Beruflich Dokumente

Kultur Dokumente

Fora500 GB1 1

Hochgeladen von

Víctor SandovskyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fora500 GB1 1

Hochgeladen von

Víctor SandovskyCopyright:

Verfügbare Formate

Industeel

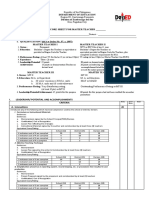

FORA 500

A 500 HB wear resistant steel

Standard

Chemical analysis - % weight

Mechanical properties

FORA 500 -10.06.2011 issue - page 1

FORA 500 steel is particularly suitable for applications

such as quarries, construction equipment, mines, cement

plants, the iron and steel industry, etc

Hardness Y.S. 0.2 UTS

El 5.65s

%

KCVL

-40C (-40F)

500 HB 1400 MPa 1600 MPa 10 30 J

51.5 HRC 195 KSI 245 KSI 10 22 ft.lbs

Typical values

Guaranteed hardness in delivery condition : 460/540 HB (49/54 HRC)

Guaranteed maximum values

C Mn P S Cr Ni Mo B

.30 1.5 .02 .003 1.0 .7 .3 .003

FORA 500 INDUSTEEL Specification

FORA 500 is a water quenched martensitic steel, with a

500HB (51.5 HRC), typical hardness, resistant to very

severe abrasion wear. Thanks to its mechanical properties,

good toughness, high hardness and strength, FORA 500

steel can be used wherever a sliding wear resistance is

required and where 400 HB steels do not provide

sufficiently long service life.

Compared to conventional steels, such as S355, FORA 500

offers a real improvement on the life time of equipment, up

to 5 times longer and consequently allows a significant

reduction in the design thickness.

15

Cu Ni

5

V Mo Cr

6

Mn

C C

eq

+

+

+ +

+ + =

Thickness range - mm () C.Eq Typ

8/50 (.31/1.97) .67

C. Equivalent

FORA 500 -10.06.2011 issue - page 2

Wear test data

Wear resistant properties Processing

Drilling

= 10mm

(.40)

20mm

(0.80)

30mm

(1.18)

Cutting speed

m/min

ft/min

4 - 6

13 - 20

4 - 6

13 - 20

4 - 6

13 - 20

Rotational speed rev/min 130 65 40

Feed mm/rev 0.1 0.2 0.3

Tapping

= 10mm

(.40)

20mm

(0.80)

30mm

(1.18)

Cutting speed

m/min

ft/min

1 - 3

3.3 - 10

1 - 3

3.3 - 10

1 - 3

3.3 - 10

Rotational speed rev/min 50 30 20

Milling

Depth

mm ()

Cutting speed

m/min ()

Feed

(mm/tooth)

HSSCO

AR 12.0.5.5 (T15)

1 (.04)

4 (.16)

8 (.31)

100-120(3.9-4.7)

80-100(3.1-3.9)

50- 80 (2-3.1)

0.08

0.10

0.15

F40M

1 to 5

.04 to .20

70 to 200

2.7 to 7.9

.15 to .35

Water jet cutting or shearing can also be used

Machining

Drilling and milling should be performed with super-

carburized cobalt high-speed steel type HSSCO, using

wherever possible an oil lubricant. However, classical

high-speed steels can be used. The typical cutting

parameters are :

Thickness

8-10mm

(.3-.4)

> 10mm

(> .4)

Cutting

temperature

10C (50F) No preheating

Pre-heating

100-150C

(212-302F)

< 10C (50F) Preheating 100-150C (212-302F)

Cutting

All the classical thermal cutting processes are compatible

with FORA 500 (gas, plasma, laser).

Plates 8 to 10 mm (.3 to .4) thick do not require pre-

heating if thermal cutting is performed at a temperature

higher than 10C (50F). Where this is not the case or

where the plates are thicker than 40mm (1.6''), pre-

heating at 100-150C (200-300F) is recommended.

Hardness

High energy impact

S355

FORA 400

FORA 500

L

i

f

e

t

i

m

e

C

a

l

c

a

r

e

o

u

s

G

y

p

s

u

m

D

o

l

o

m

i

t

e

K

a

o

l

i

n

B

a

u

x

i

t

e

F

e

,

C

u

,

Z

n

A

u

,

A

g

.

.

.

C

o

k

e

.

.

.

Q

u

a

r

t

z

i

t

e

.

.

.

5

10

15

Minerals

5

10

15

Medium energy impact - Wet media

L

i

f

e

t

i

m

e

FORA 500

FORA 400

S355

C

a

l

c

a

r

e

o

u

s

G

y

p

s

u

m

D

o

l

o

m

i

t

e

K

a

o

l

i

n

B

a

u

x

i

t

e

F

e

,

C

u

,

Z

n

A

u

,

A

g

.

.

.

C

o

k

e

.

.

.

Q

u

a

r

t

z

i

t

e

.

.

.

Minerals

Hardness

5

10

15

L

i

f

e

t

i

m

e

C

a

l

c

a

r

e

o

u

s

G

y

p

s

u

m

D

o

l

o

m

i

t

e

K

a

o

l

i

n

B

a

u

x

i

t

e

F

e

,

C

u

,

Z

n

A

u

,

A

g

.

.

.

C

o

k

e

.

.

.

Q

u

a

r

t

z

i

t

e

.

.

.

Low energy impact - Dry media

Minerals

FORA 400

FORA 500

S355

Hardness

FORA 500 -10.06.2011 issue - page 3

Pre-Post heating conditions

Combined thicknesses

FORA 500 can be welded without any crack risk and

without preheating up to a combined plate thickness of

10 mm (.4").

For higher thicknesses, the following conditions are

recommended :

th'2

th'1

th1 th2

th'3

comb.th

= th1 + th2

Comb.th

= 2xth'1 + th'2+th'3

Bending

Thanks to the high refining level of the steel (low sulphur

and phosphorous contents), FORA 500 is easy to bend

provided that following conditions are respected :

Dressing (or grinding) of the ridges caused by

gas-cutting to limit hardened zones,

Sufficiently powerful equipment,

Respect of minimum forming radius.

For plates below 20 mm (.8) thickness, forming

conditions are summarized in following table ; beyond

20 mm (0.8"), consult us.

Whitin these allowable

bending parameters, the

force required to form a

plate is function of the

bent length, the metal

thickness, die opening,

die form (V or U), punch

form etc

The following table shows the bending

forces, for the minimum die opening

(V=18 th), required for V bending plates for for 1m bent.

* 10%

FORA 500 steel is unsuitable for hot forming at a

temperature higher than 200C (392F).

v

Th

v

Th

R

i

th = thickness

Perpendicular to

the rolling direction

Parallel to

the rolling direction

Bending internal radius

R

i

(mini)

7 x th 9 x th

Die opening V (mini) 18 x th 22 x th

Bending angle = 90

Thickness

mm ()

Bending force

required per

meter of bend *

(tons/m)

5mm (.20) 60

10mm (.40) 115

15mm (.60) 170

20mm (.78) 230

th

L

Welding

FORA 500 can be welded using following parameters :

Weld preparation

Weld surfaces must be dry, clean and superficially ground

in order to eliminate any rust, scale, grease or paint

traces as well as any gas-cutting ridges.

Welding process

Any conventional fusion welding method can be used,

such as submerged arc welding (SAW), manual metal arc

welding (SMAW), flux core wire arc welding (FCAW),

MIG, MAG (GMAW) and TIG (GTAW).

Heat input should be limited to 10-30 kJ/cm with

maximum interpass temperature between preheating

temperature and 200/220C (390-430F) maxi.

Welding consumable

All products in accordance with following standards are

acceptable :

Stick Electrodes MIG-MAG

Flux core wire

gas protected

Submerged

arc welding

Wire-flux

AFNOR

NF A81-340

EY50 1NiMo Bxxx1xTBH

NF A81-322

FP/x xx/xx xB xSA31

47 05 04

ASW

A5-5-81 E 70xx

A5-28

ER 70 S-x

A5-29 E 7xT5-x A5-23 F7P4-Exxx-A2

DIN

DIN 1913 E51 55 BX

Preheating

No preheating 150C (300F) 200C (400F)

comb

th

< 10mm (.4) 12-20mm (.4-.8) > 20mm (.8)

FORA 500 - 10.06.2011 issue - page 4

For any information

Industeel France

Le Creusot Plant

56 rue Clemenceau

F-71202 Le Creusot Cedex

Tel +33 3 85 80 58 32 (Sales)

+33 3 85 80 57 29 (Mkt)

Fax +33 3 85 80 55 00

Industeel Belgium

266 rue de Chatelet

B-6030 Marchienne au Pont

Tel +32 71 44 18 26 (Sales)

Fax +32 71 44 19 50

www.industeel.info

www.arcelormittal.com

Sizes - Tolerances

FORA 500 is available in a large dimensional programme :

Applications

Quarries, Construction, Earth moving

Screens, bunkers, bulldozers...

Cement plants

Scrapers, crushers, bunkers...

Mines, coal mines

Crushers, winding and discharging machines, etc...

Iron and steel industry

Bunkers, guide and shifting plates...

Nota

1.Technical data and information are to the best of our knowledge at the time of printing. However, they may be

subject to some slight variations due to our ongoing research programme on wear resistant grades. Therefore, we

suggest that information be verified at time of enquiry or order.

Furthermore, in service, real conditions are specific for each application. The data presented here are only for the

purpose of description, and considered as guarantees when written formal approval has been delivered by our

company.

* .31 in every 40

Plates outside this dimensional programme can be available after

agreement. Please, ask us.

Thickness Quarto

Flatness

mm/m

(*)

mm inch width mm width

Tol./th

(mm)

8-10 .31 -.40 1200-2500 47-98.4 0.6 8 (.31)

10-11 .40 - .43 1200-3000 47-118 0.6 8 (.31)

11-60 .43- 2.36 1200-3000 47-118 0.7 8 (.31)

Typical lengths

mm ft ()

4 000 13.12

6 000 19.68

8 000 26.24

10 000 32.80

Das könnte Ihnen auch gefallen

- Auxiliary Sheet Geological Log N.1Dokument24 SeitenAuxiliary Sheet Geological Log N.1Víctor SandovskyNoch keine Bewertungen

- Ok TC FlotationDokument4 SeitenOk TC FlotationWilliam SalcedoNoch keine Bewertungen

- Tankcell Frothmaster: E C H N O L O G YDokument2 SeitenTankcell Frothmaster: E C H N O L O G YVíctor SandovskyNoch keine Bewertungen

- The Frothbuster - A Solution To Frothing Thickeners Authors: Ian Arbuthnot - Outokumpu Technology Pty LTD Carla Kaboth - Normandy Mining LTD (Golden Grove)Dokument2 SeitenThe Frothbuster - A Solution To Frothing Thickeners Authors: Ian Arbuthnot - Outokumpu Technology Pty LTD Carla Kaboth - Normandy Mining LTD (Golden Grove)Víctor SandovskyNoch keine Bewertungen

- Froth ConDokument4 SeitenFroth ConVíctor SandovskyNoch keine Bewertungen

- The OK Flotation ConceptDokument2 SeitenThe OK Flotation ConceptMiguel Garcia GuevaraNoch keine Bewertungen

- Froth BusterDokument2 SeitenFroth BusterVíctor Sandovsky0% (1)

- Courier® 30XPDokument4 SeitenCourier® 30XPVíctor Sandovsky100% (1)

- Courier® 3SL (Outokumpu)Dokument8 SeitenCourier® 3SL (Outokumpu)Víctor SandovskyNoch keine Bewertungen

- Peru KeyDokument12 SeitenPeru KeyVíctor SandovskyNoch keine Bewertungen

- Courier® 30SX (Outokumpu)Dokument8 SeitenCourier® 30SX (Outokumpu)Víctor SandovskyNoch keine Bewertungen

- Sirius 314: A 25% CR - 1.8 % Si Heat Resistant Stainless SteelDokument4 SeitenSirius 314: A 25% CR - 1.8 % Si Heat Resistant Stainless SteelVíctor SandovskyNoch keine Bewertungen

- Sirius 310SDokument4 SeitenSirius 310SVíctor SandovskyNoch keine Bewertungen

- Fora450GB1 1Dokument4 SeitenFora450GB1 1Víctor SandovskyNoch keine Bewertungen

- A 400 HB Wear Resistant Steel: StandardDokument4 SeitenA 400 HB Wear Resistant Steel: StandardVíctor SandovskyNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2015 English Grade 7Dokument16 Seiten2015 English Grade 7AyushNoch keine Bewertungen

- NPMHU, USPS Contract Arbitration AwardDokument73 SeitenNPMHU, USPS Contract Arbitration AwardPostalReporter.comNoch keine Bewertungen

- Desalting Opportunity CrudesDokument8 SeitenDesalting Opportunity CrudesTheophile MegueptchieNoch keine Bewertungen

- Presentation On Dysuria 1Dokument25 SeitenPresentation On Dysuria 1ankur acharyaNoch keine Bewertungen

- ITCC in Riyadh Residential Complex J10-13300 16715-1 Voice & Data Communication CablingDokument16 SeitenITCC in Riyadh Residential Complex J10-13300 16715-1 Voice & Data Communication CablinguddinnadeemNoch keine Bewertungen

- Red Sea Coral Reef InfoDokument7 SeitenRed Sea Coral Reef Infoapi-310954411Noch keine Bewertungen

- Made in His ImageThe Amazing Design of The Human BodyDokument4 SeitenMade in His ImageThe Amazing Design of The Human BodyAriam MariaNoch keine Bewertungen

- Chapter 2 Body CoordinationDokument25 SeitenChapter 2 Body CoordinationnanarahmannaimNoch keine Bewertungen

- Identification of Plastics Identification of PlasticsDokument41 SeitenIdentification of Plastics Identification of PlasticsSoumickNoch keine Bewertungen

- An Assestment of The Trinidad and Tobago Health Care SystemDokument4 SeitenAn Assestment of The Trinidad and Tobago Health Care SystemMarli MoiseNoch keine Bewertungen

- Antithesis Essay Joseph JaroszDokument3 SeitenAntithesis Essay Joseph JaroszJoseph JaroszNoch keine Bewertungen

- Whisper 500 Spec SheetDokument1 SeiteWhisper 500 Spec Sheetfranco cuaylaNoch keine Bewertungen

- I. Leadership/ Potential and Accomplishments Criteria A. InnovationsDokument5 SeitenI. Leadership/ Potential and Accomplishments Criteria A. InnovationsDEXTER LLOYD CATIAG100% (1)

- EO MNC 10 June 2022Dokument4 SeitenEO MNC 10 June 2022LeulaDianneCantosNoch keine Bewertungen

- Effect of Educational Environment On Personality and Adjustment of Female Students Studying in Colleges of UttarakhandDokument5 SeitenEffect of Educational Environment On Personality and Adjustment of Female Students Studying in Colleges of UttarakhandESSENCE - International Journal for Environmental Rehabilitation and ConservaionNoch keine Bewertungen

- Construction Quality Control PlanDokument35 SeitenConstruction Quality Control PlanMalik Riaz100% (4)

- Healthy and Unhealthy FoodDokument16 SeitenHealthy and Unhealthy FoodGeovanny ValladarezNoch keine Bewertungen

- Employement ExchangeDokument22 SeitenEmployement ExchangeNeelam ThakurNoch keine Bewertungen

- Wind Energy Wind Is Generated As The Fluid and Gaseous Parts of The Atmosphere Move Across The Surface of The EarthDokument3 SeitenWind Energy Wind Is Generated As The Fluid and Gaseous Parts of The Atmosphere Move Across The Surface of The EarthEphraim TermuloNoch keine Bewertungen

- Conut Shell: A Substitute For Aggregate in Mix Proportioning of CementDokument17 SeitenConut Shell: A Substitute For Aggregate in Mix Proportioning of CementStephanie SilaoNoch keine Bewertungen

- Daftar Pustaka ProposalDokument4 SeitenDaftar Pustaka ProposalraniNoch keine Bewertungen

- Patrick Califia Speaking Sex To Power Perverts Freethinkers and The Politics of Sex The Politics of Pleasure and PerversityDokument443 SeitenPatrick Califia Speaking Sex To Power Perverts Freethinkers and The Politics of Sex The Politics of Pleasure and PerversityStefanos PopofNoch keine Bewertungen

- The Relationship Between Date of Birth and IndividDokument13 SeitenThe Relationship Between Date of Birth and IndividAnonymous ktNyZTNoch keine Bewertungen

- Conditional Type 0Dokument16 SeitenConditional Type 0marore100% (1)

- Food Habits & Dance Culture Faridkot (Punjab) : Presented By: Kendriya Vidyalaya FaridkotDokument17 SeitenFood Habits & Dance Culture Faridkot (Punjab) : Presented By: Kendriya Vidyalaya FaridkotJagdeep KaurNoch keine Bewertungen

- Tumor Saluran Kemih (Tumors/Malignancy of Urinary Tract) : Dr.M.Galuh Richata, SpuDokument22 SeitenTumor Saluran Kemih (Tumors/Malignancy of Urinary Tract) : Dr.M.Galuh Richata, SpuLuthfiAhmadNoch keine Bewertungen

- Denon DHT-T100 Ver 3 PDFDokument34 SeitenDenon DHT-T100 Ver 3 PDFboroda241083% (6)

- Civrev2 2019 Case TitlesDokument3 SeitenCivrev2 2019 Case TitlesAnne VallaritNoch keine Bewertungen

- Eaton 092394 T5B 3 7 E en - GBDokument6 SeitenEaton 092394 T5B 3 7 E en - GBJorge AmayaNoch keine Bewertungen

- (AC-S07) Week 07 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (7573)Dokument5 Seiten(AC-S07) Week 07 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (7573)Lucero JimenezNoch keine Bewertungen