Beruflich Dokumente

Kultur Dokumente

T 80721 en

Hochgeladen von

Rengga Ahmad PrasetiaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T 80721 en

Hochgeladen von

Rengga Ahmad PrasetiaCopyright:

Verfügbare Formate

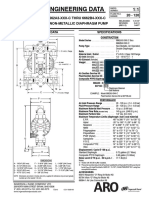

Application

Maintenance-friendly control valve for the petrochemical indus-

try and process engineering

Valve size NPS to 8

Pressure rating Class 150 to 900

Temperatures 325 to 842 F (200 to 450 C)

Type 3291 Globe Valve with:

Type 3271 Pneumatic Actuator (Type 3291-1 Control Valve)

or

Type 3277 Pneumatic Actuator (Type 3291-7 Control Valve)

for integrated positioner attachment

Valve body made of:

Cast steel

Cast stainless steel

High-temperature cast steel

Cold-resisting cast steel

Low-noise valve plug with:

Metal sealing

Soft sealing

High-performance metal sealing

Balanced for handling large differential pressures

Quick and easy maintenance

Clamped-in seat for quick maintenance

The modular design of the control valves allows them to be

equipped with various accessories:

Positioners, limit switches, solenoid valves and other accessories

according to IEC 60534-6 and NAMUR recommendation. See

Information Sheet T 8350 EN for details.

Versions

Standard version (Fig. 1) Globe valve for temperatures from

15 to 430 F (10 to 220 C) NPS to 8

Type 3291-1 (Fig. 1) Type 3291 Globe Valve and

Type 3271 Pneumatic Actuator (refer to T 8310-1/-2 EN)

Type 3291-7 Type 3291 Globe Valve and Type 3277 Pneu-

matic Actuator for integral positioner attachment (refer to

T 8310-1 EN)

Other versions

Welding ends or welding-neck ends acc. to ANSI B16.25

Flow divider For noise reduction, see Table 3c

Perforated plug trim Refer to T 8086 EN

Insulating section or bellows seal See Technical data

Heating jacket On request

Additional handwheel See Data Sheet T 8310-1/-2 EN

Type 3291-3 Hand-operated Valve With Type 3273

Hand-operated Actuator for valves with max. 30 mm rated

travel. Refer to T 8312 EN

Type 3291-2 Electric Control Valve Details on request

NACE version (sour gas) On request

Associated Information Sheets T 8000-x EN

Associated Data Sheets for

Pneumatic Actuators T 8310-1, T 8310-2 EN

Edition November 2012

Data Sheet T 8072-1 EN

Series 290

Pneumatic Control Valves Type 3291-1 and Type 3291-7

Globe Valve Type 3291

ANSI version

Fig. 1 Type 3291-1 Pneumatic Control Valve

with Type 3271 Pneumatic Actuator

Principle of operation

The process medium flows from under the plug (flow to open) in

the direction indicated by the arrow. The position of the valve

plug determines the cross-sectional area between the seat and

plug.

The version with bellows seal (Fig. 4) features a test connection

to allow the stainless steel bellows to be monitored for leakage,

e.g. when the valve is used to control explosive or toxic media.

A pressure-balanced plug (Fig. 3) can be used when high pres-

sures or differential pressures act on the valve plug.

The control valve can be fitted with a flowdivider (Fig. 4, refer to

Table 3c for further details) to reduce noise levels.

Fail-safe positions

Depending on howthe compression springs are arranged in the

actuator (see Data Sheets T 8310-1 EN and T 8310-2 EN for

details), the control valve has two different fail-safe positions

which become effective upon supply air failure:

Actuator stem extends (FA)

The actuator springs close the valve when the supply air fails.

Actuator stem retracts (FE)

The actuator springs open the valve when the supply air fails.

Note: Figs. 2 to 4 show configuration examples.

2 T 8072-1 EN

Fig. 4 Type 3291 Valve with flanges, flow divider

and bellows seal with test connection

Fig. 2 Type 3291-1 Control Valve with flanges and

Type 3271 Pneumatic Actuator

Fig. 3 Type 3291 Valve with welding ends and

insulating section

3 T 8072-1 EN

Table 1 Technical data for Type 3291

Material

Cast steel

A 352 LCC

Cast steel

A 216 WCC

Cast steel

A 217 WC6

Cast stainless steel

A 351 CF3M A 351 CF8M

Valve size NPS to 8

Pressure rating

1)

Class 150 to 900

End connections Flanges All ANSI versions

Welding ends According to ANSI B16.25

Seat/plug sealing Metal sealing Soft sealing High-performance metal sealing

Characteristic Equal percentage Linear Quick opening

Rangeability 50 : 1

Temperature ranges in F (C) Permissible operating pressures acc. to pressure-temperature diagrams (see Information Sheet T 8000-2 EN)

Body without insulating section 14 to 428 F (10 to 220 C) Up to 660 F (350 C)

with high-temperature packing depending on material

Body with Insulating

section

51 to 649 F

(46 to 343 C)

20 to 800 F

(29 to 427 C)

20 to 842 F

(29 to 450 C)

324 to 842 F

(198 to 450 C)

324 to 842 F

(198 to 450 C)

Bellows

seal

51 to 649 F

(46 to 343 C)

20 to 800 F

(29 to 427 C)

20 to 842 F

(29 to 450 C)

324 to 842 F

(198 to 450 C)

324 to 842 F

(198 to 450 C)

Valve

plug

2)

Standard

Metal sealing 324 to 842 F (198 to 450 C)

Soft sealing 324 to 428 F (198 to 220 C)

Balanced

PTFE ring 40 to 428 F (40 to 220 C) Lower temperatures on request

Graphite ring 40 to 842 F (40 to 450 C)

Leakage class according to ANSI/FCI 70-2-2006

Valve

plug

Standard

Metal sealing IV High-performance metal sealing: V

Soft sealing

3)

VI

Balanced, metal sealing Standard: IV (with PTFE or graphite ring) High-performance metal sealing: V (only with PTFE ring)

1)

Class 900 for NPS 3 and larger on request

2)

Only in combination with suitable body material

3)

On request

Table 2 Materials (EN material number)

Standard version

Body and flanges

1)

Cast steel

A 352 LCC

Cast steel

A 216 WCC

Cast steel

A 217 WC6

Cast stainless steel

A 351 CF3M A 351 CF8M

Seat and plug

2)

Metal sealing 1.4006/1.4404 1.4006/1.4404 1.4006/1.4404 1.4404 1.4404

Seal with Soft sealing PTFE with 15 % glass fiber

Balanced PTFE with carbon Graphite

Guide bushings 1.4112 1.4112 2.4610 2.4610

Packing V-ring packing PTFE with carbon, spring 1.4310 or high-temperature packing

Body gasket Graphite seal with metal core

Insulating section

3)

A352 LCC/

A350 LF2

A216 WCC/

A182 F12 Cl. 2

A105

A217 WC6/

A182 F12 Cl. 2

A351 CF3M/

A182 F316L

A351 CF8M/

A182 F316

Bellows seal

Intermediate piece

3)

A352 LCC/

A350 LF2

A216 WCC/

A182 F12 Cl. 2/

A105

A217 WC6/

A182 F12 Cl. 2

A351 CF3M/

A182 F316L

A351 CF8M/

A182 F316

Metal bellows 1.4571

Heating jacket 1.4404/A240 316L

1)

Refer also to pressure-temperature diagrams (T 8000-2 EN)

2)

Seat and metal-seated plug also available stellited or plug made of solid Stellite

3)

Depending on valve bonnet material

4 T 8072-1 EN

Table 3 C

V

and K

VS

coefficients Areas highlighted in gray indicate versions also available with balanced plug

Table 3a Overview with flow divider St I (C

V

I/K

VS

I)

C

V 0.12 0.2 0.3 0.5 0.75 1.2 2 3 5 7.5 10.5 12 20 23 30 42 47 75 105 120 170 190 290 375 420 650

K

VS 0.1 0.16 0.25 0.4 0.63 1.0 1.6 2.5 4 6.3 9 10 16 20 25 36 40 63 90 100 144 160 250 320 360 560

C

V

I

4.2 7 9.5

17 21 26 37 42 67 95 105 150 170 265 335 375 580

K

VS

I 3.6 5.7 8 14.5 18 22 32 36 57 80 90 130 144 225 290 320 500

Seat mm 6/8 12 24 31 38 50 63 80 100 125 150 200

Rated

travel

in 0.5 1.18 2.36

mm 15 30 60

Table 3b Version without flow divider Areas highlighted in gray indicate versions also available with balanced plug

C

V 0.12 0.2 0.3 0.5 0.75 1.2 2 3 5 7.5 10.5 12 20 23 30 42 47 75 105 120 170 190 290 375 420 650

NPS

1

1

2

3

4

6

8

Table 3c Versions with flow divider St I Areas highlighted in gray indicate versions also available with balanced plug

C

V

I 4.2 7 9.5 17 21 26 37 67 95 105 150 170 265 335 375 580

NPS

1

1

2

3

4

6

8

5 T 8072-1 EN

Table 4 Dimensions for Type 3291-1 and Type 3291-7 in standard version

Table 4.1 Dimensions for Type 3291 Valve

Ventil

NPS 1 1 2 3 4 6 8

Length L

Class 150

Flanges RF/

welding ends

(schedule 80)

in 7.24 7.24 8.74 10.0 11.73 13.86 17.76 21.38

mm 184 184 222 254 298 352 451 543

Flanges RTJ

in

7.76 9.25 10.51 12.24 14.37 18.27 21.89

mm 197 235 267 311 365 464 556

Length L

Class 300

Flanges RF/

welding ends

(schedule 80)

in 7.52 7.76 9.25 10.51 12.52 14.49 18.62 22.36

mm 191 197 235 267 318 368 473 568

Flanges RTJ

in 7.95 8.27 9.76 11.14 13.15 15.12 19.25 22.87

mm 202 210 248 283 334 384 489 581

Length L

Class 600

Flanges RF/

welding ends

(schedule 80)

in 7.99 8.27 9.88 11.26 13.27 15.51 20 23.98

mm 203 210 251 286 337 394 508 609

Flanges RTJ

in 7.91 8.27 9.88 11.38 13.39 15.63 20.12 24.13

mm 201 210 251 289 340 397 511 613

Length L

Class 900

Flanges RF/

welding ends

(schedule 80)

in 8.5 10 12.01 14.49 15 17.99 23.98 29.02

mm 216 254 305 368 381 457 609 737

Flanges RTJ

in 8.5 10 12.01 14.61 15.12 18.11 24.09 29.13

mm 216 254 305 371 384 460 612 740

H4

Class 150

to 600

in 5.98 5.98 6.46 8.54 8.74 9.53 13.57 16.14

mm 152 152 164 217 222 242 337 410

Class 900

in 7.32 7.32 7.68 9.88 8.74 9.53 13.27 16.14

mm 186 186 195 251 222 242 337 410

H8

Yoke height

for actuator

350 cm

in 9.45 9.45 9.45 9.45 9.45 9.45

mm 240 240 240 240 240 240

355 cm

in 9.45 9.45 9.45 9.45 9.45 9.45 15.55

mm 240 240 240 240 240 240 395

700 cm

in 9.45 9.45 9.45 9.45 9.45 9.45 15.55 15.55

mm 240 240 240 240 240 240 395 395

1000 cm

in

11.61 11.61 11.61 15.55 15.55

mm 295 295 295 395 395

1400-60 cm

in

11.61 11.61 11.61 15.55 15.55

mm 295 295 295 395 395

1400-120 cm

in

18.90 18.90 18.90

mm 480 480 480

2800 cm

in

18.90 18.90 18.90

mm 480 480 480

H2

NPS 4

and larger

including

base

Class 150

in 1.97 2.36 3.15 3.54 3.94 6.30 8.66 9.84

mm 50 60 80 90 100 160 220 250

Class 300

to 600

in 2.34 2.76 3.54 3.94 4.72 7.09 9.25 10.63

mm 60 70 90 100 120 180 235 270

Class 900

in 2.76 3.15 3.94 4.33 4.72 7.09 9.25 10.63

mm 70 80 100 110 120 180 235 270

6 T 8072-1 EN

Table 4.2 Dimensions for Type 3271 and Type 3277 Pneumatic Actuators

Actuator cm 350 355 700 1000 1400-60 1400-120 2800 2 x 2800

Diaphragm

in 11.02 11.02 15.35 18.19 20.87 21.02 30.31

mm 280 280 390 462 530 534 770

H

1)

in 3.23 4.76 7.87 14.06 11.3 19.29 24.80 44.49

mm 82 121 200 357 287 490 630 1130

H3

2)

Type 3277

in 4.33 4.72 5.12

mm 110 120 130

Type 3271

in 4.33 4.72 5.12 9.25 9.25 14.37 15.94

mm 110 120 130 235 235 365 405

H5 Typ 3277

in 3.98 3.98 3.98

mm 101 101 101

Thread

Type 3277

M30 x 1.5

Type 3271 M60 x 1.5 M100 x 2

a2 Type 3277

G

3

8

(

3

8

NPT)

a Type 3271

G

3

8

(

3

8

NPT)

G

3

4

(

3

4

NPT)

G 1 (1 NPT)

1)

Actuators 350 and 355 cm without lifting ring

2)

Minimum clearance to remove actuator

7 T 8072-1 EN

Dimensional drawings for Type 3291-7 and Type 3291-1

H4

H2

H5

H3

H

L

D

a

a2

H8

Type 3277

Pneumatic Actuator

Type 3291-7

D

a

H

H2

L

H3

H4

H8

Type 3271

Pneumatic Actuator

Type 3291-1

H4

H8

L

Type 3291

with bellows seal or insulating section

Table 5 Weights for Type 3291 Valve as well as Type 3277 and 3271 Actuators in standard version

Valve

NPS

1 1 2

3

4 6

8

Valve without

actuator

(approx. weight)

Class

150/300

lbs 34 39 50 88 137 181 465 1003

kg 15.5 17.5 22.5 40 62 82 211 455

Class 600

lbs 49 62 82 146 231 311 772 1224

kg 22 28 37 66 105 141 350 555

Class 900

lbs 77 90 134.5 218 271 362 860 1456

kg 35 41 61 99 123 164 390 665

Actuator cm 350 355 700 1000 1400-60 1400-120 2800 2 x 2800

Type 3271

(approx.

weight)

Without

handwheel

lbs 17.6 42 48.5 177 154.5 386 992 2095

kg 8 19 22 80 70 175 450 950

With

handwheel

lbs 28.7

On

request

59.5 Only with side-mounted

handwheel, see

T 8310-2 EN

On request

kg 13 27

Type 3277

(approx.

weight)

Without

handwheel

lbs 26 42 57

kg 12 19 26

With

handwheel

lbs 37 51 68

kg 17 23 31

8 T 8072-1 EN

b

a a

d

a

b

c

Type 3291 with insulating section or bellows seal Type 3291 with heating jacket (dimensions on request)

H4

H8

L

Dimensional drawings

Table 6 Dimensions and weights for Type 3291 in standard version with insulating section Without actuator

Nominal size

NPS 1 1 2 3 4 6 8

H4

Class 150

to 600

in 13.90 13.90 14.37 19.17 19.37 20.16 27.09 38.19

mm 353 353 365 487 492 512 688 970

Class 900

in 15.04 15.04 15.39 20.32 19.37 20.16 27.09 38.19

mm 382 382 391 516 492 512 688 970

Weight (kg)

without actuator

Class 150

and 300

lbs

On request

kg

Class 600

lbs 66 79 99 163 249 353 816 1444

kg 30 36 45 74 113 160 370 655

Class 900

lbs 95 108 152 236 293 406 904 1642

kg 43 49 69 107 133 184 410 745

Table 7 Dimensions and weights for Type 3291 in standard version with bellows seal Without actuator

Nominal size

NPS 1 1 2 3 4 6 8

H4

Class 150

in 13.78 13.78 14.25 23.46 23.66 23.66 29.29 41.73

mm 350 350 362 596 601 601 744 1060

Class 300

to 600

in 13.78 13.78 14.25 23.46 23.66 23.66 34.49 57.48

mm 350 350 362 596 601 601 876 1460

Class 900

in 13.46 13.46 13.86 23.03 23.66 23.66 34.49 62.80

mm 342 342 352 585 601 601 876 1595

Weight (kg)

without actuator

Class 150

and 300

lbs

On request

816

On

request

kg 370

Class 600

lbs 66 79 99 163 249 353 816 1444

kg 30 36 45 74 113 160 370 655

Class 900

lbs 95 108 152 236 293 406 904 1642

kg 43 49 69 107 133 184 410 745

Selection and sizing of control valves

1. Calculate the C

V

(K

V

) coefficient according to IEC 60534.

2. Select the valve size and C

V

(K

VS

) coefficient from Table 3.

3. Determine the permissible differential pressure Dp from the

Information Sheet T 8000-4 EN.

4. Select the valve body material from Tables 1 and 2 as well

as from the pressure-temperature diagrams in the

Information Sheet T 8000-2 EN.

The following details are required on ordering

Valve size NPS

Pressure rating Class

Body material According to Table 2

End connection Flanges/welding ends

Bonnet version Bonnet, insulating section or

bellows seal

Plug Standard/balanced

Seal Soft sealing, metal sealing or

high-performance metal sealing

Characteristic Equal percentage, linear or quick

opening

Actuator Type 3271 or Type 3277

(see T 8310-1 EN or T 8310-2 EN)

Fail-safe position Valve CLOSED or valve OPEN

Process medium Density and temperature

(other medium data, if necessary)

Flow rate Under normal or operating condition

for various cases

Pressure Upstream pressure p

1

and downstream

pressure p

2

or differential pressure Dp

for various cases

Accessories Positioner, limit switches, solenoid valve

or others

(refer to Information Sheet T 8350 EN

for details)

This document is exclusively intended to list the technical spec-

ifications. The selection and sizing of the valves must be

performed by trained personnel.

Specifications subject to change without notice.

9 T 8072-1 EN

T 8072-1 EN

SAMSON AG MESS- UND REGELTECHNIK

Weismllerstrae 3 60314 Frankfurt am Main Germany

Phone: +49 69 4009-0 Fax: +49 69 4009-1507

Internet: http://www.samson.de 2

0

1

2

-

1

1

Das könnte Ihnen auch gefallen

- Experimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFDokument6 SeitenExperimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFRengga Ahmad PrasetiaNoch keine Bewertungen

- Petrofac Improves Accuracy of Process Models, Increases Capacity 20% For Gas Plant ExpansionDokument2 SeitenPetrofac Improves Accuracy of Process Models, Increases Capacity 20% For Gas Plant ExpansionRengga Ahmad PrasetiaNoch keine Bewertungen

- JADWAL KULIAHDokument1 SeiteJADWAL KULIAHFikky FrediandikaNoch keine Bewertungen

- HIPPS Valves XV-172/173 Protect Low Pressure SectionDokument1 SeiteHIPPS Valves XV-172/173 Protect Low Pressure SectionRengga Ahmad PrasetiaNoch keine Bewertungen

- CCI Innovative Solutions For HIPPS SystemsDokument8 SeitenCCI Innovative Solutions For HIPPS SystemsRengga Ahmad PrasetiaNoch keine Bewertungen

- Sil Broschuere enDokument24 SeitenSil Broschuere enuserscribd2011Noch keine Bewertungen

- CCI Innovative Solutions For HIPPS SystemsDokument8 SeitenCCI Innovative Solutions For HIPPS SystemsRengga Ahmad PrasetiaNoch keine Bewertungen

- Pin 0907Dokument2 SeitenPin 0907amidi5555913Noch keine Bewertungen

- Layer of Protection AnalysisDokument6 SeitenLayer of Protection AnalysisRengga Ahmad PrasetiaNoch keine Bewertungen

- Little Theatre Lighting Handbook GuideDokument156 SeitenLittle Theatre Lighting Handbook Guidescribdead75% (4)

- Building A Fog MachineDokument3 SeitenBuilding A Fog MachineRengga Ahmad PrasetiaNoch keine Bewertungen

- Fuel Properties - Heat Engines and BoilersDokument50 SeitenFuel Properties - Heat Engines and BoilersRengga Ahmad PrasetiaNoch keine Bewertungen

- LOPA method analysis tool for determining risk and SIL levelsDokument9 SeitenLOPA method analysis tool for determining risk and SIL levelsYasir MehmoodNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Pump Reference PDFDokument2 SeitenPump Reference PDFRolando RodriguezNoch keine Bewertungen

- Turbulent Boundary Layer: Global ParametersDokument49 SeitenTurbulent Boundary Layer: Global Parametersshehbazi2001Noch keine Bewertungen

- ITP InstrumentationDokument9 SeitenITP InstrumentationzhangyiliNoch keine Bewertungen

- Aguadens 16-37 Component SpecDokument1 SeiteAguadens 16-37 Component SpecJosé MacedoNoch keine Bewertungen

- TurbochargersDokument193 SeitenTurbochargersGato Richy95% (22)

- Aircraft Gas Turbine EngineDokument27 SeitenAircraft Gas Turbine Enginepriyanka_667739682Noch keine Bewertungen

- Part Symbols (PMCS)Dokument7 SeitenPart Symbols (PMCS)FA. TEAMSKYNoch keine Bewertungen

- Ductile Iron Gate Valve Acc - To BS Flanged PN 16Dokument2 SeitenDuctile Iron Gate Valve Acc - To BS Flanged PN 16khai ruleNoch keine Bewertungen

- Project Standards and Specifications Steam Jacketing of Piping Rev01Dokument4 SeitenProject Standards and Specifications Steam Jacketing of Piping Rev01Vijay AnandNoch keine Bewertungen

- Inter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2Dokument1 SeiteInter-Discipline Check Routing Sheet: PEC-EN-FRM-X-2387 Rev 2sathishNoch keine Bewertungen

- Homework of Bernoulli EqDokument8 SeitenHomework of Bernoulli EqSinggih OktavianNoch keine Bewertungen

- Instruction Operation Mainteance For Turbocharger Abb VTR 354-11 Glory StarDokument39 SeitenInstruction Operation Mainteance For Turbocharger Abb VTR 354-11 Glory StarHuy Lễ NguyễnNoch keine Bewertungen

- Ponsse Spare Parts PDFDokument391 SeitenPonsse Spare Parts PDFСаняNoch keine Bewertungen

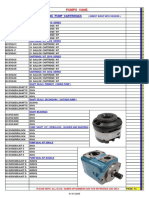

- Sales & Engineering Data: 20 - 120 6662A3-XXX-C THRU 6662B4-XXX-C 2'' Non-Metallic Diaphragm PumpDokument2 SeitenSales & Engineering Data: 20 - 120 6662A3-XXX-C THRU 6662B4-XXX-C 2'' Non-Metallic Diaphragm PumpSaul PerezNoch keine Bewertungen

- Refrigeration Training Unit Operations and Training Manual FinalDokument107 SeitenRefrigeration Training Unit Operations and Training Manual FinalDaniel James MurilloNoch keine Bewertungen

- Add Item N N°Dokument268 SeitenAdd Item N N°Bilel MahjoubNoch keine Bewertungen

- Company management system process design criteriaDokument56 SeitenCompany management system process design criteriaroy bermanaNoch keine Bewertungen

- Process Industry Practices PipingDokument4 SeitenProcess Industry Practices PipingjojonNoch keine Bewertungen

- Anek Industrial Plastics-Welding Machine, Electro Fusion Machine, Hdpe Pipes, Hdpe DWC Pipe, Hdpe PLB Duct, Hdpe Pipe Fittings in MumbaiDokument4 SeitenAnek Industrial Plastics-Welding Machine, Electro Fusion Machine, Hdpe Pipes, Hdpe DWC Pipe, Hdpe PLB Duct, Hdpe Pipe Fittings in Mumbaianek pipeNoch keine Bewertungen

- Fire Water Hydraulic CalculationsDokument23 SeitenFire Water Hydraulic Calculationsmano.ahanjNoch keine Bewertungen

- Gas Turbine QuestionsDokument4 SeitenGas Turbine Questionspramod saljoshiNoch keine Bewertungen

- Types L H PumpsDokument22 SeitenTypes L H PumpsDimitry SilinshNoch keine Bewertungen

- Model VQ Vane Pump CartridgesDokument7 SeitenModel VQ Vane Pump CartridgesglobalindosparepartsNoch keine Bewertungen

- Bungartz enDokument10 SeitenBungartz enmaheshthemtb_8197478Noch keine Bewertungen

- Bernoulli Chapter 3Dokument45 SeitenBernoulli Chapter 3Izzudin HusseinNoch keine Bewertungen

- Spirax PSVDokument62 SeitenSpirax PSVvrushi kadamNoch keine Bewertungen

- Blackmer TX TXD - ManualDokument12 SeitenBlackmer TX TXD - ManualFelipe Ignacio PaillavilNoch keine Bewertungen

- Plumbing SymbolsDokument1 SeitePlumbing Symbolsjeruel50% (2)

- Hydraulics GlossaryDokument5 SeitenHydraulics GlossaryAlan Date100% (1)

- ProjectReport - Btech PDPUDokument42 SeitenProjectReport - Btech PDPUVeviet pomataNoch keine Bewertungen