Beruflich Dokumente

Kultur Dokumente

SOP-QAD-001 - Inhouse Calibration

Hochgeladen von

danaka007Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SOP-QAD-001 - Inhouse Calibration

Hochgeladen von

danaka007Copyright:

Verfügbare Formate

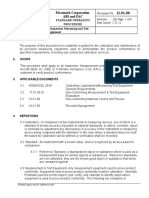

STANDARD OPERATING PROCEDURE

PAGE:

1 of 4

DOCUMENT No:

SOP- QAD-001

PREPARED BY :

HOD-QA

In-house Calibration

DOCUMENT REVISION:

D

APPROVED BY

HOD-QA

ISSUED BY :

MR

DATE:

23.09.2013

1. Purpose

The purpose of this procedure is to provide general directions for calibration.

2 Scope

This procedure covers calibration of all gauges and inspection fixtures used in INDO MIM.

3 Responsibilities

It is the responsibility of the Head of Quality to ensure that this procedure is followed properly.

No changes may be made to this instruction without the authorization of the Head of QA.

4 Process

4.1 In-house Calibration

4.1.1 General

Qualified personnel shall perform the calibration of gauges. Minimum Diploma in Mechanical engg

with six months experience in the calibration area shall be considered as qualified or in supervision of

calibration in charge.

Temperature and humidity of calibration room will be maintained as below

Temp: 222 and Humidity 50 10%.

Soaking of gauge shall be carried out at calibration room for about half an hour minimum.

Visual checking shall be carried out for all kind of damages or any markings over the gauge.

For all standard gauges, IS 3455 standard will be referred to decide the wear limits.

For all special gauges, respective gauge drawings will be referred to decide the wear limits.

For individual pin gauges 0.005mm is acceptance criteria

For parallel blocks, IS : 2949 - 1992 standard will be referred to decide the wear limits

For Surface Granite Block , IS: 7327 - 1991 standard will be referred to decide the wear limits

4.1.2 Method of Calibration

4.1.2.1 Plug Gauge, Pin Gauge and Width Gauge

Ensure only calibrated digimatic micrometer / 1-micron plunger dial is used.

Ensure that the above digimatic micrometer / micron plunger dial is used only for calibration

purpose.

Clean the base of Dial stand

Select the suitable size of Slip gauge of 0 " Grade.

Ensure proper wringing of Slips (Use Minimum number of slips).

Set the slips with only 10-20 micron pressure on the plunger dial.

Measurement shall be taken at different places of gauge.

Record the observation in calibration report / History card.

Compare the measured values against the wear limits for deciding the status.

4.1.2.2 Snap gauges

Use VMS / Bore gauge for calibration.

Measurements must be taken at different places of gauge.

The actual size of a gap is defined as the perpendicular distance between the gauging surfaces.

Record the observation in calibration report / History card.

Compare the measured values against the wear limits for deciding the status.

If calibration of gauges

by using plunger dial

STANDARD OPERATING PROCEDURE

PAGE:

2 of 4

DOCUMENT No:

SOP- QAD-001

PREPARED BY :

HOD-QA

In-house Calibration

DOCUMENT REVISION:

D

APPROVED BY

HOD-QA

ISSUED BY :

MR

DATE:

23.09.2013

4.1.2.3 Ring gauges

Use VMS / Bore gauge for calibration.

Measurements must be taken at different places of gauge.

Record the observation in calibration report / History card.

Compare the measured values against the wear limits to decide the status..

4.1.2.4 Receiver Gauges & inspection fixtures (position, pitch, distance, profile gauges, depth gauges etc.)

The receiver gauges shall be calibrated as per the gauge drawings using Height gauge /VMS/

1-micron plunger dial or appropriate instruments.

In receiver gauges the gauge pins, width gauges, holes & slots shall be calibrated and

measurement must be taken at different places of gauges.

Record the observations in calibration report / History card.

Compare the measured values against acceptable wear limit and decide the status.

4.1.2.5 Feeler gauge/Thickness gauge

Ensure only calibrated digimatic micrometer / one-micron plunger dial is used.

Measurements must be taken at different places of gauge.

Up to 0.005mm deviation will be allowed from the basic dimension on all feelers.

Record the values in calibration / history card and decide the status.

4.1.2.6 Dove tail gauges

The Dove tail gauges shall be calibrated as per the gauge drawing by using calibrated 0 grade slip

gauges, dig micrometer & measuring pins.

Select the suitable size of measuring pins & 0 grade slip gauge (given in gauge drawing) for

internal dovetail size measurement.

Ensure proper wringing of slips are (use minimum no of slips).

Use dig-micrometer and suitable size of measuring pins (given in gauge drawing) for External size

measurement.

Measurements must be taken at different places of gauge.

Record the observation in calibration / History card.

Compare the measured values against the wear limits to decide the status.

Magnetic Parallel Blocks

4.1.2.7

The parallel blocks shall be calibrated by using VMS

Measurement must be taken on entire plane by minimum 10 points

Recall for the flatness of the face & Perpendicularity as well

Measured values will be taken and monitored in the gage life monitor/ calibration history card

IS : 2949 - 1992 standard will be referred to decide the wear limits

4.1.2.8 Granite Surface Plate

The surface plate shall be calibrated by using VMS / Digital height gage

Measurement must be taken on entire plane by min 20 points

Recall for the flatness of the face & Perpendicularity as well

IS: 7327 - 1991 standard will be referred to decide the wear limits

STANDARD OPERATING PROCEDURE

PAGE:

3 of 4

DOCUMENT No:

SOP- QAD-001

PREPARED BY :

HOD-QA

In-house Calibration

DOCUMENT REVISION:

D

APPROVED BY

HOD-QA

ISSUED BY :

MR

DATE:

23.09.2013

5 Environmental Instructions

Cotton waste used for cleaning gauges should be disposed in designated bin.

Ensure there is no oil spillages while calibration.

Switch off the power in standards room when not in use.

6 Health & Safety Instructions

Ensure sufficient lighting in the area of calibration.

Use gloves while handling instruments / gauges to prevent cuts or injuries due to sharp edges.

While handling receiver gauges ensure there is no slippages. Always wear safety shoes while calibration.

Wash with soap and water after calibration.

If Isopropyl alcohol is spills on eye, immediately flush the eyes with water for at least 15 mins. Cold water

may be used.

7 Documents Reference

Control of MME - PRO-QAD-004

Master list of instrument and gauges - MSL-009 and MSL-010

Gauge drawings

8. Records Reference

Gauge calibration / history card - FORM-QAD-007

ANNEXURE - 1

STANDARDS ROOM SCOPE

SI.

N

o.

Test / calibration

carried out

Competency Required

Equipment used Method

Standards

reference

1. Plug gauges

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges,

and measurement

Dig micrometer / 1mic

plunger dial /

0gradeslip gauge

As per above

procedure

IS 3455

2. Width gauges

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges,

and measurement

Dig micrometer / 1

mic plunger dial /

0 grade slip gauge

As per above WI IS 3455

3. Receiver gauge

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges,

and measurement

VMS / Micrometer /

Plunger dial / slip

gauge / Ht.Gauge

As per drawings

As per gauge

drawing

4.

Snap gauge / Bridge

gauge

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

VMS / Bore gauge

As per above

WI

IS 3455

STANDARD OPERATING PROCEDURE

PAGE:

4 of 4

DOCUMENT No:

SOP- QAD-001

PREPARED BY :

HOD-QA

In-house Calibration

DOCUMENT REVISION:

D

APPROVED BY

HOD-QA

ISSUED BY :

MR

DATE:

23.09.2013

5. Depth gauge

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

Digital micrometer /

Ht.gauge

As per above

WI

IS 3455

8. Dovetail gauge

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

Digital micrometer /

0 grade slips with

measuring pin.

As per above

WI

As per gauge

drawing

9. Plain Ring gauge

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

VMS, Bore gauge As per above WI IS 3455

10 Pin Gauges

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

Dig Micrometer As per above WI 0.005mm

11

Product Dimensional

inspection

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

As per control

plan/FIP/WI

As per the

control plan

As per control

plan/Part

Drawing

12

Parallel Blocks & V

blocks

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

VMS

As per above

Instruction

IS : 2949 -

1992

13

Granite Surface

Plates

ITI/Diploma with Min. six months

experience in the calibration of

all type of instruments &gauges

VMS

As per above

instruction

IS: 7327 -

1991

ANNEXURE 2

SI. No. Instrument

Instrument Code

#.

Range Units Least Count

1

Digimatic

micrometer

IMM-MIC-08 0-25mm mm/inch 0.001mm

2

Digimatic Height

master

IMM-HMG-01 0-600mm mm/inch 0.001

3

Dial Height gauge

IMM-HMG-02 0-300mm mm 0.01mm

4

Video measuring

system

IMM-VMS-01 300X200X200mm mm/inch 0.001

9. Revision details

Rev level Description of change

A First Release

B Modified to address EHS requirement

C Room temp 22+/- 2 deg revised

D Included the parallel blocks and granite surface plates, Competency added in Annexure -1 , Master

list of master equipments added in Annexure-2

Das könnte Ihnen auch gefallen

- Calibrate Outside MicrometersDokument2 SeitenCalibrate Outside MicrometerserharsinghNoch keine Bewertungen

- Calibration Procedure For Calibration of External MicrometerDokument11 SeitenCalibration Procedure For Calibration of External MicrometerDiganta Hatibaruah100% (1)

- SOP For Inhouse CalibrationDokument7 SeitenSOP For Inhouse Calibrationvasudeva yasas80% (5)

- Dial Indicator Calibration Procedure TS-0051Dokument3 SeitenDial Indicator Calibration Procedure TS-0051alexrferreiraNoch keine Bewertungen

- Instrument Calibration ProcedureDokument10 SeitenInstrument Calibration ProcedureMohammad Nurayzat JohariNoch keine Bewertungen

- Calibrate Vernier Calipers ProcedureDokument2 SeitenCalibrate Vernier Calipers Proceduregiamillia100% (2)

- Vernier CaliperDokument2 SeitenVernier CaliperMechtek LabNoch keine Bewertungen

- Sample Calibration ProceduresDokument37 SeitenSample Calibration Proceduresdil1750% (2)

- SOP For Calibration of InstrumentDokument2 SeitenSOP For Calibration of InstrumentRAVI KUMAR Carpenter100% (1)

- EPA Thermometer Calibration ProceduresDokument7 SeitenEPA Thermometer Calibration ProceduresGilberto Andrés Jurado100% (1)

- Calibration of Electronic Balance SOPDokument2 SeitenCalibration of Electronic Balance SOPRavi YadavNoch keine Bewertungen

- NIST Stopwatch & Timer Calibrations 2009Dokument82 SeitenNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- CalibrationDokument6 SeitenCalibrationMadhavan RamNoch keine Bewertungen

- Vernier Calibration ProcedureDokument12 SeitenVernier Calibration ProcedureAaron QuinnNoch keine Bewertungen

- Certificate of CalibrationDokument2 SeitenCertificate of CalibrationMiguel Angel Pacahuala CristobalNoch keine Bewertungen

- Standard Calibration For Steel Ruler and Flexible ScaleDokument5 SeitenStandard Calibration For Steel Ruler and Flexible ScaleJohn Rafael Atienza100% (1)

- Template For Intermediate Check Sheet For Deadweight TesterDokument1 SeiteTemplate For Intermediate Check Sheet For Deadweight Testervasudeva yasas100% (1)

- Deutscher Kalibrierdienst: Guideline DKD-R 5-1 Calibration of Resistance ThermometersDokument24 SeitenDeutscher Kalibrierdienst: Guideline DKD-R 5-1 Calibration of Resistance Thermometersjonh66-1Noch keine Bewertungen

- SOP of Calibration of BalanceDokument3 SeitenSOP of Calibration of BalanceYousif100% (1)

- Instrument Calibration ProcedureDokument7 SeitenInstrument Calibration Procedurejosejose19Noch keine Bewertungen

- Lead Gauge Cal 7Dokument2 SeitenLead Gauge Cal 7John Dolan100% (3)

- Standard Operating Procedure: CalibrationDokument22 SeitenStandard Operating Procedure: CalibrationMaryanthony NamyaloNoch keine Bewertungen

- P-ECM Equipment Calibration ProcedureDokument9 SeitenP-ECM Equipment Calibration Procedureomar sadiq100% (1)

- Calibration Frequency TableDokument7 SeitenCalibration Frequency Tablefajar_92Noch keine Bewertungen

- SOP CAL Refrigerator FreezerDokument3 SeitenSOP CAL Refrigerator FreezerJamall Clt33% (3)

- Calibration, American Laboratory: FlijkeDokument3 SeitenCalibration, American Laboratory: FlijkeAMINE MEDDAHINoch keine Bewertungen

- Calibration Master Plan Guide for Pharmaceutical InstrumentsDokument18 SeitenCalibration Master Plan Guide for Pharmaceutical InstrumentsDoan Chi Thien100% (2)

- Thermometer CalibrationDokument8 SeitenThermometer CalibrationGeroldo 'Rollie' L. Querijero100% (1)

- Measuring Tape CalibrationDokument2 SeitenMeasuring Tape CalibrationDewi Kusuma86% (7)

- Calibration Procedure.Dokument7 SeitenCalibration Procedure.Mohammed Kamal71% (7)

- Sop-Calibration of Balances.Dokument3 SeitenSop-Calibration of Balances.asit_m0% (1)

- Calibration Procedure for Equipment at 370MW Power ProjectDokument5 SeitenCalibration Procedure for Equipment at 370MW Power ProjectAkhilesh KumarNoch keine Bewertungen

- Calibration Procedure For Calibration of Himidity Indicator/ Thermo-HygrometerDokument3 SeitenCalibration Procedure For Calibration of Himidity Indicator/ Thermo-HygrometerAmar Singh80% (5)

- Calibration and Maintenance of Measuring and Monitoring Devices SOPDokument3 SeitenCalibration and Maintenance of Measuring and Monitoring Devices SOPBPG Service100% (1)

- G 63 Quality Risk Management (QRM) Application For Critical Instrument CalibrationDokument7 SeitenG 63 Quality Risk Management (QRM) Application For Critical Instrument CalibrationDoan Chi Thien100% (1)

- Competency Matrix - Calibration InspectorDokument1 SeiteCompetency Matrix - Calibration InspectorsathyabalaramanNoch keine Bewertungen

- 11.01.00 Calibration of Inspection Measuring and Test EquipmentDokument11 Seiten11.01.00 Calibration of Inspection Measuring and Test EquipmentSanjeev Reddy Kasula100% (1)

- In-House Verification or Calibration WI ExampleDokument1 SeiteIn-House Verification or Calibration WI ExampleSachin RamdurgNoch keine Bewertungen

- LPT Written ProcedureDokument8 SeitenLPT Written ProcedureManikantaSumanthNoch keine Bewertungen

- Control of Monitoring and Measuring EquipmentDokument6 SeitenControl of Monitoring and Measuring EquipmentJaved Iqbal0% (1)

- Calibration Certificate SampleDokument1 SeiteCalibration Certificate SampleAbdul Wahaab Khokhar100% (3)

- Calibration Manual Rev ADokument20 SeitenCalibration Manual Rev Ahyyzia100% (1)

- Calibration Procedure PDFDokument10 SeitenCalibration Procedure PDFmira100% (1)

- U 929 RPM MeterDokument7 SeitenU 929 RPM MeterAmit KumarNoch keine Bewertungen

- ASME-Pressure Gauge AccuracyDokument2 SeitenASME-Pressure Gauge AccuracyVIJAYAKUMAR TNoch keine Bewertungen

- Jis B 7516Dokument10 SeitenJis B 7516loly86Noch keine Bewertungen

- Calibration of Thermal Process EquipmentsDokument3 SeitenCalibration of Thermal Process EquipmentsAmar SinghNoch keine Bewertungen

- Cal Cert FormatDokument6 SeitenCal Cert FormatINSTRUCAL CALIBRATION SERVICESNoch keine Bewertungen

- Control of Measuring, Inspection and Test EquipmentDokument3 SeitenControl of Measuring, Inspection and Test EquipmentAnonymous rSvCmFNoch keine Bewertungen

- Annexure - 31 Calibration ProcedureDokument5 SeitenAnnexure - 31 Calibration Proceduresrikanta ksNoch keine Bewertungen

- Calibration ProcedureDokument2 SeitenCalibration ProcedureSairam Edupuganti100% (1)

- Yoke Calibration ProcedureDokument1 SeiteYoke Calibration ProcedureArjun Rawat100% (3)

- Decision Rule SopDokument3 SeitenDecision Rule SopNageswara raoNoch keine Bewertungen

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Dokument34 SeitenQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNoch keine Bewertungen

- SOP-QAD-001 In-house Calibration ProcedureDokument2 SeitenSOP-QAD-001 In-house Calibration Procedurevishal jaswalNoch keine Bewertungen

- CP-003 Calibration of Vernier CaliperDokument6 SeitenCP-003 Calibration of Vernier CaliperSUNILNoch keine Bewertungen

- Pressure ProcedureDokument4 SeitenPressure ProcedureCitco IdfcNoch keine Bewertungen

- Method Statement For Clamp MeterDokument3 SeitenMethod Statement For Clamp Meteraldred_chezka100% (1)

- Calibration Procedure: 1-PurposeDokument5 SeitenCalibration Procedure: 1-PurposeHassan SleemNoch keine Bewertungen

- Method of Statement NDTDokument11 SeitenMethod of Statement NDTAhmed Iraky0% (1)

- ProEngineer Wildfire TutorialsDokument141 SeitenProEngineer Wildfire Tutorialsdanaka007Noch keine Bewertungen

- SPC PresentationDokument45 SeitenSPC Presentationdanaka007Noch keine Bewertungen

- Quality ManualDokument45 SeitenQuality Manualhmp90100% (1)

- 85-04, The BW Preventive Action Register.: Purpose and ScopeDokument2 Seiten85-04, The BW Preventive Action Register.: Purpose and Scopedanaka007Noch keine Bewertungen

- Audit SkillsDokument36 SeitenAudit SkillsSudhagarNoch keine Bewertungen

- Control of NC ComponentDokument3 SeitenControl of NC Componentdanaka007Noch keine Bewertungen

- Quality Manual TrostelDokument51 SeitenQuality Manual Trosteldanaka007Noch keine Bewertungen

- Executive OverviewDokument66 SeitenExecutive Overviewdanaka007Noch keine Bewertungen

- Iso TS 16949 2009Dokument30 SeitenIso TS 16949 2009AndroidFlaghipNoch keine Bewertungen

- UoE Internal Audit ProcedureDokument20 SeitenUoE Internal Audit Proceduredanaka007Noch keine Bewertungen

- QAS P008 Control of Non-Conforming Processes, Services or Products ProcedureDokument2 SeitenQAS P008 Control of Non-Conforming Processes, Services or Products Proceduredanaka007Noch keine Bewertungen

- PR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Dokument9 SeitenPR018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2uks444100% (1)

- SPC IntroDokument38 SeitenSPC Introdanaka007Noch keine Bewertungen

- Audit SkillsDokument36 SeitenAudit SkillsSudhagarNoch keine Bewertungen

- Limit, Fits and ToleranceDokument13 SeitenLimit, Fits and ToleranceAnkit NautiyalNoch keine Bewertungen

- Basic Components & Elements of Surface TopographyDokument30 SeitenBasic Components & Elements of Surface TopographyXin YuNoch keine Bewertungen

- GD&T Fundamentals in 40 CharactersDokument76 SeitenGD&T Fundamentals in 40 CharactersAnish PaiNoch keine Bewertungen

- Quality Improvement and Statistical Process ControlDokument64 SeitenQuality Improvement and Statistical Process ControlSakthi Tharan SNoch keine Bewertungen

- Fundamentals of GDandTDokument75 SeitenFundamentals of GDandTanjaiah_19945100% (4)

- Unified Thread StandardDokument8 SeitenUnified Thread Standarddanaka007Noch keine Bewertungen

- Pelton Wheel TurbineDokument7 SeitenPelton Wheel Turbinedanaka007Noch keine Bewertungen

- Strut Vs ColumnDokument1 SeiteStrut Vs Columndanaka007Noch keine Bewertungen

- Sample Calibration ProceduresDokument37 SeitenSample Calibration ProceduresGabriel Dediu100% (1)

- AssumptionDokument1 SeiteAssumptiondanaka007Noch keine Bewertungen

- Acceptence Criteria IMTEDokument12 SeitenAcceptence Criteria IMTEdanaka007100% (1)

- Creating Product and Process Control SystemsDokument35 SeitenCreating Product and Process Control Systemsdanaka007Noch keine Bewertungen

- CSS NC II TESDA Offers Computer System ServicingDokument4 SeitenCSS NC II TESDA Offers Computer System Servicingchandy Rendaje100% (2)

- Title Revision No. Issued Date::: Sm-90 / Sm-500 Specification List 19 28 January 2008Dokument32 SeitenTitle Revision No. Issued Date::: Sm-90 / Sm-500 Specification List 19 28 January 2008john aguirreNoch keine Bewertungen

- Laf 631 1001 1251 1601 enDokument2 SeitenLaf 631 1001 1251 1601 enCarlos PadillaNoch keine Bewertungen

- KUBOTA KC250H DUMPER Service Repair Manual PDFDokument13 SeitenKUBOTA KC250H DUMPER Service Repair Manual PDFufjjdjfkskemmdNoch keine Bewertungen

- Enable or Disable Concurrent Prog Parameters DynamicallyDokument14 SeitenEnable or Disable Concurrent Prog Parameters DynamicallykattaswamyNoch keine Bewertungen

- STORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageDokument4 SeitenSTORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageMilling and Grain magazineNoch keine Bewertungen

- CV - Edson C Ayuste - Senior Instrument Engineer - March2018Dokument8 SeitenCV - Edson C Ayuste - Senior Instrument Engineer - March2018Edson AyusteNoch keine Bewertungen

- Astm E1647Dokument4 SeitenAstm E1647Jorge SuarezNoch keine Bewertungen

- Building Services Branch Testing and Commissioning Procedure No. 8 FOR Liquefied Petroleum Gas Installation IN Government Buildings Hong KongDokument41 SeitenBuilding Services Branch Testing and Commissioning Procedure No. 8 FOR Liquefied Petroleum Gas Installation IN Government Buildings Hong KongKy Pham HongNoch keine Bewertungen

- Citizen Watch Repair 1198-101Dokument5 SeitenCitizen Watch Repair 1198-101David McFaddenNoch keine Bewertungen

- Crompton Greaves Leading Manufacturer of Power EquipmentDokument12 SeitenCrompton Greaves Leading Manufacturer of Power Equipmentcarlos vidal100% (1)

- Madvac LR50e - ExprolinkDokument4 SeitenMadvac LR50e - ExprolinkpppopNoch keine Bewertungen

- This Lab Deals With A Basic Configuration of The Cisco ASADokument15 SeitenThis Lab Deals With A Basic Configuration of The Cisco ASARaveenaNoch keine Bewertungen

- 821F - 921F Catalogo de PartesDokument912 Seiten821F - 921F Catalogo de Partesjose juan100% (12)

- Interfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncDokument38 SeitenInterfacing The MCP215X To A Host Controller: Author: Mark Palmer Microchip Technology, IncglizNoch keine Bewertungen

- 972K SpecalogDokument4 Seiten972K SpecalogMostafa SaadNoch keine Bewertungen

- Sample Code: DecisionDokument16 SeitenSample Code: Decisionhisuman100Noch keine Bewertungen

- Aa Spec 371002Dokument5 SeitenAa Spec 371002JDNoch keine Bewertungen

- Falcon 20 - ATA Chapter 5Dokument14 SeitenFalcon 20 - ATA Chapter 5zoolmiatNoch keine Bewertungen

- Export RFC Destinations Before RefreshDokument5 SeitenExport RFC Destinations Before RefreshivanNoch keine Bewertungen

- EAST+NDT+CHINA Calibration BlocksDokument6 SeitenEAST+NDT+CHINA Calibration BlocksmgmqroNoch keine Bewertungen

- Simosec enDokument44 SeitenSimosec enKumar SwamiNoch keine Bewertungen

- Appendix 6.2-G - Fire Pump Engine SpecsDokument9 SeitenAppendix 6.2-G - Fire Pump Engine Specs050678Noch keine Bewertungen

- Enerveo Quality Policy CommitmentDokument1 SeiteEnerveo Quality Policy CommitmentJohn GeddesNoch keine Bewertungen

- Juris Dev Sunat PDFDokument746 SeitenJuris Dev Sunat PDFCesar GalvezNoch keine Bewertungen

- Config Netapp AutosupportDokument10 SeitenConfig Netapp AutosupportaayoedhieNoch keine Bewertungen

- WPS - 018Dokument12 SeitenWPS - 018MAT-LIONNoch keine Bewertungen

- Z1 ManualDokument6 SeitenZ1 ManualIvana JazidzijaNoch keine Bewertungen

- CSG Type & DesignDokument45 SeitenCSG Type & Designcrown212100% (2)

- RCP/HIL FPGA-Based Real-Time SimulatorDokument2 SeitenRCP/HIL FPGA-Based Real-Time Simulatorjose_jose_jose_89Noch keine Bewertungen