Beruflich Dokumente

Kultur Dokumente

EW1EN

Hochgeladen von

Saadullah SiddiquiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EW1EN

Hochgeladen von

Saadullah SiddiquiCopyright:

Verfügbare Formate

Process Control Configuration

in Control Logix

PLEASE LEAVE THIS WORKBOOK IN THE ROOM!

EW1EN.doc

5/27/2009 Page 3 of 73

Table of Contents

TABLE OF CONTENTS___________________________________________________________3

PROCESS CONTROL CONFIGURATION IN CONTROL LOGIX _______________________________5

ABOUT THIS HANDS-ON LAB __________________________________________________5

LAB MATERIALS ___________________________________________________________6

LAB FILES _______________________________________________________________6

INTEGRATED ARCHITECTURE (IA) BASED PROCESS CONTROL SYSTEMS _________________7

EXAMPLE PROCESS APPLICATION _____________________________________________10

LAB01: THE PROCESS AUTOMATION CONTROLLER ENVIRONMENT_____________________11

LAB02: CREATE A CASCADED PIDE CONTROL STRATEGY___________________________15

LAB03: THE HMI COMPONENT OF THE CASCADED PID CONTROL STRATEGY _____________33

LAB 04: MATERIAL ADD CONTROL STRATEGY USING DISCRETE 3-STATE DEVICE

AND TOTALIZER FUNCTION BLOCKS INSTRUCTIONS ________________________________33

EW1EN.doc

5/27/2009 Page 5 of 73

Process Control Configuration in Control

Logix

About This Hands-On Lab

Welcome to the Logix Hands-On Lab series! This session provides you with an

opportunity to explore the Process Control Programming environment used for the

ControlLogix or CompactLogix platforms. The following sections explain what youll

be doing in this lab session, and what you will need to do to complete the hands-on

exercises.

As you complete the exercises in this hands-on session, you will:

Be introduced to the Integrated Architecture for Process Control System

architecture elements and how Rockwell Integrated Architecture technologies

and products are applied to one of them.

Review the Process Automation Controller organization and an example of a

process application.

Become familiar with a few of the many powerful process control instructions

in RSLogix 5000

Implement control strategies to solve real world process application scenarios

using Integrated Architecture technologies, the RSLogix Function Block

Diagramming editor and Factory Talk View.

Understand why the Logix processors are more than discrete PLCs, they are

Process Automation Controllers well suited to process applications, especially

when used in the Rockwell Automation IA based Process Automation System

architectures.

Lab Materials

For this Hands-On lab, we have provided you with the following materials that will

allow you to complete the labs in this workbook.

Hardware

This hands-on lab uses the Soft Logix 5800 soft controller environment that

requires no hardware:

Software

This hands-on lab uses the following software:

RSLogix 5000 programming software (Ver 17.00)

Factory Talk View Studio SE ( Ver 5.00)

SoftLogix 5800 V16.

Lab Files

This hands-on lab uses the following files:

Logix Project file PAC_AFLab_C1_10.ACD

Factory Talk View Project PAC_Reactor_Lab

Document Conventions

Throughout this workbook, we have used the following conventions to help guide you

through the lab materials.

This style or symbol: Indicates:

Words shown in bold italics

(e.g., RSLogix 5000 or OK)

Any item or button that you must click on, or a menu name

from which you must choose an option or command. This will

be an actual name of an item that you see on your screen or

in an example.

Words shown in bold italics,

enclosed in single quotes

(e.g., Controller1)

An item that you must type in the specified field. This is

information that you must supply based on your application

(e.g., a variable).

Note: When you type the text in the field, remember that you

do not need to type the quotes; simply type the words that

are contained within them (e.g., Controller1).

The text that appears inside of this gray box is supplemental

information regarding the lab materials, but not information

that is required reading in order for you to complete the lab

exercises. The text that follows this symbol may provide you

with helpful hints that can make it easier for you to use this

product. Most often, authors use this Tip Text style for

important information they want their students to see.

Note: If the mouse button is not specified in the text, you should click on the

left mouse button

EW1EN.doc

5/27/2009 Page 7 of 73

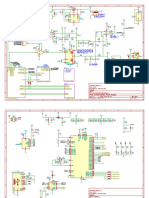

Integrated Architecture (IA) Based Process Control Systems

For process applications Rockwell leverages Integrated Architecture technologies

and a combination of standard Integrated Architecture products to create a scalable

and consistent configuration, visualization, and communications environment. The

below architecture represents a complete Rockwell Automation IA based Process

Automation System architecture combining the following core technologies:

Logix components for controller, I/O, and field device interfaces

NetLinx protocols for system networks and peer-to-peer communication

Visualization components for operator terminals and interfaces

FactoryTalk services for a consistent infrastructure across the entire plant

process and MES systems

Automation and Information Levels

Rockwell IA based Process Automation System architectures are based on

automation industry standards such as ISA-88, ISA-95, ISA-S100 and IEC 6-1131.

They also comply with emerging ARC Collaborated Process Automation System

(CPAS) model which calls for Process Automation Systems to have a common

control and configuration environment and have a common information infrastructure.

These industry standard references lay the foundation for organizing system

components into automation levels. The architectural hierarchy for the IA based

Process Automation System architectures is based on these levels. The automation

functionality defined for each of these levels is summarized below.

Automation Level 0 - Instruments, actuators, drives and the actual field devices,

this level includes field device Network components for DeviceNet,

FOUNDATION Fieldbus, and HART devices and others.

Automation Level 1 - Interfaces to the field devices including but not limited to

I/O, CNet (as Remote IO) and Logix controllers. But could also include any I/O

product that can be interfaced by the Logix controller such as Flex and distributed

I/O products.

Automation Level 2 - System elements at this level are combined software

products and dedicated PCs to provide specific functionality for configuration and

supervisory control of the system. Also included in this level are the components

that are used to provide system-wide access (communications) between the

supervisory level workstations and the control elements.

Automation Level 3 - System elements at this level are combined software

products and dedicated PCs that provide specific functionality for scheduling and

system optimization of the system. Also included in this level are the components

that are used to provide system-wide access (communications) between the

Manufacturing level workstations and the control elements including but not

limited to: Production Clients and Workstation, Patch Management, additional

Application Servers for Integrated Asset and Plant Historian, DMZ

Implementation and Business System Interfaces.

Automation Level 4 - The functionality associated with business planning and

enterprise level logistics.

The IA based Process Automation System Architectures levels contain functional

System Elements. These system elements define the hardware and control

platform, engineering environment, HMI, and information infrastructure.

EW1EN.doc

5/27/2009 Page 9 of 73

System Elements

Each level is made up of system components that provide specific system

functionality. The different functions can be labeled as system elements. These

system elements can be a single product (i.e. a Logix controller) or a combination of

both the Hardware and Software combined to provide definable system functionality.

This focus on the functional aspects of the system as opposed to individual products

is typical when discussing Process System architectures. The following table

describes the functional elements of the Rockwell IA based Process Automation

System architectures.

System Element Description

Engineering workstation (EWS) The engineering workstation (EWS) provides a single development platform

for creating and maintaining control strategies and for configuring system

elements.

Operator workstation (OWS) The operator workstation (OWS) provides an interactive graphical interface

to monitor and control the process.

Maintenance workstation (MWS) The maintenance workstation (MWS), typically a laptop, provides similar

functionality as the EWS and is designed to be portable so it can be used

locally to monitor and debug process problems.

Process application system server

(PASS)

The process application system server (PASS) is a required component

that provides central name resolution and look up services. The PASS also

hosts an HMI server and a data server.

Application server Servers provide additional system capacity. Application servers add

optional system capabilities such as:

Additional HMI servers.

Batch management for the system-wide batch management and control.

Plant historian for the collection of system process data.

Integrated asset management for change control, code management,

and field device configuration and management.

Process controller The process controller is a multitasking, multidiscipline controller that

supports continuous, batch, discrete, and motion applications. Different

control strategies are segmented to execute at the appropriate rate.

The ControlLogix controller supports continuous process applications,

including Advanced Process Control functions, with its deterministic, time-

based execution mode. The controller supports high-speed controller and

motion operations using a continuous scan mode and supports event-

driven operations using event-based control.

For this lab your work station is representative of a system

Engineering workstation (EWS). We will be using it to modify Logix

routines and Operator workstations displays to demonstrate control

strategy implementation on a few simple process application scenarios

using the Integrated Architecture technologies

Example Process Application

Process Cell Application

For this lab we will consider a theoretical process cell. The initial process blends 3

raw materials in a premix tank. This premix and an additional raw material is fed to

jacketed batch reactors. The reactors have multi-speed mixers and a Nitrogen

blanket. During the reaction process temperature is maintained by circulation of a

heat transfer fluid and associated heat exchanger. After the reaction step has

completed the product is discharged to a storage tank and ultimately used in a

continuous process.

The reactor unit requires several control strategies or control loops to control the

process. These define Equipment Modules or Control Modules in the S88 standard

terminology.

For this lab we will demonstrate the implementation of the RSLogix 5000 Function

Blocks in the context of complete control strategies within a Rockwell Automation

Integrated Architecture based Process Automation System Architecture.

EW1EN.doc

5/27/2009 Page 11 of 73

Lab01: The Process Automation Controller Environment

We will be using the Logix Automation Controller environment, RSLogix Function

Block Diagramming editor and Factory Talk View software as an Engineering Work

Station (EWS). The Logix controller is a true multi-disciplined controller that enables

the control of a total plant. This lab section is a quick overview of the Logix

environment and a description of one way it could be organized and used for a

process application.

Launch RSLogix 5000 Programming Software

In this section of the lab, you will launch the RSLogix 5000 software, which will allow

you to program the process automaton controller.

1. Double click on the RSLoogix 5000 icon on the Desktop to

launch the RSLogix5000 software. The RSLogix5000 Quick Start screen

appears.

The new Start pages help you learn about new features quickly locate relevant information

and support. The start pages offer three main areas of support: Quick Start, Resource Center

and Learning Center.

Resource Center:

Provides you with links to

online books valuable

downloads sites ns other

Rockwell Automation

support sites.

Learning Center: Allows

you to further explore

RSLogix by providing

more in depth tutorials on

and previewing new

features of the software

Quick Start: shortens the

acclimation period by

providing through sample

projects and tutorial

videos like getting started

and programming a First

Project.

Review the new start pages at your own pace, however, lab time is

limited so you may want to come back and review them after you have

completed the lab work.

2. Return to the Quick Start page (If you are not already there) and from the

Controller Projects list click on the PAC_AFLab_C1_10 project located in

the C:\Lab Files \ directory.

The lab project file opens.

The Controller Organizer

The Controller Organizer is a graphical representation of the contents of your project.

It consists of a hierarchical tree of the folders and files that contain all of the

information about the programs and data in the current project.

The default main folders in this tree are:

Controller Project Name - contains controller-scoped tags, controller fault handler and the

power up handler.

Tasks - tasks are shown in this folder. Each task shows its own programs with ladder

routines, function block routines, and program-scoped tags.

Motion Groups - Underneath the Motion Groups folder, you find groups of axes associated

with each other gathered into groups. You can assign these axes to specific motion groups

via the Axis Assignment tab of the Motion Group Properties dialog

Add-On Instructions contains Add-On Instructions, their routines, and tag collections.

Data Types - shows predefined and user-defined data types, which includes those data types

associated with Add-On Instructions. User-defined data types are created in this folder.

EW1EN.doc

5/27/2009 Page 13 of 73

Trends -RSLogix 5000 will allow you to create a trend, configure the data elements and

display attributes, and save it here as part of your project file.

In front of each folder, there is an icon containing a +sign or a - sign. The +sign

indicates that the folder is closed. Click it to expand the tree display and display the

files in the folder. The - sign indicates that the folder is already open and its contents

are visible. Clicking on the right mouse button brings up many different, context-

sensitive popup menus. Often, you find that this is a shortcut to access the property

window or to menu options from the menu bar.

Controller Tasks in a Process Control Application

Tasks are the basic scheduling mechanism for executing a program. Each task can

contain multiple programs, status information, and configuration information.

The majority of Process control applications are typically solved with periodic tasks

only. Process applications must guarantee complete execution of specific operations.

The relatively slow nature of most process applications (compared to most discrete

applications), makes periodic task a good choice for process applications. For

example, you might have a slow periodic task for control of slow process loops like

Temperature or levels in a large vessel, a faster periodic task for control of faster flow

or pressure loops.

Process Applications Consideration

By default, when you create a new project, the Main Task is

already defined as a continuous task. It is not required. For most

process applications this task is deleted and only periodic task are

used.

Although you can have up to 32 tasks in a Control Logix controller,

you typically will need no more than two or three Periodic Task for

running control strategies in Process applications. Using

additional tasks just makes it more difficult to judge your controller

loading.

3. Right click on the Area_01_100ms_Control _Task and then left click on

Properties. The Task Properties window appears

4. Left Click on the Configuration Tab to view

the task detail configuration.

Note: this is a Periodic task configured to execute

at 100ms. The Priority field shows the priority level

for the task. The Watchdog field shows the value

(in ms) for the watchdog timer which will generate a

Major Controller Fault if not maintained.

5. Select Cancel to close the properties window and return to the organizer.

Note: For this application we have created three periodic tasks to run the

control strategies. The following provides a brief explanation of the rational or

thought process for these tasks:

Area_01_50ms_Control_Task a 50ms task provided to run any logic that

requires quick execution such as processing of discrete timing signals or high

accuracy calculations.

Area_01_100ms_Control_Task a 100ms task provided to run logic for the

typical or common process control strategies. In this application it is being

used for Pressure control, pump control, valves and motors

Area_01_250ms_Control_Task a 250ms task provided task provided run to

logic for the slower process control strategies like temperature control which

does not physically change fast. The periodic rate is based on your process

characteristics. The goal is to adequately sense process changes and

update the I/O with out unnecessarily burdening the processor. For this

application second updates have been chosen.

EW1EN.doc

5/27/2009 Page 15 of 73

Lab02: Create a Cascaded PIDE Control Strategy

Casc ade Cont r ol

Cascade control is widely used within the process industries. Conventional cascade

schemes have two distinct features. There are two nested feedback control loops.

There is a secondary control loop located inside a primary control loop. In this lab the

cascade control process control strategy will be implemented with the Logix Function

Block Editor to control temperature in the reactor unit. Cascaded PID control will

allow us to take corrective action with the fast acting jacket temperature loop to

respond to disturbances within the reactor jacket heat transfer fluid system. The net

result is that the overall time that the slow responding product temperature loop

(primary loop) is out of tolerance is minimized.

In this lab you will:

Create a program and Function Block Routine

Create new PIDE blocks in a Cascade Control configuration using RSLogix

5000

Create a Split Range output using the SRTP instruction

Use Process Instructions for Process Simulation.

Create Program and Cascaded PID Function Block Routine

The task Area_01_250ms_Control_Task has been created for temperature control

routines but not the program. Create a program for Reactor 01 temperature controls.

1. Right Click on the Area_01_250ms_Control_Task and select new

program. Name the new program REACTOR_01_TempLoops and

Select OK

2. Right Click on REACTOR_01_TempLoops and select new routine.

Name the new program A1_R1_TIC_116AB

Make sure the Type: selected is Function Block Diagram and the In

Program or Phase selected is Reactor_01_TempLoops

Select OK to close the Routine properties window and Select OK

.

EW1EN.doc

5/27/2009 Page 17 of 73

3. Double click on the REACTOR_01_TempLoops program to open

properties and select the Configuration and Select A1_R1_TIC_116AB

as the Main Routine and select OK

4. Double Click on the A1_R1_TIC_116AB routine in the controller organizer

to open the empty routine

5. Select the Process tab toolbar

The Process Instruction menu bar appears.

6. Move your cursor over the instruction types to the PIDE instruction

7. On the Process tab on the toolbar, click on the PIDE function twice to

get two PIDE function blocks on the sheet. The two PIDE blocks should

now appear on the diagram (PIDE_01 and PIDE_02).

8. From the menu select View > Fit to Window to resize the sheet .

9. Move PIDE_02 over by clicking and dragging so you can see both PIDE

blocks with some room to work around each one

10. Zoom in or out if you need to by clicking the Zoom buttons on the toolbar.

11. Connect the PIDE_01 output CVEU to the PIDE_02 setpoint input

SPCascade as follows:

Click once on the PIDE_01s CVEU output pin and then PIDE_02 s

SPCascade the connection when the it turns green .

Review the additional considerations for cascading PIDE instructions below

Process Applications Consideration

The PIDE instruction has built-in capabilities to handle cascaded loops

Cascade/Ratio mode:

The secondary loop can either be in Cascade mode, in which case the

output of the primary will provide the set point of the secondary, or it

can be in Auto mode, in which case you can enter a temperature set

point for the jacket directly.

EW1EN.doc

5/27/2009 Page 19 of 73

Initialization:

If the secondary loop leaves Cascade mode, the primary loop needs

to stop trying to control since it no longer is affecting the process. It

should also set its output equal to the secondary loops set point, so

when the secondary is returned to Cascade mode, the primary will

bumplessly start controlling.

Windup:

When the secondary loop reaches an output or set point limit, you

want the primary loop to stop integrating in the direction of the limit.

For example, if the secondary reached a high output limit, primary

should no longer integrate in a positive direction. In our example, if the

secondary loop had opened the cooling valve 100%, it would make no

sense for the primary to continue to ask for more cooling since the

secondary cannot give any more cooling.

Configure Initialization and Windup Parameters

In light of the above we need to make some additional parameter settings. First on

the primary loop, you need to turn on visibility of the CVInitReq and CVInitValue pins.

These will be used to setup the initialization of the primary loop when the secondary

leaves Cascade mode.

12. Expose the primarys parameters by first clicking on the button for

PIDE_01, click on the Parameters Tab, scroll down to find the CVInitReq

and CVInitValue parameters, and enable the parameters visibility

checkbox as shown below:

Click Apply and OK to close the PIDE properties dialog.

13. Expose the InitPrimary parameter pin for secondary PIDE_02 in the

same fashion by checking the parameters visibility checkbox as you did

above.

14. Connect the initialization parameters. Click once on the secondary

setpoint output pin PIDE_02.SP and click again on the primary

CVInitValue pin PIDE_01.CVInitValue to make the initialization value

connection. Click once on the secondary InitPrimary pin

PIDE_02.InitPrimary and click again on the primary CVInitReq pin

PIDE_01.CVInitReq to make the initialization request connection. Click

anywhere on the white area to end connection process. Your sheet

should look similar to the one shown

below:

Note that the InitPrimary to CVInitReq is a Boolean connection (dashed line) and the

SP to CVInitValue is a Real connection (solid line).

These connections make provision for the secondary (PIDE_02) to assert a request

for the primary (PIDE_01) to initialize, the primary will initialize itself with the current

secondary setpoint. This provides a bumpless transfer when changing mode from

Auto to Cascade.

Next well need to enable the Anti-Windup Reset feature of the PIDE block.

15. Expose secondarys parameters again by first clicking on the button

for PIDE_02, click on the Parameters Tab, scroll down to find the

WindupHOut and WindupLOut parameters and click on the check box to

expose them.

16. Repeat this process to expose the WindupHIn and WindupLIn

parameters on the primary PIDE_01.

EW1EN.doc

5/27/2009 Page 21 of 73

17. Connect the PIDE_02.WindupHOut to PIDE_01.WindupHIn, and the

PIDE_02.WindupLOut to PIDE_01.WindupLIn. Your configuration should

now appear as follows:

Again these connections limit the action of the Primary when the

secondary has reached a limit.

18. Verify the routine by clicking the icon in the main toolbar

You should see the following errors in your results window:

If you look at your function block diagram, you will notice that you have two x marks

on both the primary and secondary PIDE blocks.

Process Applications Consideration

In Function Block, the execution flow, while important, is secondary to

the data flow. In fact, the execution flow is implied by the data flow.

As indicated below Function Block diagrams show the intermediate

mathematics and operations performed on the data on its way to the

output.

The actual order of execution of the instructions is only relevant within

a data flow path. As long as the operations (instructions) are executed

from upstream to downstream the actual execution order of the

distinct instructions is unimportant

The X is an indication that something is wrong with the blocks. In

this case the reason for errors is that there is something wrong with

the data flow. Anytime you use a feedback from a block downstream

in the data flow as an input, you must identify which input should be

resolved first to allow the execution order algorithm to determine which

block to execute first.

19. Right-click on your feedback wire leading from the PIDE_02.InitPrimary

to the PIDE_01.CVInitReq and select Assume Data Available.

20. Repeat this procedure for the other 3 connections into the PIDE_01.

This will resolve the order of execution and the routine can now be

verified. When finished, you should have the double arrowheads on each

as shown

:

EW1EN.doc

5/27/2009 Page 23 of 73

Some basic operating parameters will need to set in the PIDE instructions The

Cascaded setpoint functionality on PIDE_02 must be enabled by setting the

AllowCasRat parameter.

21. Click the view block properties ellipsis on PIDE_02 instruction to

open the Properties page and click on the Cascade/Ratio tab. Check the

Allow Cascade/ Ratio mode checkbox to enable this mode.

22. Now I/O connections need to be added to the Routine. Insert two input

references and one output references by clicking on Input reference

symbol and the Output reference symbol on the toolbar. A reference is

added each time you click on the tool bar.

23. Relocate them by dragging to something similar to below and connect

the inputs to the PV pins and outputs the CVEU pin of the PIDE_02.

The Tags for this project have already been created as Controller scoped tags but

they need to be referenced by the routine

24. For the PIDE_01 PV input reference Type TT_116 or double click and

find it in the drop down menu.

25. For the PIDE_02 PV input reference Type TT_117 or double click and

find it in the drop down menu Add the J acket Temp

26. For the PIDE_02 CVEU output reference Type Product_Temp_Dmd or

double click and find it in the drop down menu Your configuration should

look something like this:

27. Rename the PIDE_01 Instruction tag by clicking the view block

properties ellipsis on PIDE_01 instruction to open the Properties

page and then click on the Tag tab and change the tag namePIDE_01 to

TIC_116.

28. Set the Engineering Units scaling on the PIDE Instruction by clicking on

the EUs/Limits tab entering the below values:

- Set PV Max at 100% span to 250

- Set PV Min at 0% span to 0

EW1EN.doc

5/27/2009 Page 25 of 73

- Set SP Limits High: to 250

- Set SP Limits Low: to 0

Since the output of this PID is used to create the cascaded setpoint input to

PIDE_02 make the CV engineering units range the desired setpoint range for

Cascade Mode of the J acket Temperature controller as follows:

- Set CV Max at 100% output to 200

- Set CV Max at 0% output to 0

29. Set Go to the General Configuration tab and set initial Proportional an

Integral gains in the PID to get some initial movement. The Auto Tune

function will be used to replace these later in the lab select Ok.

30. Rename the PIDE_02 Instruction tag by clicking the View block

properties ellipsis on the PIDE_02 instruction to open the Properties

page and then click on the Tag tab.

Change the tag namePIDE_02 to TIC_117.

31. Set the Engineering Units scaling on the PIDE Instruction by clicking on

the EUs/Limits tab entering the below values:

- Set PV Max at 100% span to 250

- Set PV Min at 0% span to 0

- Set SP Limits High: to 250

- Set SP Limits Low: to 0

The output of this PID is used as the output demand CV engineering units %output

as follows:

- Set CV Max at 100% output to 100

- Set CV Max at 0% output to 0

32. Go to the General Configuration tab and set initial Proportional an

Integral gains in the PID to get some initial movement. The Autotune

function will be used to replace these later in the lab.

Select OK

33. Assign an Autotune tag to both of the PIDE instructions by double

clicking on the Autotune__? Tag entry area at the bottom right hand

corner of the PIDE block.

The drop down box opens

EW1EN.doc

5/27/2009 Page 27 of 73

34. Click on the drop down box double click on the tag AUTOTUNE Tag from

the menu.

35. Verify this routine again by clicking the icon in the main toolbar.

You should see the following errors in your results window:

Using the Split Range Time Proportion (SRTP) Instruction

In our example application we have a typical scenario where the reactor temperature

must be controlled. This includes heating from ambient temperature to a desired

operating temperature and cooling during the reaction. In our example the reaction is

exothermic, so, cooling will be critical to maintain the desired reactor temperature

during the reaction.

Our application uses a common split range control scheme in which the output of a

single controller is split between two control valves. In the split-range control strategy,

if the jacket temperature controller output is between 0 and 50%, the cold CTW valve

is open; if the jacket temperature controller output is between 50 and 100%, the

Dowtherm valve is open.

The Logix 5000 Split-Range Time-Proportion (SRTP) instruction takes a percent

input value (0%-100%) and converts it to a duty cycle discrete output. For example if

the input was set at 50% and the cycle time for the instruction is set at five seconds,

the discrete output would be on for 2.5 seconds and off for 2.5 seconds. This cycle

would then repeat where the on-time would be the percent input of the overall cycle

time. A common application for the SRTP instruction is in temperature applications

which use high wattage heater bands. In these applications analog control of the

power is either impractical or costly. A time proportioning a relay or like device

allows power to be proportionately applied to the heater without continuous analog

regulation. Likewise, cooling is often performed by pulsing solenoid valves to control

the flow of coolant.

This instruction also has analog outputs for split-ranging of the analog input signal

into two distinct analog TimePercentoutput ranges. The TimePercentoutput makes it

usable for applications where two actuators are controlled by the same signal but

require different scales (such as the reactor temperature control applications which

have both heat and cool valve actuators).

In general, the input % to output % mapping occurs as follows:

Note that the MaxXXXXIn can be less than or greater than the MinXXXXIn

parameter. This is useful for inverted control action on one or both regions of control

(ex: the cool action of a heat/cool pair is greater for lower values of input).

EW1EN.doc

5/27/2009 Page 29 of 73

Process Consideration

The fact that MaxXXXXIn can be less than or greater than

MinXXXXIn also enables the instruction to be used in a coarse/fine

control strategy. A course/fine strategy uses two control valves (CV)

one large and one small, connected for an additive affect on the

process. The large CV supports immediate response to demand

changes, but often lacks resolution. The small CV is used to improve

resolution and increase turndown.

Configuring the SRTP

Now lets take a look how the SRTP instruction is configured. The SRTP instruction

parameters determine for what values of the input the individual output regions are at

their minimums and maximums and for discrete outputs at what timing to repeat the

cycle (CycleTime).

In this lab the Reactor_01_TempLoops Program executes in a slow

task because the process variable is a vessel temperature which

cannot physically change that fast. Typically the SRTP instruction

executes in a faster, higher priority task so in order to keep the

resolution high and the pulse outputs more accurate. Even though we

are not using pulse outputs in this lab the SRTP instruction has been

located in an example faster 50ms periodic task that has been created

for routines that require faster execution times

36. In the Controller Organizer expand the Area _01_50ms_Fast _Control

task and the REACTOR_01_Fast_Control program.

37. Double click on the SRTP routine to open it.

This routine has been populated with SRTP instructions for multiple loops

from the Process functions in the toolbar.

38. Identify the current sheet (Sheet 1 0f 2) by entering PIC_118 Split

Range in the sheet description on the Sheet toolbar.

39. Select Sheet 2 by clicking on the sheet 2 in the drop down.

The TIC_116_out_SRange sheet opens.

40. Identify this sheet (Sheet 2 0f 2) by entering TIC_116 Split Range in

the sheet description on the Sheet toolbar Enter a description for this

sheet.

41. Click on the ellipsis in the SRTP block to gain access to the

parameters.

42. Click on the Insert Factory Defaults Button to

reset the instruction parameters

.

Graphically the desired operation is represented below

.

The following mapping will be used for the SRTP parameters:

MinHeatIn =50% When the PIDE.CV=50%, Heat%=0%

EW1EN.doc

5/27/2009 Page 31 of 73

MaxHeatIn =100% When the PIDE.CV=100%, Heat%=100%

MinCoolIn =50% When the PIDE.CV=50%, Cool%=0%

MaxCoolIn =0% When the PIDE.CV=0%, Cool%=100%

If Pulsed outputs were needed the following would also be required

MinHeatTime =0 sec The minimum heat time of 0 sec will correspond to 0% heat

MaxHeatTime =10 sec The maximum heat time of 10 sec will correspond to 100%

heat

MinCoolTime =0 sec The minimum cool time of 0 sec will correspond to 0% cool

MaxCoolTime =10 sec The maximum cool time of 10 sec will correspond to 100%

cool

The SRTP function must have the following parameters defined in

order to operate: CycleTime, MinHeatIn, MaxHeatIn, MaxHeatTime.

If Split-Ranging is required the following parameters are also needed

to operate: MinCoolIn, MaxCoolIn, MaxCoolTime.

Regardless of the application the CycleTime parameter must have a

non-zero entry for the function block.

The other parameters can remain as their default values.

Since the null point (no heat and no cool) is at PIDE.CVEU=50%, the

PIDE that is already in the program has been set to initialize at 50%

using the PIDE.CVInitValue parameter in the PIDE.

43. Based on the above required parameters enter 10 for the cycle time

parameter, MaxHeatTime, and MaxCoolTime since they are required

parameters. Change the MaxHeatIn, MinHeatIn , MaxCoolIn, MinCoolIn

Parameters to follow the mapping as follows .

44. Make sure the EnableOut parameter is set to 1 and then Select OK to

close the Properties dialog

The SRTP instruction splits the single PIDE output into two analog ranges as

indicated below

EW1EN.doc

5/27/2009 Page 33 of 73

Overview of Lab Simulation

The following section is to expose a few more function block instructions and to

stress the flexibility of the Logix platform and its programming languages.

The simulation used for this lab is fundamental but represents the kinds of tools

available to engineer more complex applications and process solutions. Since we

have no I/O for our lab we have created a dedicated task and program with routines

for simulation logic to generate Input Output tag data, close loops, represent process

changes and simulate equipment i.e., motors, valves and pumps.

Most non-integrating processes can be simulated with a deadtime delay and a first-

order lag in series. In our case, the two loops being simulated are a Primary,

Product Temperature loop which is more sluggish and the Secondary, J acket

Temperature loop which is more responsive.

The function block instructions used to generate the simulation are the Deadtime

(DEDT), Lead-Lag (LDLG) blocks and Function Generator (FGEN). The Deadtime

(DEDT) instruction performs a delay and represents the process deadtime or delay.

The Lead/Lag (LDLG) instruction provides the process lag. The Function generator

(FGEN) instruction is used to characterize the output and convert the signal back to

Process Engineering units.

Review and Edit the Temperature Simulation Logic

Expand the Simulation Task and Program

1. Right click on the All_Simulation Function Block routine and select open to

open the Routine logic.

2. Go to the second page of the routine by selecting next sheet on the sheet

tool bar.

3. Verify this is the Temperature simulation by making sure the indication on

the sheet toolbar reads. TIC116ab S Range simulation

4. You should see the following function block logic.

One set of dead time and lag instructions have been created for heating and another

for cooling since the SRTP provides two independent outputs and the fact that their

process characteristics would be unique. For this lab we will make them the same.

The combined effect of the two is then sent to the function generator which

characterizes the output and scales it into a temperature range simulating the faster

responding secondary J acket temperature TT_117. This is then fed to another

dead time and lag which simulates our sluggish primary reactor product

temperature TT_116.

5. Open the SRange DEDT_01 deadtime block parameters dialog by clicking

on the ellipsis and choosing the Parameters Tab in the properties dialog.

6. Check the dead time for this block make it 3.0 seconds and verify the

Gain is 1.25 and select OK.

7. Repeat these steps for the SRange_DEDT_02 deadtime block

parameters by double clicking on the ellipsis and choosing the

EW1EN.doc

5/27/2009 Page 35 of 73

Parameters Tab in the properties dialog. Change the dead time for this

block to 3.0 seconds and change the Gain to 1.25.

8. Open the SRange_LDLG_02 Lead Lag block parameters dialog by

clicking on the ellipsis and choosing the Parameters Tab in the properties

dialog.

9. Verify the Lag value is set to 15 seconds with a gain of 1.0

10. Repeat this step for the SRange_LDLG_01 block.

The Function Generator instruction takes an independent input variable (X_In) and

defines the output (Y_Out) as a curve fit by an XY mapping. The mapping is

achieved through arrays associate with the instruction. The X values are contained

in single dimensional arrays (X_Arrays) while the corresponding Y values are

contained in other single dimensional arrays (Y_Arrays). These arrays are identified

on the front of the instruction. When an input value is entered the function will find

that value in the X_Array (or interpolate between entries) and return the

corresponding (or interpolated) value from the Y_Array as the output

.

11. The All_Simulation routine has been populated with a Function

Generator instruction from the Process Element group.

12. Open the SRange_FGEN_02 Function Generator block parameters

dialog by clicking on the ellipsis.

13. Scroll mouse pointer over the XY1Size parameter description and hold

this parameter value indicates the number of segments the output curve

will contain. Select OK to close the dialog.

14. Right click on the output tag array SRange_FGEN_02Y1

EW1EN.doc

5/27/2009 Page 37 of 73

15. Select Monitor SRange_FGEN_02Y1 to open the tag editor

16. In the monitor tags window click on the to expand the

SRange_FGEN_02Y1 output.

This array defines the Function generators output curve segments and

also the simulation output range

17. In the monitor tags window move up a few tags and expand the

SRange_FGEN_02X1 output array.

This array defines the function generators input range corresponding

input curve segments.

18. Double click on the All_Simulation Function Block routine to return to

the routine

19. Open the SRange DEDT_03 deadtime block parameters dialog by

clicking on the ellipsis and choosing the Parameters Tab in the

properties dialog.

Note the dead time is larger than the secondary or jacket temperature.

This is an attempt recreate the delay it takes for heat transfer from the

jacket to the reactor product.

20. Select OK to close the dialog.

21. Verify this routine again by clicking the icon in the main toolbar.

You should see the following errors in your results window:

22. Save your project by clicking Save icon in the toolbar.

23. After you have saved your project download you controller by clicking on

the controller icon in the Controller status tool bar and selecting

download

EW1EN.doc

5/27/2009 Page 39 of 73

24. Select Download when the Download warning dialog appears confirming

the Project a target Controller.

25. After the project download has completed put the controller in run mode

by returning to the controller icon in the Controller Status tool bar and

selecting Run Mode from the dropdown menu.

26. Then select Yes on the confirmation dialog.

If you dont have a running controller (indicated by the green color of the

status and Routine window border) contact an Instructor to help trouble

shoot your application.

27. Minimize the RSLogix 5000 application.

EW1EN.doc

5/27/2009 Page 41 of 73

Lab03: The HMI component of the Cascaded PID Control

Strategy

About this Lab

In a Rockwell Automation IA based Process Automation System architecture the

control strategy definition is not limited to the controller. In addition to the Process

Automation Controller, the overall control strategy may have associated components

in the HMI or operator interface. Other components like Historical data collection or

advanced supervisory level control interaction from higher automation levels are also

considered part of the overall control strategy. All these things task the

communication networks, use system resources, and impact the overall system

performance.

To complete this cascaded PID strategy configuration from the Engineering

workstation we will use FactoryTalk View Studio Site Edition to configure the HMI

displays. FactoryTalk ViewSE Client provides the runtime Operator interface

environment to test the display and associated Controller logic.

In this lab you will:

Open an existing FactoryTalk ViewSE Process Project environment

Create a Global Object for use on Process displays

Modify A HMI Project Display using the new Global Objects and FactoryTalk

ViewSE standard process Faceplates

Exercise and Autotune the Cascaded PIDE pair via FactoryTalk ViewSE Client

Create a new Global Object

Now that we have created the Cascade and Simulation Routines, we need to add the

Operator interface component of the control strategy. We will set up displays in the

FactoryTalk View SE application and monitor and tune our PIDE loops. In order to

monitor the pertinent data we will use the Global Objects feature of FactoryTalk View

SE.

Lets configure the HMI component of our Control Strategy

1. From the computer desktop, double-click on the FactoryTalk View

Studio icon.

The Application Type Selection dialog appears

2. Select the Site Addition (Local) application type and then click on

Continue.

3. Click on Open to open the application called PAC_Reactor_Lab and wait

for application to completely open. Note: This takes a minute or two.

Global Objects

Global Objects have been updated in FactoryTalk View Enterprise

ver5.0 (CPR9).

After creating a global object (or group of objects), you can use it in

standard displays throughout an application. When you copy a global

object into a standard graphic display the copy is called a reference

object. The original global object (in the Global Objects folder)

becomes the copys base object. Reference objects have special

properties that allow them to link to the original, base objects. When

you modify properties of a base object, the changes are copied to all

reference objects linked to the base object.

Process Consideration

To help reduce development time Process faceplates are provided as

part of the FactoryTalk View Site Edition installation. For each

faceplate display there is a global object display (.ggfx) that contains

the basic objects for the faceplate, and a regular (.gfx) display. This

helps you to get an application up and running with minimal effort.

Faceplates have been created to support the following Process

instructions: Alarm, Enhanced Select, Totalizer, Ramp/Soak,

Discrete 2 State Device, Discrete 3 State Device, Phase Manager

and Enhanced PID.

4. Go to the Explorer Window and under the Graphics folder Double click on

the Global Objects folder to see the current global objects that already

have been created in the project.

Note: All the objects beginning with Logix_XXX are provided as part of

the Factory Talk View install by default. Only Display Blocks has been

created unique to this application. Lets have a look at what has already

been created

5. Maximize the FactoryTalk View SE application window to view the entire

display.

6. Double click on the Display Blocks Global object to open the display.

EW1EN.doc

5/27/2009 Page 43 of 73

These objects have been created as the base objects available for use on other

graphic in the display folder as references objects. When they are modified here

the changes are reflected in the reference objects.

In addition to some valves objects several display panels have been designed for

Pressure Loops, Totalization, Flow and % display. We need to create one for

Temperature loops. Lets take advantage of the work already done and reuse the

existing panel with some minor changes.

7. Duplicate the existing Pressure controller panel object.

by selecting Pressure controller panel object and then clicking on the

Duplicate button in the tool Bar.

8. Drag the new Controller object panel up so it is not on top of the Original

object and Right Click on the new duplicated panel.

9. Select Object Explorer from this menu.

The Object explorer window opens

10. Expand the Object Explorer Group6 and double click on Text6.

The Text properties window opens

11. In the Text Properties dialog Change PSI to Deg and select OK to close

the text Properties dialog.

12. Repeat steps 10 an 11 for Group 7, Text 9 to Change PSI to Deg

13. Close the Text Properties and Close the Object explorer and click in the

white space of the display to reset the focus.

14. Right Click on the new duplicated panel and select Animation then select

Touch

EW1EN.doc

5/27/2009 Page 45 of 73

This opens the Animation Dialog

The global object touch animation has been configured with a display command

(Display) calling the standard Faceplate (Logix_PIDE) using a tag placeholder (/T)

passing global object parameters (#1, #2)

Using global object parameters

Global object parameters are defined in the base objects of global

object displays. When you copy a global object from a global object

display onto a standard display from the Graphics folder, you can

assign values or reference tags to the defined global parameters in

the resulting reference object.

15. Close the animation Window then Right Click on the new duplicated panel

and select Global Object Parameter Definitions

The Global Object Parameter Definitions dialog opens showing two parameters

have been defined for this Global object. Arbitrarily named #1 for the PIDE

instruction tag and #2 for the Autotune tag

Global object parameter values or tags are assigned when the global object is

used as a reference object in graphic displays.

16. Select OK to close the Global Object Parameter Definitions dialog

17. From file menu or toolbar Save the Display Blocks Global Objects

18. Minimize the Display Blocks Global Objects screen.

EW1EN.doc

5/27/2009 Page 47 of 73

Adding Global Objects to a Display

This lab project represents a project still under construction. It contains a series of

displays associated with the Process Cell. We need to configure the operator

interface associated with the Reactor Control Strategies.

Open the existing Reactor display and build the interface to the New Cascaded

control strategy.

19. Go to the Explorer Window and under the Graphics/ Displays folder

Double click on the 3000_Reactor display.

The partially complete Area 3000 Reactor #1 display is opened.

20. From the main menu bar click on Window, then choose Display Blocks -

/PAC_Reactor_Lab//(Global Objects) to maximize the Display Blocks.

21. Drag the new global object that we just created from the Display blocks

display onto the Reactor display

The Display Blocks display is sent to the back and a reference copy of the

Controller Panel is placed on the Reactor display. We will need two

panels one for each of the cascaded PID instructions

22. Right Click and select Copy then Right Click again and select Paste to

duplicate the controller panel.

23. Locate one of the panels under the J acket Temp label and the other under

the Product Temp Label

Each of the new reference objects on the graphic display needs to have its

parameter values assigned. Use the Global Object Parameter Values dialog box to

assign unique global object parameter values.

EW1EN.doc

5/27/2009 Page 49 of 73

24. Right-click on the J acket Temp reference object on a graphic display.

25. Left -click on the Global Object Parameter Values from the context menu

to open the Global Object Parameter Values dialog box.

26. Left Click on the Parameter #1 Tag ellipsis to browse to the PIDE

instruction

27, When the Tag browser window opens Right Click on PAC_Reactor_Lab

and select Refresh All Folders.

28. Expand the PAC_Lab, Online and Program:

REACTOR_01_TempLoops folders to see the program scoped tags.

29. Left Click on TIC_117 and Select OK to save the value (tag path) and

close the tag browser.

The Global Object Parameter Value is populated with the path to the TIC_117 tag.

30. Left Click on the Parameter #2 Tag ellipsis and browse to click on the

AUTOTUNE Tag. And select OK.

The J acket Temp Parameters should look like this

31. Right-click on the Product Temp reference object on a graphic display.

32. Repeat this process to assign TIC_116 and the same Autotune tag to the

Product Temperature Control Panel and select OK.

33. From the file menu or toolbar Save the _3000_Reactor display.

EW1EN.doc

5/27/2009 Page 51 of 73

St ar t t he Fac t or y Tal k Vi ew SE Cl i ent

In this section you will verify the operation of the PIDE function block using

FactoryTalk View SE Client. Make sure that you have saved your displays.

34. From the Studio environment click on the Tools icon from the top pull-

down menu. And select Launch SE Client

35. Click on OK icon to launch FactoryTalk View SE Client application with

selected PAC_Lab.cli configuration file.

After a minute or two you should see the following Process Cell Overview

Screen:

Ignore possible error messages that may appear.

36. Select the Reactor #1 button on the navigation menu to open the Reactor

display: After it Is opened, Maximize the window to see the entire display

37. Left-click on Product Temp Controller panel. The Product Temp

TIC_116 PIDE Faceplate opens. This is your primary PIDE loop.

38. Move it to the right and repeat this step for the J acket Temperature.

Your screen should look like the following:

EW1EN.doc

5/27/2009 Page 53 of 73

Initially both Primary Product Temperature and Secondary J acket

Temperature loops in are in Operator Manual mode. The J acket

Temperature loop is enabled for cascade operation (Cas/Rat button

is enabled). The Product Temperature loop shows that its CV is

initializing. The Primary Loops CV is initializing because the

Secondary Loop will always assert InitPrimary if it is not in cascade

mode. In this way the Secondary loop can be manipulated

independently of the Primary loop; it can be put into auto or manual

modes independent of the primary but the Primary loop tracks the

Secondary loops setpoint to anticipate a bumpless transition to

cascade mode.

The Cas/Rat, Auto and Manual buttons on the PIDE faceplate are mode select

buttons. These buttons are exclusive (only one of these will be in effect). Any loop

can be in Auto or Manual modes but the Cas/Rat mode must be specifically enabled

from a PIDE instruction parameter

39. With the J acket Temp (TIC_117) PIDE in Manual mode, change its

SetPoint and observe the changes in the Product Temperature loop.

As long as the secondary loop is not in cascade mode, the operator can

manipulate its SP and the primary temperature loops CV will track these

changes.

40. Change the mode of the Product Temp (TIC_116) PIDE from Manual to

Auto and change its SetPoint.

Note that since the Primary PIDE is still initializing, these changes only update its

internal parameters and have no effect upon its output (CV).

41. Place the Product Temp (TIC_116) PIDE back in Manual mode and

place the J acket Temp (TIC_117) PIDE into Cas/Rat mode.

Note that the Primary PIDE status is no longer being held in an initialization state and

is actively controlling the setpoint of the Secondary Pressure loop. Verify this.

42. Change the CV of the Product Temp (TIC_116) loop to see the SP of the

J acket Temp (TIC_117) loop track the change.

Auto tuning the Cascade PID Pair

Note this section is optional. If your lab time is limited you may

want to skip to the next Lab to review and use the Discrete 3

state Device and Totalizer instruction then return to this section if

you have time.

43. Place the J acket Temp (TIC_117) PIDE in Manual mode.

44. Left-click on the Trend Object button of Jacket Temperature PIDE to

open a Trend Display:

45. Left-click on the Autotune button to open an Autotune Display:

46. Left-click on Acquire button to acquire an Autotune Tag called Autotune

that youve created in your RSLogix 5000 project.

FYI

Once all the Global Objects and their corresponding displays are

added into your FactoryTalk View SE application, the main PIDE

Faceplate automatically calls all the other displays associated with it

like Autotune, Trend, etc.

EW1EN.doc

5/27/2009 Page 55 of 73

More Details about the Autotune Dialog

Referencing the Autotune dialog above, notice that there are 5

functional areas:

Acquire Tag/Release Tag

Process Type/PV Change Limit/CV Step Size

Start/Abort Tune

Autotune Gains

Time Constant/Deadtime/Gain

Acquire/Release Tags

The Autotune tag that was entered at the bottom of the PIDE in

RSLogix 5000 is a resource that can either be dedicated to a single

PIDE or shared between many PIDEs. In a shared resource situation,

a single PIDE can use the Autotune tag at a time for an individual

tuning. This can be especially valuable when you are dealing with

smaller controllers with less memory available. In this scenario, we

would want to make sure that we do not corrupt data in the other loop

if it is being tuned simultaneously. The Acquire Tag and Release Tag

buttons assure that the tag is used exclusively by only one PID loop at

a time. The dialog also contains input and gain parameters as well as

tuning status.

Process Type/PV Change Limit/CV Step Size

These tags deal with the constraints of the Autotune execution.

Process Type: Specifies what type of system is to be tuned. This is

important because it may influence the type of model (integrating/non-

integrating, etc.) chosen for the autotune test. It also influences the

PID gain calculation once a model is determined.

PV Change Limit: This is an absolute limit in the engineering units of

the referenced PIDE configuration to stop (abort) the Autotune

procedure. The autotune procedure will be aborted if the system

experiences a PV exceeding this value.

CV Step Size: This is the amount by which the Autotune will change

the PIDE CV to exercise the system. The amount (in percent) entered

here will be added to the current CV amount for the duration of the

Autotune run. Once the Autotune has terminated (normally or

abnormally) the PIDE CV will be returned to the value that it was

before the Autotune run. It is desirable to make this value as high as

possible to get the best (greatest) response from the system, but

should not be so high as to violate the PV Change Limit or create an

unsafe condition in the system.

Start/Abort Tune

Once the Autotune run has been configured, these tags provide

runtime command and status access.

Start Tune: commands the autotune run to begin

Abort: this is available anytime during the course of an autotune run in

the event that the user must terminate the run

Execution State and Autotune Status: indicates current state of

autotune procedure (refer to the Getting Results guide for specific

state and status reference)

Autotune Gains

The gains section displays recommended gain values based upon the

last successful autotune run as well as current gains being used in the

PIDE. The radio buttons are available to select the gains for the

desired system response (Slow, Medium, or Fast). Clicking on the

Load Gains to PIDE button writes the desired gains to the PIDE for

immediate use; the Current gain set indicates the values of the gains

which currently reside in the referenced PIDE.

Time Constant/Deadtime/Gain

These are the resulting process model parameters estimated during

the autotune run.

47. Configure the Autotune as follows:

FYI

Very Important!!! Make sure to press Enter key after typing your

numbers in, otherwise they will not be entered!!!

48. Click on the Start button to begin the Autotune run (this could take a

couple minutes).

The Autotune will tune a J acket Temperature loop by increasing the PIDE CV by 20

percent from its current value and will abort the Autotune run if the process variable

is going to rise above 150 before the Autotune run is complete.

Autotune Status

During execution, the status window will display In Progress and

OK messages to let the user know that there is activity.

EW1EN.doc

5/27/2009 Page 57 of 73

49. When the Autotune is finished, you will see something similar to the

following (although the Gains values may not be the same):

Note the Process Model parameters estimated by the Autotune. Are these values

close to the values entered previously in the DeadTime and LeadLag blocks?

50. Load the Medium Response set of gains into the PIDE by selecting the

radio button for Medium Response and clicking the Load Gains button.

This will change the Current gains in the PIDE to reflect the Medium Response

selection as shown below:

51. Click on Release button to release the Autotune tag.

52 Close the Autotune and Trend display so that you are back to the

main faceplate.

53. On the main faceplate of the Jacket Temp (TIC_117) PIDE, click the

Auto button to go to automatic mode, and change the SP to a value of

150.0. Watch the result on the trend in the tune/trend page.

54. On the main faceplate of the Jacket Temp (TIC_117) PIDE, change the

SP to a value of approximately 125 by either entering the value in the

SP edit field or by the vertical SP slider. Wait for the PV to settle to

around 125.

55. Place the Jacket Temp (TIC_117) PIDE in cascade mode by clicking

once on the Cas/Rat button on the main faceplate. The mode indicators

should reflect the change to Cascade mode.

Note: Make sure TIC117 is in Cascade Mode the Autotune will not

work on TIC116 if it is Initializing.

56. Verify that the Product Temp (TIC_116) PID is in Manual mode and

repeat the previous autotuning procedure using a 10%CV StepSize in

the Autotune configuration (remember that the Autotuning process takes

a couple minutes). The results from the Autotune should be similar.

57. Again, select the gains for a Medium Response and load the

Temperature PIDE with those gains by clicking on the Load Gains to

PIDE button.

58. Click on Release button to release the Autotune tag.

59. On the main faceplate of the Product Temp (TIC_116) PIDE, place the

PIDE into Auto mode.

60. The cascade pair is has tuning parameters and in full automatic mode as

a cascade pair. Feel free to change the setpoint of the Product Temp

(TIC_116) loop and observe responses of both Product Temp

(TIC_116) and Jacket Temp (TIC_117) loops. You can also go back to

the tuning windows for either of the PIDEs and select a different gain set

for a different response, by selecting that gain set and loading it to the

PIDE.

EW1EN.doc

5/27/2009 Page 59 of 73

Lab 04: Material Add Control Strategy Using Discrete 3-State

Device and Totalizer Function Blocks Instructions

In this application we are using the Discrete 3-State Device (D3SD) instruction to

control material addition to the reactor in control strategy consisting of a pair of

solenoid valves controlling liquid flow into the tank. Valve 1 (VLV106A) is on a large

diameter feed pipe into the tank, and Valve 2 (VLV106B) is plumbed in parallel on a

small diameter feed

pipe. When liquid is

first added, the D3SD

instruction is

commanded to the

fast feed state

(State2) where both

valves are opened.

When the liquid

added approaches

the target amount,

the D3SD instruction

is commanded to the

slow feed state

(State1) where the

Valve 1 is closed and

the Valve 2 is kept

open (Slow). When

the target is reached,

the D3SD instruction

is commanded to go to the off state (State0) and both valves are closed. As long as

the D3SD instruction is in Program control, the valves open according to the Off,

Slow, and Fast inputs. The operator can also take Operator control of the feed

system if necessary. The solenoid valves in this example have limit switches which

indicate when the valves are fully closed or opened. These switches are wired into

the FB0, FB1, FB2, and FB3 feedback inputs. This allows the D3SD instruction to

generate a FaultAlarm if the solenoid valves do not reach their commanded states

within the configured FaultTime. We will also use a Totalizer TOT (Totalizer) to

accumulate the volumetric flow produced by the valve action and control the valves

based on the totalization result.

In this lab you will:

Get familiar with capabilities of D3SD and TOT Function Blocks.

Review an example of Process Application programmed in Logix5000 with utilization of

these Blocks.

Overview of Device Driver Function block Instructions

The Device Driver function blocks (D2SD and D3SD) are instructions which supply

control and feedback functionality for devices which have specific states of operation

(open/closed, forward/off/reverse, etc). The states of the devices are usually

indicated by some form of feedback from the device (limit switches in the case of a

valve). The Device Driver function can issue the command to the device to go to a

specific state and can accept the feedback from the device to verify that it has

actually attained the requested state.

A simple valve control using a D2SD would look like this.

The connections shown here are solely the electrical connections to the system.

They merely send the signal to request the appropriate state and monitor the

feedback to verify that the device is in the appropriate state. These are not the

commands that drive the device. The commands to tell the D2SD or D3SD devices

to direct the device to a specific state are issued by the operator or the program

through command requests. In Operator Mode this is through OperxReq

parameters which would typically be controlled from an operator faceplate. In

Program Mode this is through the ProgCommand parameter which would typically

be wired from command decision logic.

Reviewing a Typical D3SD Block Setup

The typical D3SD Setup consists of connecting the appropriate feedback signals as

input and output signals to perform the required actuation.

The D2SD and D3SD functions must have outputs tied to them in order to operate

(its no fun alone).

1. Maximize your RSLogix 5000 project AI_CLX_FB_Lab.

2. Expand the Program Reactor_01_VLVs and double-click on the

R01_XV106ab routine to open the function block workspace.

Lets review our Program.

EW1EN.doc

5/27/2009 Page 61 of 73

As you can see we have four inputs and two outputs connected to our D3SD

Function Block.

There are four different feedbacks from the limit switches: XV_106A_LS_CLOSED,

XV_106A_LS_OPEN, XV_106B_LS_CLOSED, and XV_106B_LS_OPEN. These

exist as controller scoped tags in the project and are representative of limit switch

discrete inputs.

We have entered the respective limit switch tag names into the Input Reference

blocks.

XV_106A_LS_CLOSED ->FB0

XV_106A_LS_OPEN ->FB1

XV_106B_LS_CLOSED->FB2

XV_106B_LS_OPEN ->FB3

The Input References look like this:

There are two different actuator signals used to manipulate the valves:

XV_106A_Cmd, XV_106B_Cmd. These exist as controller scoped tags in the project

and are representatives of actuator discrete outputs.

We have entered the respective actuator tag names into the Output Reference

blocks by either double-clicking the question mark and typing them, or browse to the

controller scoped tags and assigning them. The result should be as follows:

Out0 ->XV_106A_Cmd

Out1 ->XV_106B_Cmd

The Output References look like this:

Note that Out2 is not being used for this application (use only as many as you need).

EW1EN.doc

5/27/2009 Page 63 of 73

Reviewing the Minimum D3SD Block Configuration

Now the D3SD must be configured so that it knows what outputs to assert when a

state is commanded and what feedbacks to expect as the result of the command. To

do this, parameters within the D3SD must be set to accurately reflect the conditions

of the physical situation.

The D2SD and D3SD functions must have states, feedbacks and

outputs defined in the parameters in order to operate.

The other parameters can remain at their default values.

State 0 Off: Valve 1 is closed, Valve 2 is closed

Out0 - Off (close valve 1)

Out1 - Off (close valve 2)

XV_106A_LS_CLOSED - On (valve 1 is at its closed limit

switch)

XV_106A_LS_OPEN - Off (valve 1 is not at its open limit

switch)

XV_106B_LS_CLOSED - On (valve 2 is at its closed limit

switch)

XV_106B_LS_OPEN - Off (valve 2 is not at its open limit

switch)

State 1 Slow: Valve 1 is closed, Valve 2 is open

Out0 - Off (open valve 1)

Out1 - On (close valve 2)

XV_106A_LS_CLOSED - On (valve 1 is not at its closed limit

switch)

XV_106A_LS_ OPEN - Off (valve 1 is at its open limit switch)

XV_106B_LS_CLOSED - Off (valve 2 is at its closed limit

switch)

XV_106B_LS_OPEN - On (valve 2 is not at its open limit

switch)

State 2 Fast: Valve 1 is open, Valve 2 is open

Out0 - On (open valve 1)

Out1 - On (open valve 2)

XV_106A_LS_CLOSED - Off (valve 1 is not at its closed limit

switch)

XV_106A_LS_OPEN - On (valve 1 is at its open limit switch)

XV_106B_LS_CLOSED - Off (valve 2 is not at its closed limit

switch)

XV_106B_LS_OPEN - On (valve 2 is at its open limit switch)

3. Click on the ellipsis in the D3SD block to gain access to the

parameters and select the Configure tab.

The Feedback State table provides an easy way to define the feedback status

expected for each Device state. The Output State table provides an easy way to

define the device output configuration for each device state.

4. Review the D3SD tables against the previous page

We have completed an overview of the basic functionality for the D3SD required for

our application.

Reviewing Optional D3SD Configuration

There are many options included to aid in manipulating the function without added

programming. While it is not practical to examine every option in this format, this lab

will explore a few of the more commonly used options.

Timeout Fault

The D3SD block issues commands to devices and monitors the feedback to verify

completion of the state transition. It is often desirable to know if the commanded

state has not been achieved in a certain amount of time. Within the block a time can

be set to establish this threshold. If that time has elapsed and the commanded state

has not been achieved, an alarm will be generated by the block. The Fault Alarm will

also be generated if a device suddenly leaves a state without being commanded to

do so (as evidenced by the feedback).

FaultTime (Input): the time in seconds to wait for the feedback to indicate the

commanded state before declaring a fault.

FaultAlarmLatch (Input): Boolean value that configures the block to latch the alarm if

it occurs. This is useful when the performance of a commanded device is degrading

and becoming marginally operational. The alarm may be issued for a very brief time

if it was not latched.

FaultAlarmUnlatch (Input): Boolean value that unlatches the alarm once it has been

latched.

FaultAlarm (Output): Boolean value used to indicate that a time out fault has

occurred.

EW1EN.doc

5/27/2009 Page 65 of 73

Mode Alarm

The ModeAlarm output is a Boolean output that indicates that the D3SD block is

being commanded by the Program but is in the Operator Mode of Control. If the

D3SD is in Operator mode and the program is trying to assert one of the

ProgxCommand inputs, the Prog command will be ignored and the ModeAlarm will

be asserted.

ModeAlarm (Output): boolean output from the block to indicate that a command is

being received from the Program but Operator is the current Mode of Control.

Permissives

Permissives are inputs which allow or, more importantly, disallow a transition to a

specific state in the function. In our previous example there may be a maintenance

mode on the machine which would preclude an operator from opening the valves on

the machine. In this case, a Boolean tag could be monitored for maintenance activity

and not permit states 1 or 2 where either of the valves would be open. Note that

losing a permissive will not cause the D3SD to leave a state; it just wont allow the

D3SD to go into that state.

State0Perm, State1Perm, State2Perm (Inputs): boolean inputs to the block to

individually allow/disallow any of the three states.

Override

The Override Mode can be used for interlock conditions where you want to force the

device to a predefined safe state.

ProgOverrideReq (Input): Boolean input to the block to receive the programmed

interlock logic.

OverrideState (Input): DINT input to define the output state when in Override Mode:

0, 1 or 2.

Override (Output): Boolean output from the block to indicate that it is in the Override

State.

5. Click Cancel to exit the D3SD Properties.

Learning About Totalizer (TOT) Blocks

The Totalizer function block instruction (TOT) is a function which uses an analog

value as an input and accumulates the value to reflect an accurate total. A typical

application would be the totalization of a flow. In this case it is desirable to know the

volume of material transferred through the pipe as accurately as possible (limited by

the accuracy of the flow transmitter). There are many considerations which must be

made in this type of application to guarantee accuracy: time base of sampling

(coordination to the analog sample), double-precision floating point so that no

accumulation stalls occur, etc. Also, many applications base events on achieving

some target value in accumulation. These functions and options, and many other

common operations associated with this type of application are contained onboard

the TOT function itself so that no other programming needs to be done.

The typical TOT setup consists of connecting the appropriate analog signal as input

and connecting output signal(s) (Total, Target indicators, etc) to any desired

downstream processing.

FYI

The TOT function must have an analog input in order to operate.

Typically there are other connections for the Total and Target outputs

but they are application specific.

For the two-valve scenario material add strategy created in the D3SD section, we

use a Totalizer to accumulate the volumetric flow produced by the valve action. This

is done by monitoring a Flow Transmitter and accumulating the flow signal by