Beruflich Dokumente

Kultur Dokumente

Vehicle Emissionsa

Hochgeladen von

Doddy Syamsu RizalCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Vehicle Emissionsa

Hochgeladen von

Doddy Syamsu RizalCopyright:

Verfügbare Formate

I N T E R D I S C I P L I N A R Y L I V E L Y A P P L I C A T I O N S P R O J E C T

AUTHORS:

Lei Yu

(Transportation Studies)

yu_lx@tsu.edu

Texas Southern University

3100 Cleburne Avenue

Houston, TX 77004

Don Small

(Mathematics)

U.S. Military Academy

West Point, NY 10996

Lafayette College

Easton, PA 18042

CONTENTS

1. Introduction

2. Remote Emission-Sensing

Technique

3. Emission Data Collection

4. Data Conversion

5. Regression Analysis

6. Emission-Based Speed

Optimization

7. Real-World Applications

References

Sample Solution

Notes for the Instructor

About the Authors

The UMAP Journal 24 (4) 451-472. Copyright 2003 by COMAP, Inc. All rights

reserved. Permission to make digital or hard copies of part or all of this work for per-

sonal or classroom use is granted without fee provided that copies are not made or

distributed for profit or commercial advantage and that copies bear this notice.

Abstracting with credit is permitted, but copyrights for components of this work

owned by others than COMAP must be honored. To copy otherwise, to republish, to

post on servers, or to redistribute to lists requires prior permission from COMAP.

Vehicle Emissions 451

Vehicle Emissions

MATHEMATICS CLASSIFICATIONS:

Algebra

DISCIPLINARY CLASSIFICATIONS:

Traffic Engineering

PREREQUISITE SKILLS:

1. Elementary algebra

2. Regression techniques

3. Elementary optimization

PHYSICAL CONCEPTS EXAMINED:

1. Concept of a mobile source for vehicle emissions

2. Optimal driving speeds to minimize emissions

3. Total vehicle emissions for a given speed profile

COMPUTING REQUIREMENT:

1. Spreadsheet and ability to use it

2. Calculator and ability to use it

452 24.4 (2003)

Contents

1. Introduction

2. Remote Emission-Sensing Technique

3. Emission Data Collection

4. Data Conversion

5. Regression Analysis

6. Emission-Based Speed Optimization

7. Real-World Applications

References

Sample Solution

Notes for the Instructor

About the Authors

1. Introduction

Cars, trucks, motorcycles, and buses emit signicant quantities of carbon

monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and ne particles

(PM). These chemical compounds play dominant roles in air pollution prob-

lems. In the densely populated Northeast, where the air pollution problem is

especially severe, the Environmental Protection Agency (EPA) has projected

that highway vehicles will account for approximately 38% of the total NOx in-

ventory and 22%of the total HCinventory in 2005, in spite of the tighter motor

vehicle standards in the 1990 Clean Air Act Amendment (CAAA) (Figure 1).

Figure 1. Trafc.

Vehicle emissions, especially CO, NOx, and HC, are harmful to the health

of humans. CO is a tasteless, odorless, and colorless gas produced through

the incomplete combustion of carbon-based fuels. CO enters the bloodstream

through the lungs and reduces the delivery of oxygen to the bodys organs

and tissues. The health threat from exposure to CO is most serious for those

Vehicle Emissions 453

who suffer from cardiovascular disease, particularly those with angina or pe-

ripheral vascular disease. Exposure to elevated CO levels is associated with

impairment of visual perception, work capacity, manual dexterity, learning

ability and performance of complex tasks. NOx emissions also produce a wide

varietyof healthandwelfare effects. Nitrogendioxide canirritate the lungs and

lower resistance to respiratory infection (such as inuenza). NOx emissions are

important in acid rain, affecting both terrestrial and aquatic ecosystems. At-

mospheric deposition of nitrogen leads to excess nutrient enrichment problems

(eutrophication). Finally, HC, in combination with NOx in the presence of

heat and sunlight, will form ozone. Ozone forms readily in the atmosphere,

usually during hot summer weather. Ground-level ozone is the prime ingre-

dient of smog, the pollution that blankets many areas during the summer.

Short-term exposures (13 hours) to high ambient ozone concentrations have

been linked to increased hospital admissions and emergency room visits for

respiratory problems.

With the rapid increase of the number of motor vehicles along with world-

wide economic development, the vehicle emission problem has worsened.

Many governments have started to implement certain vehicle emission-control

strategies. Steady progress in reducing certain air pollution problems is occur-

ring in the US, Europe and Japan. Globally, the use of advanced pollution-

control technology, especially catalysts has been spreading, as has the use of

unleaded gasoline. However, the continued economic growth in the world re-

quires the use of strategies that do not impose negative effect on the economic

development, in other words, do not restrict vehicle ownership. Examples

of such strategies that have already been implemented in many cities in the

world include advanced trafc-control techniques, integrated transportation

planning process, and Intelligent Transportation Systems (ITS) technologies.

Past research has shown that driving patterns greatly inuence the amount

of vehicle emissions. Frequent acceleration and deceleration tend to generate

more emissions than smoother driving. An effective trafc signal timing plan

cansmoothtrafc owina manner that reduces the emissions. Inaddition, well

planned transportation projects or activities can change the driving patterns of

vehicles in the city at a more macroscopic level.

2. Remote Emission-Sensing Technique

The key to success in developing an emission-control strategy is obtaining

accurate quantication of vehicle emissions under various trafc and envi-

ronmental scenarios. The remote emission-sensing device that is used in this

project is calledSMOGDOG. It performs environmental monitoringtomeasure

automotive emissions. The SMOGDOGcan simultaneously measure emission

concentrations of CO, HC, NOx, and CO2 in the dispersing exhaust cloud of

vehicles. A special feature of the SMOG DOG is its capability in detecting a

vehicles instantaneous speed and acceleration rate.

454 24.4 (2003)

Figure 2. SMOG DOG in action.

3. Emission Data Collection

SMOG DOG was used to collect vehicle emission data from a freeway on-

ramp in Houston, TX (Figure 2). The operation of SMOG DOG requires that

the vehicle be in motion. Hence, the emission data for the idling mode are

not collected. Instead, vehicle idling emissions will be calculated based on the

regression models that are developed. Table 1 illustrates the emission data on

CO and HC concentrations that were collected.

Problem: Developmodels relatingvehicle speedandvehicle exhaust emissions

of CO and HC. Formulate speed recommendations based on your model and

the given data. Use of spreadsheet technology is strongly recommended. Input

the data in Table 1 into a spreadsheet (4 columns). You will add four more

columns in Requirement 2 and two more in Requirement 4.

Requirement 1

Use the data in Table 1 to

plot the CO concentration (%) vs. speed data, and

plot the HC concentration (%) vs. speed data.

Vehicle Emissions 455

Table 1.

CO and HC concentration data collected by SMOG DOG in Houston.

Data # Speed (mph) CO% HC% Data # Speed (mph) CO% HC%

1 9.98 0.27 0.000027 31 43.22 0.32 0.000032

2 10.97 0.22 0.000022 32 44.20 0.29 0.000029

3 15.40 0.30 0.00003 33 45.05 0.39 0.000039

4 15.69 0.03 0.000003 34 46.59 0.79 0.000079

5 16.44 0.21 0.000021 35 47.06 0.73 0.000073

6 17.11 0.89 0.000089 36 47.51 0.54 0.000054

7 18.66 0.19 0.000019 37 47.86 0.07 0.000007

8 19.04 0.79 0.000079 38 48.92 0.33 0.000033

9 20.95 0.08 0.000008 39 49.78 0.43 0.000043

10 21.52 0.07 0.000007 40 49.81 0.55 0.000055

11 23.41 1.61 0.000161 41 50.50 0.72 0.000072

12 24.82 0.77 0.000077 42 50.52 0.21 0.000021

13 25.15 0.76 0.000076 43 51.48 0.18 0.000018

14 26.35 1.91 0.000191 44 52.18 0.61 0.000061

15 27.02 0.40 0.00004 45 52.87 0.92 0.000092

16 27.62 0.06 0.000006 46 53.25 0.19 0.000019

17 29.90 0.36 0.000036 47 53.62 0.44 0.000044

18 30.04 0.18 0.000018 48 54.32 0.22 0.000022

19 30.67 0.58 0.000058 49 55.19 0.34 0.000034

20 31.99 0.12 0.000012 50 56.07 0.49 0.000049

21 34.97 1.02 0.000102 51 56.33 0.15 0.000015

22 35.10 0.53 0.000053 52 56.56 0.76 0.000076

23 35.94 1.11 0.000111 53 58.29 0.12 0.000012

24 36.98 0.29 0.000029 54 58.75 0.12 0.000012

25 37.69 1.67 0.000167 55 59.44 0.35 0.000035

26 37.90 0.62 0.000062 56 61.40 0.83 0.000083

27 38.74 0.27 0.000027 57 62.00 0.21 0.000021

28 40.58 0.09 0.000009 58 63.65 0.35 0.000035

29 41.63 0.30 0.00003 59 67.11 0.35 0.000035

30 42.12 0.54 0.000054 60 76.68 0.47 0.000047

4. Data Conversion

To develop models relating vehicle speed to emission quantities, we intro-

duce two emission quantities: emission factor (g/mi) and emission rate (g/s).

Theemissionfactor is thenumber of grams emittedwhenthevehicle

travels one mile.

The emission rate is the total emission in grams that a vehicle emits

per second.

We dene the following variables:

CO%: CO emission concentration (%);

HC%: HC emission concentration (%);

COs: CO emission rate in grams per second (g/s);

456 24.4 (2003)

HCs: HC emission rate in grams per second (g/s);

COm: CO emission factor in grams per mile (g/mi);

HCm: HC emission factor in grams per mile (g/mi);

u: a vehicles instantaneous speed in miles per hour (mph);

u

optimal

: optimal speed (mph) that minimizes emissions;

b

0

, b

1

, c

0

, c

1

: constant values (regression model coefcients).

Conversion of emission concentrations to emission rates is problematic.

Manyscientists andengineers use the followinglinear correlationrelationships,

developed for the emission concentrations and emissions factors by the South

Coast Air Quality Management District (SCAQMD).

Conversion from emission concentrations to emission factors:

COm (g/mi) = 11.1 CO% + 21.3, (1)

HCm (g/mi) = 63.3 HC% + 1.7. (2)

Conversion from emission concentrations to emission rates:

COs (g/s) =

COm (g/mi) u mph

3600

, (3)

HCs (g/s) =

HCm (g/mi) u mph

3600

. (4)

Requirement 2

Use (1)(4) to convert the CO/HC concentrations in Table 1 to CO/HC

emission factors and CO/HC emission rates. Expand your spreadsheet table

to include the 8 columns: Data #, Speed, CO%, HC%, COm, HCm, COs, and

HCs.

Requirement 3

Draw four graphs to show the relationships between speed and CO/HC

emission factors as well as CO/HC emission rates using the data prepared in

Requirement 2. Based on your visual analysis of these graphs, which rela-

tionships display a better regularity of shapes and trends; emission factors or

emission rates?

Vehicle Emissions 457

5. Regression Analysis

Inmany engineering andscientic applications, relationships betweenvari-

ables are established by rst collecting data fromexperimental studies in either

the laboratory or the eld. This data is then plotted and relationship discerned.

In this project, the two variables in the relationship represent the speed and

the CO/HC emission rates. Because of potential errors in measurement, the

data shown in the graphs drawn in Requirement 3 may not fall precisely on a

smooth curve. For this reason, the task of the analysis becomes threefold:

to hypothesize the mathematical form of the relationship between the two

variables (model postulation);

to estimate the parameters of the model based on the collected eld data

(model calibration); and

to determine howwell the calibratedrelationshipexplains the observeddata

(goodness of t).

This analysis process is called regression.

Scientic research on vehicle emissions has shown that the best mathemat-

ical function to model the relationship between the speed and the CO or HC

emission rate is the natural logarithm, expressed in the following forms:

ln(COs) = b

0

+ b

1

u, (5)

ln(HCs) = c

0

+ c

1

u. (6)

The speed u is the independent or explanatory variable. The emission rates, COs

or HCs, are called the dependent or explained variables. The constant coefcients

c

0

and c

1

are the model parameters. Data from Requirement 2 can be used to

plot ln(COs) vs. speed and ln(HCs) vs. speed. Calibrating the model means

determining the unknown values of the parameters in (5) or (6) to obtain the

best t to these plots. The goodness of t is measured by the coefcient of

correlation, r. Its value can range from1 to +1. If r is near +1, there exists a

highpositive correlation; if it is near 1, there exists a highnegative correlation;

and if it is around zero, there exists no correlation between the independent

and the dependent variables.

Requirement 4

Use the regression technique and the data prepared in Requirement 2 to

calibrate (5) and (6). The data for COs and HCs prepared in Requirement 2

need to be transformed by the natural logarithm (ln) before a simple linear

regression can be carried out. Hint: Add columns for ln(C0s) and ln(HCs) to

your spreadsheet table constructed in Requirement 2. Then plot the ln(C0s)

vs. speed and form the linear regression. Repeat for ln(HCs) vs. speed.

458 24.4 (2003)

Requirement 5

Calculate the coefcient correlations for the regressions in Requirement 4.

Are the models acceptable? Why? Drawthe line plot for each of the regression

equations generated.

6. Emission-Based Speed Optimization

Emission rates (g/s) can be transformed into emission factors (g/mi) by

solving (3) for COm and (4) for HCm. The new equations are:

COm (g/mi) =

COs (g/s) 3600 (s/h)

u (mi/h)

, (7)

HCm (g/mi) =

HCs (g/s) 3600 (s/h)

u (mi/h)

. (8)

Equations (3) and (4) for the emission rates are in the form y = mx, where the

slopes are COm/3600 and HCm/3600. Because these slopes are positive, the

emission rates are monotonically increasing functions of speed; hence, there

are no minimum values for a moving vehicle. The situation is less clear for the

emission factors described by (7) and (8). These equations can be transformed

into explicit functions of speed by solving for COs and HCs in the results of

Requirement 4 and then substituting these results into (7) and (8). Doing this

yields

COs (g/s) =

3600e

b

0

+b

1

u

u

, (9)

HCm (g/s) =

3600e

c

0

+c

1

u

u

. (10)

A graphical analysis can now be made to determine what speeds will min-

imize the emission factors. Knowledge of these speeds is critical information

for developing an advanced trafc management scheme to reduce emission

amounts.

Requirement 6

Draw a graph with two curves, one for the relationship between the speed

and the COemission rate, and the other for the relationship between the speed

and the CO emission factor. Draw a second graph with two curves, one for the

relationship between the speed and the HCemission rate, and the other for the

relationship between the speed and the HC emission factor. Let the speed be

measured starting from 0 to 70 mph in increments of 5 mph. Then calculate

the emission rates by solving for COs and HCs in the equations generated in

Requirement 4, and the emission factors using (9) and (10). Based on the visual

analysis of the graphs, is there a speed that can minimize the emission factor?

Vehicle Emissions 459

Requirement 7

Approximate the speeds corresponding to the minimumpoints onthe emis-

sion factor plots. What speed do you recommend for minimizing both the CO

and HC emission factors? Hint: On a graphing calculator, use the trace feature

to trace a point along the curve to the minimumposition or use the table feature

to determine the coordinates of the minimum point. For a spreadsheet, iterate

the function values to determine the minimum.

7. Real-World Applications

If all drivers traveled at the optimal speed, the total CO or HC emissions

would be the minimum. On the other hand, if vehicles are driven at varying

speeds, the resulting emissions will be higher. To analyze such a pattern, we as-

sume two different speed proles experienced by two different vehicles. Both

vehicles are driven for 30 s, but the rst vehicle travels at a constant speed of

35 mphwhile the speedof the secondvehicle varies between29 and42 mph(see

Table 2). After 30 s, both vehicles have driven the same distance, 1540 ft. Al-

though both vehicles have been driven the same distance during the same time

period, it is expected that the resulting vehicle emissions would be different.

Table 2 illustrates the details of these two different speed proles.

Requirement 8

Based on Table 2, plot two graphs, one for the constant speed prole, and

one for the varying speed prole. For each speed prole, there should be

two curves, one for the relationship between time and speed, and one for the

relationship between time and the distance. Use different y-axes for speed and

distance.

Requirement 9

Use the regression equations derived from Requirement 4 to calculate the

CO and HC emissions at each second for the two different speed proles in

Table 2. Make your calculation in a table. Then, calculate the total CO and HC

emissions for the entire travel of the two speedproles. What can youconclude

from your calculations?

Requirement 10

Assume that an accident happened on a location of a freeway segment. A

police ofcer came to the scene to process the necessary paperwork for this

accident and towing vehicles came to remove all vehicles involved. It took a

Time (Sec) Speed (mph) Distance (ft) Time (Sec) Speed (mph) Distance (ft)

1 35 51 1 42 62

2 35 103 2 41 122

3 35 154 3 40 180

4 35 205 4 39 238

5 35 257 5 38 293

6 35 308 6 38 349

7 35 359 7 37 403

8 35 411 8 36 456

9 35 462 9 35 507

10 35 513 10 34 557

11 35 565 11 33 606

12 35 616 12 32 653

13 35 667 13 31 698

14 35 719 14 30 742

15 35 770 15 30 786

16 35 821 16 30 830

17 35 873 17 29 873

18 35 924 18 29 915

19 35 975 19 30 959

20 35 1027 20 31 1005

21 35 1078 21 32 1052

22 35 1129 22 33 1100

23 35 1181 23 34 1150

24 35 1232 24 35 1201

25 35 1283 25 36 1254

26 35 1335 26 37 1308

27 35 1386 27 38 1364

28 35 1437 28 39 1421

29 35 1489 29 40 1480

30 35 1540 30 41 1540

Constant Speed Profile Varying Speed Profile

460 24.4 (2003)

Table 2.

Speed proles driven by two vehicles.

total of 40 min fromthe start of the accident to the time when the accident scene

is completely cleared. During this period, a total of 200 vehicles have to stop.

Assume the average wait is 30 min per vehicle. Calculate the total additional

CO and HC emissions that were generated by these 200 vehicles due to the

trafc accident. What can you conclude from your calculation? Hint: Derive

the idling emissions rates by setting the speed equal to zero in the results of

Requirement 4.

References

European Conference of Ministers of Transport (ECMT). 291. Vehicle Emission

Reductions. Paris, France: OECDPublications Services (2, rue Andr e Pascal,

75775 Paris Cedex 16, France).

Sorbe, N. 1995. Hughes Employee Vehicle Exhaust Remote Sensing and Emis-

sions Evaluation Project. Report prepared for the Mobile Source Air Pollu-

tion Reduction Review Committee (MSRC) under the AB2766 Program. El

Segundo, CA: Hughes Environmental Systems, Inc.

Vehicle Emissions 461

Yu, L. 1998a. CollectionandEvaluationof Modal Trafc Data for Determination

of Vehicle Emission Rates under Certain Driving Conditions. Research

Reports 1485-1, 1485-2, and 1485-3F for TxDOT Project No. 0-1485, Center

for Transportation Training and Research. Houston, TX: Texas Southern

University.

. 1998b. Remote vehicle exhaust emission-sensing for trafc simu-

lation and optimization models. Journal of Transportation Research Part D:

Transport and Environment 3: 337347.

CO% Versus Speed

0

0.5

1

1.5

2

2.5

0 10 20 30 40 50 60 70 80 90

Speed (mph)

C

O

C

o

n

c

e

n

t

r

a

t

i

o

n

(

%

)

462 24.4 (2003)

Title: Vehicle Emissions

Sample Solution

Requirement 1: The graphs between the speed and COand HCconcentrations

are shown in Figures S1 and S2.

Figure S1. CO concentration vs. speed.

Based on visual analysis of these graphs, clearly the speed is not correlated

with the COor HCconcentrations. The data are scattered and do not showany

regularity of shapes or trends.

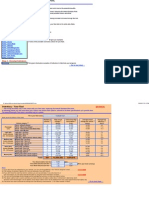

Requirement 2: The generated table is shown in Table S1.

Requirement 3: See Figures S3S6. A visual analysis of the graphs suggests

that the CO/HCemission rates have greater regularity of shape and trend with

the speed than do the CO/HC emission factors.

Requirement 4: The resulting regression equations are:

ln(COs) = 2.46215 + 0.028383u, or COs = e

2.46215+0.028383u

,

ln(HCs) = 4.91624 + 0.030929u, or COs = e

4.91624+0.030929u

.

HC% Versus Speed

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0 10 20 30 40 50 60 70 80 90

Speed (mph)

H

C

C

o

n

c

e

n

t

r

a

t

i

o

n

(

%

)

CO (g/mi) Versus Speed

0.0000

5.0000

10.0000

15.0000

20.0000

25.0000

30.0000

35.0000

40.0000

45.0000

0 10 20 30 40 50 60 70 80 90

Speed (mph)

C

O

E

m

i

s

s

i

o

n

s

(

g

/

m

i

)

Vehicle Emissions 463

Figure S2. HC concentration vs. speed.

Figure S3. CO emission factor vs. speed.

Data # Speed CO% HC% COm(g/mi) HCm(g/mi) COs(g/sec) HCs(g/sec)

1 9. 98 0. 27 0. 0096 24.2970 2.3077 0.0674 0.0064

2

10. 97 0. 22 0. 0058

23.7420 2.0671 0.0723 0.0063

3 15. 40 0. 30 0. 0038 24.6300 1.9405 0.1054 0.0083

4

15. 69 0. 03 0. 0031

21.6330 1.8962 0.0943 0.0083

5 16. 44 0. 21 0. 0161 23.6310 2.7191 0.1079 0.0124

6

17. 11 0. 89 0. 0031

31.1790 1.8962 0.1482 0.0090

7

18. 66 0. 19 0. 0055

23.4090 2.0482 0.1213 0.0106

8

19. 04 0. 79 0. 0241

30.0690 3.2255 0.1590 0.0171

9

20. 95 0. 08 0. 0065

22.1880 2.1115 0.1291 0.0123

10

21. 52 0. 07 0. 0007

22.0770 1.7443 0.1319 0.0104

11

23. 41 1. 61 0. 0063

39.1710 2.0988 0.2547 0.0136

12 24. 82 0. 77 0. 0187 29.8470 2.8837 0.2057 0.0199

13

25. 15 0. 76 0. 0257

29.7360 3.3268 0.2077 0.0232

14 26. 35 1. 91 0. 0370 42.5010 4.0421 0.3110 0.0296

15

27. 02 0. 40 0. 0206

25.7400 3.0040 0.1932 0.0225

16 27. 62 0. 06 0. 0050 21.9660 2.0165 0.1685 0.0155

17

29. 90 0. 36 0. 0256

25.2960 3.3205 0.2101 0.0276

18 30. 04 0. 18 0. 0041 23.2980 1.9595 0.1944 0.0163

19

30. 67 0. 58 0. 0036

27.7380 1.9279 0.2363 0.0164

20

31. 99 0. 12 0. 0161

22.6320 2.7191 0.2011 0.0242

21

34. 97 1. 02 0. 0013

32.6220 1.7823 0.3169 0.0173

22

35. 10 0. 53 0. 0084

27.1830 2.2317 0.2650 0.0218

23

35. 94 1. 11 0. 0122

33.6210 2.4723 0.3356 0.0247

24

36. 98 0. 29 0. 0061

24.5190 2.0861 0.2518 0.0214

25 37. 69 1. 67 0. 0350 39.8370 3.9155 0.4171 0.0410

26

37. 90 0. 62 0. 0206

28.1820 3.0040 0.2967 0.0316

27 38. 74 0. 27 0. 0152 24.2970 2.6622 0.2615 0.0286

28

40. 58 0. 09 0. 0037

22.2990 1.9342 0.2514 0.0218

29 41. 63 0. 30 0. 0063 24.6300 2.0988 0.2848 0.0243

30

42. 12 0. 54 0. 0133

27.2940 2.5419 0.3193 0.0297

31 43. 22 0. 32 0. 0147 24.8520 2.6305 0.2983 0.0316

32

44. 20 0. 29 0. 0141

24.5190 2.5925 0.3010 0.0318

33

45. 05 0. 39 0. 0247

25.6290 3.2635 0.3207 0.0408

34

46. 59 0. 79 0. 0239

30.0690 3.2129 0.3891 0.0416

35

47. 06 0. 73 0. 0079

29.4030 2.2001 0.3844 0.0288

36

47. 51 0. 54 0. 0171

27.2940 2.7824 0.3602 0.0367

37

47. 86 0. 07 0. 0071

22.0770 2.1494 0.2935 0.0286

38 48. 92 0. 33 0. 0248 24.9630 3.2698 0.3392 0.0444

39

49. 78 0. 43 0. 0345

26.0730 3.8839 0.3605 0.0537

40 49. 81 0. 55 0. 0150 27.4050 2.6495 0.3791 0.0367

41

50. 50 0. 72 0. 0138

29.2920 2.5735 0.4109 0.0361

42 50. 52 0. 21 0. 0173 23.6310 2.7951 0.3316 0.0392

43

51. 48 0. 18 0. 0056

23.2980 2.0545 0.3332 0.0294

44 52. 18 0. 61 0. 0352 28.0710 3.9282 0.4068 0.0569

45

52. 87 0. 92 0. 0186

31.5120 2.8774 0.4627 0.0423

46

53. 25 0. 19 0. 0282

23.4090 3.4851 0.3462 0.0515

47

53. 62 0. 44 0. 0013

26.1840 1.7823 0.3900 0.0265

48

54. 32 0. 22 0. 0329

23.7420 3.7826 0.3582 0.0571

49

55. 19 0. 34 0. 0211

25.0740 3.0356 0.3844 0.0465

50

56. 07 0. 49 0. 0054

26.7390 2.0418 0.4165 0.0318

51 56. 33 0. 15 0. 0039 22.9650 1.9469 0.3593 0.0305

52

56. 56 0. 76 0. 0351

29.7360 3.9218 0.4671 0.0616

53 58. 29 0. 12 0. 0169 22.6320 2.7698 0.3664 0.0448

54

58. 75 0. 12 0. 0103

22.6320 2.3520 0.3693 0.0384

55 59. 44 0. 35 0. 0038 25.1850 1.9405 0.4158 0.0320

56

61. 40 0. 83 0. 0068

30.5130 2.1304 0.5204 0.0363

57 62. 00 0. 21 0. 0084 23.6310 2.2317 0.4070 0.0384

58

63. 65 0. 35 0. 0068

25.1850 2.1304 0.4452 0.0377

59

67. 11 0. 35 0. 0089

25.1850 2.2634 0.4695 0.0422

60

76. 68 0. 47 0. 0073

26.5170 2.1621 0.5648 0.0460

464 24.4 (2003)

Table S1.

Speed proles driven by two vehicles.

HC (g/mi) Versus Speed

0.0000

0.5000

1.0000

1.5000

2.0000

2.5000

3.0000

3.5000

4.0000

4.5000

0 10 20 30 40 50 60 70 80 90

Speed (mph)

H

C

E

m

i

s

s

i

o

n

s

(

g

/

m

i

)

CO (g/sec) Versus Speed

0.0000

0.1000

0.2000

0.3000

0.4000

0.5000

0.6000

0 10 20 30 40 50 60 70 80 90

Speed (mph)

C

O

E

m

i

s

s

i

o

n

s

(

g

/

s

e

c

)

Vehicle Emissions 465

Figure S4. HC emission factor vs. speed.

Figure S5. CO emission rate vs. speed.

HC (g/sec) Versus Speed

0.0000

0.0100

0.0200

0.0300

0.0400

0.0500

0.0600

0.0700

0 10 20 30 40 50 60 70 80 90

Speed (mph)

H

C

E

m

i

s

s

i

o

n

s

(

g

/

s

e

c

)

Speed Line Plot

-4

-2

0

0 50 100

Speed

l

n

(

C

O

)

LN(CO)

Predicted LN(CO)

466 24.4 (2003)

Figure S6. HC emission rate vs. speed.

Requirement 5: r(COs) = 0.9089, r(HCs) = 0.8644.

Both correlation coefcients are close to one, so both regression equations

have acceptable goodness of t. Since r(COs) is slightly higher than r(HCs),

the regression equation for COs is better than the one for HCs.

Figure S7. Line plot for the speed and the CO emission factor.

Requirement 6: From Figures S9S10, there clearly exists a speed value that

minimizes either the CO emission factor or the HC emission factor. On the

other hand, the emission rates are monotonically increasing functions of the

speed.

Requirement 7: u

optimal

for CO = 35 mph; u

optimal

for HC = 32 mph.

Speed Line Plot

-10

-5

0

0 50 100

Speed

l

n

(

H

C

)

LN(HC)

Predicted LN(HC)

CO Emissions Versus Speed

0

10

20

30

40

50

60

70

80

0 20 40 60 80

Speed (mph)

C

O

(

g

/

m

i

)

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

C

O

(

g

/

s

e

c

)

CO (g/mi)

CO (g/sec)

HC Emissions Versus Speed

0

1

2

3

4

5

6

7

0 20 40 60 80

Speed (mph)

H

C

(

g

/

m

i

)

0.00

0.01

0.02

0.03

0.04

0.05

0.06

0.07

H

C

(

g

/

s

e

c

)

HC (g/mi)

HC (g/sec)

Vehicle Emissions 467

Figure S8. Line plot for the speed and the HC emission factor.

Figure S9. Relationships between the CO emission rates/factors and the speed.

Figure S10. Relationships between the HC emission rates/factors and the speed.

Speed Profile 1 - Constant Speed

0

200

400

600

800

1000

1200

1400

1600

1800

0 5 10 15 20 25 30

Time (sec)

A

c

c

u

m

u

l

a

t

i

v

e

D

i

s

t

a

n

c

e

(

f

t

)

0

5

10

15

20

25

30

35

40

S

p

e

e

d

(

m

i

/

h

r

)

Distance (ft)

Speed (mph)

Speed Profile 2 - Varying Speed

0

200

400

600

800

1000

1200

1400

1600

1800

0 5 10 15 20 25 30

Time (sec)

A

c

c

u

m

u

l

a

t

i

v

e

D

i

s

t

a

n

c

e

(

f

t

)

0

5

10

15

20

25

30

35

40

45

S

p

e

e

d

(

m

i

/

h

r

)

Distance (ft)

Speed (mph)

468 24.4 (2003)

Requirement 8: See Figures S11S12.

Figure S11. Illustration of constant speed prole.

Figure S12. Illustration of varying speed prole.

Vehicle Emissions 469

Requirement 9: See Table S2.

Table S2.

Second-by-second calculations.

Constant Speed Prole Varying Speed Prole

Time Speed 1 CO 1 HC 1 Speed 2 CO 2 HC 2

1 35 0.2302 0.02163 42 0.2808 0.02686

2 35 0.2302 0.02163 41 0.2730 0.02604

3 35 0.2302 0.02163 40 0.2653 0.02525

4 35 0.2302 0.02163 39 0.2579 0.02448

5 35 0.2302 0.02163 38 0.2507 0.02373

6 35 0.2302 0.02163 38 0.2507 0.02373

7 35 0.2302 0.02163 37 0.2437 0.02301

8 35 0.2302 0.02163 37 0.2437 0.02301

9 35 0.2302 0.02163 37 0.2437 0.02301

10 35 0.2302 0.02163 36 0.2368 0.02231

11 35 0.2302 0.02163 35 0.2302 0.02163

12 35 0.2302 0.02163 34 0.2238 0.02097

13 35 0.2302 0.02163 33 0.2175 0.02033

14 35 0.2302 0.02163 32 0.2114 0.01971

15 35 0.2302 0.02163 31 0.2055 0.01911

16 35 0.2302 0.02163 30 0.1998 0.01853

17 35 0.2302 0.02163 29 0.1942 0.01797

18 35 0.2302 0.02163 29 0.1942 0.01797

19 35 0.2302 0.02163 30 0.1998 0.01853

20 35 0.2302 0.02163 31 0.2055 0.01911

21 35 0.2302 0.02163 32 0.2114 0.01971

22 35 0.2302 0.02163 33 0.2175 0.02033

23 35 0.2302 0.02163 34 0.2238 0.02097

24 35 0.2302 0.02163 35 0.2302 0.02163

25 35 0.2302 0.02163 36 0.2368 0.02231

26 35 0.2302 0.02163 37 0.2437 0.02301

27 35 0.2302 0.02163 38 0.2507 0.02373

28 35 0.2302 0.02163 39 0.2579 0.02448

29 35 0.2302 0.02163 40 0.2653 0.02525

30 35 0.2302 0.02163 41 0.2730 0.02604

TOTAL EMISSIONS 6.9064 0.6489 7.0382 0.66273

For the CO emissions, the varying speed prole generates a total of 7.04 g

comparing with the 6.91 g for the constant speed prole (2% higher). Similarly

for the HCemissions, the varying speed prole generates a total of 0.663 g com-

paring with the 0.649 g of emissions for the constant speed prole (2% higher).

Since the optimal speed is 35 mph for CO and 32 mph for HC, the constant

speed prole in this requirement should result in the minimum CO emissions

and close to minimum HC emissions. Although the 2% higher emissions does

not seem like a signicant amount, this is just for 30 s for a single vehicle. You

can imagine howmuch additional emissions would be generated if all vehicles

in the city drive at varying speeds of a signicant level. On the other hand, the

trafc managers should try to implement trafc management strategies that

would encourage or force drivers to drive at desired and constant speeds.

470 24.4 (2003)

Requirement 10: Set speed to 0 in the regression equations in Requirement 4

to derive the idling emission rate in units of grams per second:

COs when idling = e

2.46215+0.028383u

= 0.08525 g/s,

HCs when idling = e

4.91624+0.030929u

= 0.00733 g/s.

Therefore, during the 30 min delay, a vehicle will emit the following total CO

and HC emissions:

CO idling emissions for one vehicle for 30 min = 0.08525 30 60=153.45 g,

HC idling emissions for one vehicle for 30 min = 0.00733 30 60= 13.194 g.

Therefore, the total COemissions for 200 vehicles = 153.45 200 = 30,690 g and

the total HC emissions for 200 vehicles = 13.194 200 = 2,639 g.

From the above calculation, we can see that one trafc accident can result

in considerable additional CO and HC emissions. Considerably more emis-

sions will be produced if many trafc accidents happen in the city. Therefore,

reducing the number of trafc accidents can reduce the vehicle emissions.

Vehicle Emissions 471

Title: Vehicle Emissions

Notes for the Instructor

This project is designed for students to practice algebraic calculations, data

analysis, and optimization using real-world vehicle emission data. The vehicle

emission issue is becoming more and more important because of the stricter

regulations imposed by the U.S. Environmental Protection Agency (EPA). Ve-

hicle emissions are a big source of air pollution and are related to many of our

health problems.

The key to the successful completion of this project is a clear understanding

of the sequence of the data, the denitions of the variables, the relationships

between variables, as well as the algebraic, data analysis, and optimization

concepts. Any additional information related to vehicle emission-control can

be introduced in the class. The instructor can introduce various emission data

collectiontechniques. Theinstructor canalsointroducemorecomplicatedmod-

eling and data analysis techniques.

The simplest regression equation is used in this project, which although

nonlinear, includes only one variable. The instructor can encourage students

to test various regression formulas and different combinations of variables. For

instance, other regression models to consider include

COs = b

0

+ b

1

u + b

2

u

2

,

HCs = c

0

+ c

1

u + c

2

u

2

.

Requirements 49 can be repeated with these other regression formulas.

The instructor can also encourage students to search literature on other

existing vehicle emission models. Students can compare the calculation results

between the models developed in this project and other models.

472 24.4 (2003)

About the Authors

Lei Yu is Professor and Chairperson of the Trans-

portation Studies Department at Texas Southern Uni-

versity. He is also a Changjiang Scholar of Beijing Jiao-

tong University. He received a bachelors degree in

TransportationEngineeringfromNorthernJiaotongUni-

versity, Beijing, China and a masters degree in Pro-

duction and Systems Engineering from Nagoya Insti-

tute of Technology, Nagoya, Japan. His Ph.D. degree

in Civil Engineering was awarded by Queens Univer-

sity in Kingston, Ontario, Canada. His research inter-

ests involve highway trafc operations and modeling,

urban transportation planning, the ITS-related technologies and applications,

and vehicle exhaust emission modeling. Since 1994, Yu has been the Princi-

pal Investigator (PI) of more than 25 research projects that were sponsored by

Texas Department of Transportation (TxDOT), Federal Highway Administra-

tion (FHWA), Federal Transit Administration (FTA), Southwest Region Univer-

sity Transportation Center (SWUTC) program, National Institute of Standards

and Technology (NIST), and Houston Advanced Research Center (HARC); the

total funding amount is over $2 million. Dr. Yu has published more than 50

research papers in the Journal of Transportation Research, Transportation Research

Records, and the Journal of Transportation Engineering, as well as in various peer-

reviewed conference proceedings. Dr. Yu is an active member of the Institute of

TransportationEngineers (ITE), the AmericanSocietyof Civil Engineers (ASCE)

and the Transportation Research Board (TRB). He is a registered engineer in

the State of Texas. He also belongs to numerous committees, councils, and task

forces in regional, state, national, and international organizations.

Don Small graduated from Middlebury College and

received his Ph.D. degree in mathematics from the Uni-

versity of Connecticut. He taught mathematics at Colby

College for 23years before joiningthe Mathematics Depart-

ment at the U.S. Military Academy in 1991. He is active

in the calculus and college algebra reform movements

developing curricula, authoring texts, and leading faculty

development workshops. Active in the Mathematical As-

sociation of America (MAA), Don served a term as Chairman and two terms

as Governor of the Northeast Section and has been a long-term member of

the MAAs CRAFTY committee. His interests are in developing curriculum

that focuses on student growth while meeting the needs of partner disciplines,

society, and the workplace. He is also a member of AMATYC and AMS.

Das könnte Ihnen auch gefallen

- 16dka19f2054 - Nurul Nabilah Binti BaharinDokument13 Seiten16dka19f2054 - Nurul Nabilah Binti Baharinmoneesha sriNoch keine Bewertungen

- On-Board Emissions Measurements Reveal London HotspotsDokument34 SeitenOn-Board Emissions Measurements Reveal London HotspotscroyamNoch keine Bewertungen

- Influence of Skidded Distance On The Initial Velocity of Vehicle in Chain Accidents at IntersectionsDokument5 SeitenInfluence of Skidded Distance On The Initial Velocity of Vehicle in Chain Accidents at IntersectionsIJMERNoch keine Bewertungen

- Speed Spot Study Lab ReportDokument9 SeitenSpeed Spot Study Lab ReportXamen50% (4)

- Speed Spot StudiesDokument16 SeitenSpeed Spot StudiesLuqman YusofNoch keine Bewertungen

- Urban Arterial Travel Time VariabilityDokument23 SeitenUrban Arterial Travel Time Variabilityparupuk9Noch keine Bewertungen

- Automotive Telemetry System DesignDokument23 SeitenAutomotive Telemetry System DesignKee Chong TeoNoch keine Bewertungen

- Emission Estimation from Driving Cycle for Dhaka CityDokument43 SeitenEmission Estimation from Driving Cycle for Dhaka CityIshtiaque Karim RobinNoch keine Bewertungen

- 2008 IAMOTNunespdfDokument13 Seiten2008 IAMOTNunespdfabc8110cbaNoch keine Bewertungen

- On Board Diagnostics (OBD) Scan Tool To Diagnose Emission Control SystemDokument5 SeitenOn Board Diagnostics (OBD) Scan Tool To Diagnose Emission Control SystemEditor IJRITCCNoch keine Bewertungen

- Air Pollution M-Wps OfficeDokument28 SeitenAir Pollution M-Wps Officejustine daquioag100% (1)

- A Web-Based Data Management and Analysis System For CO Capture ProcessDokument17 SeitenA Web-Based Data Management and Analysis System For CO Capture Processmanzoor ansariNoch keine Bewertungen

- New Formulas of Side Friction Factor Based On Three Dimensional Model in Horizontal Curves For Various VehiclesDokument11 SeitenNew Formulas of Side Friction Factor Based On Three Dimensional Model in Horizontal Curves For Various Vehiclesbkswain2003Noch keine Bewertungen

- Spot Speed Study Lab ReportDokument8 SeitenSpot Speed Study Lab ReportMuhammad ArbainNoch keine Bewertungen

- Air Quality Index Analysis & PredictionDokument34 SeitenAir Quality Index Analysis & PredictionGottumukkala Sravan KumarNoch keine Bewertungen

- Obstacle Detection Using Ultrasonic SensorsDokument56 SeitenObstacle Detection Using Ultrasonic Sensorsmymdb100% (3)

- A Novel Statistical Method To Analyze The Competitive Adsorption of Heavy Metal Ions in Aqueous SolutionsDokument5 SeitenA Novel Statistical Method To Analyze The Competitive Adsorption of Heavy Metal Ions in Aqueous SolutionsBarathan RajandranNoch keine Bewertungen

- Lab Report W4 - Spot Speed Study (Stopwatch)Dokument11 SeitenLab Report W4 - Spot Speed Study (Stopwatch)hanna humairaNoch keine Bewertungen

- Spot Speed ManualDokument15 SeitenSpot Speed ManualAdib AjeNoch keine Bewertungen

- Clean Fleet ToolkitDokument21 SeitenClean Fleet ToolkitFleetForumNoch keine Bewertungen

- Sample Paint EmcalcDokument46 SeitenSample Paint EmcalctlchrisNoch keine Bewertungen

- National Pollutant Inventory Fugitive Emissions ManualDokument54 SeitenNational Pollutant Inventory Fugitive Emissions ManualAbhishek JainNoch keine Bewertungen

- Traffic Study ReportDokument19 SeitenTraffic Study ReportRaji De Cypress Oladapo100% (1)

- Sec B Group 4 EstimationDokument10 SeitenSec B Group 4 EstimationVijay GhatoleNoch keine Bewertungen

- Manual CopertDokument86 SeitenManual CopertNicolás HoloveskiNoch keine Bewertungen

- Spot Speed Study EssentialsDokument8 SeitenSpot Speed Study Essentialsrowell naragNoch keine Bewertungen

- Final Master Thesis Marti SZJDokument51 SeitenFinal Master Thesis Marti SZJmasteranicaNoch keine Bewertungen

- Developing A Gating Management Strategy For Salterhebble Hill, HalifaxDokument152 SeitenDeveloping A Gating Management Strategy For Salterhebble Hill, HalifaxBen FadidaNoch keine Bewertungen

- Road Traffic Data: Collection Methods and Applications: January 2008Dokument56 SeitenRoad Traffic Data: Collection Methods and Applications: January 2008Carl Os SeintNoch keine Bewertungen

- ABSEXECDokument7 SeitenABSEXECRenee Pascual SalipotNoch keine Bewertungen

- Lab Spot SpeedDokument18 SeitenLab Spot Speedhasan67% (3)

- Faa Ada280477 Dot Faa Rd-93 5Dokument411 SeitenFaa Ada280477 Dot Faa Rd-93 5anantiaNoch keine Bewertungen

- Traffic Volume StudyDokument9 SeitenTraffic Volume StudyMohamad Taufik88% (8)

- Vehicle Speed Mearurement System Final2Dokument71 SeitenVehicle Speed Mearurement System Final2yrikkiNoch keine Bewertungen

- Traffic Survey Manual Guideline - Genap 2019Dokument39 SeitenTraffic Survey Manual Guideline - Genap 2019Imam MumtazNoch keine Bewertungen

- Impact of Stops On Vehicle Fuel Consumption and emDokument18 SeitenImpact of Stops On Vehicle Fuel Consumption and emPaolo Angelo GutierrezNoch keine Bewertungen

- Snap NomenklaturaDokument10 SeitenSnap NomenklaturaNejra KarovicNoch keine Bewertungen

- Model 500 Series Manual - Method 5Dokument137 SeitenModel 500 Series Manual - Method 5spohanNoch keine Bewertungen

- Spot Speed StudyDokument8 SeitenSpot Speed StudyMuhammad AimiNoch keine Bewertungen

- 2011-Comparison of Methodologies Estimating Emissions of Aircraft Pollutants, Environmental Impact Assessment Around AirportsDokument13 Seiten2011-Comparison of Methodologies Estimating Emissions of Aircraft Pollutants, Environmental Impact Assessment Around Airportsipagoni1Noch keine Bewertungen

- 5 - Computer Controled SystemDokument203 Seiten5 - Computer Controled SystemZoscalesNoch keine Bewertungen

- Automotive Sensors: Past, Present and Future: Home Search Collections Journals About Contact Us My IopscienceDokument7 SeitenAutomotive Sensors: Past, Present and Future: Home Search Collections Journals About Contact Us My IopscienceanilmendruNoch keine Bewertungen

- Implementing Automated Road Transport Systems in Urban SettingsVon EverandImplementing Automated Road Transport Systems in Urban SettingsNoch keine Bewertungen

- Evaluating the Effect of Energy Efficient Intersections on CO2 EmissionsDokument111 SeitenEvaluating the Effect of Energy Efficient Intersections on CO2 EmissionsKrishan AcharyaNoch keine Bewertungen

- Bahan AnriskDokument99 SeitenBahan AnriskasriNoch keine Bewertungen

- CEMT - Reducing NOx Emissions On The RoadDokument51 SeitenCEMT - Reducing NOx Emissions On The RoadSlobodan VidovichNoch keine Bewertungen

- COTS HW and SW For Train Control Applications - System Safety ConsiderationsDokument48 SeitenCOTS HW and SW For Train Control Applications - System Safety ConsiderationsfrixiofrixioNoch keine Bewertungen

- Statistical Methods Report: Topic: Analysis of Emission LevelsDokument27 SeitenStatistical Methods Report: Topic: Analysis of Emission LevelsAakash ChhariaNoch keine Bewertungen

- Carbon Emission and Battery Monitoring SystemDokument17 SeitenCarbon Emission and Battery Monitoring SystemIJRASETPublicationsNoch keine Bewertungen

- A Tank-To-wheel Analysis Tool For Energy and Emissions Studies in Road VehiclesDokument7 SeitenA Tank-To-wheel Analysis Tool For Energy and Emissions Studies in Road VehiclesMuhammad Imran KhanNoch keine Bewertungen

- COPERT Australia: A New Software To Estimate Vehicle Emissions in AustraliaDokument11 SeitenCOPERT Australia: A New Software To Estimate Vehicle Emissions in AustraliaNikhil ahireNoch keine Bewertungen

- ASPEN Plan Simulation of CO2 Recovery ProcessDokument63 SeitenASPEN Plan Simulation of CO2 Recovery ProcessMo HaoNoch keine Bewertungen

- Remote Vehicle Emission Monitoring SystemDokument5 SeitenRemote Vehicle Emission Monitoring SystemNitish GauravNoch keine Bewertungen

- Automobile air conditioning using vehicle exhaust heatDokument8 SeitenAutomobile air conditioning using vehicle exhaust heatDarshan JethwaNoch keine Bewertungen

- Automobile air conditioning using vehicle exhaust heatDokument8 SeitenAutomobile air conditioning using vehicle exhaust heatDarshan JethwaNoch keine Bewertungen

- New Technologies for Emission Control in Marine Diesel EnginesVon EverandNew Technologies for Emission Control in Marine Diesel EnginesNoch keine Bewertungen

- Gas Chromatography and Mass Spectrometry: A Practical GuideVon EverandGas Chromatography and Mass Spectrometry: A Practical GuideBewertung: 5 von 5 Sternen5/5 (3)

- Archinteriors Vol 15Dokument10 SeitenArchinteriors Vol 15Nelson Fabian Alvarez RubioNoch keine Bewertungen

- NotesaDokument1 SeiteNotesaDoddy Syamsu RizalNoch keine Bewertungen

- Archshaders Vol 2Dokument115 SeitenArchshaders Vol 2Anali Huamani0% (2)

- Katalog Deltacrete 2010Dokument54 SeitenKatalog Deltacrete 2010Adhani1234Noch keine Bewertungen

- Efektivitas Pengolahan Limbah Cair Rumah Sakit Dengan Sistem Dewats Dalam Menurunkan Angka Bakteri Coliform Di RS Panti Wilasa Citarum SemarangDokument8 SeitenEfektivitas Pengolahan Limbah Cair Rumah Sakit Dengan Sistem Dewats Dalam Menurunkan Angka Bakteri Coliform Di RS Panti Wilasa Citarum SemarangDoddy Syamsu RizalNoch keine Bewertungen

- RecyclingDokument8 SeitenRecyclingRoci12345678 Roci123Noch keine Bewertungen

- Prelab VOCs Shoe SprayDokument10 SeitenPrelab VOCs Shoe SprayAdNoch keine Bewertungen

- K-FLEX K996 Glue Safety Data SheetDokument10 SeitenK-FLEX K996 Glue Safety Data SheetkempeeNoch keine Bewertungen

- Citizenguide Maine Shoreland Zone PDFDokument42 SeitenCitizenguide Maine Shoreland Zone PDFbruceNoch keine Bewertungen

- Wastewater Treatment: PDF Generated At: Fri, 03 Jun 2011 10:58:38 UTCDokument181 SeitenWastewater Treatment: PDF Generated At: Fri, 03 Jun 2011 10:58:38 UTCJo Wiart100% (4)

- Env Impact RPT - Esp FP - Section 4-State of Our WaterwaysDokument3 SeitenEnv Impact RPT - Esp FP - Section 4-State of Our Waterwaysapi-126230957Noch keine Bewertungen

- Laboratory ReportDokument9 SeitenLaboratory ReportXuan ChuaNoch keine Bewertungen

- Regulation of Greenhouse GasesDokument3 SeitenRegulation of Greenhouse GasesALECNoch keine Bewertungen

- MSDS - GulfSea Cylcare DCA 5040H PDFDokument4 SeitenMSDS - GulfSea Cylcare DCA 5040H PDFObydur Rahman0% (1)

- Hydraulic Profile - Rev. 1.1Dokument8 SeitenHydraulic Profile - Rev. 1.1unconformistNoch keine Bewertungen

- CE DAC CCS ComparisonDokument2 SeitenCE DAC CCS ComparisonMigNoch keine Bewertungen

- BossBro Q4Dokument12 SeitenBossBro Q4mahotkatNoch keine Bewertungen

- Fossil FuelDokument17 SeitenFossil FuelYra SamanthaNoch keine Bewertungen

- Topic 1Dokument33 SeitenTopic 1Nur HananiNoch keine Bewertungen

- FINAL TEST 1 K 2Dokument4 SeitenFINAL TEST 1 K 2Nguyen Cuong100% (1)

- Lab 1 Jar Test ConclusionDokument9 SeitenLab 1 Jar Test ConclusionUmmiey SyahirahNoch keine Bewertungen

- Thermal Treatment of Solid Waste PDFDokument40 SeitenThermal Treatment of Solid Waste PDFRhea MambaNoch keine Bewertungen

- Organophilic Lignite - Hoja Tecnica - InglesDokument2 SeitenOrganophilic Lignite - Hoja Tecnica - InglesLupita LoraNoch keine Bewertungen

- RHI Air Quality Emissions Certificate - Dragon D370 - 370kW-V7 PDFDokument4 SeitenRHI Air Quality Emissions Certificate - Dragon D370 - 370kW-V7 PDFJMNoch keine Bewertungen

- RWL Water Nirobox SWDokument3 SeitenRWL Water Nirobox SWAlexander HerreraNoch keine Bewertungen

- GE15 - SIM Week 6-7Dokument4 SeitenGE15 - SIM Week 6-7Althea Nicole QuindoNoch keine Bewertungen

- Dewatering Systems: WJ Groundwater LimitedDokument2 SeitenDewatering Systems: WJ Groundwater LimitedmojmaxNoch keine Bewertungen

- Delhi's Air Pollution Crisis & SolutionsDokument22 SeitenDelhi's Air Pollution Crisis & SolutionsRati SindhwaniNoch keine Bewertungen

- Grundfosliterature 146158Dokument16 SeitenGrundfosliterature 146158AddeNifiraNoch keine Bewertungen

- Sustainable Construction: Shamsher SadiqDokument22 SeitenSustainable Construction: Shamsher Sadiqdaanial khanNoch keine Bewertungen

- Cruis ES: Course: Conversation Class 22Dokument4 SeitenCruis ES: Course: Conversation Class 22Eliana GodoyNoch keine Bewertungen

- CLAY CUTTER™ PRO - SDS US - English - Drilling Products Group - 015730 - US PDFDokument6 SeitenCLAY CUTTER™ PRO - SDS US - English - Drilling Products Group - 015730 - US PDFEnrique Alejandro OvandoNoch keine Bewertungen

- Lime Hydrating ProcessDokument24 SeitenLime Hydrating ProcessKalai SelvanNoch keine Bewertungen

- Pnabx861 PDFDokument145 SeitenPnabx861 PDFBindu ChaurasiaNoch keine Bewertungen

- Journal of Indian Water Works Association (JIWWA, Vol-4, Issue-47) - Oct-Dec-2015Dokument80 SeitenJournal of Indian Water Works Association (JIWWA, Vol-4, Issue-47) - Oct-Dec-2015Santosh Kumar100% (1)