC motor. The stator windings of BLDC are

similar to those in a polyphase AC motor, and the rotor is

composed of one or more permanent magnets. Brushless DC

motors (BLDC) contain a powerful permanent magnet

rotor and fixed stator windings. The stationary stator

windings are usually three phases, which means that three

separate voltages are supplied to the three different sets of

windings [5]. Brushless DC motors are different from AC

synchronous motors in that the former incorporates some

means to detect the rotor position (or magnetic poles) to

produce signals to control the electronic switches as shown

in fig. 2.

Fig. 1. Transverse section structure of a brushless dc motor

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 02 13

114202-6464 IJECS-IJENS April 2011 IJENS

I J E N S

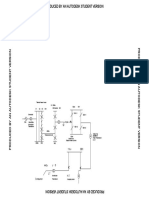

Fig. 2. Diagram for BLDC motor systems

Fig. 3 shows the electrical diagram of BLDC motor. It

consists of a phase resistance (R) and an inductance (L)

respectively.

Fig. 3. Electrical diagram of BLDC motor

B. Structure of fuzzy logic controller

Fig. 4 shows the Fuzzy logic for a BLDC motor drive

system. The system contains two loops, the first loop is the

current control loop that accomplishes torque control of

BLDC motor and the second loop is the speed control loop

that adjusts the speed of t h e BLDC motor.

Fig. 4. Fuzzy logic for BLDC motor drive system

Fig. 5 shows the basic structure of a fuzzy logic

controller. Fuzzy logic linguistic terms are most often

expressed in the form of logical implications, such as If-

Then rules. These rules define a range of values known as

fuzzy membership functions [4]. Fuzzy membership

functions may be in the form of a triangle, a trapezoid, a

bell as shows in fig. 6, or of another appropriate form [6].

Fig. 5. Structure of fuzzy logic controller

Fig. 6. (a) triangle, (b) trapezoid, and (c) bell membership function

Fig. 7 illustrates the membership function of fuzzy logic

controller that used the fuzzification of two input values

and defuzzification output of the controller. There are

seven clusters in the membership functions, wi t h seven

linguistic variables defined as: Negative Big (NB),

Negative Medium (NM), Negative Small (NS), Zero (Z),

Positive Small (PS), Positive Medium (PM), and Positive Big

(PB).

Fig. 7. Membership functions of fuzzy logic controller

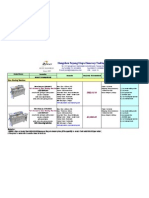

A sliding mode rule-base, used in the fuzzy logic

controller is given in Table 1. The fuzzy inference operation

is implemented by using the 49 rules. The min-max

compositional rule of inference and the center of gravity

method have been used in the defuzzification process [5].

If p1 is NB and p2 is NB Then out is PB,

If p1 is NB and p2 is NM Then out is PB,

If p1 is NB and p2 is NS Then out is PM,

If p1 is NB and p2 is Z Then out is PM,

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 02 14

114202-6464 IJECS-IJENS April 2011 IJENS

I J E N S

Fig. 8. Matlab simulation diagram of fuzzy logic control

TABLE I.

RULE BASE OF FUZZY LOGIC CONTROLLER

C. Simulation structure of fuzzy in Matlab

Fig. 8 shows the Matlab simulation diagram of the Fuzzy

logic controller. The developed Matlab model is use to

observe the phase current waveforms, speed, torque and

maximun current.

III. MATHEMATICAL EQUATIONS

The trapezoidal back-EMF wave forms are modeled

as a function of rotor position so that rotor position can

be actively calculated according to the operation speed.

The back EMFs are expressed as a function of rotor

position ().

(1)

Where ke is back-EMF constant, fa ( ) , fb() , and fc

() are functions of rotor position.

(2)

Where; va , vb , and vc are phase voltages, R is

resistance, L is inductance, M is mutual inductance, ea ,

eb , and ec are trapezoidal back EMFs.

The motion equation is:

(3)

The trapezoidal shape functions with limit values between

+1 and -1:

(4)

The expression of electromagnetic torque:

Te = ke ( fa () ia + fa () ib + fc () ic ) (5)

Speed and torque characteristics of BLDC motor:

(6)

The error and the change in error:

e1[n] = wref [n] wr [n] (7)

e2[n] = e1 [n] e1 [n-1] (8)

IV. RESULTS

A. MATLAB Simulations

In order to validate the control strategies as

described, digital simulations were carried out on a

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 02 15

114202-6464 IJECS-IJENS April 2011 IJENS

I J E N S

converter f o r a DC motor drive system using

MATLAB/SIMULINK, whe r e the parameters used for the

DC motor drive system is given in table II.

TABLE II.

THE PARAMETER OF DC MOTOR DRIVE SYSTEM

Fig. 9 shows the phase current waveforms based on the

rotor position at 4000 rpm. The phase difference between Ia,

Ib and Ic is approximately 120

0

. The peak current value is

approximately 9 A for all Ia, Ib and Ic.

Fig. 9. Phase current waveforms based on the rotor position at 4000 rpm

Fig. 10 shows the dynamic responses of the

speed, torque and Imax, respectively. The reference value

of maximum current (Imax) is computed from the

generated constant torque reference.

Fig. 10. Speed of BLDC motor, Electromagnetic torque and maximum current

(Imax)

Fig. 11 shows the speed response for the FLC model

developed in Matlab. The speeds reach the desired value of

4000 rpm in 5ms.

Fig. 11. Speeds responce for FLC

Fig. 12 demonstrates the speed response for FLC on load

change that BLDC motor manage to set back to 4000 rpm

successfully when the load torque changes occurs either load

increased or decrease.

Armature resistance (Ra) 0.5

Armature inductance (La) 8 mH

Back e.m.f constant (K) 0.55 V/rad/s

Mechanical inertia (J) 0.0465 kg.m2

Friction coefficient (B) 0.004 N.m/rad/s

Rated armature current (Ia) 10 A

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 02 16

114202-6464 IJECS-IJENS April 2011 IJENS

I J E N S

Fig. 12. Speeds responce for FLC on load change

B. Experimental Results

A TMS320F2808 DSP and BLDC motor was used to

observe the speed response and the phase current waveforms.

Fig. 13 shows the experimental results for phase current

waveforms of the BLDC motor via an oscilocope when the

rotor speed is 4000 rpm. The phase difference between Ia, Ib

and Ic is approximately 120

0

and the value of the current

magnitude for Ia, Ia and Ic is about 9A.

Fig. 13. Phase current waveforms based on the rotor position at 4000 rpm

Fig. 14 shows the experimental results of speed of

BLDC motor, Electromagnetic torque and maximum current

(Imax) by CCStudio when the rotor speed is 4000 rpm.

Fig. 14. Speed of BLDC motor, Electromagnetic torque and maximum current

(Imax)

Fig. 15 shows the BLDC rotor position as indicated by the

Hall effect sensor outputs of the BLDC motor as observed on

an oscilloscope when the rotor speed is 4000 rpm. The phase

difference between the 3 waveforms is about 120

0

.

Fig. 15. Hall effects of BLDC motor

Fig. 16 shows the speed response of the BLDC motor for

the experimental set observed by Code Composer Studio

(CCStudio). The speed of the motor reached the desired value

or steady state at approximately 5ms. A very small value of

CCStudio overshoot and the experimental result, is about 50

rpm from the desired value.

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 11 No: 02 17

114202-6464 IJECS-IJENS April 2011 IJENS

I J E N S

Fig. 16. Speed responce of BLDC motor

V. CONCLUSION

As a conclusion, the increasing demand for using fuzzy

logic as a controller for BLDC permanent magnet motor in

modern intelligent motion control of BLDC motors, both

simulation and experimental set-up have provided a good

dynamic performance of the fuzzy logic controller system.

The speed of the BLDC motor is detected by Hall-sensor ICs

accurately instead of the usual, expensive and complicated

encoder system. Besides, fuzzy reasoning algorithm designed

to control BLDC to get the optimum control under the

unstable rotor turning situation or sudden load change, the

proposed fuzzy logic controller system has a good adaptability

and strong robustness whenever the system is disturbed. The

simulation model which is implemented in a modular manner

under MATLAB environment allows dynamic characteristics

such as phase currents, rotor speed, and mechanical torque to

be effectively considered. The result paired with

Matlab/simulink is a good simulation tool for modeling

and analyzing fuzzy logic controlled brushless DC motor

drives. Besides, both simulated results and experimental

results shows very good agreement. Some of other adaptive

enhancements technique such as artificial neural networks or

neuro-fuzzy implementations could be use for future work.

REFFRENCES

[1] P. Yedamale, Brushless DC (BLDC) Motor

Fundamentals. Chandler, AZ: Microchip Technology, Inc.,

last access; March 15,

2009.[Online].Available:http://ww1.microchip.com/downloads/e

n/Market_Communication/Feb%202009%20microSOLUTIONS.

[2] R. Akkaya, A.A. Kulaksz, and O Aydogdu, DSP

implementation of a PV system with GA-MLP-NN based

MPPT controller supplying BLDC motor drive, Energy

Conv. and Management 48, 210-218, 2007.

[3] Tan Chee Siong, Baharuddin; M.Fayzul; M.Faridun N.T, Study of

Fuzzy and PI Controller for Permanent-Magnet Brushless DC

Motor Drive, IEEE International Power Engineering and

Optimization Conference.PEOCO 2010.

[4] C.W. Hung; C.T. Lin, and C.W. Liu, An Efficient

Simulation Technique for the Variable Sampling Effect of

BLDC Motor Applications, IECON 2007, pp. 11751179,

2007

[5] A. Rubai, A. Ofoli, and M. Castro, dSPACE DSP-Based

Rapid Prototyping of Fuzzy PID Controls for High

Performance Brushless Servo Drives, IEEE Industry

Applications Conference, 41st IAS Annual Meeting,

page(s):13601364, 2006

[6] B. Sing, A.H.N. Reddy, and S.S. Murthy, Gain

Scheduling Control of Permanent Magnet Brushless dc Motor,

IE(I) Journal-EL 84, 52-62, 2003

[7] Tan Chee Siong, Baharuddin Ismail, Siti Fatimah Siraj, M.Fayzul,

Analysis of Fuzzy logic controller for permanent magnet BLDC

Motor Drives, 2010 IEEE Student Conference on Research and

Development, ScoRED 2010.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- GautierDokument164 SeitenGautierDimitar NedkovNoch keine Bewertungen

- Lector: Aleksandar Karamfilov Skype: Sanders - Kar E-Mail: Aleksandar - Karamfilov@Pragmatic - BG Linkedin: 2013 - 2014Dokument19 SeitenLector: Aleksandar Karamfilov Skype: Sanders - Kar E-Mail: Aleksandar - Karamfilov@Pragmatic - BG Linkedin: 2013 - 2014Diana DikovaNoch keine Bewertungen

- A Modified Vince Gingery PlasticDokument13 SeitenA Modified Vince Gingery PlasticgeppaNoch keine Bewertungen

- Alexandria University Faculty of Engineering: Electromechanical Engineering Sheet 1 (Synchronous Machine)Dokument5 SeitenAlexandria University Faculty of Engineering: Electromechanical Engineering Sheet 1 (Synchronous Machine)Mahmoud EltawabNoch keine Bewertungen

- Camsco Breaker PDFDokument12 SeitenCamsco Breaker PDFMichael MaiquemaNoch keine Bewertungen

- Quick Start Guide: Digital Camera D7000Dokument2 SeitenQuick Start Guide: Digital Camera D7000foosome12Noch keine Bewertungen

- VbeltDokument7 SeitenVbeltMinaBasconNoch keine Bewertungen

- HDR-HC1 Hc1e HC1K Hc1ek Ver.1.3 2006.07 Service Manual Suplemento 1Dokument8 SeitenHDR-HC1 Hc1e HC1K Hc1ek Ver.1.3 2006.07 Service Manual Suplemento 1Javier GutiérrezNoch keine Bewertungen

- Xerox Corporation - TonerDokument2 SeitenXerox Corporation - Tonerjaredf@jfelectric.com100% (3)

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsDokument4 SeitenPerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaNoch keine Bewertungen

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolDokument58 SeitenH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANNoch keine Bewertungen

- Redundant Power Supply Installation Guide EP-DCX205Dokument38 SeitenRedundant Power Supply Installation Guide EP-DCX205Anonymous zLwP4FjLNoch keine Bewertungen

- k2601 enDokument12 Seitenk2601 enRobert MasaNoch keine Bewertungen

- TPMS - A Learning GuideDokument14 SeitenTPMS - A Learning GuideOrangeElectronicUsaNoch keine Bewertungen

- HL780 9SDokument583 SeitenHL780 9SAnonymous yjK3peI7100% (3)

- White Products CatalogDokument49 SeitenWhite Products CatalogjesusNoch keine Bewertungen

- 3D - Quick Start - OptitexHelpEnDokument26 Seiten3D - Quick Start - OptitexHelpEnpanzon_villaNoch keine Bewertungen

- HTK Fortune Delivery NoteDokument3 SeitenHTK Fortune Delivery NoteVu Duc QuangNoch keine Bewertungen

- BOB SO Information HandoutDokument5 SeitenBOB SO Information HandoutKabya SrivastavaNoch keine Bewertungen

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Dokument1 SeiteQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargNoch keine Bewertungen

- Functions SolutionDokument10 SeitenFunctions SolutionOwais Afzal JanNoch keine Bewertungen

- As 2812-2005 Welding Brazing and Cutting of Metals - Glossary of TermsDokument6 SeitenAs 2812-2005 Welding Brazing and Cutting of Metals - Glossary of TermsSAI Global - APAC0% (1)

- Norma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Dokument42 SeitenNorma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Jorge Roman SantosNoch keine Bewertungen

- CM29, 03-16-17Dokument3 SeitenCM29, 03-16-17Louie PascuaNoch keine Bewertungen

- 11kv BB1Dokument1 Seite11kv BB1Hammadiqbal12Noch keine Bewertungen

- Booklet ThrusterDokument5 SeitenBooklet ThrusterNeo ZaoNoch keine Bewertungen

- MCSL-045 Solved Assignments 2014-15Dokument6 SeitenMCSL-045 Solved Assignments 2014-15manishNoch keine Bewertungen

- Intel Artificial Intelligence EguideDokument15 SeitenIntel Artificial Intelligence Eguidenikhil_805Noch keine Bewertungen

- d350 Taper Lock End Anchor Tech Data SheetDokument2 Seitend350 Taper Lock End Anchor Tech Data SheetEdsantadNoch keine Bewertungen

- Group 2 (Oacc39)Dokument3 SeitenGroup 2 (Oacc39)viernazanne.viadoNoch keine Bewertungen