Beruflich Dokumente

Kultur Dokumente

Liq Manual 51-242

Hochgeladen von

andy175Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Liq Manual 51-242

Hochgeladen von

andy175Copyright:

Verfügbare Formate

Model 242

Flow-Through Toroidal Conductivity Sensor

Instruction Manual

PN 51-242/rev E

March 2012

CAUTION

SENSOR/PROCESS

APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible

with process com position and operating conditions.

Replacement of original components with those con-

structed from alternative materials might change the

pressure, temperature, and/or performance specifi-

cations from those of the original sensor configura-

tion. Application compat ibility is entirely the respon-

sibility of the user.

DANGER

HAZARDOUS AREA INSTALLATION

Installations near flammable liquids or in hazardous

area locations must be carefully evaluated by qual-

ified on site safety personnel. This sensor is not

Intrinsically Safe or Explosion Proof.

To secure and maintain an intrinsically safe installa-

tion, the certified safety barrier, transmitter, and

sensor combi nation must be used. The installation

system must comply with the governing approval

agency (FM, CSA, BASEEFA/CENELEC, or ATEX)

hazardous area classification requirements.

Consult your analyzer/transmitter instruc tion manu-

al for details.

Replacement of original components with those con-

structed from alternative materials will void any

CSA, FM, and BASEEFA/CENELEC agency

approvals that were applicable to the original device.

Proper installation, operation and servicing of this

sensor in a Hazardous Area Instal lation is entirely

the responsibility of the user.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to

meet many national and international standards. Because these instru-

ments are sophisticated technical products, you must properly install,

use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions must be adhered to and

integrated into your safety program when installing, using, and maintain-

ing Rosemount Analytical products. Failure to follow the proper/ instruc-

tions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and

warranty invalidation.

Read all instructions prior to installing, operating, and servicing the

product. If this Instruction Manual is not the correct manual, tele-

phone 1-800-654-7768 and the requested manual will be provided.

Save this Instruction Manual for future reference.

If you do not understand any of the instructions, contact your

Rosemount representative for clarification.

Follow all warnings, cautions, and instructions marked on and

supplied with the product.

Inform and educate your personnel in the proper installation, opera-

tion, and maintenance of the product.

Install your equipment as specified in the Installation Instructions of

the appropriate Instruction Manual and per applicable local and

national codes, for example, ANSI B16.5. Connect all products to the

proper electrical and pressure sources.

To ensure proper performance, qualified personnel should install,

operate, and maintain the product.

When replacement parts are required, ensure that qualified people

use replacement parts specified by Rosemount Analytical.

Replacement of original components with those constructed from

alternative materials will void any CSA, FM, and BASEEFA/CEN-

ELEC agency approvals that were applicable to the original device.

Furthermore, replacement of original components with those con-

structed from alternative materials might change the pressure, tem-

perature, and/or performance specifications from those of the original

configuration. Ensure replacement parts are compatible with process

requirements. Unauthorized parts and procedures can affect the

products performance, place the safe operation of your process at

risk, and may result in fire, electrical hazards, or improper operation.

Ensure that all equipment doors are closed and protective covers are

in place, except when maintenance is being performed by qualified

persons, to prevent electrical shock and personal injury.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.rosemountanalytical.com

Rosemount Analytical Inc. 2012

i

MODEL 242 TABLE OF CONTENTS

MODEL 242

TOROIDAL CONDUCTIVITY SENSOR

TABLE OF CONTENTS

Section Title Page

1.0 MODEL 242 SENSOR............................................................................................. 1

1.1 Features and Applications........................................................................................ 1

1.2 Specifications........................................................................................................... 2

1.3 Ordering Information................................................................................................ 5

1.4 Installation................................................................................................................ 7

1.5 Calibration................................................................................................................ 10

1.6 Maintenance ............................................................................................................ 13

2.0 Troubleshooting..................................................................................................... 14

3.0 Replacement Parts................................................................................................. 16

3.1 General .................................................................................................................... 16

3.2 Remove the Sensor From the Process.................................................................... 16

3.3 Disassemble the Sensor .......................................................................................... 16

3.4 Re-assemble the Sensor ......................................................................................... 19

3.5 Re-install the Sensor into the Process..................................................................... 19

4.0 Return of Materials ................................................................................................ 20

LIST OF TABLES

Table No. Title Page

1-1 Nominal Cell Constants for 242 Sensors................................................................. 10

2-1 Resistance vs. Temperature for RTD (Resistance Temperature Detector) ............. 14

2-2 Sensor Resistance Check........................................................................................ 14

3-1 Replacement Parts and Accessories....................................................................... 17

3-2 Sensor Bolt Removal & Installation Guide............................................................... 18

LIST OF FIGURES

Figure No. Title Page

1-1 Pressure-Temperature Specs for 1, 1.5, & 2 Sensors: Models 242-02/03/04 .... 3

1-2 Pressure-Temperature Specs for 3 & 4 Sensors: Models 242-06/08 ................... 3

1-3 Pressure-Temperature Specs for 1 & 2 Sensors: Alumina Liner .......................... 4

1-4 Pressure-Temperature Specs for 3 & 4 Sensors: Alumina Liner .......................... 4

1-5 Dimensional Drawing............................................................................................... 7

1-6 Installation and Torque Guidelines........................................................................... 8

1-7 Sensor to Junction Box Wiring ................................................................................ 9

1-8 Sensor/Junction Box/RTD Assembly ....................................................................... 9

1-9 Extension Cable ...................................................................................................... 10

1-10 Extension Cable to Instrument Model 54eC Wiring................................................ 11

1-11 Extension Cable to Instrument Model 1055 Wiring ................................................. 11

1-12 Extension Cable to Instrument Models 3081T & 4081T Wiring............................... 12

1-13 Extension Cable to Instrument Model 81T Wiring ................................................... 12

1-14 Extension Cable to Instrument Model Xmt Pipe/Wall Mount Enclosure.................. 12

1-15 Extension Cable to Instrument Model Xmt Panel Mount Enclosure........................ 13

2-1 Sensor Circuit for Troubleshooting .......................................................................... 15

3-1 Model 242 Sensor - Exploded View ........................................................................ 18

3-2 Flange Assembly...................................................................................................... 19

MODEL 242 TABLE OF CONTENTS

MODEL 242

TOROIDAL CONDUCTIVITY SENSOR

ii

About This Document

This manual contains instructions for installation and operation of the Model 242 Flow-Through

Toroidal Conductivity Sensor. The following list provides notes concerning all revisions of this doc-

ument.

Rev. Level Date Notes

A 11/02 This is the initial release of the product manual. The manual has been

reformatted to reflect the Emerson documentation style and updated to reflect

any changes in the product offering.

B 8/03 Corrected wiring references in text and drawings. Added information regarding

ATEX approvals with Model 5081T.

C 5/04 Added information regarding the alumina liner, and updated wiring diagrams.

D

E 03/12 Update addresses pages 22 and 24

1

MODEL 242 SECTION 1.0

242 SENSOR

SECTION 1.0

242 SENSOR

1.1 FEATURES AND APPLICATIONS

Rosemount Analytical Toroidal Conductivity Sensors

are ideal for use in processes where contacting sen-

sors -- those with electrodes exposed to the measured

solution -- would corrode or become fouled.

The 242 Flow Through Toroidal conductivity sensor

consists of two toroids surrounding a pipe through

which the process liquid flows. One toroid acts as a

transmitter and the other as a receiver. Energizing the

transmitter toroid induces an electric current in the

process solution which induces an electric current in

the receiver toroid. The strength of the induced current

is directly proportional to the conductivity of the solu-

tion.

The 242 sensor is available in over two hundred fifty

configurations to meet the needs of many applications

and installations. Line sizes of 1, 1.5, 2, 3, and 4 inch-

es (25, 40, 50, 80, and 100 mm) are available with

both ANSI and DIN compatible flanges. A variety of

liner materials and O-rings are available to ensure

compatibility with most process liquids.

The 242 sensor is easy to install. It fits in the process

piping between mounting flanges. Special grounding

rings are not needed because the sensor has con-

tact rings built into it. Recessed bolts hold the sensor

together to ensure all internal parts stay in perfect

alignment. A junction box and a Pt 100 RTD are

included. The RTD slips easily into one of the sensor

contact rings. There is no need to install a separate

thermowell, and temperature measurements are

made at the same point as the conductivity measure-

ments.

The sensor is not sensitive to flow rate or direction.

It does not obstruct the process flow. The sensor is

rugged and constructed from chemically resistant

materials. All these features make the sensor ideal

for applications in mining and metals processing,

pulp and paper processing, and the chemical pro-

cessing industry.

The 242 Flow Through Conductivity Sensor is com-

patible with instrument instumentsL 54eC, 1055,

3081T, 4081T, 5081-T, and Xmt-T.

FLOW THROUGH DESIGN is ideal for use with viscous,

abrasive, or fibrous process liquids.

OVER 250 CONFIGURATIONS to meet customers' needs.

REPLACEABLE LINER in glass-filled PEEK, TEFLON, or

ALUMINA reduces long-term operating costs.

DIN and ANSI FLANGES compatible with all piping instal-

lations.

LINE SIZES of 1 through 4 inches (DN 25, 40, 50, 80 and

100).

IN-LINE CALIBRATION saves money by reducing labor

and down-time.

TEMPERATURE SENSOR and JUNCTION-BOX included.

2

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

1.2 SPECIFICATIONS

The Model 242 Flow Through Sensor comprises a toroid

housing constructed from 316 stainless steel and polyeth-

yleneterephthalate, process connection flanges of 316

stainless steel, two metal contact rings (available in choice

of three materials), an insulating liner (choice of three

materials), O-rings (choice of three materials), a Pt 100

RTD, and a sensor-mounted junction box. Only the liner,

contact rings, and O-rings are wetted by the process. The

Pt 100 RTD is designed for insertion into one pre-drilled

contact ring. The NEMA 7D junction box is constructed of

heavy duty epoxy-painted cast aluminum. The conductivity

range is user-selectable with the tapped toroid windings.

In-line calibration can be performed with resistors connect-

ed to an integral wire around the toroids that is terminated

in the junction box.

Liners are available in Teflon, glass-filled Polyetheretherketone (PEEK), and alumina. These materials provide

excellent chemical resistance. PEEK is recommended for high pressure or high temperature applications.

Teflon is recommended when the process solution contains hydrofluoric acid or other strong oxidizing agents.

Alumina is recommended if the process solution is abrasive, such as in alumina/caustic ratio applications.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

Viton is a registered trademark of Du Pont Dow Elastomers.

Carpenter 20Cb-3 is a registered trademark of Carpenter Technologies.

Hastelloy is a registered trademark of Haynes International.

Chemraz is a registered trademark of Greene, Tweed, & Co.

Installation Type Flow Through

Conductivity Range 100 S/cm to 2 S/cm

Process Connections 150# ANSI, 300# ANSI, PN16 DIN 2501 compatible flanges

Maximum Temperature Depends on configuration. For plastic-lined sensors, see charts on facing page.

For alumina-lined sensors, see charts on page 4.

Maximum Pressure Depends on configuration. For plastic-lined sensors, see charts on facing page.

For alumina-lined sensors, see charts on page 4.

Wetted Materials: Liner Teflon

(PTFE), glass-filled PEEK, or alumina

Contact Rings 316 SST, Carpenter 20Cb-3

SST, or Hastelloy

C-276

O-rings EPDM, Viton

(FKM), or Chemraz

(FFKM)

Shipping Weight 1 to 2: 22 lbs. (10kg)

3 to 4: 86 lbs. (39 kg)

Pt 100 RTD

Flange

Contact Ring

Liner

O-ring (not visible)

3

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

FIGURE 1-1. Pressure - Temperature Specifications for 1, 1.5, and 2 (25, 40, and 50 mm) Sensors:

Models 242-02, 242-03, and 242-04

FIGURE 1-2. Pressure - Temperature Specifications for 3 and 4 (80 and 100 mm) Sensors:

Models 242-06 and 242-08

s

t

e

a

m

s

t

e

a

m

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

4

FIGURE 1-3. Pressure - Temperature Specifications for 1 and 2 Sensors: Alumina Liner

FIGURE 1-4. Pressure - Temperature Specifications for 3 and 4 Sensors: Alumina Liner

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

5

1.3 ORDERING INFORMATION

The 242 Flow-Through Sensor is configurable to meet the needs of many applications and installations (both

ANSI and DIN). After specifying line size and flange type, the customer selects the wetted materials most compat-

ible with the process stream. A NEMA 7D junction box and Pt 100 RTD are also included. Compatible instruments

include Rosemount Analytical Models 54eC, 1055, 3081T, 4081T, 5081-T, and Xmt-T.

The extension cable required for wiring from the junction box to the instrument must be ordered separately. The

customer supplies the gaskets, mating flanges, and flange bolts.

CODE LINE SIZE (Required Selection)

02 1 DN 25

03 1-1/2 DN 40

04 2 DN 50

06 3 DN 80 (no ATEX approval with 5081T)

08 4 DN 100 (no ATEX approval with 5081T)

CODE PROCESS CONNECTION (Required Selection)

10 150# ANSI Flange (Line sizes 1", 1-1/2", 2, 3, 4)

11 300# ANSI Flange (Line sizes 1", 1-1/2", 2, 3, 4)

14 PN 16 Metric Flange (Line sizes DN 25, 40, 50, 80, 100)

242 FLOW THROUGH TOROIDAL CONDUCTIVITY SENSOR

CODE CONTACT RING MATERIAL (Required Selection)

SS 316 Stainless Steel

H4 Hastelloy C-276 (Line Sizes 1", 1-1/2", 2, 25mm, 40mm, 50mm)

H8 Hastelloy C-276 (Line Sizes 3", 4", 80mm, 100mm)

C4 Carpenter 20-Cb3 (Line Sizes 1", 1-1/2", 2, 25mm, 40mm, 50mm)

C8 Carpenter 20-Cb3 (Line Sizes 3", 4", 80mm, 100mm)

CODE PROCESS O-RING MATERIAL (Required Selection)

EP Ethylene Propylene Rubber

VT Fluorocarbon Rubber (Viton

)

F4 High Temp. Perfluoroelastomer (Chemraz

) (Line Sizes 1", 1-1/2", 2, 25mm, 40mm, 50mm)

F8 High Temp. Perfluoroelastomer (Chemraz

) (Line Sizes 3", 4", 80mm, 100mm)

CODE LINER MATERIAL (Required Selection)

TE PTFE (Teflon

)

G4 PEEK, 30% Glass-Filled (Line Sizes 1", 1-1/2", 2, 25mm, 40mm, 50mm)

G8 PEEK, 30% Glass-Filled (Line Sizes 3", 4", 80mm, 100mm)

A4 Alumina (Line sizes 1, 2, 25 mm, 50 mm); available only with option F4

A8 Alumina (Line sizes 3, 4, 80 mm, 100 mm); available only with option F8

242 -0611SSG8VT EXAMPLE

6

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

PART NUMBER DESCRIPTION

23909-00 Extension cable, Pre-prepped, for connection to Instrument Models 54eC, 1055, 3081T,

4081T, 5081-T, and Xmt-T (Specify length)

KIT PN DESCRIPTION FOR SENSOR MODELS

24005-00 Kit, Liner, 1 DN 25, Teflon PTFE 242-02[ ]TE[ ]

24005-01 Kit, Liner, 1 DN 25, glass-filled PEEK 242-02[ ]G4[ ]

24005-02 Kit, Liner, 1 DN 25, Alumina 242-02[ ]A4[ ]

24006-00 Kit, Liner, 1-1/2 DN 40, Teflon PTFE 242-03[ ]TE[ ]

24006-01 Kit, Liner, 1-1/2 DN 40, glass-filled PEEK 242-03[ ]G4[ ]

24007-00 Kit, Liner, 2 DN 50, Teflon PTFE 242-04[ ]TE[ ]

24007-01 Kit, Liner, 2 DN 50, glass-filled PEEK 242-04[ ]G4[ ]

24007-02 Kit, Liner, 2 DN 50, Alumina 242-04[ ]A4[ ]

24008-00 Kit, Liner, 3 DN 80, Teflon PTFE 242-06[ ]TE[ ]

24008-01 Kit, Liner, 3 DN 80, glass-filled PEEK 242-06[ ]G8[ ]

24008-02 Kit, Liner, 3 DN 80, Alumina 242-06[ ]A8[ ]

24009-00 Kit, Liner, 4 DN 100, Teflon PTFE 242-08[ ]TE[ ]

24009-01 Kit, Liner, 4 DN 100, glass-filled PEEK 242-08[ ]G8[ ]

24009-02 Kit, Liner, 4 DN 100, Alumina 242-08[ ]A8[ ]

KIT PN DESCRIPTION FOR SENSOR MODELS

24010-00 Kit, O-Ring, 1 DN 25, EPDM 242-02[ ]EP[ ]

24010-01 Kit, O-Ring, 1 DN 25, Viton 242-02[ ]VT[ ]

24010-02 Kit, O-Ring, 1 DN 25, Chemraz 242-02[ ]F4[ ]

24010-03 Kit, O-Ring, 1 DN 25, Chemraz for use with Alumina liner 242-02[ ]A4-F4

24011-00 Kit, O-Ring, 1-1/2 DN 40, EPDM 242-03[ ]EP[ ]

24011-01 Kit, O-Ring, 1-1/2 DN 40, Viton 242-03[ ]VT[ ]

24011-02 Kit, O-Ring, 1-1/2 DN 40, Chemraz 242-03[ ]F4[ ]

24012-00 Kit, O-Ring, 2 DN 50, EPDM 242-04[ ]EP[ ]

24012-01 Kit, O-Ring, 2 DN 50, Viton 242-04[ ]VT[ ]

24012-02 Kit, O-Ring, 2 DN 50, Chemraz 242-04[ ]F4[ ]

24012-03 Kit, O-Ring, 2 DN 50, Chemraz for use with Alumina liner 242-04[ ]A4-F4

24013-00 Kit, O-Ring, 3 DN 80, EPDM 242-06[ ]EP[ ]

24013-01 Kit, O-Ring, 3 DN 80, Viton 242-06[ ]VT[ ]

24013-02 Kit, O-Ring, 3 DN 80, Chemraz 242-06[ ]F8[ ]

24013-03 Kit, O-Ring, 3 DN 80, Chemraz for use with Alumina liner 242-06[ ]A8-F8

24014-00 Kit, O-Ring, 4 DN 100, EPDM 242-08[ ]EP[ ]

24014-01 Kit, O-Ring, 4 DN 100, Viton 242-08[ ]VT[ ]

24014-02 Kit, O-Ring, 4 DN 100, Chemraz 242-08[ ]F8[ ]

24014-03 Kit, O-Ring, 4 DN 100, Chemraz for use with Alumina liner 242-08[ ]A8-F8

ACCESSORIES

7

1.4 INSTALLATION

In the instructions below, the Junction Box is installed

after the sensor is bolted into the process line. If appropri-

ate for the site and final mounting configuration, the

Junction Box can be installed prior to bolting the sensor

into the process line.

CAUTION

The liner of the Model 242 sensor can be damaged if mis-

handled. Do NOT place any object through the liner for

the purpose of lifting the Model 242 sensor.

CAUTION

Support structures should be installed as appropriate on

or around process pipes and sensor location to sufficient-

ly support the weight of the sensor during installation and

minimize strain on adjacent process pipes during the

operational life of the sensor.

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

Installation of the Model 242 Flow Through Sensor is simi-

lar to installation of a section of pipe. Consequently, be

prepared to use tools, supplies, equipment, and tech-

niques similar to those used to install process pipes. Use

common piping practices to minimize torque and bending

loads on process connections. Observe all applicable

safety standards. Dimensional information is shown in

Figure 1-5 below. Refer to Figures 1-6 to 1-8 for assembly

and installation diagrams.

NOTES

1. Allow at least four pipe diameters of straight pipe run

on either side of the sensor.

2. Install the sensor so that it is filled with process liquid

at all times when measurements are being made.

Avoid downward flow as such a configuration might

leave the sensor partially empty.

3. Use a sling and hoist to lift and position the sensor.

FIGURE 1-5. DIMENSIONAL DRAWING

INCH

MILLIMETER

8

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

INSTALLING THE SENSOR IN THE PROCESS LINE

1. Install process flanges in accordance with applicable instructions, standards, and local regulations.

2. Position the sensor between the process mating flanges with flange gaskets inserted between each set of

flanges. Ensure that the locations of the junction box connection and the RTD hole in the contact ring are in

the correct position for easy wiring and use.

3. Align the bolt holes in the sensor and process flanges.

4. Lubricate the bolt threads. Using a torque wrench, bolt the sensor into place. Tighten the bolts in 1/3 incre-

ments of the final desired torque. Follow the bolt-tightening sequence and torque suggestions provided in

Figure 1-6.

5. Re-torque the bolts 12 to 24 hours after installation. Make a final check of torque values by moving consecu-

tively from bolt to bolt.

FIGURE 1-6. Installation and Torque Guidelines

Torque values in the table above are from Garlock Sealing Technologies. Other values might apply

when using different bolt and gasket materials.

Gylon

is a registered Trademark of Garlock Sealing Technologies.

9

ATTACHING THE JUNCTION BOX

1. Pull the sensor wires up into the junction box.

2. Screw the junction box onto the threaded male connection on

the sensor. Use of pipe sealing tape or other compound is at the

discretion of the customer.

3. Connect the sensor wires to the junction box terminal as indicat-

ed in Figure 1-7.

INSTALLING THE Pt100 RTD

1. Use of the included Pt100 RTD is recommended. Use of a cus-

tomer-supplied Pt100 or Pt1000 TC mounted in a separate ther-

mowell is also acceptable. The accuracy specifications provided

by Rosemount Analytical apply only to situations wherein the

Pt100 RTD supplied with the sensor is used.

2. Refer to Figure 1-8. Screw the threaded nipple onto the conduit

connector of the junction box. Screw the tee onto the nipple, and

screw the RTD cable connector onto the tee.

3. Attach the bracket to the shaft of the RTD using the #10 washer

and small screw enclosed in the RTD kit. The purpose of the

bracket is to retain the RTD in the contact ring after installation.

4. Slide the Pt100 RTD into the pre-drilled hole in the contact ring.

Rotate the bracket to a position beneath the junction box, and

tighten the set screw.

5. Thread the RTD wires through cable connector, tee, nipple, and into junction box. Wire the RTD to the junction box terminals as

indicated in Figure 1-7. Install the white jumper wire between terminals 1 and 2.

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

FIGURE 1-7. Sensor to Junction Box Wiring

*For optimal performance below 10,000 S/cm, connect

green wire from extension cable to terminal indicated by *

FIGURE 1-8. Sensor/J-box/RTD Assembly

Items 1-9 are included with the Model 242

sensor. Items 3-9, the white jumper wire,

and Teflon tape are included in the TC kit.

Items 10 and 11 are sold separately as

accessories.

10

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

EXTENSION CABLE HOOK UP

1. Do not run sensor cable in conduit or open trays

with A.C. power wiring. Do not route sensor cable

near heavy electrical equipment.

2. For best sensor/instrument loop performance, use

factory-terminated extension cable (PN 23909-00).

(Using a different cable can introduce noise into

the signal and/or reduce loop accuracy.)

3. One end of extension cable (PN 23909-00) has 8

wires, and the other end has 11 wires. Refer to

Figure 1-9. The end with 8 wires goes into the junc-

tion box. The end with 11 wires goes to the instru-

ment. The extension cable enters the junction box

through the open side of the female threaded tee.

Use of conduit, the optional cable connector (PN

9310137), or other strain relief device to protect the

cable is at the discretion of the customer and

should comply with applicable agency guidelines.

NOTE

If starting with unprepped cable (PN 9200276), remove

only as much insulation as is necessary. The instru-

ment end needs 11 leads: four leads from the green-

white-black-drain bundle, three from each of the two

coaxial cable bundles (the inner conductor, the insulat-

ing braid, and the drain wire), and one from the outer-

most overall braided-copper shield. For the junction

box end, only 8 leads are used: the white coaxial con-

ductor, its braided shield, the green coaxial conductor,

its braided shield, its drain wire, and the green, white,

and black conductors from the green-white-black-drain

bundle. The remaining shields and drain wires are not

used on the junction box end and should be removed -

- they should NOT be connected.

4. Connect the 8 wires of the extension cable to the

terminal block inside the sensor junction box as

indicated in Figure 1-7. Note: If all process meas-

urements will be less than 10,000 S/cm, connect

the green wire from the black-green-clear wire bun-

dle of the extension cable to the terminal receiving

the orange sensor wire. See Figure 1-7.

5. Connect the 11 wires of the instrument-end of the

extension cable according to the applicable dia-

gram from Figures 1-10 through 1-15.

1.5 CALIBRATION

After sensor and transmitter/analyzer wiring is com-

pleted, calibrate the sensor.

NOTE

Most analyzers require the input of the approximate

sensor cell constant before the analyzer calculates the

true cell constant. The nominal cell constant of the

Model 242 sensor depends on the size of the sensor

and the terminal to which the receive wire of the inter-

connecting cable is attached. Refer to Table 1-1 for

the appropriate nominal cell constant value.

FIGURE 1-9. Extension Cable

TABLE 1-1: Nominal Cell Constants for 242 Sensors

Sensor Size Cell Constant (/cm)*

Black Orange

1, DN 25 20 2.0

1.5, DN 40 9.0 0.90

2, DN 50 5.0 0.50

3, DN 80 4.0 0.40

4, DN 100 2.3 0.23

* The table gives the cell constant when the green receive

wire (from black-green-clear bundle) of the interconnect-

ing cable is attached to either the black wire terminal or

the orange wire terminal in the sensor junction box. See

Figures 1-7 and 2-1.

11

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

FIGURE 1-10. Extension Cable to

Model 54eC Wiring

FIGURE1-11. Extension Cable to Model 1055 Wiring

NOTE: If wiring to a single

channel 1055-21 or to a dual

channel 1055-21-xx or 1055-

xx-31, the toroidal sensor is

wired only to Terminal Blocks

3 and 4. If wiring 2 sensors to

a dual toroidal 1055-21-31, use

TB 3, 4, and 5 as shown.

FIGURE 1-12. Extension Cable to Models 3081T,

4081T, and 5081T Wiring

FIGURE 1-13. Extension Cable to Model 81T

Wiring

FIGURE 1-14. Extension Cable to Model Xmt Pipe/Wall Mount Enclosure

*

* Applies only to 3081T

and 4081T.

12

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

SELECT

HI OR

LO

13

FIGURE 1-15. Extension Cable to Model Xmt Panel Mount Enclosure

MODEL 242 SECTION 1.0

MODEL 242 SENSOR

A. To perform liquid calibration prior to installing the sensor in the process line, first seal one end of the sensor,

and then proceed with the following steps.

1. Stand the sensor on the sealed end.

2. Fill the sensor completely with a standard conductivity solution.

3. Insert the Pt100 RTD into the contact ring.

4. Adjust the analyzer reading so that it matches the conductivity of the standard solution at the solution tem-

perature. Refer to the analyzer/ transmitter instruction manual for complete calibration procedures.

B. Use of the Integral Calibration Loop Wire: This internal wire can be used to facilitate future in-process loop cal-

ibration and to perform a quick verification that the loop is functioning properly. Performing this additional (but

optional) step is highly recommended.

1. The sensor must be empty of all fluids, reasonably clean, and preferably completely dry.

2. Attach a variable resistance decade box to the sensor yellow Cal Loop wires (in the junction box).

3. Adjust the applied resistance until the instrument reads the same conductivity value that it did during the

liquid calibration process. Record the conductivity, applied resistance value, and temperature for future ref-

erence.

4. To recalibrate the loop at a later date, optimal results will be achieved if the sensor is returned to a condi-

tion approximating its condition during the initial performance of steps C.1 to C.3 above. If this is not pos-

sible, the sensor must at least be empty of process fluids. Reapply the same resistance to the Cal Loop

and adjust the instrument reading.

1.6 MAINTENANCE

The only routine maintenance required during the operational life of the sensor is to ensure that there are no

deposits plugging the sensor or coating the inside of the contact rings. Some customers find it advantageous to

periodically replace process gaskets and/or re-tighten the flange bolts to ensure adequate process seals. Refer to

Figure 1-6 for flange bolting sequence and torque recommendations.

14

MODEL 242 SECTION 2.0

TROUBLESHOOTING

SECTION 2.0

TROUBLESHOOTING

2.1 TROUBLESHOOTING. The simplest method of trou-

bleshooting is to run a resistance test on the inductive

sensing device. It is also recommended to check the

resistance of the RTD and resistance between various

pairs of the sensor wires.

To perform a quick resistance check of the sensor, recall

the data obtained during Part C of the Calibration

Process (Refer to Section 1.5) With the sensor empty of

process fluids (preferably also clean and dry), reapply

the resistance to the sensor yellow Cal Loop wires in the

junction box. The reading should be with 20% of the

original value.

To check the RTD, measure the resistance across the

RTD wires. See Figure 1-4. The resistance value should

be close to the value shown in Table 2-1.

Refer to Figure 2-1 for a circuit diagram of the sensor to

use as an aid when performing the resistance checks.

Use Table 2-2 to determine the resistance values that

should be found across various pairs of sensor wires.

TABLE 2-1 Resistance Values for Pt100 RTD

Temperature Resistance

(C/F) (Ohms)

18 / 64.4 106.9

19 / 66.2 107.3

20 / 68.0 107.7

21 / 69.8 108.1

22 / 71.6 108.4

23 / 73.4 108.9

24 / 75.2 109.2

25 / 77.0 109.6

26 / 78.8 110.0

27 / 80.6 110.4

C = Celsius / F = Fahrenheit

TABLE 2-2 Sensor Wire Resistance Values

Connection Resistance

(Wire colors are for sensor wires unless indicated)

GREEN to ORANGE < 1 Ohm

GREEN to BLACK 1 to 5 Ohms

GREEN to GROUND screw in J-box (GRAY wire) > 20 MegOhms

GREEN to WHITE > 20 MegOhms

GREEN to YELLOW > 20 MegOhms

WHITE to GRAY < 1 Ohm

WHITE to GROUND screw in J-box (GRAY wire) > 20 MegOhms

WHITE to YELLOW > 20 MegOhms

WHITE to RED > 20 MegOhms

YELLOW to YELLOW < 1 Ohm

YELLOW to GROUND screw in J-box (GRAY wire) > 20 MegOhms

15

MODEL 242 SECTION 2.0

MODEL 242 SENSOR

FIGURE 2-1. Sensor Circuit for Troubleshooting

*The green wire from the extension cables black-green-clear bundle might be connected opposite the

sensors orange wire, as indicated by * to utilize the sensors alternative cell constant.

16

3.1 GENERAL

When replacement parts are required, ensure that

qualified people install the parts specified by

Rosemount. Replacement of original components with

those constructed from alternative materials might

change the temperature, pressure, and/or performance

specifications from those of the original configuration

and will void any CSA, FM, and BASEEFA/CENELEC

agency approvals that were applicable to the original

device. Table 3-1 lists the replacement parts kits for the

Model 242 Sensor. An instruction manual is included

with each kit.

3.2 REMOVE THE SENSOR

The RTD can be removed either before or after the

sensor is removed from the process. The junction box

should be left attached to the toroid subassembly. After

ensuring that it is safe to remove the sensor from the

process line, loosen the flange bolts in 1/3 increments

in the same order in which they were tightened as

shown in Figure1-4. Remove the bolts and sensor.

3.3 DISASSEMBLE THE SENSOR

Using the tool indicated in Table 3-2, remove the

Sensor Bolts (Item 2). Note that these bolts were

installed using a thread-locking adhesive. Any use of

heat to loosen the adhesive should not exceed the tem-

perature ratings of the sensor. Figure 3-1 is an explod-

ed view of the all the parts of the Model 242 sensor.

MODEL 242 SECTION 3.0

REPLACEMENT PARTS

SECTION 3.0

REPLACEMENT PARTS

CAUTION

Before removing the sensor from the process piping,

ensure that the process has been shut down and liq-

uid drained from the sensor line. For personal safety,

NOTE REGARDING O-RINGS

There are two pairs of O-rings inside the sensor:

process O-rings (item 6) and secondary or backup

O-rings (item 7). Refer to Figure 3-1 to identify these

items. The two pairs of O-rings are not interchange-

able.

Older O-ring replacement kits contained only the pair

of process O-rings. New O-ring replacement kits con-

tain both pairs of O-rings. To distinguish the process

O-ring from the backup O-ring:

For sensors with plastic liners:

1. The process O-ring has a much smaller cross sec-

tional area than the secondary O-ring. The cross-

section diameter of the process O-ring is 0.07 in.

The cross-section diameter of the secondary O-ring

is 0.139 in.

2. The diameter of the process O-ring is less than

the secondary O-ring. The size difference is

immediately obvious when the two O-rings are

allowed to dangle from a pencil.

For sensors with alumina liners:

1. The process and secondary O-rings have the

same cross sectional area. (0.139 in).

2. The diameter of the process O-ring is less than

the secondary O-ring. The size difference is

immediately obvious when the two O-rings are

allowed to dangle from a pencil.

17

MODEL 242 SECTION 3.0

MODEL 242 SENSOR

PART NUMBER DESCRIPTION

23909-00 Extension cable, Pre-prepped, for connection to Instrument Models 54eC, 1055, 3081T,

4081T, 5081-T, and Xmt-T (Specify length)

KIT PN DESCRIPTION FOR SENSOR MODELS

24005-00 Kit, Liner, 1 DN 25, Teflon PTFE 242-02[ ]TE[ ]

24005-01 Kit, Liner, 1 DN 25, glass-filled PEEK 242-02[ ]G4[ ]

24005-02 Kit, Liner, 1 DN 25, Alumina 242-02[ ]A4[ ]

24006-00 Kit, Liner, 1-1/2 DN 40, Teflon PTFE 242-03[ ]TE[ ]

24006-01 Kit, Liner, 1-1/2 DN 40, glass-filled PEEK 242-03[ ]G4[ ]

24007-00 Kit, Liner, 2 DN 50, Teflon PTFE 242-04[ ]TE[ ]

24007-01 Kit, Liner, 2 DN 50, glass-filled PEEK 242-04[ ]G4[ ]

24007-02 Kit, Liner, 2 DN 50, Alumina 242-04[ ]A4[ ]

24008-00 Kit, Liner, 3 DN 80, Teflon PTFE 242-06[ ]TE[ ]

24008-01 Kit, Liner, 3 DN 80, glass-filled PEEK 242-06[ ]G8[ ]

24008-02 Kit, Liner, 3 DN 80, Alumina 242-06[ ]A8[ ]

24009-00 Kit, Liner, 4 DN 100, Teflon PTFE 242-08[ ]TE[ ]

24009-01 Kit, Liner, 4 DN 100, glass-filled PEEK 242-08[ ]G8[ ]

24009-02 Kit, Liner, 4 DN 100, Alumina 242-08[ ]A8[ ]

KIT PN DESCRIPTION FOR SENSOR MODELS

24010-00 Kit, O-Ring, 1 DN 25, EPDM 242-02[ ]EP[ ]

24010-01 Kit, O-Ring, 1 DN 25, Viton 242-02[ ]VT[ ]

24010-02 Kit, O-Ring, 1 DN 25, Chemraz 242-02[ ]F4[ ]

24010-03 Kit, O-Ring, 1 DN 25, Chemraz for use with Alumina liner 242-02[ ]A4-F4

24011-00 Kit, O-Ring, 1-1/2 DN 40, EPDM 242-03[ ]EP[ ]

24011-01 Kit, O-Ring, 1-1/2 DN 40, Viton 242-03[ ]VT[ ]

24011-02 Kit, O-Ring, 1-1/2 DN 40, Chemraz 242-03[ ]F4[ ]

24012-00 Kit, O-Ring, 2 DN 50, EPDM 242-04[ ]EP[ ]

24012-01 Kit, O-Ring, 2 DN 50, Viton 242-04[ ]VT[ ]

24012-02 Kit, O-Ring, 2 DN 50, Chemraz 242-04[ ]F4[ ]

24012-03 Kit, O-Ring, 2 DN 50, Chemraz for use with Alumina liner 242-04[ ]A4-F4

24013-00 Kit, O-Ring, 3 DN 80, EPDM 242-06[ ]EP[ ]

24013-01 Kit, O-Ring, 3 DN 80, Viton 242-06[ ]VT[ ]

24013-02 Kit, O-Ring, 3 DN 80, Chemraz 242-06[ ]F8[ ]

24013-03 Kit, O-Ring, 3 DN 80, Chemraz for use with Alumina liner 242-06[ ]A8-F8

24014-00 Kit, O-Ring, 4 DN 100, EPDM 242-08[ ]EP[ ]

24014-01 Kit, O-Ring, 4 DN 100, Viton 242-08[ ]VT[ ]

24014-02 Kit, O-Ring, 4 DN 100, Chemraz 242-08[ ]F8[ ]

24014-03 Kit, O-Ring, 4 DN 100, Chemraz for use with Alumina liner 242-08[ ]A8-F8

TABLE 3-1. Replacement Parts and Accessories

18

MODEL 242 SECTION 3.0

MODEL 242 SENSOR

FIGURE 3-1. Exploded View of Model 242

* REPLACEMENT PARTS AVAILABLE.

Sensor Type Model Wrench Torque (ft-lbs) Torque (N-m)

1", 150# flange 242-02-10 5/16" Hex Allen 18 ft-lbs 24 Nm

1", 300# flange 242-02-11 5/16" Hex Allen 18 ft-lbs 24 Nm

DN 25, PN 16 242-02-14 5/16" Hex Allen 18 ft-lbs 24 Nm

1.5", 150# flange 242-03-10 5/16" Hex Allen 18 ft-lbs 24 Nm

1.5", 300# flange 242-03-11 3/8" Hex Allen 42 ft-lbs 57 Nm

DN 40, PN 16 242-03-14 5/16" Hex Allen 18 ft-lbs 24 Nm

2", 150# flange 242-04-10 5/16" Hex Allen 18 ft-lbs 24 Nm

2", 300 # flange 242-04-11 3/8" Hex Allen 42 ft-lbs 57 Nm

DN 50, PN 16 242-04-14 3/8" Hex Allen 42 ft-lbs 57 Nm

3", 150# flange 242-06-10 3/4" Socket 42 ft-lbs 57 Nm

3", 300 # flange 242-06-11 3/4" Socket 42 ft-lbs 57 Nm

DN 80, PN 16 242-06-14 3/4" Socket 42 ft-lbs 57 Nm

4", 150# flange 242-08-10 3/4" Socket 42 ft-lbs 57 Nm

4", 300 # flange 242-08-11 3/4" Socket 42 ft-lbs 57 Nm

DN 100, PN 16 242-08-14 3/4" Socket 42 ft-lbs 57 Nm

Table 3-2. Sensor Bolt Removal & Installation Guide

19

MODEL 242 SECTION 3.0

MODEL 242 SENSOR

3.4 RE-ASSEMBLE THE SENSOR

It is recommended that a press be used during the assembly process to ensure tight seals between compo-

nents.

Locate the part to be changed on the diagram and substitute the new part from the kit. Complete disassembly

of the sensor might not be necessary and in that case is not recommended. If new O-rings are to be used, they

should be lubricated prior to installation.

Assuming the sensor has been completely disassembled, begin by placing both Contact Rings (Item 1) side by

side on their flat faces. Set a Flange (Item 4) on each Contact Ring (Item 1). Install a Retainer Ring (Item 5)

onto the step on the outside of each Contact Ring (Item 1). Insert a lubricated Process O-ring (Item 6) in the

lower groove (closest to the flat face) located inside each Contact Ring (Item 1). Place a lubricated Secondary

Back-up O-ring (Item 7) on the upper step inside each Contact Ring (Item 1). The flange-assembly should look

like Figure 3-2.

Place one of these flange-assemblies onto a press and install the Liner (Item 8). It is advisable to place a flat

surface between the press and the liner to protect the liner from damage during pressing. Be careful to ensure

O-rings do not slip or twist. Slip the Toroid Housing (Item 9) over the Liner (Item 8) to nest inside the flange-

assembly. The pins on the toroid housing must seat into the small holes in the flanges. Place the second flange-

assembly on top of the first flange assembly with the Liner (Item 8) and Toroid Housing (Item 9) in between.

Check for pin alignment, pinched O-rings, and straight, even insertion. The Sensor Bolts (Item 2) can be tem-

porarily preplaced in the bolt holes to align the two Flanges. Press the entire sensor together to begin assem-

bly of all the components. Install and tighten the Sensor Bolts and Nuts (Items 2 and 3), using thread-locking

compound. Using the torquing sequence shown in Figure 1-6, tighten the bolts in 1/3 increments of their final

torque values as listed in Table 3-2.

3.5 RE-INSTALL THE SENSOR INTO THE PROCESS

Please see Section 1.4 of this manual for instructions.

FIGURE 3-2. Flange Assembly: Contact Ring, Flange, and O-rings.

Back-up O-ring

Contact Ring

Retainer Ring

Flange

Process O-ring

MODEL 242 SECTION 4.0

RETURN OF MATERIALS

SECTION 4.0

RETURN OF MATERIALS

4.1 GENERAL. To expedite the repair and return of

instruments, proper communication between the cus-

tomer and the factory is important. A return material

authorization number is required. Call (949) 757-

8500. The Return of Materials Request form is pro-

vided for you to copy and use in case the situation

arises. The accuracy and completeness of this form

will affect the processing time of your materials.

4.2 WARRANTY REPAIR. The following is the proce-

dure for returning products still under warranty.

1. Contact the factory for authorization.

2. Complete a copy of the Return of Materials

Request form as completely and accurately as

possible.

3. To verify warranty, supply the factory sales order

number or the original purchase order number. In

the case of individual parts or sub-assemblies, the

serial number on the mother unit must be sup-

plied.

4. Carefully package the materials and enclose your

Letter of Transmittal and the completed copy of

the Return of Materials Request form. If possi-

ble, pack the materials in the same manner as it

was received.

IMPORTANT

Please see second section of Return of

Materials Request Form. Compliance to

the OSHA requirements is mandatory for

the safety of all personnel. MSDS forms

and a certification that the instruments

have been disinfected or detoxified are

required.

5. Send the package prepaid to:

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606

Attn: Factory Repair

Mark the package: Returned for

Repair RMA No. __________

Model No. _________

4.3 NON-WARRANTY REPAIR.

1. Contact the factory for authorization.

2. Fill out a copy of the Return of Materials Request

form as completely and accurately as possible.

3. Include a purchase order number and make sure

to include the name and telephone number of the

right individual to be contacted should additional

information be needed.

4. Do Steps 4 and 5 of Section 4.2.

NOTE

Consult the factory for additional infor -

mation regarding service or repair.

20

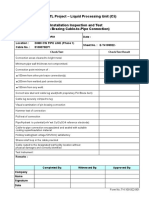

FROM: RETURN BILL TO:

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

CUSTOMER/USER MUST SUBMIT MATERIAL SAFETY SHEET (MSDS) OR COMPLETE STREAM COMPOSITION, AND/OR

LETTER CERTIFYING THE MATERIALS HAVE BEEN DISINFECTED AND/OR DETOXIFIED WHEN RETURNING ANY PROD-

UCT, SAMPLE OR MATERIAL THAT HAVE BEEN EXPOSED TO OR USED IN AN ENVIRONMENT OR PROCESS THAT CON-

TAINS A HAZARDOUS MATERIAL ANY OF THE ABOVE THAT IS SUBMITTED TO ROSEMOUNT ANALYTICAL WITHOUT

THE MSDS WILL BE RETURNED TO SENDER C.O.D. FOR THE SAFETY AND HEALTH OF OUR EMPLOYEES. WE THANK

YOU IN ADVANCE FOR COMPLIANCE TO THIS SUBJECT.

SENSOR OR CIRCUIT BOARD ONLY:

(Please reference where from in MODEL / SER. NO. Column)

1. PART NO.__________________________1. MODEL_________________________________1. SER. NO. ________________

2. PART NO.__________________________2. MODEL_________________________________2. SER. NO. ________________

3. PART NO.__________________________3. MODEL_________________________________3. SER. NO. ________________

4. PART NO.__________________________4. MODEL_________________________________4. SER. NO. ________________

PLEASE CHECK ONE:

n REPAIR AND CALIBRATE n DEMO EQUIPMENT NO. __________________________

n EVALUATION n OTHER (EXPLAIN) _______________________________

n REPLACEMENT REQUIRED? n YES n NO _________________________________________________

DESCRIPTION OF MALFUNCTION:

______________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

WARRANTY REPAIR REQUESTED:

n YES-REFERENCE ORIGINAL ROSEMOUNT ANALYTICAL ORDER NO. ________________________________________

CUSTOMER PURCHASE ORDER NO. _________________________________________________

n NO-PROCEED WITH REPAIRS-INVOICE AGAINST P.O. NO. _________________________________________________

n NO-CONTACT WITH ESTIMATE OF REPAIR CHARGES: LETTER n __________________________________________

PHONE n ___________________________________________

NAME ____________________________________________________ PHONE _________________________________________

ADDRESS ___________________________________________________________________________________________________

______________________________________________________________ ZIP _________________________________________

RETURN AUTHORITY FOR CREDIT ADJUSTMENT [Please check appropriate box(s)]

n WRONG PART RECEIVED n REPLACEMENT RECEIVED

n DUPLICATE SHIPMENT REFERENCE ROSEMOUNT ANALYTICAL SALES ORDER NO.__________

n RETURN FOR CREDIT RETURN AUTHORIZED BY: ______________________________________

WARRANTY DEFECT ___________________________________________________________________________________

24-6047

RETURN OF MATERIALS REQUEST

IMPORTANT!

This form must be completed to ensure expedient factory service.

R

E

P

A

I

R

S

T

A

T

U

S

R

E

A

S

O

N

F

O

R

R

E

T

U

R

N

C

U

S

T

O

M

E

R

N

O

T

I

C

E

T

O

S

E

N

D

E

R

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

Rosemount Analytical Inc. 2003

A Worldwide Network of Sales and Service

Emerson Process Managements field sales offices are your source for more information on the fill line of Rosemount Analytical

products. Field sales personnel will work closely with you to supply technical data and application information.

For more information, please contact your nearest Emerson Process Management sales office.

Immediate, Reliable Analytical Support

Now theres a way to quickly get the right answers for your liquid analytical instrumentation questions: the Analytical

Customer Support Center.

Our staff of trained professionals is ready to provide the information you need. If you are placing an order, verifying delivery,

requesting application information, or just want to contact an Emerson Process Management representative, a call to the

Customer Support Center will provide you with the right people, the right answers, right now.

The right people, the right answers, right now.

THE AMERICAS -

HEADQUARTERS

Emerson Process Management

Rosemount Analytical Inc.

Liquid Center of Excellence

2400 Barranca Parkway

Irvine, CA 92606

Phone: +1.949.757.8500

Toll Free: +1.800.854.8257

Fax: +1.949.474.7250

ASIA-PACIFIC

Emerson Process Management

Asia Pacific Private Ltd.

1 Pandan Crescent

Singapore 0512

Republic of Singapore

Phone: 65.777.8211

Fax: 65.777.0947

EUROPE

Emerson Process Management AG

Blegistrasse 21

CH-6341 Baar-Walterswil

Switzerland

T 41.41.768.6111

T 41.41.761.8740

VISIT OUR WEBSITE AT

www.rosemountanalytical.com

GERMANY

Emerson Process Management Process

Gas Analyzer Center of Excellence

GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T 49.6055.884.0

F 49.6055.884.20

LATIN AMERICA

Emerson Process Management

Rosemount Analytical

10241 West Little York, Suite #200

Houston, TX 77040 USA

T 713.467.6000

F 713.827.3328

MIDDLE EAST AND AFRICA

Emerson Process Management

EPM Building

P. O. Box 17033

Jebe Ali Free Zone

Dubai, United Arab Emirates

T 971.4.8835235

F 971.4.8835312

WARRANTY

Seller warrants that the firmware will execute the programming instructions provided by Seller, and that the Goods manufactured

or Services provided by Seller will be free from defects in materials or workmanship under normal use and care until the expira-

tion of the applicable warranty period. Goods are warranted for twelve (12) months from the date of initial installation or eighteen

(18) months from the date of shipment by Seller, whichever period expires first. Consumables, such as glass electrodes,

membranes, liquid junctions, electrolyte, o-rings, catalytic beads, etc., and Services are warranted for a period of 90

days from the date of shipment or provision.

Products purchased by Seller from a third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by

the original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable commercial

effort to arrange for procurement and shipping of the Resale Products.

If Buyer discovers any warranty defects and notifies Seller thereof in writing during the applicable warranty period, Seller shall, at

its option, promptly correct any errors that are found by Seller in the firmware or Services, or repair or replace F.O.B. point of man-

ufacture that portion of the Goods or firmware found by Seller to be defective, or refund the purchase price of the defective por-

tion of the Goods/Services.

All replacements or repairs necessitated by inadequate maintenance, normal wear and usage, unsuitable power sources, unsuit-

able environmental conditions, accident, misuse, improper installation, modification, repair, storage or handling, or any other

cause not the fault of Seller are not covered by this limited warranty, and shall be at Buyer's expense. Seller shall not be obligat-

ed to pay any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance by an

authorized Seller representative. All costs of dismantling, reinstallation and freight and the time and expenses of Seller's person-

nel for site travel and diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by Seller.

Goods repaired and parts replaced during the warranty period shall be in warranty for the remainder of the original warranty peri-

od or ninety (90) days, whichever is longer. This limited warranty is the only warranty made by Seller and can be amended only

in a writing signed by an authorized representative of Seller. Except as otherwise expressly provided in the Agreement, THERE

ARE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FIT-

NESS FOR PARTICULAR PURPOSE, OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES.

RETURN OF MATERIAL

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Emerson Process Management

Rosemount Analytical

2400 Barranca Parkway

Irvine, CA 92606

The shipping container should be marked:

Return for Repair

Model _______________________________

The returned material should be accompanied by a letter of transmittal which should include the following information (make a

copy of the "Return of Materials Request" found on the last page of the Manual and provide the following thereon):

1. Location type of service, and length of time of service of the device.

2. Description of the faulty operation of the device and the circumstances of the failure.

3. Name and telephone number of the person to contact if there are questions about the returned material.

4. Statement as to whether warranty or non-warranty service is requested.

5. Complete shipping instructions for return of the material.

Adherence to these procedures will expedite handling of the returned material and will prevent unnecessary additional charges

for inspection and testing to determine the problem with the device.

If the material is returned for out-of-warranty repairs, a purchase order for repairs should be enclosed.

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Specifications subject to change without notice.

8

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.rosemountanalytical.com

Rosemount Analytical Inc. 2012

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Mobileye c2-270 Insallation Guide ps3 Mam v3-1Dokument77 SeitenMobileye c2-270 Insallation Guide ps3 Mam v3-1Olivares EduardoNoch keine Bewertungen

- 2018 Aar - MSRP A1Dokument118 Seiten2018 Aar - MSRP A1wilian_coelho33090% (1)

- Dekoron Data Sheet2Dokument6 SeitenDekoron Data Sheet2MarioNoch keine Bewertungen

- EMEA WC Sec 6Dokument55 SeitenEMEA WC Sec 6andy175Noch keine Bewertungen

- Industry Guidelines: Identification of Buried Pipe SystemsDokument13 SeitenIndustry Guidelines: Identification of Buried Pipe Systemsandy175Noch keine Bewertungen

- 01 PressacaviDokument42 Seiten01 Pressacaviandy175Noch keine Bewertungen

- REDMUD Brief 6.5Dokument9 SeitenREDMUD Brief 6.5andy175Noch keine Bewertungen

- Atasheet Liycy Electronic Control Cable With Tinned Copper BraidingDokument3 SeitenAtasheet Liycy Electronic Control Cable With Tinned Copper Braidingandy175Noch keine Bewertungen

- PreventDokument9 SeitenPreventandy175Noch keine Bewertungen

- Process Safety Engineer-ALDokument1 SeiteProcess Safety Engineer-ALAhmedAmer1Noch keine Bewertungen

- E3000 GB 3406Dokument100 SeitenE3000 GB 3406lsilverNoch keine Bewertungen

- Guide Nexans O&G GB PDFDokument20 SeitenGuide Nexans O&G GB PDFandy175Noch keine Bewertungen

- Example Job DescriptionDokument2 SeitenExample Job DescriptiontheauctionhunterNoch keine Bewertungen

- Lec 3Dokument116 SeitenLec 3Cheng Chao HanNoch keine Bewertungen

- Calor I MetricDokument2 SeitenCalor I Metricandy175Noch keine Bewertungen

- ORBIT v30n1 2010 r15Dokument60 SeitenORBIT v30n1 2010 r15mathewaj100% (1)

- Process Safety Engineer-Sycamore Technical RecruitersDokument1 SeiteProcess Safety Engineer-Sycamore Technical Recruitersandy175Noch keine Bewertungen

- Stone Nixon - Distillation of Alcohol-Professional Guide For Amateur Distillers (2000)Dokument73 SeitenStone Nixon - Distillation of Alcohol-Professional Guide For Amateur Distillers (2000)moreherbsNoch keine Bewertungen

- Process Safety Engineer-Sycamore Technical RecruitersDokument1 SeiteProcess Safety Engineer-Sycamore Technical Recruitersandy175Noch keine Bewertungen

- Process Safety Engineer-ALDokument1 SeiteProcess Safety Engineer-ALAhmedAmer1Noch keine Bewertungen

- Connecting and Interpreting Limit SwitchesDokument7 SeitenConnecting and Interpreting Limit SwitchesbatoqkaNoch keine Bewertungen

- Engineering - Dynamic Analysis of The Internal Combustion EngineDokument13 SeitenEngineering - Dynamic Analysis of The Internal Combustion Engineamirreza_eng3411Noch keine Bewertungen

- 8 11 031Dokument4 Seiten8 11 031andy175Noch keine Bewertungen

- (Distillation) - Packed Distillation ColunmDokument12 Seiten(Distillation) - Packed Distillation Colunmandy175Noch keine Bewertungen

- D1093Dokument2 SeitenD1093rimi7alNoch keine Bewertungen

- Compound Water Meter Model M-WT: ARAD LTD. DALIA - Water Meters DivisionDokument2 SeitenCompound Water Meter Model M-WT: ARAD LTD. DALIA - Water Meters Divisionandy175Noch keine Bewertungen

- Calcined Alumina - Technical Specification 2012Dokument1 SeiteCalcined Alumina - Technical Specification 2012andy175Noch keine Bewertungen

- Design of Fuzzy ControllersDokument27 SeitenDesign of Fuzzy ControllerssayedmhNoch keine Bewertungen

- ACADE FaqDokument4 SeitenACADE Faqandy175Noch keine Bewertungen

- AutoCad 2006 Electrical ManualDokument88 SeitenAutoCad 2006 Electrical Manualand2094Noch keine Bewertungen

- PDFSigQFormalRep PDFDokument1 SeitePDFSigQFormalRep PDFJim LeeNoch keine Bewertungen

- Getting Started - Using Acrobat Reader - Searching Catalog IndexesDokument79 SeitenGetting Started - Using Acrobat Reader - Searching Catalog IndexesLuis Gustavo Choque BordaNoch keine Bewertungen

- AcrobatDokument1 SeiteAcrobatanon-107705Noch keine Bewertungen

- LT Cable AnnexureDokument4 SeitenLT Cable Annexureqwertyui123321Noch keine Bewertungen

- BT08 PDFDokument4 SeitenBT08 PDFAfdhalNoch keine Bewertungen

- Halogen ADokument25 SeitenHalogen APratham KashyapNoch keine Bewertungen

- Cahier Technique No. 203: Basic Selection of MV Public Distribution NetworksDokument24 SeitenCahier Technique No. 203: Basic Selection of MV Public Distribution NetworksnbnbNoch keine Bewertungen

- SAT-101 User Manual: Document No: MAN-0013 Issue No: 2 Dated: 16 December 2003Dokument22 SeitenSAT-101 User Manual: Document No: MAN-0013 Issue No: 2 Dated: 16 December 2003VM ServicesNoch keine Bewertungen

- Iec TS 62257-7-1-2010 PDFDokument86 SeitenIec TS 62257-7-1-2010 PDFSe SamnangNoch keine Bewertungen

- General Brochure ConductorsDokument12 SeitenGeneral Brochure ConductorsAhmed Bilal KhanNoch keine Bewertungen

- Fujitsu UTY-RNBYU Wired Remote ControlDokument2 SeitenFujitsu UTY-RNBYU Wired Remote Controle-ComfortUSANoch keine Bewertungen

- BA DM 197 12 13 EN Dulcometer D1Cb Gesamtanleitung ENDokument148 SeitenBA DM 197 12 13 EN Dulcometer D1Cb Gesamtanleitung ENRicardo LinaresNoch keine Bewertungen

- Fuente de Alimentacion ELMDEME-STX2405Dokument8 SeitenFuente de Alimentacion ELMDEME-STX2405Jose Maria CamberoNoch keine Bewertungen

- Plenum N Male To N Male Low PIM Cable 50 CM Length Using SPP-250-LLPL Coax Using Times Microwave PartsDokument6 SeitenPlenum N Male To N Male Low PIM Cable 50 CM Length Using SPP-250-LLPL Coax Using Times Microwave Partsjunak72Noch keine Bewertungen

- ESD-5550/5570 Series - Speed Control Unit: Technical InformationDokument12 SeitenESD-5550/5570 Series - Speed Control Unit: Technical InformationCarlos Molina100% (1)

- Bounded Media, or Cable Media. This Includes Cable Types Such As Coaxial CableDokument18 SeitenBounded Media, or Cable Media. This Includes Cable Types Such As Coaxial CableUmme AbdullahNoch keine Bewertungen

- Method Statement For Installation of Wiring and Cable PullingDokument56 SeitenMethod Statement For Installation of Wiring and Cable PullingAnandu Ashokan100% (1)

- Amrex Ultrasonido U50Dokument42 SeitenAmrex Ultrasonido U50jordy cruz toroNoch keine Bewertungen

- Digiguard Manual v0.9Dokument84 SeitenDigiguard Manual v0.9lundiexNoch keine Bewertungen

- eTRS-IO ENGDokument21 SeiteneTRS-IO ENGbeyamikalNoch keine Bewertungen

- How To Use This Parts CatalogDokument22 SeitenHow To Use This Parts Catalogoleg-spbNoch keine Bewertungen

- MSP Duct Installation ManualDokument48 SeitenMSP Duct Installation ManualPablo DenisNoch keine Bewertungen

- Safety Manual: Mitsubishi Electric Industrial RobotDokument36 SeitenSafety Manual: Mitsubishi Electric Industrial Robotemil100% (1)

- 00 - Control Loop and Instrument DrawingsDokument23 Seiten00 - Control Loop and Instrument Drawingsminhtrieu999Noch keine Bewertungen

- Netcol 5000 A 050Dokument360 SeitenNetcol 5000 A 050Gustavo GomezNoch keine Bewertungen

- Pin Brazing - DN80 Ph.1Dokument14 SeitenPin Brazing - DN80 Ph.1Nickath BanuNoch keine Bewertungen

- Method Statement For Data & Communication Equipments & FOC InstallationDokument13 SeitenMethod Statement For Data & Communication Equipments & FOC InstallationziaurrehmanNoch keine Bewertungen

- Convection Oven COES061-101Dokument92 SeitenConvection Oven COES061-101Nikola UroševićNoch keine Bewertungen

- Chattanooga High Power Laser 2879-2979Dokument44 SeitenChattanooga High Power Laser 2879-2979Business DevelopmentNoch keine Bewertungen

- Konica MINOLTAMagicolor 5650 5670 SERVICE MANUAL PDFDokument370 SeitenKonica MINOLTAMagicolor 5650 5670 SERVICE MANUAL PDFYury Kobzar100% (2)