Beruflich Dokumente

Kultur Dokumente

Capitulo 5

Hochgeladen von

Murilo Alves PadilhaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Capitulo 5

Hochgeladen von

Murilo Alves PadilhaCopyright:

Verfügbare Formate

for the preparation of a

much lower than the tem-

micron dimensions (see

salt decomposition

particle, as is shown in

ln

growth during decompo-

PART III

MA TERIALS CHARACTERIZA TION

The properties of a fired product are very dependent on the characteristics of

the starting material and their subsequent modification during processing. ln

order to select and control these materiais, it is necessary to have a knowledge

of their more important characteristics. Some of this information is supplied in

the material specifications provided by the raw-material supplier. However, the

material system will have to be characterized at different processing stages, and

the processing engineer must be familiar with the techniques used and the

information obtained. The general characteristics of a material system and

common specifications of severa I commercial ceramic materiais are presented

in Chapter 5. Chemical and microstructure analyses are discussed in Chapter

6. Chapters 7 and 8 describe principies and techniques for characterizing the

size, shape, density, surface area, and porosity of ceramic particle systems.

, ~ "I

67

CHAPTER 5

CHARACTERISTICS ANO

SPECIFICATIONS OF CERAMIC

MATERIALS

The characteristics of a material are those parameters that specify the chemical

and physical aspects of its composition and structure. "Composition" denotes

the proportions of chemically and physically different constituents. "Structure"

refers to the spatial distribution, orientation, and association of these constit-

uents.

The properties of a material are its responses to changes in the physical or

chemical environment. Every particle system will have particular properties-

for example, a particular thermal conductivity, elastic modulus, and dielectric

constant. Flow and deformation properties are commonly referred to as !:heo-

logical properties. Responses to the chemical environment such as adsorption

or dissolution are chemical properties. Porous particle systems may have special

properties such as capillarity, permeability, and electroosmotic flow. Dispersed

systems have special properties such as settling rate, electrophoretic mobility,

and optical scattering. A system is said to be with respect to a

particular property if the property varies with direction in the material.

This chapter will consider the general characteristics of particle systems and

specifications provided for ceramic raw materiais. The student should keep in

mind the distinct difference between the properties and characteristics of a

material system.

5.1 PARTICLES, POWOERS, COLLOIOS, ANO AGGLOMERATES

The size range of particles used in ceramics processing covers a wide range of

sizes, as is indicated in Fig. 5.1. A particle is a discrete, solid unit of material

and may be single or multiphase in composition. Groups of particles that are

69

I

!

70 CHARACTERISTICS AND SPECIFICATIONS OF CERAMIC MATERIALS

10

18

Colloidal Powder

Sand

Cemenl

10

1

'

-

:2

10

13

li

Q.

eaclerla

10

10

c

::l

:;

PalnlPlgmenl

10

7

E

TobaeeoSmoke

o

II.

10

4

Vlru.e.

10

1

ParticleOlameter(tlm)

Fig. 5.1 Increase in fonnula units per AI

2

0

3

particle with particle size and particle

size range ofgranular materiaIs, powders, and col\oidal materiaIs and some common

substances.

bonde<.tJogether may behave as a fragile, larger pseudoparticle called

an agglomerate (see Fig. 3.5). If bonded together, the larger particle

is noteasilydispersed and is referred to asan aggregateorahard agglomerate.

Bonds in hard agglomerates are generally primary chemcal bonds formed by

achemical reactionorsintering. lnsoftagglomerates, therelativelyweakbonds

may beofelectrostatic, magnetic, Van derWaals, orcapillary adhesion type.

The magnitude ofthe inertial force ofa particle relative to surface forces

hasamajoreffecton particle behavior. Aparticlesystem is said to begranular

ifthegravitational force is predominant(thematerial isfree-flowing), apowder

ifthe surface force is ofthe sarne order as the gravitational force (naturally

agglomerates), and colloidal ifthe particles are so fine that the inertial force

ofa particle is insignificant and the surface forces dominate the behavior. The

surface forces aredependent on theenvironment ofthe particles. But for prac-

tical purposes, particles largerthan 44 pm (opening in a 325-mesh sieve) can

generally be considered to be granular and particles smaller than I pm as

colloidal. Colloids dispersed in a low-viscosity Iiquid typically exhibitBrown-

ian motion at 20C. The behavior ofpowders and colloids can be markedly

altered by adsorbed surfactants that modify the surface forces.

5.2 RAW-MATERIAL SPECIFICATIONS

The general characteristics ofone particle and a system ofparticIes are listed

in Table 5.1. Complete characterization is an impossible task, and for each

TABLE5.1 Characterisdc

Single ParticIe'

'.

1. PrimaI)' chemical complj

2. Impurity composition, d

and partitioning

3. Phase compositon

4. Point and line defects, d

5. Structureofphases, boII

6. Porosity and pore

7. Size

8. Shape

9. Density

10. surface area

TABLE5.2

Characteristici

""

cI)'stal phase .1

Purity (%)1

Impurity analysis of

grade (ppm)

Na!

Pb

Si

Cr

Fe

Ga

Ca

Mg

Zn

Ti

Mn

V

Cu

Si0

2

Fe203

CaO

Na20

Ga203

Others

Ultimate partic\e size (ILm]

Specific surface area (mll.

Agglomerate size (ILm) mi

Cl)'stal density (Mg/m

3

)

Apparent bulk density (M.

"Products of8aikowskiInterl

bproductofAluminum Comp

RAW-MATERIAL SPECIFICATIONS 71

TABLE5.1 Characteristicsofa ParticleSystem

Sing1e Particle Particle System

1. Primary chemical composition 1. Distribution ofchemical composition

2. lmpurity composition, distribution, 2. Distribution ofimpurities

and partitioning 3. Distribution ofphase composition

3. Phase composition 4. Distribution ofcrystal defects

4. Point and line defects, domains, etc. 5. Porosity and pore structure

5. Structure ofphases, boundaries 6. Particle structure distribution

6. Porosity and pore structure 7. Particle size distribution

7. Size 8. Particle shape distribution

8. Shape 9. Particle density distribution

9. Density 10. Bulkdensity

10. Specific surface area 11. Specific surface area

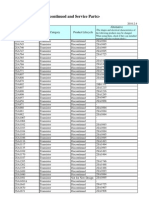

TABLE5.2 Speciftcation ofSpeciaIHigh-Purity Aluminas

Characteristic Calcined

G

Calcined

G

Calcined

b

particle size and particle

Crystal phase >90% gamma 85% alpha alpha

materiais and some common

Purity (%) 99.99 99.99 99.99

Impurity analysis ofceramic

grade (ppm)

Na 20 20

pseudoparticle called

Pb 4 4

, the larger particle

Si 18 18

orahardagglomerate.

Cr 4 4

bonds formed by

Fe 10 10

therelativelyweakbonds

Ga 15 15

capillary adhesion type. Ca 10 10

relative to surface forces

Mg 5 5

is said to be granular

Zn 4 4

Ti 5 5

is free-flowing), a powder

Mn 3 3

force (naturally

V 3 3

fine that the inertial force

Cu 2 2

the behavior. The

Si0

2

<50

particles. But for prac-

Fe20J <20

in a 325-mesh sieve) can

CaO

<10

smaller than 1 Ilm as

Na

2

0

<10

typcally exhibitBrown-

Ga203 <10

colloids can be markedly Others

<10

forces. Ultimate particle size (Ilm) 0.01 0.15 <0.5

Specific surface area (m

2

/g) 115 10 5-50

Agglomerate size (JLm) mean 2 0.6 0.5

Crystal density (Mg/m

3

) 3.67 3.98 3.98

Apparent bulk density (Mg/m

J

) 0.12 0.51

"Products ofBaikowski Intemational Corp., Charlotte, NC.

bProduct ofAluminum Company ofAmerica, Pittsburgh, PA.

72 CHARACTERISTICS ANO SPECIFICATIONS OF CERAMIC MATERIALS

material and application we must consider what characterization is necessary

and sufficient. Sorne ofthis information may be supplied by the raw-material

vendoron a specification sheet for the material. Table 5.2 lists typical speci-

fications forspecial very high purity, very fine aluminamateriais. Theimpurity

composition is quite complete, and the crystalline phase is identified. The

specific surfacearea and nominal information about agglomeration and crystal

sizearepresented. Sincethese are relatively expensive materiais, thecustomer

will certainly determine additional characteristics ofeach lot and perhaps pro-

cess and fabricate a small amount ofthe material in the laboratory orfactory

to verify that it is satisfactory.

Typical specifications ofthree calcined Bayerprocess aluminas arelisted in

Table5.3. Theparameters specifiedaresimilarto those forthe pureralumina,

but we can readily see from the specifications that these aluminas are quite

different in chemical purity and particle size (see Figs. 3.5 and 4.2). A plant

TABLE5.3 Speci6cationsofThreeBayerProcess Aluminas

Calcined

Intennediate Reactive Tabular

Characteristic Soda Low Soda (-325 Mesh)

Chemical analysis (wt%)

AI

2

0

3

99.4 99.7 99

Si0

2

0.02 0.02 0.2

Na20 0.25 0.08 0.10

Fe

2

O) 0.04 0.01 0.3

CaO 0.04 0.01 0.07

LOI (l100C) 0.2

Total water" 0.3

ex Alumina phase (%) 90+ -100 -100

Ultimate crystal size (/Lm) <5.0 >0.5

Particle size distribution >95

Sieve analysis (wt %)

+100 mesh

+200mesh

+325 mesh

-325 mesh

Sedimentation analysis

b

(/Lm)

90%< 40 1.5

50%< 12 0.5

10%< 3 0.2

Specific surface area

c

(m

2

/g) 1.0 3-6

Specific gravity 3.8 3.98 >3.4

Bulk density (Mg/m

3

) 1.0

Source: Products ofAlumnum Company ofAmerica, Pittsburgh, PA.

"I100C gnton loss afteradsorption ai 44% relatve humidity.

hOravity settling.

'Nilrogenadsorption.

engineer examines the preshiprn

lhe particular10t ofmaterial. De

applcation, aseIofcharacteristic

standardized test procedures, in

orrejecting a shipment.

Specifications for threedilfere

ceramics are listed in Table 5.4

chemicalandparticlesizechame

concentrationofCO

2

and S03m

tants during calcination. DilfereJ

reflectthe variations in thecheIJI

ofthe raw materiais and microsl

Specifications for the COIIllll4

basic chemical and particle size

eral types and mineral impuritie

index is a relative indication 01

sorption ofmethylene blue dye.

sions, and the pH index ofa

TABLE5.4 TypicalSpecificatio

Character

Chemical analysis (wt%)

Si0

2

AI

2

0)

Ti0

2

srO

BaO

Na20

S03

CO

2

LOI

Size analysis (/Lmt

90%<

50%<

10%<

+325 Mesh (%)

Bulkdensity (Mg/m

3

)

Electrical Property Analyses (bodl

magnesium zirconate):

Dielectric constant (25C)

Dissipation factor(% at 25C)

.:l Dielectric constant (\00C)

.:l Dielectric constant (- 10C)

Fired density (Mg/m

J

)

"Products ofTAM Ceramics lnc., NI

cha.racterization is necessary

by the raw-material

5.2 lists typicaJ speci-

materiais. The impurity

phase is identified. The

agglomeration and crystal

materiais, the customer

each lot and perhaps pro-

in the laboratory or factory

aluminas are listed in

for the purer alumina,

these aluminas are quite

3.5 and 4.2). A plant

Reactive

Tabular

Low Soda

(-325 Mesh)

99.7

99

0.02

0.2

0.08

0.10

0.01

0.3

0.01

0.07

-100

-100

>0,5

>95

1.5

0.5

0.2

3-6

3.98 >3.4

PA.

RAWMATERIAL SPECIFICATIONS 73

engineer examines the preshipment specifications supplied by the vendor for

the particular lot of material. Depending on past experience and the particular

application, a set of characteristics may be determined for a small sample using

standardized test procedures, in the purchaser' s labo rato ry , before authorizing

or rejecting a shipment.

Specifications for three different barium titanate powders used for electronic

ceramics are listed in Table 5.4. These materiaIs are prepared with different

chemical and particle size characteristics, as indicated in the specifications. The

concentration of CO

2

and S03 indicates the incomplete decomposition of reac-

tants during calcination. Differences in the electrical properties of a fired body

reflect the variations in the chemical stoichiometry and physical characteristics

of the raw materiaIs and microstructure developed during firing.

Specifications for the commercial kaolins listed in Table 5.5 include the

basic chemicaI and particle size characteristics. The composition of c1ay min-

eral types and mineral impurities such as free quartz are not listed. The MBI

index is a relative indication of the specific surface area determined by ad-

sorption of methylene blue dye. Clay bodies are usually processed as suspen-

sions, and the pH index of a suspension may suggest the compatibility or

TABLE 5.4 Typical Specifications of Calcined Barium Titanates

Character Capacito r MLC Piezoelectric

Chemical analyss (wt %)

8i0

2

0.10 0.12 0.15

AI

2

0

i

0.10 0.14 0.16

Ti0

2

34.64 33.95 33.38

8rO 0.90 0.78 0.91

BaO 63.59 64.28 64.18

Na20

0.10 0.17 0.15

80

3

0.15 0.14 0.18

CO

2

0.09 0.15 0.43

LOI 0.17 0.32 0.57

8ize analysis (/lmt

90%< 4.5 5.5 5.4

50%< 1.6 2.3 2.0

10%< 0.8 1.0 0.8

+325 Mesh (%) 0.02 0.02 0.02

Bulk density (Mg/m

3

) 1.8 2.4 2.0

Electrical Property Analyses (body contains 10% calciurn zirconate and 1 %

magnesium zirconate):

Dielectric constant (25C) 5250 4000 4400

Dissipation factor (% at 25C) 1.18 0.83 0.67

Ll Dielectric constant (l00C) -52.9 -48.9 -54.0

Ll Dielectric constant (-10C) -33.7 -2.4 -4.9

Fired density (Mg/rn

J

) 5.30 5.54 5.60

"Produets of TAM Ceramics Ine., Niagara Falis, NY.

74 CHARACTERISTICS ANO SPECIFICATIONS OF CERAMIC MATERIALS

cations ofthe lot-to-Iol reprocl

TABLE5.5 Typical SpecificationsofCeramic-Grade Kaolins

material cost. Processing alten

Characteristic NC

a

GA-p

b

GA-C

b

terials processors should deter

Chemical analysis (%)

uisite for control ofthe proces

Si0

2

47.72 45.36 45.74

AIP3

37.53 38.26 38.25

Fe

l

O) 1.16 0.36 0.41

SUGGESTED READING

Ti0

2

0.08 1.52 1.55

CaO 0.47 0.06

1. F. H. Norton, Fine Ceramics,

MgO 0.04 0.12

2. W. M. Flock, "Characterizati

Kp 1.17 0.21 0.06

before Firing, GeorgeY.Ono

Na20 0.15 0.11 0.14

New York, 1978, Chapter4.

LOI 14.04 13.47 13.66

3. G. Y. Onoda]r. and L. L. f

Total 99.85 99.80 99.99

Ceramic Processing before Fil

Particle sizeanalysis

Wiley-Jnterscience. New Yorl

(cumulative mass percent finer)

20 (/-tm) 97.5 98.0 97.0

4. Y. S. Kim, "EffectsofPowd

10 89.0 93.5 88.0

and Technology, Vol. 9, Fm

5 75.0 83.0 74.5

1976, pp. 51-67.

2 53.0 65.0 54.0

I 35.0 48.5 38.0

0.5 32.0 21.5

PROBLEMS

0.2 15.0 11.0

c

MBI (meq/IOO g) - 7.8 2.0

5.1 What is the relatonship

pH 5 7.2 4.3

porting the impurity in a

PCE 33-34 34-35 34-35

Dry MOR (MPa) 1.2 3.4 0.9

5.2 Calculate and compare t

in the two alphaalumil1ll

"North Carolina kaolin, Harris Mining Co. Inc., Spruce Pine, NC.

bGeorgia kaolin, Cyprus Industrial Minerais, Inc., Sandersville, GA. (GA-P torplastic forming,

5.3Calculateandcomparetil

GA-C for casting.)

size 50%< for thetwo

'Contains halloysite with tubular particle shape.

5.4Calculate the bulkdensi

and compare your resull

5.3.

changein pHifoneclay is substituted foranother. Thepyrometricconeequiv-

alent (PCE) indicates the relative resistance ofa material to vitrification and

5.5 Ca1culate the impurity I

creep on heating. The MOR is the flexural strength ofdried bars formed by

barium titanate powders

extrusion. The pH, PCE, and MOR are not characteristics; rather, they are

rities?

indices that indicate something about effects ofsoluble chemical impurities,

impurity phases, and the particle size distribution on the chemical, thermal,

5.6Thechemicalanalyses(

and mechanical behavior, respectively.

grade barium titanate3.1

SrO

SUMMARV

BaO

Ti0

2

The characteristics ofa material are the parameters necessary for its identifi-

cationordescription. Specifications provided by suppliersofmateriais provide

What is the reproducibi

some ofthese characteristics. More complete specifications or tighter specifi-

MATERIALS

Kaolins

45.36

38.26

0.36

1.52

0.47

0.04

0.21

0.1I

13.47

99.80

98.0

93.5

83.0

65.0

48.5

32.0

15.0

7.8

7.2

34-35

3.4

45.74

38.25

0.41

1.55

0.06

0.12

0.06

0.14

13.66

99.99

97.0

88.0

74.5

54.0

38.0

21.5

11.0

2.0

4.3

34-35

0.9

(GA-P for plastic fonning,

pyrometric coneequiv-

to vitrification and

dried bars fonned by

; rather, they are

chemical impurities,

the chemical, thennal,

.ece:ssalty for its identifi-

ofmateriaIs provide

_ltiOllS ortighter specifi-

PROBlEMS 75

cations ofthe lot-to-Iot reproducibility ofa material commonly increase the

material cost. Processng alters the characteristics ofthe particle system. Ma-

teriaIs processors should detennine the materiaIs characteristics that are req-

uisite for control ofthe processing and the properties oftheirproducts.

SUGGESTED READING

l. F. H. Norton, Fine Ceramics, Krieger, Malabar, FL, 1978.

2. W. M. Flock, "Characterizationand Process Interactions," in Ceramic Processing

before Firing, George Y. OnodaJr. and LanyL.Hench, Eds., Wiley-Interscience,

New York, 1978, Chapter4.

3. G. Y. Onoda Jr. and L. L. Hench, "Physcal Characterization Tennnology," in

Ceramic Processing before Firing, GeorgeY. OnodaJr. andLanyL.Hench, Eds.,

Wiley-Interscience, New York, 1978, Chapter5.

4. Y. S. Kim, "EffectsofPowderCharacteristics," in Treatise on MateriaIs Science

and Technology, Vol. 9, Franklin F. Y. Wang, Ed., Academic Press, New York,

1976, pp. 51-67.

PROBLEMS

5.1 What is the relationship between parts per million and percent when re-

porting the impurity in a solid substance?

5.1 CaIculate and compare the impurity analysis ofthe five major impurities

in the two alpha aluminas in Table 5.2. Use an elementary oxide basis.

5.3 Calculateandcomparethesharpnessindex (size90%< size 10%<)1

size 50%< for the two Bayerprocess aluminas in Table 5.3.

5.4 Calculate the bulk density as a percent forthe two aluminas in Table 5.2

and compare your results to the value for the calcined alumina in Table

5.3.

5.5 Calculate the impurity leveI ofCO

2

and S03 in parts per million for the

barium titanate powders in Table 5.4. What is the source ofthese impu-

rities?

5.6 Thechemicalanalyses (wt%)ofthreeproductionlotsofcaIcinedcapacitor

grade barium titanate areas follows:

SrO 0.95 0.82 0.84

BaO 63.71 64.00 63.94

Ti0

2

34.67 34.61 34.59

What is the reproducibilty ofthe molar ratio (BaO +SrO)/Ti0

2

?

76 CHAAACTEAISTICS ANO SPECIFICATlDNS DF CEAAMIC MATEAIALS

5.7 Which parameters in Table 5.5 are characteristics and which are pro per-

ties? Explain your reasoning.

5.8 Compare the content of colloidal sizes for the two Georgia kaolins in Table

5.5.

5.9 Explain why the tubular particles in NC kaolin may cause a misinterpre-

tation of dye adsorption index MBI (see Table 5.5).

EXAMPLES

Example 5. 1 What are diferences n agglomerate characteristics for the spe-

cial caIcined aluminas in Table 5.2.

Solution. The mostly gamma phase alumina has the largest mean agglomerate

size of 2 ,um and the smallest crystallite size (ultimate particle size) of 0.01

,um; the size ratio is 2/0.01 or 200. For the other aluminas calcined at a higher

temperature, the agglomerate size is smaller and the crystallite size is larger;

therefore, the agglomerate size and the number of particles in a mean agglom-

erate is lower. The greater agglomeration of the gamma alumina is reftected in

its lower apparent bulk density.

Example 5.2 What is the nominal purity of the barium titanates in Table

5.4?

Solution. The elementary oxides forming the perovskite structure are BaO,

SrO, and Ti0

2

Summing the weights of these gives 99.1 % purity for the

capacitor, 99.0% for the MLC, and 98.5% for the piezoelectric type of ma-

terial. The nominal purity is 99 % .

Example 5.3 Compare the stoichiometry for the three types of barium titan-

ates in Table 5.4.

Solution. Ideally, stoichiometric barium ttanate contains 1 mole of alkaline

earth oxides (BaO + SrO) and 1 mole of Ti0

2

The moles of the oxide com-

ponents are found by dividing each by its molecular weight. For the capacitor

grade material,

moles BaO = 63.54 g/153.34 g/mol = 0.415

moles SrO = 0.90 g/103.62 g/mol = 0.009

moles Ti0

2

= 34.64 g179.88 g/mol = 0.434

(BaO + SrO)/Ti0

2

mole ratio (0.415 + 0.009)/0.434 = 0.976

Calculating in a similar mannel

Piezoel

It is observed, after sintering,

the mole ratio > I; the grain s

Example 5.4 What are the in

powders, and colloids?

Solution. The diferences in p:

in the table below:

Parameter

Size (/km)

>44

F

A

vs. Fw

F

A

Flowabilty GoodC

Agglomeration

Vol. Ads./Vol. Par.

InsigniJ

Note: F

A

is Van der Waals attractivl

volume of adsorbed processing additi

EXAMPLES 77

and which are proper-

Calculating in a similar manner, the mole ratio for the other types is

MLC Type 1.005

Georgia kaolins in Table

Piezoelectric 1.02

may cause a misinterpre-

It is observed, after sintering, that a much larger grain size is obtained when

5.5).

the mole ratio > 1; the grain size strongly influences the electrical properties.

Example 5.4 What are the important differences between granular materiais,

powders, and colloids?

characteristics for the spe-

So/ution. The differences in particle characteristics and behavior may be seen

in the table below:

largest mean agglomerate

Parameter Granular Material Powder Colloid

particIe size) of O. O 1

Size (ltm) >44 44 - 1 <1

calcined at a higher

F

A

vs. Fw F

A

Fw F

A

= Fw F

A

Fw

crystallite size is larger;

Flowability Good (free ftowing) Poor Very poor

in a mean agglom-

Agglomeration Minimal Spontaneous Spontaneous

alumina is reftected in

Vol. Ads.lVol. Par. Insignificant Significant Very significant

Note: F

A

is Van der Waals attractive force. Fw is particle weight. Vol. Ads.lVol. Par. is lhe

volume of adsorbed processing additive relative to the volume of the partcle.

barium titanates in Table

structure are Ba,

99.1 % purity for the

piezoelectric type of ma-

types of barium titan-

I mole of alkaline

moles of the oxide com-

weight. For the capacitor

.434 = 0.976

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Capillary Pressure: Daniel Fernàndez Garcia UPC - Gen. Darcy LawDokument51 SeitenCapillary Pressure: Daniel Fernàndez Garcia UPC - Gen. Darcy LawHananMANoch keine Bewertungen

- Current Electricity - PYQ Practice Sheet (Physics)Dokument10 SeitenCurrent Electricity - PYQ Practice Sheet (Physics)om.dropyear2023Noch keine Bewertungen

- Summative_Gen-Physics-2_Final-Term_SY-2022-2023Dokument4 SeitenSummative_Gen-Physics-2_Final-Term_SY-2022-2023Jeffa Mae IsioNoch keine Bewertungen

- Conley Et Al. - 2018 - 2.24 Insulation MaterialsDokument36 SeitenConley Et Al. - 2018 - 2.24 Insulation Materialsminsara madtNoch keine Bewertungen

- Sla 4037Dokument29 SeitenSla 4037Franklin Miranda RoblesNoch keine Bewertungen

- Footing Pad Design CalculationDokument1 SeiteFooting Pad Design CalculationAsif BillalNoch keine Bewertungen

- Example On The Analysis of Statically Determinate FramesDokument8 SeitenExample On The Analysis of Statically Determinate FramesJaaferNoch keine Bewertungen

- End Block PDFDokument22 SeitenEnd Block PDFHAFEELNoch keine Bewertungen

- Weld CrackDokument3 SeitenWeld CrackHoangNoch keine Bewertungen

- Design Calculations for Worm & Worm Gear Endurance StrengthDokument9 SeitenDesign Calculations for Worm & Worm Gear Endurance StrengthVenkateswaran venkateswaranNoch keine Bewertungen

- Case Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve BodyDokument12 SeitenCase Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve Bodypinkan25Noch keine Bewertungen

- Lectura 4. Structural Units For Polymers - Osswald (67 - 71)Dokument6 SeitenLectura 4. Structural Units For Polymers - Osswald (67 - 71)Jhon SolanoNoch keine Bewertungen

- Lesson Plan: Heat and Mass TransferDokument6 SeitenLesson Plan: Heat and Mass TransferNithyanandmNoch keine Bewertungen

- Kafuter K 704Dokument2 SeitenKafuter K 704ketab_doostNoch keine Bewertungen

- MIXER POSITIONING PRINCIPLESDokument30 SeitenMIXER POSITIONING PRINCIPLESGustavo1722Noch keine Bewertungen

- Thermoplastic Elastomers-Terminology and Abbreviations: Standard Practice ForDokument3 SeitenThermoplastic Elastomers-Terminology and Abbreviations: Standard Practice ForJ MrNoch keine Bewertungen

- Worksheet 5.1: Chapter 5: Energetics - GlossaryDokument4 SeitenWorksheet 5.1: Chapter 5: Energetics - GlossaryBrandeice BarrettNoch keine Bewertungen

- Accelerators in India Group 3Dokument9 SeitenAccelerators in India Group 3CYCON OSRISNoch keine Bewertungen

- Grade 10 Chemistry Week 3 Lesson 1Dokument4 SeitenGrade 10 Chemistry Week 3 Lesson 1Nikoli MajorNoch keine Bewertungen

- Centralized Resource Laboratories, University of Peshawar: S.No Name of Equipment Status Particulars of The TestsDokument2 SeitenCentralized Resource Laboratories, University of Peshawar: S.No Name of Equipment Status Particulars of The TestsAliNoch keine Bewertungen

- Fibre Carbon - Tensile Test (Unidirection)Dokument5 SeitenFibre Carbon - Tensile Test (Unidirection)AlsonChinNoch keine Bewertungen

- Material Data Sheet for 52CrMoV4 Spring SteelDokument3 SeitenMaterial Data Sheet for 52CrMoV4 Spring SteelMartin HristovNoch keine Bewertungen

- Asme Section II A Sa-302 Sa-302mDokument4 SeitenAsme Section II A Sa-302 Sa-302mAnonymous GhPzn1xNoch keine Bewertungen

- Subsea Pipeline Design Engineering MethodologyDokument11 SeitenSubsea Pipeline Design Engineering MethodologyKumarJR86100% (1)

- Tutorial 4 Solution (Updated)Dokument7 SeitenTutorial 4 Solution (Updated)Jayden Chan33% (3)

- Quick Start - FLOW-3D v11.1Dokument67 SeitenQuick Start - FLOW-3D v11.1Xinwei LiNoch keine Bewertungen

- Cam Clay and Modified Cam Clay Material Models ExplainedDokument11 SeitenCam Clay and Modified Cam Clay Material Models ExplainedJonathan TeixeiraNoch keine Bewertungen

- Natural Convection Heat Transfer From Immersed BodiesDokument3 SeitenNatural Convection Heat Transfer From Immersed BodiesJanneNoch keine Bewertungen

- Euro Tech Maritime Academy Class TestDokument3 SeitenEuro Tech Maritime Academy Class TestSTUDENTS OF DOE CUSATNoch keine Bewertungen

- Fractional Fringe DeterminationDokument18 SeitenFractional Fringe Determinationprashanthatti100% (1)