Beruflich Dokumente

Kultur Dokumente

Overhead Distribution Systems

Hochgeladen von

mujeeb.alam40 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

367 Ansichten13 SeitenOverhead Distribution System, Aramco Standards, Electrical Systems Designs,

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenOverhead Distribution System, Aramco Standards, Electrical Systems Designs,

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

367 Ansichten13 SeitenOverhead Distribution Systems

Hochgeladen von

mujeeb.alam4Overhead Distribution System, Aramco Standards, Electrical Systems Designs,

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 13

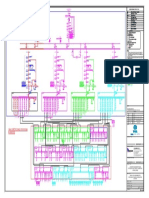

Engineering Standard

SAES-P-107 19 October 2008

Overhead Distribution Systems

Electrical Systems Designs and Automation Standards Committee Members

Hamrani, Majed Muhsen, Chairman

Sultan, Mansour Ramadan, Vice Chairman

Hassouneh, Awwad Shaban

Fateel, Adel Mahdi

Ghamdi, Abdulaziz Abdullah

Hamood, Abdulrazaq Abduljabbar

Almadi, Soloman Musa

Ba Hamdan, Mohammed Omar

Lourido Martelo, Lisardo

Bugshan, Jamal Ahmed

Shaikh Nasser, Ahmed Nasser

Badrani, Hamed Sulaiman

Zayan, Mahmoud Bahi El-Din

Saudi Aramco DeskTop Standards

Table of Contents

1 Scope........................................................... 2

2 Conflicts and Deviations............................... 2

3 References................................................... 2

4 General......................................................... 5

5 Supporting Structures................................... 7

6 Armless Construction................................... 8

7 Guys, Messengers and Anchors.................. 8

8 Insulator Requirements................................ 9

9 Primary Conductors...................................... 10

10 Accessory Equipment................................... 12

11 Protective Devices........................................ 12

Previous Issue: 7 April 2008 Next Planned Update: 7 April 2013

Revised paragraphs are indicated in the right margin Page 1 of 13

Primary contact: Hamrani, Majed Muhsen on 44-118-9135640

CopyrightSaudi Aramco 2008. All rights reserved.

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 2 of 13

1 Scope

This Standard prescribes minimum mandatory requirements for the design and

installation of overhead distribution systems rated through 34.5 kV. This document

may not be attached to nor made a part of purchase orders.

2 Conflicts and Deviations

2.1 Any conflicts between this Standard and other Mandatory Saudi Aramco

Engineering Requirements (MSAERs*) or referenced industry standards shall be

resolved in writing by the Chairman, Electrical Systems Designs & Automation

Standards Committee, Consulting Services Department, Saudi Aramco,

Dhahran.

* Examples of MSAERs are Saudi Aramco Materials System Specifications

(SAMSSs), Engineering Standards (SAESs) and Standard Drawings (SASDs).

2.2 Deviation from this Standard shall be approved by the Chairman, Electrical

Systems Designs & Automation Standards Committee, Consulting Services

Department, Saudi Aramco, Dhahran, and shall follow Saudi Aramco procedure

SAEP-302.

2.3 The designation "Commentary" is used to label a sub-paragraph that contains

comments that are explanatory or advisory. These comments are not mandatory,

except to the extent that they explain mandatory requirements contained in this

SAMSS.

3 References

All referenced Standards, Specifications, Codes, Forms, Drawings, and similar material

shall be of the latest issue (including all revisions, addenda, and supplements) unless

stated otherwise.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302 Instructions for Obtaining a Waiver of a

Mandatory Saudi Aramco Engineering

Requirement

Saudi Aramco Engineering Standards

SAES-A-112 Meteorological and Seismic Design Data

SAES-B-064 Onshore and Nearshore Pipeline Safety

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 3 of 13

SAES-P-104 Wiring Methods and Materials

SAES-T-903 Telecommunications Outside Plant Electrical

Protection and Grounding

The following SAMSSs and drawings are applicable to overhead line

construction:

Saudi Aramco Materials System Specifications

14-SAMSS-600 Material, Manufacture, and Preservation of Wood

Poles

14-SAMSS-602 Material, Manufacture, and Preservative

Treatment of Wood Crossarms

Saudi Aramco Standard Drawings

AE-036014 Pole Setting (2 Sheets)

AA-036015 Armless Construction, Double Deadend Structure,

2.4, 4.16, 13.8, and 34.5 kV

AD-036016 Bonding Details, Armless Construction, Angle

Structure, 60 to 90 deg

AC-036021 Armless Construction, Angle Structure, 15 to 30

deg, 2.4, 4.16, 13.8, and 34.5 kV

AC-036022 Armless Construction, Angle Structure, 60 to 90

deg, 2.4, 4.16, 13.8, and 34.5 kV

AD-036023 Guy and Anchors, Down Guys (3 Sheets)

AE-036034 Pole Footing Increased Bearing Area

AE-036036 Pole Rake

AE-036037 Pole Protection Guard

AD-036063 Guy and Anchors, 10.8 k Sidewalk Guy

Installation

AD-036064 Guy Anchors Power Installed Screw

AD-036066 Guy and Anchors, 8 k Overhead Guy (3 Sheets)

AD-036070 Rock Anchor Installation

AC-036079 Armless Construction, Tangent Structure, 0 to 2

deg, 2.4, 4.16, 13.8, and 34.5 kV

AC-036085 Armless Construction, Angle Structure, 0 to 15

deg, 2.4, 4.16, 13.8, and 34.5kV

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 4 of 13

AC-036102 Armless Construction, Angle Structure, 30 to 60

deg, 2.4, 4.16, 13.8, and 34.5 kV

AC-036104 Armless Construction, Full Deadend Structure,

2.4, 4.16, 13.8, and 34.5 kV

AC-036112 Armless Construction, 3-Phase Tap Structure, 2.4,

4.16, 13.8, and 34.5 kV

AA-036121 Sh. 1 Deadend Riser Pole with Fuse Disconnect

AA-036121 Sh. 2 Tap-Off Tangent Riser Pole with Fuse Disconnect

AD-036133 Switch Grounding Detail

AD-036135 Bonding Details, Post Insulators

AD-036136 Bonding Details, Armless Construction, Angle

Structure, 30 to 60 deg

AA-036390 Deadend/Tap-off Pole with Transformer

Installation (2 sheets)

3.2 National Standards

Kingdom of Saudi Arabia Ministry of Transportation

Highway Design Manual

3.3 Industry Codes and Standards

American National Standards Institute

ANSI/IEEE C2 National Electrical Safety Code (NESC)

ANSI/NFPA 70 National Electrical Code (NEC)

ANSI O5.1 Wood Poles - Specifications and Dimensions

ANSI C29.1 Electrical Power Insulators - Test Methods

ANSI C29.2 Insulators - Wet-Process Porcelain and

Toughened Glass - Suspension Type

ANSI C29.4 Wet-Process Porcelain Insulators - Strain Type

ANSI/NEMA C29.7 Porcelain Insulators - High-Voltage Line-Post

Type

ANSI/NEMA C29.9 Wet-Process Porcelain Insulators - Apparatus,

Post-Type

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 5 of 13

American Society for Testing Materials

ASTM B549 Standard Specification for Concentric-Lay-

Stranded Aluminum Conductors, Aluminum-

Clad Steel Reinforced (ACSR/AW)

4 General

4.1 Overhead distribution systems shall be in accordance with ANSI/IEEE C2

(NESC), as supplemented by this Standard and the Saudi Aramco standard

drawings listed above.

4.2 Overhead lines shall be designed and constructed to NESC Grade B

requirements for light loading conditions.

4.3 Overhead line design shall be based on the following environmental conditions:

Minimum temperature : 0C

Maximum temperature : 50C

Wind speed (50 yr.) : 160 km/hr

Exception:

In specific locations covered by SAES-A-112, environmental data from

SAES-A-112 may be used with concurrence of Coordinator, CSD/Electrical

Systems Division.

4.4 The following shall be submitted to Coordinator, CSD/Electrical Systems

Division for review during detailed design of new overhead distribution lines

which exceed 5 spans in length:

Sag and tension calculations

Sag/Temperature Templates

Plan and profile drawings

Exception:

Plan and profile drawings are not required if:

1) The changes in elevation between any two poles would not result in

variations of more than 2 meters in the vertical clearance of the lowest

conductor. (i.e., the terrain is flat).

2) The span lengths do not exceed 90 m.

3) Drawings are provided that show the route of the line.

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 6 of 13

Commentary Note 4.4:

Distribution line spans should normally not exceed 90 m in length. Vertical

clearances required by Section 4.7 of this standard must be maintained

regardless of terrain variations.

4.5 Compression type (gripping force is provided by compressing the connector

onto the conductor using a tool designed for the purpose and is non-reversable)

connectors shall be used for splicing and tapping. Connectors for aluminum

(ACSR) conductors shall be filled with an oxide inhibiting and sealing

compound such as Burndy PENETROX.

4.5.1 Compression type lugs shall be used for overhead line connections to

equipment furnished with pad type terminals.

4.5.2 Compression lugs or splices used for connections of insulated or covered

cables to overhead lines shall have a closed barrel or solid center stop to

prevent ingress of water into the insulated cable.

4.6 Non-current carrying metallic enclosures, brackets, and braces shall be bonded

together via grounding lugs and shall be connected to a grounding electrode

conductor. Pole ground conductors shall be minimum 4 AWG, stranded, soft

drawn, bare copper. Refer to AA-036015, AD-036016, AD-036135 and/or

AD-036136 for details.

4.7 Vertical clearances above grade for desert installations of conductors, including

service drops, messengers, and guys shall be minimum 8.5 m at final unloaded

sag, no wind, and 50C ambient temperature. For designs using emergency

service conditions, minimum vertical clearance shall be calculated using 120C

total conductor temperature. In plants, construction camps, residential areas,

and other non-desert areas minimum clearance shall be per ANSI/IEEE C2

unless larger clearances are required by the facility proponent.

4.8 Vertical clearances above grade for plant entrances shall be determined by the

proponent. Minimum clearance shall be 8.5 m under the conditions specified in

Paragraph 4.7 above.

4.9 Aerial-to-underground transitions shall be in rigid galvanized steel conduit or

PVC coated galvanized rigid steel conduit in accordance with the requirements

of SAES-P-104.

4.10 See SAES-B-064 for requirements relating to horizontal clearances between

pipelines and powerline conductors and for horizontal clearances between

pipelines and powerline support structures.

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 7 of 13

4.11 Designs for single phase circuits shall include provisions for future conversion

to three phase without requiring additional design work. Clearances, pole

heights, guys, crossarm dimensions, pole loadings, etc., shall be designed

assuming addition of a third phase conductor identical to those being installed.

Exception:

Not required if proponent of the line verifies that future upgrade of the line will not

be necessary.

5 Supporting Structures

5.1 Supporting structures for overhead lines shall hotdipped galvanized steel or

seamless aluminum alloy poles in plants and other industrial facilities and

fiberglass poles or wood poles meeting the requirements of 14-SAMSS-600 for

non-industrial locations.

Exception:

Wood poles shall be permitted for use in stand alone Water Injection Plants,

Water Treatment Plants, and for supply lines located outside of industrial and

plant areas (for example, Cathodic Protection supply lines in desert areas).

5.2 Wood poles used for supporting structures shall be Class 4 or better as defined

in ANSI O5.1.

5.3 Supporting structure, guy, messenger, and anchor locations shall be selected

based on accessibility, limited use of guys, minimal obstructions to pedestrian

and vehicular traffic, and shall be as inconspicuous as possible.

5.4 Where required (as determined by the Superintendent of the Area Loss

Prevention Division and the proponent organization), supporting structures

located less than 9 m from a roadway shall be protected by barriers meeting the

requirements of the Highway Design Manual, Volume 2, Part 1, Section 1.15.

Supporting structure clearance from curbs shall be maintained at a minimum of

0.6 m from face of curb.

5.5 Wood supporting structures shall have a dating nail indicating the year of

installation located at approximately 2 m above grade

5.6 Setting depths for wood poles shall be as shown on standard drawing

AE-036014.

5.7 Support structures shared by power conductors and communications cables

shall also meet requirements of SAES-T-903.

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 8 of 13

6 Armless Construction

6.1 Armless type construction shall be used for the conductor support system

(See referenced Standard Drawings).

Commentary Note 6.1:

"Armless" refers to the general type of construction. Crossarms may be used for

deadend structures, tap-off structures, etc., in accordance with the referenced

standard drawings.

6.2 Horizontal loading for line post insulators shall not exceed 2.2 kN for initial sag

at the minimum temperature per paragraph 4.3, and wind loading of 430 pa.

6.3 Line conductors up to 336.4 kcmil ACSR shall be dead-ended for line angles

larger than 30. Line conductors 336.4 kcmil and larger shall be dead-ended for

line angles larger than 5.

6.4 Lines more than 2 km long shall be double dead-ended a minimum of every

1.5 km.

7 Guys, Messengers and Anchors

7.1 All materials and dimensions shall withstand loads developed from sag

conditions at the minimum temperature per paragraph 4.3. Strand ultimate

strength shall be the weakest component of guy and messenger assemblies.

7.2 The angle between a down-guy and the supporting structure shall not exceed

60.

7.3 The use of sidewalk guys shall be limited to supporting structure loads of less

than 6.6 kN. Sidewalk guy horizontal member shall consist of a 2 in galvanized

pipe at a minimum height of 2.4 m above grade.

7.4 Sidewalk guys shall have reflective finished guy guards with the open side of

the guard facing away from the sidewalk.

7.5 Overhead guys shall be connected to the supporting structure grounding

electrode conductor at both ends. Down guys shall be connected at the upper

end.

7.6 Guys from supporting structures having ungrounded or resistance grounded

circuits shall be insulated with strain insulators.

7.7 For installations where a section of the guy crosses under or over supply

conductor circuits connected to other supporting structures rated in excess of

300 V, or which pass within a 3 m radius of such circuit conductors, the guy

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 9 of 13

section shall be insulated from ground. The exposed section shall be isolated

from points within 1.8 m of the supporting structure. Insulators shall be located

a minimum of 2.4 m above grade and below the lowest power conductor.

7.8 Guy insulators shall not be used with guy strands having ultimate strengths

greater than 80 kN.

7.9 Guy insulators shall have a rated ultimate strength greater than the rated

breaking strength of the guy.

7.10 Insulators are not required for messengers supporting street lighting cables,

secondary conductors of series lighting circuits, and traffic signal conductors.

7.11 Guy and messenger attachment hardware shall be preformed type dead end

fittings or automatic guy grips.

7.12 Messengers shall be of the stranded steel type. Messengers shall be sized for the

ultimate number of cables to be installed.

7.13 Power-installed screw anchors or rock anchors shall be used, except in hard marl

soil where expanding type anchors are permitted. Anchors shall not be loaded in

excess of 35% of their ultimate allowable holding strength. If required for

holding in poor soils, other anchor designs may be used with the concurrence of

Coordinator, Electrical Systems Division, Consulting Services Department.

7.14 Anchors shall not extend above ground in excess of the length necessary for

attachment requirements.

8 Insulator Requirements

8.1 Except where specifically noted otherwise in this document or the referenced

standard drawings, minimum insulator creepage for components shall be 40 mm

per kV line-to-line nominal system voltage.

8.2 Post and suspension type insulators shall be used. Pin type insulators shall not

be used. Insulator brackets shall be metallic. Semiconducting or resistive glaze

insulators shall not be used.

8.3 Insulators used on overhead distribution systems shall meet the requirements of

the ANSI C29 series of standards. Specifically: (1) Insulators shall be tested in

accordance with C29.1; (2) Suspension type insulators shall be in accordance

with ANSI C29.2; (3) Strain type insulators shall be in accordance with ANSI

C29.4; (4) Line-post type insulators shall be in accordance with ANSI/NEMA

C29.7; (5) Station-post type insulators shall be in accordance with ANSI C29.9;

(6) Preferred insulator color is chocolate brown.

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 10 of 13

8.4 Insulators shall not be loaded in excess of 40% of their rated ultimate strength.

8.5 Fog type porcelain suspension insulators shall be used to terminate overhead

circuits at a substation bay or supporting strain bus. For these applications, an

insulating string shall consist of a minimum of 2 units at 13.8 kV and 4 units at

34.5 kV.

9 Primary Conductors

9.1 Conductors shall be ACSR/AW (aluminum conductor, aluminum clad steel

reinforced)/AW per ASTM B549 and Table 1.

Table 1

Code Word mm Awg Kcmil

SWAN/AW 21.1 4 41.7

SPARROW/AW 33.6 2 66.36

RAVEN/AW 53.5 1/0 105.6

QUAIL/AW 67.4 2/0 133.1

PENGUIN/AW 107.2 4/0 211.6

MERLIN/AW 170.2 336.4

ORIOLE/AW 170.5 336.4

DRAKE/AW 402.8 795.0

9.2 Phase rotation shall be x y z (a b c) counterclockwise.

9.3 Phase positions shall be per Table 2.

Table 2

Construction Phase/Neutral Position

HORIZONTAL X OR A EAST OR NORTH

Y OR B CENTER

Z OR C WEST OR SOUTH

NEUTRAL

OR SOUTH

BELOW, EAST

VERTICAL X OR A TOP

Y OR B CENTER

Z OR C BOTTOM

NEUTRAL BELOW

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 11 of 13

9.4 Bare conductor rated ampacities shall be as per Table 3.

Table 3

Service Condition

Code Word Kcmil Normal

(Amperes)

Emergency

(Amperes)

SWAN/AW 41.74 110 165

SPARROW/AW 66.36 150 215

RAVEN/AW 105.6 200 300

QUAIL/AW 133.1 260 335

PENGUIN/AW 211.6 305 445

MERLIN/AW 336.4 440 650

RAKE/AW 795.0 760 1105

Table 3 Notes:

(1) Normal service conditions are defined as follows:

80C conductor temperature

50C ambient temperature

0.6 m/sec wind velocity

(2) Emergency service conditions are defined as follows:

120C conductor temperature

50C ambient temperature

0.6 m/sec wind velocity

(3) Radial lines shall be designed based on normal service conditions for the maximum

operating load. Distribution loops and lines feeding double-ended substations shall be

designed using normal service conditions.

Exception:

The emergency service conditions may be used for designing for abnormal

operation during outages which cause a distribution loop to be fed from only one

end or a double ended substation to be fed from one line only.

9.5 Conductor tension shall not exceed 10% of the conductor ultimate strength. Sag

and tension calculations shall be based on maximum and minimum ambient

temperatures per Paragraph 4.3. For lines subject to emergency service

conditions, maximum sag shall be calculated based on emergency service

conditions shown in Paragraph 9.4 Note 2.

9.6 Overhead ground wires terminating on a substation structure shall be connected

to an equivalent cross section copper conductor which is connected to the

ground grid or bus.

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 12 of 13

10 Accessory Equipment

10.1 Accessories, including terminating devices, shall be rated for application at line-

to-line system voltages.

10.2 Transformer primary connections shall be made with hot line clamps connected

to a bail (stirrup) compressed on the line conductor.

10.3 Minimum height between any part of a pole mounted transformer or its

mounting bracket or platform and grade shall be 4.9 m.

10.4 Supporting structures for accessories shall have a minimum stress safety factor

of 4.0.

10.5 Minimum separation between ungrounded conductors shall be per Table 4.

Table 4

System Voltage (kV) Clearance mm

4.16 230

13.8 410

34.5 710

10.6 Loadbreak switches shall be provided at sectionalizing points.

11 Protective Devices

11.1 Surge arresters shall be installed at distribution transformer installations,

capacitor bank installations, recloser installations, metering installations, and

aerial-to-underground cable termination points.

11.2 Surge arresters shall be of the distribution class, metal-oxide, gapless type rated

per Table 5.

Table 5

System Voltage (kV) Arrester Rating (kV)

4.16 6.0

13.8 12

34.5 27

11.3 The grounding electrode for surge arresters shall be minimum 16 mm (5/8 in)

diameter by 3 m (10 ft) local copper or copper clad ground rod(s) driven along

the center line of the circuit. The ground rod(s) shall also be bonded to the plant

or substation ground grid if located within 15 m of the rod. The resistance to

ground of the surge arrester ground shall not exceed 25 ohms. The surge

Document Responsibility: Electrical Systems Designs and Automation SAES-P-107

Issue Date: 19 October 2008

Next Planned Update: 7 April 2013 Overhead Distribution Systems

Page 13 of 13

arrester grounding terminals shall be connected, with minimum bends, directly

to the local ground rod.

11.4 Minimum arrester-to-arrester clearance shall be per Table 4.

11.5 Fused cutouts shall be provided for transformers fed directly from overhead

distribution lines.

11.6 Loadbreak switches and fused cutouts shall be provided for capacitor

installations on overhead distribution lines.

Revision Summary

7 April 2008 Revised the "Next Planned Update". Reaffirmed the contents of the document and

reissued with editorial revisions.

19 October 2008 Editorial revision to replace Electrical Systems Designs and Automation Standards

Committee Chairman and Vice Chairman.

Das könnte Ihnen auch gefallen

- Saes P 121Dokument19 SeitenSaes P 121aglegarte50% (2)

- TransfformerDokument21 SeitenTransfformerMadhavasrinivasan SathiamoorthyNoch keine Bewertungen

- Eex10601 PDFDokument29 SeitenEex10601 PDFcvg ertd100% (1)

- Double Circuit Transmission Line Protection Using Line Trap & Artificial Neural Network MATLAB ApproachDokument6 SeitenDouble Circuit Transmission Line Protection Using Line Trap & Artificial Neural Network MATLAB ApproachAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Ground System TestingDokument31 SeitenGround System TestingJellyn BaseNoch keine Bewertungen

- Standard for Sub-Transmission Overhead Line DesignDokument147 SeitenStandard for Sub-Transmission Overhead Line DesignvitorNoch keine Bewertungen

- Sabp P 004Dokument17 SeitenSabp P 004Hassan MokhtarNoch keine Bewertungen

- Designing Low Voltage Feeder CircuitsDokument86 SeitenDesigning Low Voltage Feeder Circuitscoopen100% (4)

- Easypact Cvs 2011engDokument84 SeitenEasypact Cvs 2011engthiago_gomes7953Noch keine Bewertungen

- Select Instrum TransfmerDokument75 SeitenSelect Instrum TransfmerJheny B. Bayon100% (1)

- Symmetrical and UnsymmetricalDokument8 SeitenSymmetrical and Unsymmetricalwillquicksilver04Noch keine Bewertungen

- Transformer Accessories GuideDokument44 SeitenTransformer Accessories Guidehajimak100% (2)

- SP-1102A Specification For Design of 33kV Overhead Power Lines On Wooden PolesDokument118 SeitenSP-1102A Specification For Design of 33kV Overhead Power Lines On Wooden Polesarjunprasannan7Noch keine Bewertungen

- Earthing DesignDokument90 SeitenEarthing Designabdulkadhir83% (6)

- 16 Samss 502 - PDFDokument12 Seiten16 Samss 502 - PDFShahraiz KhanNoch keine Bewertungen

- NS220Dokument267 SeitenNS220Victor IkeNoch keine Bewertungen

- Static Var Compensators ExplainedDokument30 SeitenStatic Var Compensators Explainedsubbu2051100% (1)

- Satr-P-3210 Rev 7 FinalDokument11 SeitenSatr-P-3210 Rev 7 FinalzhangNoch keine Bewertungen

- Low Voltage Capacitance & Tan Delta Testing, Measurement Method &Dokument6 SeitenLow Voltage Capacitance & Tan Delta Testing, Measurement Method &intrudentalert100% (1)

- Interactive simulation of power systems using ETAPDokument12 SeitenInteractive simulation of power systems using ETAPAnirban ChakrabortyNoch keine Bewertungen

- 15 Saip 51Dokument5 Seiten15 Saip 51malika_00Noch keine Bewertungen

- Busbar Arrangement (BUSBAR SCHEME) PDFDokument7 SeitenBusbar Arrangement (BUSBAR SCHEME) PDFRaditya Ghani100% (1)

- General Calculations Rev 4Dokument20 SeitenGeneral Calculations Rev 4KARTHIGEYAN.RNoch keine Bewertungen

- Saes P 101Dokument9 SeitenSaes P 101Shawkat Ali KhanNoch keine Bewertungen

- Pages From 241-1990 Gray Book Power Systems Commercial BuildingsDokument1 SeitePages From 241-1990 Gray Book Power Systems Commercial BuildingsArnel Pascual LaquindanumNoch keine Bewertungen

- IEEE-PES PSRC Report On Design and Testing of Selected System Integrity Protection SchemesDokument5 SeitenIEEE-PES PSRC Report On Design and Testing of Selected System Integrity Protection Schemesdes1982Noch keine Bewertungen

- Catenary Voltage SupplyDokument5 SeitenCatenary Voltage SupplyAmir ZulfiNoch keine Bewertungen

- Earthing Design PDFDokument90 SeitenEarthing Design PDFfarooq_whizkidNoch keine Bewertungen

- Electric Traction Supply System On Indian RailwaysDokument5 SeitenElectric Traction Supply System On Indian Railwaystyagimanoj90100% (1)

- Qcs 2010 Section 21 Part 4 Motor StartersDokument6 SeitenQcs 2010 Section 21 Part 4 Motor Startersbryanpastor106100% (1)

- Protection Study SOWDokument1 SeiteProtection Study SOWnknfiveNoch keine Bewertungen

- IEEE Standard Requirements For Instrument Transformers: SASO IEEE C 57:2018 IEEE C 57:2013Dokument81 SeitenIEEE Standard Requirements For Instrument Transformers: SASO IEEE C 57:2018 IEEE C 57:2013ivaneg825Noch keine Bewertungen

- Protection Relay CoordinationDokument19 SeitenProtection Relay CoordinationDennis MendozaNoch keine Bewertungen

- EEX10002 Interprting StandardsDokument80 SeitenEEX10002 Interprting StandardsHonesto BautistaNoch keine Bewertungen

- TES-P-119-41-R0-Non-Linear Resistor Application in GISDokument16 SeitenTES-P-119-41-R0-Non-Linear Resistor Application in GISZain-Ul- AbdeenNoch keine Bewertungen

- Senior Electrical Design Engineer CVDokument3 SeitenSenior Electrical Design Engineer CVMohamedNoch keine Bewertungen

- EarthingDokument40 SeitenEarthingbdaminda6701Noch keine Bewertungen

- Grounding 4 PDF FreeDokument74 SeitenGrounding 4 PDF FreeShiaTVfanNoch keine Bewertungen

- Capacitor BanksDokument15 SeitenCapacitor BanksChandni SharmaNoch keine Bewertungen

- Tender Documents for 33kV Underground Cables ProjectDokument37 SeitenTender Documents for 33kV Underground Cables Projectzaheer2931100% (1)

- Factors Affecting StabilityDokument8 SeitenFactors Affecting StabilitySteve MusarurwaNoch keine Bewertungen

- SEC Distribution Materials TestingDokument14 SeitenSEC Distribution Materials TestingMaktoob M Knif100% (1)

- EEX10602 Protection OverviewDokument40 SeitenEEX10602 Protection OverviewHonesto Bautista100% (1)

- EMTP - RV - IC-part2 Tower Foot ResistanceDokument19 SeitenEMTP - RV - IC-part2 Tower Foot ResistanceRaja Shekar NalluriNoch keine Bewertungen

- 16 Samss 521Dokument8 Seiten16 Samss 521Eagle SpiritNoch keine Bewertungen

- 3AP1DTC-245kV - With FES - Standard TDS CMT 6sept19Dokument4 Seiten3AP1DTC-245kV - With FES - Standard TDS CMT 6sept19MrTomNoch keine Bewertungen

- STD - C37.2 - 1991 - IEEE Standard Electrical Power System Device Function NumbersDokument22 SeitenSTD - C37.2 - 1991 - IEEE Standard Electrical Power System Device Function Numberslisused100% (2)

- StandardDokument3 SeitenStandardAnonymous m4MF1gNoch keine Bewertungen

- Specifications for Cable Joints and AccessoriesDokument17 SeitenSpecifications for Cable Joints and AccessoriesMohammed NouzalNoch keine Bewertungen

- Distribution Line StandardDokument64 SeitenDistribution Line StandardEduardo QuintanaNoch keine Bewertungen

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDokument15 Seiten000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- Selecting Low Voltage Motor StartersDokument114 SeitenSelecting Low Voltage Motor StartersJellyn BaseNoch keine Bewertungen

- Knowledge is "Real Power": Introduction to Power QualityVon EverandKnowledge is "Real Power": Introduction to Power QualityNoch keine Bewertungen

- Saes P 100Dokument17 SeitenSaes P 100Anonymous m4MF1gNoch keine Bewertungen

- Materials System SpecificationDokument6 SeitenMaterials System SpecificationCherukunnon JubuNoch keine Bewertungen

- 12TMSS02R0, Saudi Electriicity Company StandardsDokument0 Seiten12TMSS02R0, Saudi Electriicity Company StandardsMohammed NazeeruddinNoch keine Bewertungen

- 16 Samss 520Dokument11 Seiten16 Samss 520HatemS.MashaGbehNoch keine Bewertungen

- 56-SDMS, Specs For 13.8KV Unit Substation PDFDokument14 Seiten56-SDMS, Specs For 13.8KV Unit Substation PDFA. Hassan100% (1)

- Transmission Materials Specification for Composite InsulatorsDokument0 SeitenTransmission Materials Specification for Composite Insulatorsrenjithas2005Noch keine Bewertungen

- TESP12201R0Dokument20 SeitenTESP12201R0Muhammad AliNoch keine Bewertungen

- Testing & Commissioning Procedure (Electrical)Dokument100 SeitenTesting & Commissioning Procedure (Electrical)Roland Nicolas100% (1)

- Arcadis IT GuideDokument48 SeitenArcadis IT Guidemujeeb.alam4Noch keine Bewertungen

- Megger InsulationtesterDokument67 SeitenMegger InsulationtesterNh Chuminda YapaNoch keine Bewertungen

- Guideline of 11-22 KV Substation-26 01 2009Dokument49 SeitenGuideline of 11-22 KV Substation-26 01 2009mujeeb.alam4Noch keine Bewertungen

- Regulations Handbook-DEWADokument93 SeitenRegulations Handbook-DEWArksubu82100% (4)

- IP CCTV System Design GuideDokument50 SeitenIP CCTV System Design Guidemujeeb.alam4100% (6)

- ICT Systems Design for National Guard Health Affairs Specialized HospitalsDokument26 SeitenICT Systems Design for National Guard Health Affairs Specialized Hospitalsmujeeb.alam4Noch keine Bewertungen

- Substation Design - ManualDokument127 SeitenSubstation Design - Manualmujeeb.alam489% (9)

- Stadium Tech Rec Req Guide To Lighting en 7306Dokument12 SeitenStadium Tech Rec Req Guide To Lighting en 7306Alberth Noa MaytaNoch keine Bewertungen

- Stadium Tech Rec Req Guide To Lighting en 7306Dokument12 SeitenStadium Tech Rec Req Guide To Lighting en 7306Alberth Noa MaytaNoch keine Bewertungen

- CV - Ahmad Abdul NafiDokument2 SeitenCV - Ahmad Abdul NafiMustafa HussainNoch keine Bewertungen

- Adavanced Distribution Automation PDFDokument232 SeitenAdavanced Distribution Automation PDFMarcosGodoyPereyraNoch keine Bewertungen

- Electrical DesignDokument80 SeitenElectrical DesignPardeep KhosaNoch keine Bewertungen

- Over Voltage RelayDokument6 SeitenOver Voltage Relayee306087Noch keine Bewertungen

- (GIS) 696 En-ADokument28 Seiten(GIS) 696 En-AhnphuocNoch keine Bewertungen

- Apr 2022 EE Board Exam Refresher Part5Dokument2 SeitenApr 2022 EE Board Exam Refresher Part5Bugoy2023Noch keine Bewertungen

- Electricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFDokument331 SeitenElectricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFMiguel CbNoch keine Bewertungen

- AdnanAnwar ETS Print Final 131120121Dokument158 SeitenAdnanAnwar ETS Print Final 131120121HARMET UP3 PEMATANGSIANTARNoch keine Bewertungen

- DC Traction Power Grounding MethodsDokument6 SeitenDC Traction Power Grounding Methodsasheesh_k_singh1190Noch keine Bewertungen

- Steel Limited: Conceptual Master Plan For Tata Steel Sez at Gopalpur, Odisha, IndiaDokument1 SeiteSteel Limited: Conceptual Master Plan For Tata Steel Sez at Gopalpur, Odisha, Indiaask.kulkarni KulkarniNoch keine Bewertungen

- REB500 V8.3 ProductGuide 1MRK505402 BENDokument53 SeitenREB500 V8.3 ProductGuide 1MRK505402 BENGanesh DuraisamyNoch keine Bewertungen

- ++++IEC61850 Unites LV and MVDokument7 Seiten++++IEC61850 Unites LV and MVMato RošićNoch keine Bewertungen

- Seeme Complete Resolution Corr W Comparison FDokument30 SeitenSeeme Complete Resolution Corr W Comparison Fraul_bsuNoch keine Bewertungen

- Typical Layout of Power System NetworkDokument14 SeitenTypical Layout of Power System Networkneenu_tNoch keine Bewertungen

- Dynamic Line Ratings Based on Weather MeasurementsDokument10 SeitenDynamic Line Ratings Based on Weather MeasurementsNataGB100% (1)

- RFB Supply Installation of 33 11kV Substations 33kV Subtransmission Lines Vol I Final Final Rev WB-EDSA-r2aaDokument577 SeitenRFB Supply Installation of 33 11kV Substations 33kV Subtransmission Lines Vol I Final Final Rev WB-EDSA-r2aaRaulier NtombaNoch keine Bewertungen

- Practical Guide SequelecDokument24 SeitenPractical Guide SequelecDevi PrasadNoch keine Bewertungen

- ABB Industrie AG UNITROL 6800 Commissioning ScheduleDokument2 SeitenABB Industrie AG UNITROL 6800 Commissioning ScheduleAdriana MartinezNoch keine Bewertungen

- 56-SDMS-02 Rev.01 13.8kV Pakage SubstationsDokument17 Seiten56-SDMS-02 Rev.01 13.8kV Pakage Substations张勇Noch keine Bewertungen

- Phy HSCDokument47 SeitenPhy HSCNiroshan KarunarathnaNoch keine Bewertungen

- National Grid Evolution and StructureDokument30 SeitenNational Grid Evolution and StructureSouvik DattaNoch keine Bewertungen

- Summer Trainning Presentation at DTLDokument38 SeitenSummer Trainning Presentation at DTLabhishek_kumar_5Noch keine Bewertungen

- Impact of Lightning Frequency on Substation Grounding SystemsDokument5 SeitenImpact of Lightning Frequency on Substation Grounding Systemsrobert_rjcNoch keine Bewertungen

- SP 1109 1 Earthing and Bonding (ERD 64 10) 2Dokument45 SeitenSP 1109 1 Earthing and Bonding (ERD 64 10) 2RaghuNoch keine Bewertungen

- Global Standard for Directional Fault Passage IndicatorDokument86 SeitenGlobal Standard for Directional Fault Passage IndicatorrazvansasuNoch keine Bewertungen

- Insulation Coordination Study Report - 2019phxp0901u PDFDokument16 SeitenInsulation Coordination Study Report - 2019phxp0901u PDFSudhir Ravipudi100% (1)

- ADokument72 SeitenAMohit KothariNoch keine Bewertungen

- Sadiq ReportDokument55 SeitenSadiq ReportLaxman KiranNoch keine Bewertungen

- TNN January 2007Dokument16 SeitenTNN January 2007Luis Aguero CantilloNoch keine Bewertungen

- ESP Microproject of Group 13 PratikDokument14 SeitenESP Microproject of Group 13 Pratikprachi parabNoch keine Bewertungen