Beruflich Dokumente

Kultur Dokumente

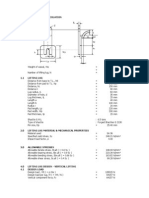

Element Thickness, Pressure, Diameter and Allowable Stress

Hochgeladen von

agusnnn0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

5 Ansichten3 SeitenFILTER

Originaltitel

44-MAJ-103

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenFILTER

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

5 Ansichten3 SeitenElement Thickness, Pressure, Diameter and Allowable Stress

Hochgeladen von

agusnnnFILTER

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

PV El i t e 2014 Li censee: SPLM Li censed User

Fi l eName : 44- MAJ - 103 Page 1 of 3

I nt er nal Pr essur e Cal cul at i ons : St ep: 5 10: 06a J ul 3, 2014

Element Thickness, Pressure, Diameter and Allowable Stress :

| | I nt . Pr ess | Nomi nal | Tot al Cor r | El ement | Al l owabl e |

Fr om| To | + Li q. Hd | Thi ckness | Al l owance | Di amet er | St r ess( SE) |

| | KPa. | mm. | mm. | mm. | N. / mm |

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Bot t om| 7943. 5 | 9. 2700 | . . . | 273. 05 | 177. 20 |

Shel l | 7942. 6 | 9. 2700 | 3. 1750 | 273. 05 | 177. 20 |

Body f l ang| 7928. 8 | . . . | 3. 1750 | 276. 35 | 177. 20 |

body f l ang| 7928. 8 | . . . | 3. 1750 | 508. 00 | 177. 20 |

Element Required Thickness and MAWP :

| | Desi gn | M. A. W. P. | M. A. P. | Mi ni mum | Requi r ed |

Fr om| To | Pr essur e | Cor r oded | New & Col d | Thi ckness | Thi ckness |

| | KPa. | KPa. | KPa. | mm. | mm. |

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Bot t om| 7928. 79 | 12352. 9 | 12814. 2 | 9. 27000 | 5. 88312 |

Shel l | 7928. 79 | 8040. 51 | 12367. 1 | 9. 27000 | 9. 18694 |

Body f l ang| 7928. 79 | 9802. 11 | 10210. 0 | 63. 5000 | No Cal c |

body f l ang| 7928. 79 | 9802. 11 | 10210. 0 | 63. 5000 | No Cal c |

Mi ni mum 8040. 512 10209. 989

MAWP: 8040.512 KPa., limited by: Shell.

Internal Pressure Calculation Results :

ASME Code, Section VIII, Division 1, 2013

Elliptical Head From 10 To 20 SA-815 at 66 C

Bottom

Longitudinal J oint: Full Radiography per UW-11(a) Type 1

Circumferential J oint: Full Radiography per UW-11(a) Type 1

Material UNS Number: S31803

Required Thickness due to Internal Pressure [tr]:

= ( P*Do*Kcor ) / ( 2*S*E+2*P*( Kcor - 0. 1) ) per Appendi x 1- 4 ( c)

= ( 7943. 513*273. 0500*1. 000) / ( 2*177. 20*1. 00+2*7943. 513*( 1. 000- 0. 1) )

= 5. 8831 + 0. 0000 = 5. 8831 mm.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 14.723 KPa.

= ( 2*S*E*t ) / ( Kcor *Do- 2*t *( Kcor - 0. 1) ) per Appendi x 1- 4 ( c)

= ( 2*177. 20*1. 00*9. 2700) / ( 1. 000*273. 0500- 2*9. 2700*( 1. 00- 0. 1) )

= 12814. 191 - 14. 723 = 12799. 468 KPa.

Maximum Allowable Pressure, New and Cold [MAPNC]:

= ( 2*S*E*t ) / ( K*Do- 2*t *( K- 0. 1) ) per Appendi x 1- 4 ( c)

= ( 2*177. 20*1. 00*9. 2700) / ( 1. 000*273. 0500- 2*9. 2700*( 1. 000- 0. 1) )

= 12814. 191 KPa.

Actual stress at given pressure and thickness, corroded [Sact]:

= ( P*( Kcor *Do- 2*t *( Kcor - 0. 1) ) ) / ( 2*E*t )

= ( 7943. 513*( 1. 000*273. 0500- 2*9. 2700*( 1. 000- 0. 1) ) ) / ( 2*1. 00*9. 2700)

= 109. 846 N. / mm

PV El i t e 2014 Li censee: SPLM Li censed User

Fi l eName : 44- MAJ - 103 Page 2 of 3

I nt er nal Pr essur e Cal cul at i ons : St ep: 5 10: 06a J ul 3, 2014

Straight Flange Required Thickness:

= ( P*Ro) / ( S*E+0. 4*P) + ca per Appendi x 1- 1 ( a) ( 1)

= ( 7943. 513*136. 5250) / ( 177. 20*1. 00+0. 4*7943. 513) +0. 000

= 6. 013 mm.

Straight Flange Maximum Allowable Working Pressure:

Less Operating Hydrostatic Head Pressure of 14.106 KPa.

= ( S*E*t ) / ( Ro- 0. 4*t ) per Appendi x 1- 1 ( a) ( 1)

= ( 177. 20 * 1. 00 * 9. 2700 ) / ( 136. 5250 - 0. 4 * 9. 2700 )

= 12367. 006 - 14. 106 = 12352. 900 KPa.

Cylindrical Shell From 20 To 30 SA-790 at 66 C

Shell

Material UNS Number: S31803

Required Thickness due to Internal Pressure [tr]:

= ( P*Ro) / ( S*E+0. 4*P) per Appendi x 1- 1 ( a) ( 1)

= ( 7942. 604*136. 5250) / ( 177. 20*1. 00+0. 4*7942. 604)

= 6. 0119 + 3. 1750 = 9. 1869 mm.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 13.815 KPa.

= ( S*E*t ) / ( Ro- 0. 4*t ) per Appendi x 1- 1 ( a) ( 1)

= ( 177. 20*1. 00*6. 0950) / ( 136. 5250- 0. 4*6. 0950)

= 8054. 327 - 13. 815 = 8040. 512 KPa.

Maximum Allowable Pressure, New and Cold [MAPNC]:

= ( S*E*t ) / ( Ro- 0. 4*t ) per Appendi x 1- 1 ( a) ( 1)

= ( 177. 20*1. 00*9. 2700) / ( 136. 5250- 0. 4*9. 2700)

= 12367. 111 KPa.

Actual stress at given pressure and thickness, corroded [Sact]:

= ( P*( Ro- 0. 4*t ) ) / ( E*t )

= ( 7942. 604*( ( 136. 5250- 0. 4*6. 0950) ) / ( 1. 00*6. 0950)

= 174. 744 N. / mm

Hydrostatic Test Pressure Results:

Pr essur e per UG99b = 1. 3 * M. A. W. P. * Sa/ S 10452. 665 KPa.

Pr essur e per UG99b[ 34] = 1. 3 * Desi gn Pr es * Sa/ S 10307. 427 KPa.

Pr essur e per UG99c = 1. 3 * M. A. P. - Head( Hyd) 13268. 006 KPa.

Pr essur e per UG100 = 1. 1 * M. A. W. P. * Sa/ S 8844. 563 KPa.

Pr essur e per PED = 1. 43 * MAWP 11497. 932 KPa.

UG-99(b), Test Pressure Calculation:

= Test Fact or * MAWP * St r ess Rat i o

= 1. 3 * 8040. 512 * 1. 000

= 10452. 665 KPa.

Horizontal Test performed per: UG-99b

Please note that Nozzle, Shell, Head, Flange, etc MAWPs are all considered

when determining the hydrotest pressure for those test types that are based

on the MAWP of the vessel.

Stresses on Elements due to Test Pressure:

PV El i t e 2014 Li censee: SPLM Li censed User

Fi l eName : 44- MAJ - 103 Page 3 of 3

I nt er nal Pr essur e Cal cul at i ons : St ep: 5 10: 06a J ul 3, 2014

Fr om To St r ess Al l owabl e Rat i o Pr essur e

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Bot t om 144. 6 230. 4 0. 628 10455. 34

Shel l 149. 8 230. 4 0. 650 10455. 34

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Elements Suitable for Internal Pressure.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2014

Das könnte Ihnen auch gefallen

- ASME Horizontal Vessel AnalysisDokument16 SeitenASME Horizontal Vessel AnalysisAsep Darojat100% (1)

- Torisperical - Element ThicknessDokument6 SeitenTorisperical - Element ThicknessVipul GandhiNoch keine Bewertungen

- Beltconv (1) - Is11592Dokument17 SeitenBeltconv (1) - Is11592Taha ZiaNoch keine Bewertungen

- Line-by-line conveyor code for material handling parameters and calculationsDokument4 SeitenLine-by-line conveyor code for material handling parameters and calculationskmats2Noch keine Bewertungen

- How To Review PV Elite Design Report PDFDokument9 SeitenHow To Review PV Elite Design Report PDFprocess process100% (1)

- How To Review PV Elite Report: (Specific To Forbes Marshall)Dokument9 SeitenHow To Review PV Elite Report: (Specific To Forbes Marshall)thomas_v501925Noch keine Bewertungen

- Earthquake Analysis and Horizontal Vessel Stress ResultsDokument20 SeitenEarthquake Analysis and Horizontal Vessel Stress ResultsankitNoch keine Bewertungen

- Element ThicknessDokument10 SeitenElement ThicknesskhairulakbarNoch keine Bewertungen

- 500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal DishDokument8 Seiten500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal Dishprakash KaleNoch keine Bewertungen

- Hydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other StandardsDokument15 SeitenHydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other Standardsबिपन गुलेरियाNoch keine Bewertungen

- Wind load calc O2 reactorDokument5 SeitenWind load calc O2 reactormechmohan26Noch keine Bewertungen

- New wind tunnel tests boundary layersDokument9 SeitenNew wind tunnel tests boundary layerslmjNoch keine Bewertungen

- External Pressure Calculation Results SummaryDokument8 SeitenExternal Pressure Calculation Results SummaryAndika DearsonNoch keine Bewertungen

- Minimum clearances and voltage levels for substation equipmentDokument32 SeitenMinimum clearances and voltage levels for substation equipmentVíctor RojasNoch keine Bewertungen

- FIRE WATER TANK-API-650-Calculation-Report - RVDDokument42 SeitenFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNoch keine Bewertungen

- Horizontal Vessel Stress AnalysisDokument12 SeitenHorizontal Vessel Stress AnalysissridharNoch keine Bewertungen

- 123Dokument29 Seiten123Pravin Narkhede100% (1)

- Perhitungan Propeller KM NuladaniDokument17 SeitenPerhitungan Propeller KM NuladanirizqyagungnuladaniNoch keine Bewertungen

- University of Salahaddin-Hewler College of Engineering Department of Civil Eng. Multistorey Design ProjectDokument36 SeitenUniversity of Salahaddin-Hewler College of Engineering Department of Civil Eng. Multistorey Design Projectdev6483% (12)

- Meta/Shl-Gas: Well Location DataDokument8 SeitenMeta/Shl-Gas: Well Location DataDhaffer Al-MezhanyNoch keine Bewertungen

- Calculation Storage Tank1000 KL PDFDokument58 SeitenCalculation Storage Tank1000 KL PDFemre gedikli100% (1)

- Tank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Dokument52 SeitenTank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Tony Lozada Mahuen100% (1)

- API 579 Input ValuesDokument6 SeitenAPI 579 Input ValuesSajal Kulshrestha67% (3)

- Design of Padeye CalcDokument3 SeitenDesign of Padeye CalcBolarinwa89% (9)

- ASME Horizontal Vessel Analysis - Friction 0.025 PDFDokument10 SeitenASME Horizontal Vessel Analysis - Friction 0.025 PDFSyed Zain AliNoch keine Bewertungen

- Generating Electricity from Speed BreakersDokument19 SeitenGenerating Electricity from Speed BreakersRoshanNoch keine Bewertungen

- 1-Pwq Iso Grup 1 Wi'89Dokument25 Seiten1-Pwq Iso Grup 1 Wi'89Ir FankovicNoch keine Bewertungen

- Design of MonorailDokument9 SeitenDesign of MonorailAnonymous Q8XIGqHyCNoch keine Bewertungen

- 297 - Pipe and Shell Design Tool Ver E4.01 MMDokument1 Seite297 - Pipe and Shell Design Tool Ver E4.01 MMBAHADIRNoch keine Bewertungen

- EscalatorDokument10 SeitenEscalatorbernabasNoch keine Bewertungen

- Lifting LugDokument8 SeitenLifting LugAzwan ShahNoch keine Bewertungen

- Exhaust Gas Pressure Drop in DuctDokument6 SeitenExhaust Gas Pressure Drop in DuctMyungkwan HaNoch keine Bewertungen

- Overview:: RemarksDokument5 SeitenOverview:: RemarksThinh ViproNoch keine Bewertungen

- Pipe Rack Design Calculation for 54Dokument4 SeitenPipe Rack Design Calculation for 54moseslugtu6324Noch keine Bewertungen

- Control Engineering RevisionDokument4 SeitenControl Engineering Revisionemlynmuriuki29Noch keine Bewertungen

- Optimize Your Gear Drive Design with Proper Material SelectionDokument8 SeitenOptimize Your Gear Drive Design with Proper Material SelectionLovely BalajiNoch keine Bewertungen

- 吊耳计算Dokument4 Seiten吊耳计算huangjlNoch keine Bewertungen

- Tugas Perancangan TankiDokument47 SeitenTugas Perancangan Tankimuh irchamNoch keine Bewertungen

- TK-ALCOZAP-2020-01-06-Rev. DDokument65 SeitenTK-ALCOZAP-2020-01-06-Rev. DDaniel Gómez100% (1)

- Duct Static Pressure Loss CalculationDokument8 SeitenDuct Static Pressure Loss CalculationYe Thiha Min100% (2)

- Crgo MTCDokument4 SeitenCrgo MTCGupta Gupta100% (1)

- Final Design of Angle Members For 4leged Single Angle TowersDokument65 SeitenFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerNoch keine Bewertungen

- CLM2 0Dokument2 SeitenCLM2 0samwong87Noch keine Bewertungen

- TK-500MB - DB - Rev. 00Dokument173 SeitenTK-500MB - DB - Rev. 00Daniel GómezNoch keine Bewertungen

- Design 1Dokument29 SeitenDesign 1Nikki RobertsNoch keine Bewertungen

- Ysd P02 0208 Ar SJF CD F0005 BDokument47 SeitenYsd P02 0208 Ar SJF CD F0005 BChandra MohanNoch keine Bewertungen

- Face WidthDokument24 SeitenFace WidthDipak100% (1)

- Dynamic Behavior of Jack-Up ISOPE10Dokument36 SeitenDynamic Behavior of Jack-Up ISOPE10Imran Siddiqui100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesVon EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNoch keine Bewertungen

- Laboratory Exercises in Astronomy: Solutions and AnswersVon EverandLaboratory Exercises in Astronomy: Solutions and AnswersNoch keine Bewertungen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Wireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesVon EverandWireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesNoch keine Bewertungen

- Grading Equipment DTU - Setelah TA - 17apr2023 - FINALDokument30 SeitenGrading Equipment DTU - Setelah TA - 17apr2023 - FINALagusnnnNoch keine Bewertungen

- Latihan Soal Refresh - WeldingDokument3 SeitenLatihan Soal Refresh - WeldingagusnnnNoch keine Bewertungen

- Progress ReportDokument32 SeitenProgress ReportagusnnnNoch keine Bewertungen

- Kalkulasi HEDokument4 SeitenKalkulasi HEagusnnnNoch keine Bewertungen

- Natural gas odorization techniques and odorantsDokument19 SeitenNatural gas odorization techniques and odorantsagusnnn100% (1)

- Confirmation - List of Data NeedsDokument1 SeiteConfirmation - List of Data NeedsagusnnnNoch keine Bewertungen

- Daily Report 03082019Dokument2 SeitenDaily Report 03082019agusnnnNoch keine Bewertungen

- Jadwal Shift Tim NDT Dan AsistenDokument3 SeitenJadwal Shift Tim NDT Dan AsistenagusnnnNoch keine Bewertungen

- Daily Report 08082019Dokument4 SeitenDaily Report 08082019agusnnnNoch keine Bewertungen

- 12438153Dokument3 Seiten12438153agusnnnNoch keine Bewertungen

- Centrifugal pump troubleshooting guideDokument5 SeitenCentrifugal pump troubleshooting guideagusnnnNoch keine Bewertungen

- Waukesha Gas Engine Maintenance ManualDokument7 SeitenWaukesha Gas Engine Maintenance Manualagusnnn56% (9)

- Klasifikasi PompaDokument1 SeiteKlasifikasi PompaagusnnnNoch keine Bewertungen

- Expense Report - Biaya Perjalanan Dinas: Description Travel History & Work StageDokument1 SeiteExpense Report - Biaya Perjalanan Dinas: Description Travel History & Work StageagusnnnNoch keine Bewertungen

- Date: Time: Subject: Venue: Attendees: NO. Name Company / Position SignatureDokument2 SeitenDate: Time: Subject: Venue: Attendees: NO. Name Company / Position SignatureagusnnnNoch keine Bewertungen

- Tiket Agus Boy Simanjuntak & Riza Mirza Nasution (Balikpapan-JKT) (TGL 26-10-18)Dokument1 SeiteTiket Agus Boy Simanjuntak & Riza Mirza Nasution (Balikpapan-JKT) (TGL 26-10-18)agusnnnNoch keine Bewertungen

- GA Job 1214Dokument1 SeiteGA Job 1214agusnnnNoch keine Bewertungen

- Engineering Units ConverterDokument19 SeitenEngineering Units ConverteragusnnnNoch keine Bewertungen

- Texteam 5100-1Dokument3 SeitenTexteam 5100-1agusnnnNoch keine Bewertungen

- Texsteam 5100 Series Gas Consumption Cost AnalysisDokument1 SeiteTexsteam 5100 Series Gas Consumption Cost AnalysisagusnnnNoch keine Bewertungen

- Support PlateDokument1 SeiteSupport PlateagusnnnNoch keine Bewertungen

- Lampiran - 1 Definisi IstilahDokument5 SeitenLampiran - 1 Definisi IstilahagusnnnNoch keine Bewertungen

- Intalox SP PDFDokument1 SeiteIntalox SP PDFagusnnnNoch keine Bewertungen

- Lampiran 9-1Dokument2 SeitenLampiran 9-1agusnnnNoch keine Bewertungen

- Liquid Holdup in Large-Diameter Horizontal Multiphase PipelinesDokument8 SeitenLiquid Holdup in Large-Diameter Horizontal Multiphase PipelinesagusnnnNoch keine Bewertungen

- Iso 7Dokument3 SeitenIso 7agusnnnNoch keine Bewertungen

- Calibrate a Current to Pressure TransducerDokument3 SeitenCalibrate a Current to Pressure TransduceragusnnnNoch keine Bewertungen

- Pro I I Silent Install GuideDokument6 SeitenPro I I Silent Install GuideagusnnnNoch keine Bewertungen

- Saturate Stream User GuideDokument3 SeitenSaturate Stream User GuideagusnnnNoch keine Bewertungen

- 3 Generation Scada SystemsDokument3 Seiten3 Generation Scada SystemsagusnnnNoch keine Bewertungen

- ZSoil GettingStartedDokument287 SeitenZSoil GettingStartedRyszard TęczaNoch keine Bewertungen

- Flow Characteristics of Skimming Flows in Stepped Channels: I. Ohtsu Y. Yasuda and M. TakahashiDokument10 SeitenFlow Characteristics of Skimming Flows in Stepped Channels: I. Ohtsu Y. Yasuda and M. Takahashiorlando delgadoNoch keine Bewertungen

- The Development of Polyurethane Modified Bitumen Emulsions For Cold Mix ApplicationsDokument8 SeitenThe Development of Polyurethane Modified Bitumen Emulsions For Cold Mix Applications王玏Noch keine Bewertungen

- Assignment-3 FM LeetDokument5 SeitenAssignment-3 FM LeetŔÄHÙŁ ÇHÓÜĐHÃŔŸNoch keine Bewertungen

- Mud Viscocities and Other Rheological PropertiesDokument23 SeitenMud Viscocities and Other Rheological PropertiesMuhammad Naqiuddin Bin Zahid67% (3)

- BoschAndZeuchMethod-basedFlowmetersFor fuelInjectionRateFerrari21Dokument12 SeitenBoschAndZeuchMethod-basedFlowmetersFor fuelInjectionRateFerrari21ennioNoch keine Bewertungen

- Lec 34Dokument23 SeitenLec 34lvb123Noch keine Bewertungen

- Pipeline Sizing: Learning ObjectivesDokument7 SeitenPipeline Sizing: Learning Objectivesbikas_sahaNoch keine Bewertungen

- C6 Fluid Friction Measurement (Issue 2) PDFDokument4 SeitenC6 Fluid Friction Measurement (Issue 2) PDFdjafarNoch keine Bewertungen

- Water Hammer Calculation Software (WHC) : IMEC04-3065Dokument7 SeitenWater Hammer Calculation Software (WHC) : IMEC04-3065Souvik DasNoch keine Bewertungen

- Flow Meter Lab ReportDokument19 SeitenFlow Meter Lab Reportahmad pidotNoch keine Bewertungen

- Camarines Norte State College: College of Engineering SummDokument3 SeitenCamarines Norte State College: College of Engineering SummjefreyNoch keine Bewertungen

- Piping SystemsDokument137 SeitenPiping SystemsSwapnil KoshtiNoch keine Bewertungen

- WST - Formation Damage Part 1Dokument31 SeitenWST - Formation Damage Part 1NorNoch keine Bewertungen

- Autodyn Verberne Pieter 201411 MAS Thesis PDFDokument115 SeitenAutodyn Verberne Pieter 201411 MAS Thesis PDFYousaf SaidalaviNoch keine Bewertungen

- ANSYS Advantage V6 I1 2012Dokument56 SeitenANSYS Advantage V6 I1 2012j_c_garcia_dNoch keine Bewertungen

- Ijest NG Vol.1 No.1 pp.245 253Dokument9 SeitenIjest NG Vol.1 No.1 pp.245 253prabhjot singh1Noch keine Bewertungen

- Fluid Film Bearing Code Development for Rocket Engine TurbopumpsDokument2 SeitenFluid Film Bearing Code Development for Rocket Engine Turbopumpstanha56313955Noch keine Bewertungen

- Journal Of: TransactionsDokument155 SeitenJournal Of: TransactionsAnoopNoch keine Bewertungen

- CFD - Hot Air RecirculationDokument79 SeitenCFD - Hot Air Recirculationmhajaraswadi2023Noch keine Bewertungen

- Remote indicators for measuring signalsDokument11 SeitenRemote indicators for measuring signalscaat_06Noch keine Bewertungen

- Water Ret DesignDokument13 SeitenWater Ret DesignasrafNoch keine Bewertungen

- Theoretical analysis of ejector refrigeration system performance using real gas propertiesDokument11 SeitenTheoretical analysis of ejector refrigeration system performance using real gas propertiesAldi RezalNoch keine Bewertungen

- Lecture 11 - Forced ConvectionDokument35 SeitenLecture 11 - Forced ConvectionNiaz Muhammad Khan MehmotiNoch keine Bewertungen

- Fluidized Bed Heat Transfer MechanismsDokument8 SeitenFluidized Bed Heat Transfer Mechanismstanzil10Noch keine Bewertungen

- 9a23303-Fluid Flow in Bio ProcessesDokument4 Seiten9a23303-Fluid Flow in Bio ProcessessivabharathamurthyNoch keine Bewertungen

- Development of The Pressure Screen Foil: Saimaa University of Applied Sciences Technology, Imatra Paper TechnologyDokument23 SeitenDevelopment of The Pressure Screen Foil: Saimaa University of Applied Sciences Technology, Imatra Paper TechnologygonzaliuxxxNoch keine Bewertungen

- Transferencia de Calor Analitico PDFDokument318 SeitenTransferencia de Calor Analitico PDFdraggusNoch keine Bewertungen

- IITM Faculty Expertise Updated - 8th Oct 2021Dokument645 SeitenIITM Faculty Expertise Updated - 8th Oct 2021ARAVINDHAKUMAR GNoch keine Bewertungen

- Linear Algebraic Equations: - Direct MethodsDokument202 SeitenLinear Algebraic Equations: - Direct Methodseegala100% (1)