Beruflich Dokumente

Kultur Dokumente

Melting Practice

Hochgeladen von

Jaya Ram MOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Melting Practice

Hochgeladen von

Jaya Ram MCopyright:

Verfügbare Formate

Melting practices for ferrous alloys

Ferrous alloys

- Process of refining by oxidation & reduction

- melting of scrap/ pig iron and alloying through addition of ferro-alloys

- removal of oxides by slag-metal reactions

Furnaces for Ferrous alloys

- Cupola for cast iron

Advantage: Simple design, low maintenance, low fuel rate, high output

Objective: melt metal at high tapping temperature

Types: Cold blast/ hot blast acid cupola,

Coke-less cupola, Water cooled cupola, oxygen cupola

- Arc furnace

Operations: charging, melting, oxidation, deoxidation

- Induction furnace

Types: Coreless

(Mains frequency, Medium Frequency 50-1000 Hz, High Frequency)

Cored: 60Hz electromagnetic induction pumps liquid through channel around core

- Vacuum metallurgy (arc f/c, induction f/c, degassing)

Sieverts Law: dissolved gas (H2, N2) in liquid metal depends on pressure

Solubility = k

P

g

Cupola

basic design

- shaft support

- chimney with spark arrester

- wind belt with tuyere

- fore-hearth/receiver

metallurgical reactions

- CaCO3->Cao+(CO2)

- 2Fe+SO2= FeS+2(FeO)

- gas fuel CO2+C =2CO

- liq. SiO2 react with CaO to form slag

- Near tuyere 2Fe + O2 = 2FeO

factors

- blast rate/temperature

incomplete combustion

reduced thermal efficiency

insufficient heat transfer

- charge material (lump size, coke reactivity/quality)

- preparation of coke bed (height of the bed)

coke less cupola

(coke bed replaced by refractory balls)

- gas/oil burner (higher tapping/ladle temperature)

- advantage: low sulfur, clean, low dart

hot blast cupola

- advantage: energy efficient, low coke consumption,

thermal performance increases with increasing blast

temperature, reduced FeO content in slag

FeO +Si = SiO2 + Fe

FeO + Mn = MnO +Fe

FeO + C = CO + Fe

Charge material: pig iron, Cast iron scrap, steel, coke and flux

Non-Ferrous alloys

- No possibility of refining

(No removal of elements by oxidation/slag-metal reactions)

- melting practice is governed by some physical and physico-chemical reactions

Problems during melting

- wide variation in densities

- segregation (non uniform chemical

composition)

- wide variation in melting temperatures

- Loss by vaporization and oxidation (reactive

metals)

- Formation of non-metallic inclusions

- absorption of gas during melting

Melting practices for nonferrous alloys

Possible solutions

- Master alloys

- maintain proper atmosphere over the melt

- vacuum (titanium, alloy-steels)

- neutral Ar, N2,

- fluxes (chloride, fluoride, glass,

limestone) Ti, Al, Mg

- reducing CO/CO2 (charcoal, CaC2), H2

Zn, Brass, Bronze (S for Mg)

- oxidizing Cu, Ni

Degassing

- Al alloys - Ar, N2, Chlorine, C2Cl6

- Cu alloys - P, Cu-P, Ca

Foundry refractories

Refractories for ferrous alloys

Acid (to resist acid slag)

silica (quartz/cristobalite)

fireclay (cristobalite + mullite 3Al2O3.2SiO2)

high alumina fireclay (alumina+mullite)

Basic (to resist basic slag)

magnesia (MgO)-dolomite (CaMg(CO

3

)

2

)

magnesia (MgO)-chrome (Cr

2

O

3

)

Neutral (react very slowly with acid/ basic slag)

chrome

carbon

Refractories for non-ferrous alloys

- clay-graphite (Cu, Cu-alloys)

- SiC+coal tar+ resin ( Cu-Ni, Al-alloys)

- used for lining in melting and heat treatment furnaces

- should resist thermal stress, physical wear, impact, corrosion, erosion by molten slag,

high refractoriness under load.

- impurities can form low melting compounds that diminish refractoriness

extremely versatile, in that they may be tailored to have a wide range of mechani-

cal and physical properties. The principal disadvantage of many ferrous alloys is

their susceptibility to corrosion. This section discusses compositions, microstructures,

and properties of a number of different classes of steels and cast irons. A taxonomic

classification scheme for the various ferrous alloys is presented in Figure 11.1.

Steels

Steels are ironcarbon alloys that may contain appreciable concentrations of other

alloying elements; there are thousands of alloys that have different compositions

and/or heat treatments. The mechanical properties are sensitive to the content of

carbon, which is normally less than 1.0 wt%. Some of the more common steels are

classified according to carbon concentrationnamely, into low-, medium-, and high-

carbon types. Subclasses also exist within each group according to the concentration

of other alloying elements. Plain carbon steels contain only residual concentrations

of impurities other than carbon and a little manganese. For alloy steels, more alloying

elements are intentionally added in specific concentrations.

Low-Carbon Steels

Of all the different steels, those produced in the greatest quantities fall within the

low-carbon classification. These generally contain less than about 0.25 wt% C and

are unresponsive to heat treatments intended to form martensite; strengthening is ac-

complished by cold work. Microstructures consist of ferrite and pearlite constituents.

360 Chapter 11 / Applications and Processing of Metal Alloys

Figure 11.1 Classification scheme for the various ferrous alloys.

Metal alloys

Nonferrous Ferrous

Steels

Low alloy

Low-carbon

Plain High strength,

low alloy

Plain Heat

treatable

Plain Tool Stainless

Medium-carbon High-carbon

High alloy

Gray

iron

Ductile

(nodular) iron

White

iron

Malleable

iron

Compacted

graphite iron

Cast irons

plain carbon steel

alloy steel

1496T_c11_358-413 11/30/05 18:58 Page 360

REVISED PAGES

Classification of ferrous alloys

<0.25 0.25-0.6 >0.6

Microalloying (Nb, V = <0.2%)

Hadfield Mn-steel

6

Cast Iron

Fe-C alloys which undergo eutectic solidification

more commonly 3 - 4.5 wt%C

low melting (also brittle), low shrinkage, easier to cast,

Cementite decomposes to ferrite + graphite

Fe

3

C --> 3 Fe (!) + C (graphite, hexagonal)

generally a slow process

Advantages:

Good castability, good wear resistance, good dampening capacity

Typical Use:

Anti-friction: sleeve, bearing, bushing

Engine block

7

Fe-C Equilibrium Diagram

Graphite formation

promoted by

Si > 1 wt%

slow cooling

Wall thickness increases

with amount of (C+Si)

Modification on the

shape size and

morphology of Graphite

can be promoted by

ladle additives

1600

1400

1200

1000

800

600

400

0 1 2 3 4 90

L

!

+L

" + Graphite

Liquid +

Graphite

(Fe)

C

o

, wt% C

0

.

6

5

740C

T(C)

! + Graphite

100

1153C

!

Austenite 4.2 wt% C

" + !

inoculant: Ferrosilicon (FeSi)

8

Types of Cast Iron

White cast iron

Fracture surface appear as white

All the Carbon in form of cementite

<1wt% Si so harder but brittle

more cementite

Malleable cast iron

heat treat at 800-950C for 100 h

(tempering)

graphite in rosettes (temper carbon)

more ductile

Good dampening; used in static/dynamic

loads; gear housing, axle housing, heads,

yokes, nuts, flanges, roller of conveyer

chain

H

T

Heat treatments of synthesizing Malleable CI

Black tempering White tempering

Oxidizing atmosphere

CO2 + C = 2CO

Surface layer (4-8 mm) is fully ferritic

Fe3C --> 3Fe+C

Decomposition of Cementite in

Ledeburite (!+Fe3C): 950

o

C

Decomposition of Cementite in

Pearlite (Ferrite + Fe3C) : 800-600

o

C

10

Types of Cast Iron

Gray cast iron

graphite flakes (stress raiser)

weak & brittle under tension

stronger under compression

excellent vibrational dampening

wear resistant: piston rings

Nodular/ductile cast iron

form directly during solidification

add Mg (0.3-1.2%) or Ce

Insoluble MgSi intermetallics cause

crystallization of Graphite nodules

matrix often pearlite - better ductility/strength

good machinability

components for forging, hammer anvils, mill

rolls, pump housing, diesel engine block

ladle additives

Maurer diagram

(Transition from White-to-Gray Cast Iron)

III

m

e

l

t

s

a

t

(

)

.

A

l

l

t

h

e

s

e

c

h

a

n

g

e

s

a

r

e

a

p

p

a

r

e

n

t

a

l

o

n

g

t

h

e

l

e

f

t

v

e

r

t

i

c

a

l

a

x

i

s

o

f

t

h

e

p

h

a

s

e

d

i

a

g

r

a

m

.

1

T

h

e

c

o

m

p

o

s

i

t

i

o

n

a

x

i

s

i

n

F

i

g

u

r

e

9

.2

4

e

x

t

e

n

d

s

o

n

l

y

t

o

6

.7

0

w

t

%

C

;

a

t

t

h

i

s

c

o

n

c

e

n

-

t

r

a

t

i

o

n

t

h

e

i

n

t

e

r

m

e

d

i

a

t

e

c

o

m

p

o

u

n

d

i

r

o

n

c

a

r

b

i

d

e

,

o

r

c

e

m

e

n

t

i

t

e

(

F

e

3

C

)

,

i

s

f

o

r

m

e

d

,

w

h

i

c

h

i

s

r

e

p

r

e

s

e

n

t

e

d

b

y

a

v

e

r

t

i

c

a

l

l

i

n

e

o

n

t

h

e

p

h

a

s

e

d

i

a

g

r

a

m

.

T

h

u

s

,

t

h

e

i

r

o

n

c

a

r

b

o

n

s

y

s

t

e

m

m

a

y

b

e

d

i

v

i

d

e

d

i

n

t

o

t

w

o

p

a

r

t

s

:

a

n

i

r

o

n

-

r

i

c

h

p

o

r

t

i

o

n

,

a

s

i

n

F

i

g

u

r

e

9

.2

4

,

a

n

d

t

h

e

o

t

h

e

r

(

n

o

t

s

h

o

w

n

)

f

o

r

c

o

m

p

o

s

i

t

i

o

n

s

b

e

t

w

e

e

n

6

.7

0

a

n

d

1

0

0

w

t

%

C

(

p

u

r

e

g

r

a

p

h

i

t

e

)

.

I

n

p

r

a

c

-

t

i

c

e

,

a

l

l

s

t

e

e

l

s

a

n

d

c

a

s

t

i

r

o

n

s

h

a

v

e

c

a

r

b

o

n

c

o

n

t

e

n

t

s

l

e

s

s

t

h

a

n

6

.7

0

w

t

%

C

;

t

h

e

r

e

f

o

r

e

,

w

e

c

o

n

s

i

d

e

r

o

n

l

y

t

h

e

i

r

o

n

i

r

o

n

c

a

r

b

i

d

e

s

y

s

t

e

m

.

F

i

g

u

r

e

9

.2

4

w

o

u

l

d

b

e

m

o

r

e

a

p

p

r

o

p

r

i

-

a

t

e

l

y

l

a

b

e

l

e

d

t

h

e

F

e

F

e

3

C

p

h

a

s

e

d

i

a

g

r

a

m

,

s

i

n

c

e

F

e

3

C

i

s

n

o

w

c

o

n

s

i

d

e

r

e

d

t

o

b

e

a

c

o

m

-

p

o

n

e

n

t

.

C

o

n

v

e

n

t

i

o

n

a

n

d

c

o

n

v

e

n

i

e

n

c

e

d

i

c

t

a

t

e

t

h

a

t

c

o

m

p

o

s

i

t

i

o

n

s

t

i

l

l

b

e

e

x

p

r

e

s

s

e

d

i

n

w

t

%

C

r

a

t

h

e

r

t

h

a

n

w

t

%

F

e

3

C

;

6

.7

0

w

t

%

C

c

o

r

r

e

s

p

o

n

d

s

t

o

1

0

0

w

t

%

F

e

3

C

.

C

a

r

b

o

n

i

s

a

n

i

n

t

e

r

s

t

i

t

i

a

l

i

m

p

u

r

i

t

y

i

n

i

r

o

n

a

n

d

f

o

r

m

s

a

s

o

l

i

d

s

o

l

u

t

i

o

n

w

i

t

h

e

a

c

h

o

f

a

n

d

f

e

r

r

i

t

e

s

,

a

n

d

a

l

s

o

w

i

t

h

a

u

s

t

e

n

i

t

e

,

a

s

i

n

d

i

c

a

t

e

d

b

y

t

h

e

a

n

d

s

i

n

g

l

e

-

p

h

a

s

e

f

i

e

l

d

s

i

n

F

i

g

u

r

e

9

.

2

4

.

I

n

t

h

e

B

C

C

f

e

r

r

i

t

e

,

o

n

l

y

s

m

a

l

l

c

o

n

c

e

n

t

r

a

t

i

o

n

s

o

f

c

a

r

-

b

o

n

a

r

e

s

o

l

u

b

l

e

;

t

h

e

m

a

x

i

m

u

m

s

o

l

u

b

i

l

i

t

y

i

s

0

.0

2

2

w

t

%

a

t

(

)

.

T

h

e

l

i

m

i

t

e

d

s

o

l

u

b

i

l

i

t

y

i

s

e

x

p

l

a

i

n

e

d

b

y

t

h

e

s

h

a

p

e

a

n

d

s

i

z

e

o

f

t

h

e

B

C

C

i

n

t

e

r

s

t

i

t

i

a

l

p

o

s

i

t

i

o

n

s

,

w

h

i

c

h

m

a

k

e

i

t

d

i

f

f

i

c

u

l

t

t

o

a

c

c

o

m

m

o

d

a

t

e

t

h

e

c

a

r

b

o

n

a

t

o

m

s

.

E

v

e

n

t

h

o

u

g

h

p

r

e

s

e

n

t

i

n

r

e

l

a

-

t

i

v

e

l

y

l

o

w

c

o

n

c

e

n

t

r

a

t

i

o

n

s

,

c

a

r

b

o

n

s

i

g

n

i

f

i

c

a

n

t

l

y

i

n

f

l

u

e

n

c

e

s

t

h

e

m

e

c

h

a

n

i

c

a

l

p

r

o

p

e

r

t

i

e

s

o

f

f

e

r

r

i

t

e

.

T

h

i

s

p

a

r

t

i

c

u

l

a

r

i

r

o

n

c

a

r

b

o

n

p

h

a

s

e

i

s

r

e

l

a

t

i

v

e

l

y

s

o

f

t

,

m

a

y

b

e

m

a

d

e

m

a

g

-

n

e

t

i

c

a

t

t

e

m

p

e

r

a

t

u

r

e

s

b

e

l

o

w

(

)

,

a

n

d

h

a

s

a

d

e

n

s

i

t

y

o

f

7

.

8

8

g

/

c

m

3

.

F

i

g

-

u

r

e

9

.

2

5

a

i

s

a

p

h

o

t

o

m

i

c

r

o

g

r

a

p

h

o

f

f

e

r

r

i

t

e

.

a

1

4

1

4

F

7

6

8

C

1

3

4

1

F

7

2

7

C

a

g

a

,

d

,

d

a

2

8

0

0

F

1

5

3

8

C

9

.

1

8

T

h

e

I

r

o

n

I

r

o

n

C

a

r

b

i

d

e

(

F

e

F

e

3

C

)

P

h

a

s

e

D

i

a

g

r

a

m

2

9

1

F

i

g

u

r

e

9

.2

5

P

h

o

t

o

m

i

c

r

o

g

r

a

p

h

s

o

f

(

a

)

f

e

r

r

i

t

e

a

n

d

(

b

)

a

u

s

t

e

n

i

t

e

(

C

o

p

y

r

i

g

h

t

1

9

7

1

b

y

U

n

i

t

e

d

S

t

a

t

e

s

S

t

e

e

l

C

o

r

p

o

r

a

t

i

o

n

.)

(

3

2

5

)

.

(

9

0

)

a

(a

)

(b

)

c

e

m

e

n

t

i

t

e

1

T

h

e

r

e

a

d

e

r

m

a

y

w

o

n

d

e

r

w

h

y

n

o

p

h

a

s

e

is

f

o

u

n

d

o

n

t

h

e

F

e

p

h

a

s

e

d

ia

g

r

a

m

,

F

ig

u

r

e

9

.2

4

(

c

o

n

s

is

t

e

n

t

w

it

h

t

h

e

e

t

c

.

la

b

e

lin

g

s

c

h

e

m

e

d

e

s

c

r

ib

e

d

p

r

e

v

io

u

s

ly

)

.

E

a

r

ly

in

v

e

s

t

ig

a

-

t

o

r

s

o

b

s

e

r

v

e

d

t

h

a

t

t

h

e

f

e

r

r

o

m

a

g

n

e

t

ic

b

e

h

a

v

io

r

o

f

ir

o

n

d

is

a

p

p

e

a

r

s

a

t

a

n

d

a

t

t

r

ib

u

t

e

d

t

h

is

p

h

e

n

o

m

e

n

o

n

t

o

a

p

h

a

s

e

t

r

a

n

s

f

o

r

m

a

t

io

n

;

t

h

e

la

b

e

l

w

a

s

a

s

s

ig

n

e

d

t

o

t

h

e

h

ig

h

-

t

e

m

p

e

r

a

t

u

r

e

p

h

a

s

e

.

L

a

t

e

r

it

w

a

s

d

is

c

o

v

e

r

e

d

t

h

a

t

t

h

is

lo

s

s

o

f

m

a

g

n

e

t

is

m

d

id

n

o

t

r

e

s

u

lt

f

r

o

m

a

p

h

a

s

e

t

r

a

n

s

-

f

o

r

m

a

t

io

n

(

s

e

e

S

e

c

t

io

n

2

0

.6

)

a

n

d

,

t

h

e

r

e

f

o

r

e

,

t

h

e

p

r

e

s

u

m

e

d

p

h

a

s

e

d

id

n

o

t

e

x

is

t

.

b

b

7

6

8

C

a

, b

, g

,

F

e

3

C

b

1

4

9

6

T

_

c

0

9

_

2

5

2

-

3

1

0

1

1

/

2

9

/

0

5

1

1

:

3

3

P

a

g

e

2

9

1

R

E

V

I

S

E

D

P

A

G

E

S

F

o

r

i

r

o

n

c

a

r

b

o

n

a

l

l

o

y

s

o

f

o

t

h

e

r

c

o

m

p

o

s

i

t

i

o

n

s

,

a

p

r

o

e

u

t

e

c

t

o

i

d

p

h

a

s

e

(

e

i

t

h

e

r

f

e

r

r

i

t

e

o

r

c

e

m

e

n

t

i

t

e

)

w

i

l

l

c

o

e

x

i

s

t

w

i

t

h

p

e

a

r

l

i

t

e

,

a

s

d

i

s

c

u

s

s

e

d

i

n

S

e

c

t

i

o

n

9

.1

9

.

T

h

u

s

a

d

d

i

t

i

o

n

a

l

c

u

r

v

e

s

c

o

r

r

e

s

p

o

n

d

i

n

g

t

o

a

p

r

o

e

u

t

e

c

t

o

i

d

t

r

a

n

s

f

o

r

m

a

t

i

o

n

a

l

s

o

m

u

s

t

b

e

i

n

-

c

l

u

d

e

d

o

n

t

h

e

i

s

o

t

h

e

r

m

a

l

t

r

a

n

s

f

o

r

m

a

t

i

o

n

d

i

a

g

r

a

m

.

A

p

o

r

t

i

o

n

o

f

o

n

e

s

u

c

h

d

i

a

g

r

a

m

f

o

r

a

1

.1

3

w

t

%

C

a

l

l

o

y

i

s

s

h

o

w

n

i

n

F

i

g

u

r

e

1

0

.1

6

.

B

a

i

n

i

t

e

I

n

a

d

d

i

t

i

o

n

t

o

p

e

a

r

l

i

t

e

,

o

t

h

e

r

m

i

c

r

o

c

o

n

s

t

i

t

u

e

n

t

s

t

h

a

t

a

r

e

p

r

o

d

u

c

t

s

o

f

t

h

e

a

u

s

t

e

n

i

t

i

c

t

r

a

n

s

f

o

r

m

a

t

i

o

n

e

x

i

s

t

;

o

n

e

o

f

t

h

e

s

e

i

s

c

a

l

l

e

d

b

a

i

n

i

t

e

.

T

h

e

m

i

c

r

o

s

t

r

u

c

t

u

r

e

o

f

b

a

i

n

i

t

e

c

o

n

s

i

s

t

s

o

f

f

e

r

r

i

t

e

a

n

d

c

e

m

e

n

t

i

t

e

p

h

a

s

e

s

,

a

n

d

t

h

u

s

d

i

f

f

u

s

i

o

n

a

l

p

r

o

c

e

s

s

e

s

a

r

e

i

n

v

o

l

v

e

d

3

2

8

C

h

a

p

t

e

r

1

0

/

P

h

a

s

e

T

r

a

n

s

f

o

r

m

a

t

io

n

s

in

M

e

t

a

l

s

F

ig

u

r

e

1

0

.1

5

P

h

o

t

o

m

ic

r

o

g

r

a

p

h

s

o

f

(

a

)

c

o

a

r

s

e

p

e

a

r

lit

e

a

n

d

(

b

)

f

in

e

p

e

a

r

lit

e

.

(

F

r

o

m

K

.

M

.

R

a

lls

e

t

a

l.,

A

n

I

n

tr

o

d

u

c

tio

n

to

M

a

te

r

ia

ls

S

c

ie

n

c

e

a

n

d

E

n

g

in

e

e

r

in

g

,

p

.

3

6

1

.

C

o

p

y

r

ig

h

t

b

y

J

o

h

n

W

ile

y

&

S

o

n

s

,

N

e

w

Y

o

r

k

.

R

e

p

r

in

t

e

d

b

y

p

e

r

m

is

s

io

n

o

f

J

o

h

n

W

ile

y

&

S

o

n

s

,

I

n

c

.)

1

9

7

6

3

0

0

0

.

F

ig

u

r

e

1

0

.1

6

I

s

o

t

h

e

r

m

a

l

t

r

a

n

s

f

o

r

m

a

t

io

n

d

ia

g

r

a

m

f

o

r

a

1

.1

3

w

t

%

C

ir

o

n

c

a

r

b

o

n

a

llo

y

:

A

,

a

u

s

t

e

n

it

e

;

C

,

p

r

o

e

u

t

e

c

t

o

id

c

e

m

e

n

t

it

e

;

P

,

p

e

a

r

lit

e

.

[

A

d

a

p

t

e

d

f

r

o

m

H

.

B

o

y

e

r

(

E

d

it

o

r

)

,

A

tla

s

o

f

I

s

o

th

e

r

m

a

l

T

r

a

n

s

f

o

r

m

a

tio

n

a

n

d

C

o

o

lin

g

T

r

a

n

s

f

o

r

m

a

tio

n

D

ia

g

r

a

m

s

,

A

m

e

r

ic

a

n

S

o

c

ie

t

y

f

o

r

M

e

t

a

ls

,

1

9

7

7

,

p

.

3

3

.]

b

a

in

it

e

T

im

e

(s

)

T e m p e r a t u r e ( C )

T e m p e r a t u r e ( F )

1

1

0

1

0

2

1

0

3

1

0

4 1

0

0

0

1

2

0

0

1

4

0

0

1

6

0

0

5

0

0

6

0

0

7

0

0

8

0

0

A

A

+

C

A

P

E

u

te

c

to

id

te

m

p

e

ra

tu

re

9

0

0

A

+

P

1

4

9

6

T

_

c

1

0

_

3

1

1

-

3

5

7

1

1

/

3

0

/

0

5

7

:

3

7

P

a

g

e

3

2

8

R

E

V

I

S

E

D

P

A

G

E

S

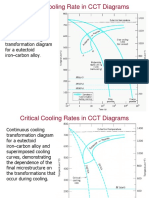

a)Annealing

b)Normalizing

c)Austempering

d) Quenching

Common heat treatment processes

e)

e) Tempered

Martensite

time (s)

10 10

3

10

5

10

-1

400

600

800

T(C)

Austenite (stable)

200

P

B

T

E

0

%

1

0

0

%

5

0

%

A

A

M + A

M + A

0%

50%

90%

F

o

r

i

r

o

n

c

a

r

b

o

n

a

l

l

o

y

s

o

f

o

t

h

e

r

c

o

m

p

o

s

i

t

i

o

n

s

,

a

p

r

o

e

u

t

e

c

t

o

i

d

p

h

a

s

e

(

e

i

t

h

e

r

f

e

r

r

i

t

e

o

r

c

e

m

e

n

t

i

t

e

)

w

i

l

l

c

o

e

x

i

s

t

w

i

t

h

p

e

a

r

l

i

t

e

,

a

s

d

i

s

c

u

s

s

e

d

i

n

S

e

c

t

i

o

n

9

.1

9

.

T

h

u

s

a

d

d

i

t

i

o

n

a

l

c

u

r

v

e

s

c

o

r

r

e

s

p

o

n

d

i

n

g

t

o

a

p

r

o

e

u

t

e

c

t

o

i

d

t

r

a

n

s

f

o

r

m

a

t

i

o

n

a

l

s

o

m

u

s

t

b

e

i

n

-

c

l

u

d

e

d

o

n

t

h

e

i

s

o

t

h

e

r

m

a

l

t

r

a

n

s

f

o

r

m

a

t

i

o

n

d

i

a

g

r

a

m

.

A

p

o

r

t

i

o

n

o

f

o

n

e

s

u

c

h

d

i

a

g

r

a

m

f

o

r

a

1

.1

3

w

t

%

C

a

l

l

o

y

i

s

s

h

o

w

n

i

n

F

i

g

u

r

e

1

0

.1

6

.

B

a

i

n

i

t

e

I

n

a

d

d

i

t

i

o

n

t

o

p

e

a

r

l

i

t

e

,

o

t

h

e

r

m

i

c

r

o

c

o

n

s

t

i

t

u

e

n

t

s

t

h

a

t

a

r

e

p

r

o

d

u

c

t

s

o

f

t

h

e

a

u

s

t

e

n

i

t

i

c

t

r

a

n

s

f

o

r

m

a

t

i

o

n

e

x

i

s

t

;

o

n

e

o

f

t

h

e

s

e

i

s

c

a

l

l

e

d

b

a

i

n

i

t

e

.

T

h

e

m

i

c

r

o

s

t

r

u

c

t

u

r

e

o

f

b

a

i

n

i

t

e

c

o

n

s

i

s

t

s

o

f

f

e

r

r

i

t

e

a

n

d

c

e

m

e

n

t

i

t

e

p

h

a

s

e

s

,

a

n

d

t

h

u

s

d

i

f

f

u

s

i

o

n

a

l

p

r

o

c

e

s

s

e

s

a

r

e

i

n

v

o

l

v

e

d

3

2

8

C

h

a

p

t

e

r

1

0

/

P

h

a

s

e

T

r

a

n

s

f

o

r

m

a

t

i

o

n

s

i

n

M

e

t

a

l

s

F

ig

u

r

e

1

0

.1

5

P

h

o

t

o

m

ic

r

o

g

r

a

p

h

s

o

f

(

a

)

c

o

a

r

s

e

p

e

a

r

lit

e

a

n

d

(

b

)

f

in

e

p

e

a

r

lit

e

.

(

F

r

o

m

K

.

M

.

R

a

lls

e

t

a

l.,

A

n

I

n

tr

o

d

u

c

tio

n

to

M

a

te

r

ia

ls

S

c

ie

n

c

e

a

n

d

E

n

g

in

e

e

r

in

g

,

p

.

3

6

1

.

C

o

p

y

r

ig

h

t

b

y

J

o

h

n

W

ile

y

&

S

o

n

s

,

N

e

w

Y

o

r

k

.

R

e

p

r

in

t

e

d

b

y

p

e

r

m

is

s

io

n

o

f

J

o

h

n

W

ile

y

&

S

o

n

s

,

I

n

c

.)

1

9

7

6

3

0

0

0

.

F

ig

u

r

e

1

0

.1

6

I

s

o

t

h

e

r

m

a

l

t

r

a

n

s

f

o

r

m

a

t

io

n

d

ia

g

r

a

m

f

o

r

a

1

.1

3

w

t

%

C

ir

o

n

c

a

r

b

o

n

a

llo

y

:

A

,

a

u

s

t

e

n

it

e

;

C

,

p

r

o

e

u

t

e

c

t

o

id

c

e

m

e

n

t

it

e

;

P

,

p

e

a

r

lit

e

.

[

A

d

a

p

t

e

d

f

r

o

m

H

.

B

o

y

e

r

(

E

d

it

o

r

)

,

A

tla

s

o

f

I

s

o

th

e

r

m

a

l

T

r

a

n

s

f

o

r

m

a

tio

n

a

n

d

C

o

o

lin

g

T

r

a

n

s

f

o

r

m

a

tio

n

D

ia

g

r

a

m

s

,

A

m

e

r

ic

a

n

S

o

c

ie

t

y

f

o

r

M

e

t

a

ls

,

1

9

7

7

,

p

.

3

3

.]

b

a

in

it

e

T

im

e

(s

)

T e m p e r a t u r e ( C )

T e m p e r a t u r e ( F )

1

1

0

1

0

2

1

0

3

1

0

4 1

0

0

0

1

2

0

0

1

4

0

0

1

6

0

0

5

0

0

6

0

0

7

0

0

8

0

0

A

A

+

C

A

P

E

u

te

c

to

id

te

m

p

e

ra

tu

re

9

0

0

A

+

P

1

4

9

6

T

_

c

1

0

_

3

1

1

-

3

5

7

1

1

/

3

0

/

0

5

7

:

3

7

P

a

g

e

3

2

8

R

E

V

I

S

E

D

P

A

G

E

S

located vary with alloy composition but, nevertheless, must be relatively low because

carbon diffusion must be virtually nonexistent.

4

The horizontal and linear character

of these lines indicates that the martensitic transformation is independent of time;

it is a function only of the temperature to which the alloy is quenched or rapidly

cooled. A transformation of this type is termed an athermal transformation.

Consider an alloy of eutectoid composition that is very rapidly cooled from a

temperature above ( ) to, say, ( ). From the isothermal

transformation diagram (Figure 10.22) it may be noted that 50% of the austenite

will immediately transform to martensite; and as long as this temperature is main-

tained, there will be no further transformation.

The presence of alloying elements other than carbon (e.g., Cr, Ni, Mo, and W)

may cause significant changes in the positions and shapes of the curves in the isother-

mal transformation diagrams. These include (1) shifting to longer times the nose of

the austenite-to-pearlite transformation (and also a proeutectoid phase nose, if such

exists), and (2) the formation of a separate bainite nose. These alterations may be

observed by comparing Figures 10.22 and 10.23, which are isothermal transforma-

tion diagrams for carbon and alloy steels, respectively.

Steels in which carbon is the prime alloying element are termed plain carbon

steels, whereas alloy steels contain appreciable concentrations of other elements,

including those cited in the preceding paragraph. Section 11.2 tells more about the

classification and properties of ferrous alloys.

Concept Check 10.2

Cite two major differences between martensitic and pearlitic transformations.

[The answer may be found at www.wiley.com/college/callister (Student Companion Site).]

330F 165C 1341F 727C

332 Chapter 10 / Phase Transformations in Metals

4

The alloy that is the subject of Figure 10.21 is not an iron-carbon alloy of eutectoid com-

position; furthermore, its 100% martensite transformation temperature lies below the

ambient. Since the photomicrograph was taken at room temperature, some austenite

(i.e., the retained austenite) is present, having not transformed to martensite.

Figure 10.21 Photomicrograph showing the

martensitic microstructure. The needle-

shaped grains are the martensite phase, and

the white regions are austenite that failed to

transform during the rapid quench.

(Photomicrograph courtesy of United States

Steel Corporation.)

1220.

athermal

transformation

plain carbon steel

alloy steel

1496T_c10_311-357 11/30/05 7:37 Page 332

REVISED PAGES

a)

t

e

m

p

e

r

a

t

u

r

e

s

b

e

t

w

e

e

n

2

5

0

a

n

d

(

4

8

0

a

n

d

F

)

;

i

n

t

e

r

n

a

l

s

t

r

e

s

s

e

s

,

h

o

w

e

v

e

r

,

m

a

y

b

e

r

e

l

i

e

v

e

d

a

t

t

e

m

p

e

r

a

t

u

r

e

s

a

s

l

o

w

a

s

(

F

)

.

T

h

i

s

t

e

m

p

e

r

i

n

g

h

e

a

t

t

r

e

a

t

-

m

e

n

t

a

l

l

o

w

s

,

b

y

d

i

f

f

u

s

i

o

n

a

l

p

r

o

c

e

s

s

e

s

,

t

h

e

f

o

r

m

a

t

i

o

n

o

f

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

,

a

c

c

o

r

d

i

n

g

t

o

t

h

e

r

e

a

c

t

i

o

n

(

1

0

.

2

0

)

w

h

e

r

e

t

h

e

s

i

n

g

l

e

-

p

h

a

s

e

B

C

T

m

a

r

t

e

n

s

i

t

e

,

w

h

i

c

h

i

s

s

u

p

e

r

s

a

t

u

r

a

t

e

d

w

i

t

h

c

a

r

b

o

n

,

t

r

a

n

s

-

f

o

r

m

s

t

o

t

h

e

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

,

c

o

m

p

o

s

e

d

o

f

t

h

e

s

t

a

b

l

e

f

e

r

r

i

t

e

a

n

d

c

e

m

e

n

t

i

t

e

p

h

a

s

e

s

,

a

s

i

n

d

i

c

a

t

e

d

o

n

t

h

e

i

r

o

n

i

r

o

n

c

a

r

b

i

d

e

p

h

a

s

e

d

i

a

g

r

a

m

.

T

h

e

m

i

c

r

o

s

t

r

u

c

t

u

r

e

o

f

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

c

o

n

s

i

s

t

s

o

f

e

x

t

r

e

m

e

l

y

s

m

a

l

l

a

n

d

u

n

i

-

f

o

r

m

l

y

d

i

s

p

e

r

s

e

d

c

e

m

e

n

t

i

t

e

p

a

r

t

i

c

l

e

s

e

m

b

e

d

d

e

d

w

i

t

h

i

n

a

c

o

n

t

i

n

u

o

u

s

f

e

r

r

i

t

e

m

a

t

r

i

x

.

T

h

i

s

i

s

s

i

m

i

l

a

r

t

o

t

h

e

m

i

c

r

o

s

t

r

u

c

t

u

r

e

o

f

s

p

h

e

r

o

i

d

i

t

e

e

x

c

e

p

t

t

h

a

t

t

h

e

c

e

m

e

n

t

i

t

e

p

a

r

t

i

-

c

l

e

s

a

r

e

m

u

c

h

,

m

u

c

h

s

m

a

l

l

e

r

.

A

n

e

l

e

c

t

r

o

n

m

i

c

r

o

g

r

a

p

h

s

h

o

w

i

n

g

t

h

e

m

i

c

r

o

s

t

r

u

c

t

u

r

e

o

f

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

a

t

a

v

e

r

y

h

i

g

h

m

a

g

n

i

f

i

c

a

t

i

o

n

i

s

p

r

e

s

e

n

t

e

d

i

n

F

i

g

u

r

e

1

0

.

3

3

.

T

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

m

a

y

b

e

n

e

a

r

l

y

a

s

h

a

r

d

a

n

d

s

t

r

o

n

g

a

s

m

a

r

t

e

n

s

i

t

e

,

b

u

t

w

i

t

h

s

u

b

s

t

a

n

t

i

a

l

l

y

e

n

h

a

n

c

e

d

d

u

c

t

i

l

i

t

y

a

n

d

t

o

u

g

h

n

e

s

s

.

F

o

r

e

x

a

m

p

l

e

,

o

n

t

h

e

h

a

r

d

n

e

s

s

-

v

e

r

s

u

s

-

w

e

i

g

h

t

p

e

r

c

e

n

t

c

a

r

b

o

n

p

l

o

t

o

f

F

i

g

u

r

e

1

0

.

3

2

i

s

i

n

c

l

u

d

e

d

a

c

u

r

v

e

f

o

r

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

.

T

h

e

h

a

r

d

n

e

s

s

a

n

d

s

t

r

e

n

g

t

h

m

a

y

b

e

e

x

p

l

a

i

n

e

d

b

y

t

h

e

l

a

r

g

e

f

e

r

r

i

t

e

c

e

m

e

n

t

i

t

e

p

h

a

s

e

b

o

u

n

d

a

r

y

a

r

e

a

p

e

r

u

n

i

t

v

o

l

u

m

e

t

h

a

t

e

x

i

s

t

s

f

o

r

t

h

e

v

e

r

y

f

i

n

e

a

n

d

n

u

m

e

r

o

u

s

c

e

m

e

n

t

i

t

e

p

a

r

t

i

c

l

e

s

.

A

g

a

i

n

,

t

h

e

h

a

r

d

c

e

m

e

n

t

i

t

e

p

h

a

s

e

r

e

i

n

f

o

r

c

e

s

t

h

e

f

e

r

-

r

i

t

e

m

a

t

r

i

x

a

l

o

n

g

t

h

e

b

o

u

n

d

a

r

i

e

s

,

a

n

d

t

h

e

s

e

b

o

u

n

d

a

r

i

e

s

a

l

s

o

a

c

t

a

s

b

a

r

r

i

e

r

s

t

o

d

i

s

-

l

o

c

a

t

i

o

n

m

o

t

i

o

n

d

u

r

i

n

g

p

l

a

s

t

i

c

d

e

f

o

r

m

a

t

i

o

n

.

T

h

e

c

o

n

t

i

n

u

o

u

s

f

e

r

r

i

t

e

p

h

a

s

e

i

s

a

l

s

o

v

e

r

y

d

u

c

t

i

l

e

a

n

d

r

e

l

a

t

i

v

e

l

y

t

o

u

g

h

,

w

h

i

c

h

a

c

c

o

u

n

t

s

f

o

r

t

h

e

i

m

p

r

o

v

e

m

e

n

t

o

f

t

h

e

s

e

t

w

o

p

r

o

p

-

e

r

t

i

e

s

f

o

r

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

.

T

h

e

s

i

z

e

o

f

t

h

e

c

e

m

e

n

t

i

t

e

p

a

r

t

i

c

l

e

s

i

n

f

l

u

e

n

c

e

s

t

h

e

m

e

c

h

a

n

i

c

a

l

b

e

h

a

v

i

o

r

o

f

t

e

m

-

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

;

i

n

c

r

e

a

s

i

n

g

t

h

e

p

a

r

t

i

c

l

e

s

i

z

e

d

e

c

r

e

a

s

e

s

t

h

e

f

e

r

r

i

t

e

c

e

m

e

n

t

i

t

e

p

h

a

s

e

b

o

u

n

d

a

r

y

a

r

e

a

a

n

d

,

c

o

n

s

e

q

u

e

n

t

l

y

,

r

e

s

u

l

t

s

i

n

a

s

o

f

t

e

r

a

n

d

w

e

a

k

e

r

m

a

t

e

r

i

a

l

y

e

t

o

n

e

t

h

a

t

i

s

t

o

u

g

h

e

r

a

n

d

m

o

r

e

d

u

c

t

i

l

e

.

F

u

r

t

h

e

r

m

o

r

e

,

t

h

e

t

e

m

p

e

r

i

n

g

h

e

a

t

t

r

e

a

t

m

e

n

t

d

e

t

e

r

m

i

n

e

s

t

h

e

s

i

z

e

o

f

t

h

e

c

e

m

e

n

t

i

t

e

p

a

r

t

i

c

l

e

s

.

H

e

a

t

t

r

e

a

t

m

e

n

t

v

a

r

i

a

b

l

e

s

a

r

e

t

e

m

-

p

e

r

a

t

u

r

e

a

n

d

t

i

m

e

,

a

n

d

m

o

s

t

t

r

e

a

t

m

e

n

t

s

a

r

e

c

o

n

s

t

a

n

t

-

t

e

m

p

e

r

a

t

u

r

e

p

r

o

c

e

s

s

e

s

.

S

i

n

c

e

c

a

r

b

o

n

d

i

f

f

u

s

i

o

n

i

s

i

n

v

o

l

v

e

d

i

n

t

h

e

m

a

r

t

e

n

s

i

t

e

-

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

t

r

a

n

s

f

o

r

m

a

t

i

o

n

,

i

n

c

r

e

a

s

i

n

g

t

h

e

t

e

m

p

e

r

a

t

u

r

e

w

i

l

l

a

c

c

e

l

e

r

a

t

e

d

i

f

f

u

s

i

o

n

,

t

h

e

r

a

t

e

o

f

c

e

m

e

n

t

i

t

e

p

a

r

t

i

c

l

e

g

r

o

w

t

h

,

a

n

d

,

s

u

b

s

e

q

u

e

n

t

l

y

,

t

h

e

r

a

t

e

o

f

s

o

f

t

e

n

i

n

g

.

T

h

e

d

e

p

e

n

d

e

n

c

e

o

f

t

e

n

s

i

l

e

a

n

d

y

i

e

l

d

s

t

r

e

n

g

t

h

a

n

d

d

u

c

t

i

l

i

t

y

o

n

t

e

m

p

e

r

i

n

g

t

e

m

p

e

r

a

t

u

r

e

f

o

r

a

n

a

l

l

o

y

s

t

e

e

l

i

s

s

h

o

w

n

m

a

r

t

e

n

s

i

t

e

1

B

C

T

,

s

i

n

g

l

e

p

h

a

s

e

2

S

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

1

a

F

e

3

C

p

h

a

s

e

s

2

3

9

0

2

0

0

C

1

2

0

0

6

5

0

C

3

4

4

C

h

a

p

t

e

r

1

0

/

P

h

a

s

e

T

r

a

n

s

f

o

r

m

a

t

i

o

n

s

i

n

M

e

t

a

l

s

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

M

a

r

t

e

n

s

i

t

e

t

o

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

t

r

a

n

s

f

o

r

m

a

t

i

o

n

r

e

a

c

t

i

o

n

F

i

g

u

r

e

1

0

.3

3

E

l

e

c

t

r

o

n

m

i

c

r

o

g

r

a

p

h

o

f

t

e

m

p

e

r

e

d

m

a

r

t

e

n

s

i

t

e

.

T

e

m

p

e

r

i

n

g

w

a

s

c

a

r

r

i

e

d

o

u

t

a

t

(

)

.

T

h

e

s

m

a

l

l

p

a

r

t

i

c

l

e

s

a

r

e

t

h

e

c

e

m

e

n

t

i

t

e

p

h

a

s

e

;

t

h

e

m

a

t

r

i

x

p

h

a

s

e

i

s

-

f

e

r

r

i

t

e

.

.

(

C

o

p

y

r

i

g

h

t

1

9

7

1

b

y

U

n

i

t

e

d

S

t

a

t

e

s

S

t

e

e

l

C

o

r

p

o

r

a

t

i

o

n

.)

9

3

0

0

a

1

1

0

0

F

5

9

4

C

1

4

9

6

T

_

c

1

0

_

3

1

1

-

3

5

7

1

1

/

3

0

/

0

5

7

:

3

7

P

a

g

e

3

4

4

R

E

V

I

S

E

D

P

A

G

E

S

c)

c)

d)

b)

Das könnte Ihnen auch gefallen

- Unit I Foundry TechnologyDokument164 SeitenUnit I Foundry TechnologyBlessy KamalaNoch keine Bewertungen

- Ferrous Alloys Metallurgy ReviewDokument80 SeitenFerrous Alloys Metallurgy ReviewAlvin Garcia PalancaNoch keine Bewertungen

- Callister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysDokument35 SeitenCallister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysRini ArtikaNoch keine Bewertungen

- SteelDokument47 SeitenSteeljayant5253100% (1)

- Ferrous Material Structure and Binary Alloy SystemDokument68 SeitenFerrous Material Structure and Binary Alloy SystemUsman FarooqNoch keine Bewertungen

- Cupola Furnace A Practical Treatise On The Construction and Management of Foundry Cupolas .. (1899)Dokument430 SeitenCupola Furnace A Practical Treatise On The Construction and Management of Foundry Cupolas .. (1899)SPYDERSKILL89% (9)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelVon EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNoch keine Bewertungen

- MetallurgyDokument190 SeitenMetallurgyJose J. Nuñez100% (2)

- Charge CalculationsDokument4 SeitenCharge CalculationsAbhishek Kumar100% (1)

- Cupola Melting CostDokument3 SeitenCupola Melting CostnirevievNoch keine Bewertungen

- Cast IronDokument43 SeitenCast IronThulasi Ram100% (1)

- Unit 1 Metals and Melting Practices: StructureDokument45 SeitenUnit 1 Metals and Melting Practices: StructureTapas BanerjeeNoch keine Bewertungen

- Extraction of IronDokument4 SeitenExtraction of IronNadita100% (1)

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDokument2 SeitenAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNoch keine Bewertungen

- Types of Furnaces Used in CastingDokument29 SeitenTypes of Furnaces Used in CastingMurali100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- METALLURGY AND MATERIALS PROPERTIESDokument55 SeitenMETALLURGY AND MATERIALS PROPERTIESTina Miller100% (2)

- Ch-19 Gas Welding, Gas Cutting - Arc WeldingDokument85 SeitenCh-19 Gas Welding, Gas Cutting - Arc WeldingdiptyaNoch keine Bewertungen

- Foundry Environmental IssuesDokument11 SeitenFoundry Environmental Issuesmecaunidos777150% (2)

- 211 2aDokument33 Seiten211 2aMada ChohNoch keine Bewertungen

- FC-06-Engineering Material & Metallurgy PDFDokument431 SeitenFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Ahmedabad Cluster: FoundryDokument24 SeitenAhmedabad Cluster: FoundrySonal PatelNoch keine Bewertungen

- Chapter 5 - Metal AlloysDokument75 SeitenChapter 5 - Metal AlloysAnonymous LSRTDBL100% (1)

- Ch13 Materials ApplicationsDokument63 SeitenCh13 Materials ApplicationsThefairman UnkownNoch keine Bewertungen

- Steel and Iron Production ProcessesDokument59 SeitenSteel and Iron Production ProcessesGianardo Satria PrimandanuNoch keine Bewertungen

- Sci 401pptDokument107 SeitenSci 401pptNiña Viaña BinayNoch keine Bewertungen

- Steel Making2Dokument147 SeitenSteel Making2satish_trivediNoch keine Bewertungen

- Metals: Sci 401 Lecture 8Dokument54 SeitenMetals: Sci 401 Lecture 8Niña Viaña BinayNoch keine Bewertungen

- Smarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaDokument219 SeitenSmarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaJEANNoch keine Bewertungen

- Iron and Steel MakingDokument219 SeitenIron and Steel Makingpahnin86% (7)

- 9-Chapter - 17 - Thermal Processing of AlloysDokument31 Seiten9-Chapter - 17 - Thermal Processing of AlloysZain FarhanNoch keine Bewertungen

- Lecture 8 MetalsDokument53 SeitenLecture 8 MetalsManga 01Noch keine Bewertungen

- Ch13 Materials ApplicationsDokument69 SeitenCh13 Materials ApplicationsRhanganath ArivudainambiNoch keine Bewertungen

- Materials For High Temperature High Pressure Applications andDokument28 SeitenMaterials For High Temperature High Pressure Applications andDrVRKNoch keine Bewertungen

- Non-Ferrous Alloy: 1-Light Alloys: These Alloys Are Characterized by Low Density, in General About (6.6) MG/MDokument4 SeitenNon-Ferrous Alloy: 1-Light Alloys: These Alloys Are Characterized by Low Density, in General About (6.6) MG/Mحسين كاظم ياسينNoch keine Bewertungen

- Materials Science and Engineering-Chapter 11Dokument3 SeitenMaterials Science and Engineering-Chapter 11JurgenNoch keine Bewertungen

- Classification of Materials NotesDokument9 SeitenClassification of Materials NotesJohn K KikwaiNoch keine Bewertungen

- Maraging Steel - WikipediaDokument5 SeitenMaraging Steel - WikipediaVysakh VasudevanNoch keine Bewertungen

- Steel and Other Alloying ElementDokument62 SeitenSteel and Other Alloying ElementJoby Jobzz SebellinoNoch keine Bewertungen

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDokument63 SeitenCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNoch keine Bewertungen

- Alloy CarbidesDokument2 SeitenAlloy Carbidesmp87_ing100% (1)

- PM - Lecture 02Dokument45 SeitenPM - Lecture 02Sheikh Sabbir SarforazNoch keine Bewertungen

- Fe Si MGDokument30 SeitenFe Si MGamitkkambleNoch keine Bewertungen

- Aeronautical Alloys Part IiDokument6 SeitenAeronautical Alloys Part IimaximinogarciaalejandraNoch keine Bewertungen