Beruflich Dokumente

Kultur Dokumente

Model 1151 Alphaline Pressure Transmitters: 00809-0100-4360 English Rev. AA

Hochgeladen von

RgQuiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Model 1151 Alphaline Pressure Transmitters: 00809-0100-4360 English Rev. AA

Hochgeladen von

RgQuiCopyright:

Verfügbare Formate

Model 1151

Alphaline

Pressure

Transmitters

00809-0100-4360

English

Rev. AA

Product Manual

Model 1151 Alphaline

Pressure

Transmitters

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307 (7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American 1-800-654-7768 (24 hours a day Includes Canada)

Response Center: Equipment service needs.

For equipment service or support needs outside the United States, contact your

local Rosemount representative.

The products described in this document are NOT designed for nuclear-

qualified applications.

Using non-nuclear qualified products in applications that require nuclear-

qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local

Rosemount Sales Representative.

S

N

F

-

0

0

0

4

NOTICE

Fisher-Rosemount satisfies all obligations coming from legislation

to harmonize product requirements in the European Union.

Rosemount I nc.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Telex 4310012

Fax (612) 949-7001

1997 Rosemount, Inc.

P

R

I NTE

D

IN

U. S. A

.

http://www.rosemount.com

May be protected by one or more of the following U.S. Patent Nos. 3,195,028; 3,271,669; 3,318,153;

3,618,390; 3,646,538; 3,793,885; 3,800,413; 3,854,039; 3,859,594; 3,975,719; 4,339,750; 5,237,285;

Re. 30,603. May Depend on Model. Other U.S. and Foreign Patents Issued and Pending.

Rosemount, the Rosemount logotype, Alphaline, and SMART FAMILY are registered trademarks of

Rosemount Inc.

HART is a registered trademark of the HART Communication Foundation.

-Cell is a trademark of Rosemount Inc.

Hastelloy, Hastelloy C, and Hastelloy C-276 are registered trademarks of Cabot Corp.

Monel is a registered trademark of International Nickel Co.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

Aflas is a registered trademark of Asahi Glass Co., Ltd.

Kynar is a trademark of Pennwalt Inc.

Flourolube is a registered trademark of Hooker Chemical Co.

Loctite is a registered trademark of Loctite Corporation.

Cover Photo: 1151-001AB

Table of Contents

i

Introduction

Usi ng Thi s Manua. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Model 1151 Al phal i nePressure Transmi tters . . . . . . . . . . . . . . 9

Transmi tter overvi ew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation

General Consi derati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechani cal Consi derati ons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Envi r onmental Requi rements . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Access Requi rements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Process Fl ange Ori entati on . . . . . . . . . . . . . . . . . . . . . . . 13

Housi ng Rotati on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Termi nal Si de of El ectr oni cs Housi ng . . . . . . . . . . . . . . . 13

Ci rcui t Si de of El ectroni cs Housi ng . . . . . . . . . . . . . . . . . 13

Exteri or of El ectr oni cs Housi ng . . . . . . . . . . . . . . . . . . . 13

Mounti ng Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Process Connecti ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounti ng Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mounti ng Requi rements (for Steam, Li qui d, Gas) . . . . . . . . 17

Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Drai n/Vent Val ves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

I mpul se Pi pi ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

El ectri cal Consi derati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wi ri ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Condui t Seal i ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Suppl y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Groundi ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Si gnal Wi ri ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Transmi tter Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Gr oundi ng Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hazar dous Locati ons Certi fi cati ons. . . . . . . . . . . . . . . . . . . . 24

Li qui d Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Open Vessel s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cl osed Vessel s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dry Leg Condi ti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wet Leg Condi ti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bubbl er System i n Open Vessel . . . . . . . . . . . . . . . . . . . . 26

Calibration

Qui ck Cal i brati on Pr ocedure (for E, G, and J El ectroni cs). . . . . 29

Qui ck Cal i brati on Pr ocedure (For L and M El ectroni cs) . . . . . . 29

Data Fl ow wi th Cal i brati on Opti ons . . . . . . . . . . . . . . . . . . . . . . 31

Span Adjustment Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Zero Adjustment Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Zero and Span Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

El evated or Suppressed Zeros . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Li neari ty Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Dampi ng Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Stati c Pressur e Span Correcti on Factor . . . . . . . . . . . . . . . . . . . . 37

ii

Options

Mounti ng Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

(Opti on Codes B1B7 and B9) . . . . . . . . . . . . . . . . . . . . . 39

Anal og Meters (420 ma onl y) . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

LCD Meters (420 ma onl y) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

LCD Meter Confi gurati on . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Remove the Cove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .r 42

Posi ti on the Deci mal Poi nt and Sel ect the Meter Functi on 42

Store the I nformati on. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Set the Di spl ay Equi val ent to a 4 mA Si gnal . . . . . . . . . 43

Set the Di spl ay Equi val ent to a 20 mA Si gnal . . . . . . . . 43

Repl ace the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

LCD Meter Assembl y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

LCD Meter Speci fi cati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Termi nal Bl ocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fi l ter Termi nal Bl ock (Opti on Code R2) . . . . . . . . . . . . . . . . 46

Transi ent Pr otecti on and Fi l ter Termi nal Bl ock

(Opti on Code R1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Retr ofi tabl e Transi ent Termi nal Bl ock(Opti on Code R9) . . . 46

R9 Termi nal Bl ock I nstal l ati on . . . . . . . . . . . . . . . . . . . . 47

Termi nal Bl ock Speci fi cati ons (for R1, R2, and R9) . . . . . . . 49

Maintenance and

Troubleshooting

Hardware Di agnosti cs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Transmi tter Di sassembl y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

54

Process Sensor Body Removal 55

Removi ng the Sensor from the El ectri cal Housi ng . . . . 56

Sensor Modul e Checkout . . . . . . . . . . . . . . . . . . . . . . . . . 57

Reassembl y Pr ocedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Prel i mi nary Precauti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connecti ng the El ectri cal Housi ng to the Sensor . . . . . . . . . 58

Backup Ri ng and O-ri ng I nstal l ati on . . . . . . . . . . . . . . . . . . 58

Opti onal Pl ug-i n Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .s 60

Return of Materi al . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Specifications and

Reference Data

Functi onal Speci fi cati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Performance Speci fi cati ons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Physi cal Speci fi cati ons (Standar d Confi gurati on). . . . . . . . . . . . 68

Section

1-1

1 Introduction

USING THIS MANUAL

Thi s manual i s desi gned to assi st i n i nstal l i ng, operati ng, and

mai ntai ni ng the Rosemount Model 1151 Anal og Pressur e Transmi tter

Fami l y.

Section 2 Installation

pr ovi des mechani cal and el ectri cal i nstal l ati on i nstructi ons.

Section 3 Calibration

expl ai ns techni que for cal i brati on of the devi ce.

Section 4 Options

expl ai ns the opti ons avai l abl e for the Model 1151, i ncl udi ng mounti ng

brackets, LCD meters, custom confi gurati on, transi ent protecti on, and

fi l ter termi nal bl ocks.

Section 5 Maintenance and Troubleshooting

descri bes tri m procedures and offers tr oubl eshooti ng i nstructi ons for

deal i ng wi th potenti al mechani cal or el ectri cal di ffi cul ti es.

Section 6 Specifications and Reference Data

l i sts functi onal , performance, and physi cal speci fi cati ons data as wel l

as orderi ng i nformati on for the transmi tter.

Appendix A Approval Drawings

contai ns approval drawi ngs for Canadi an Standards Associ ati on (CSA)

and Factory Mutual (FM) i ntri nsi c safety drawi ngs.

Glossary

provi des bri ef defi ni ti ons of the terms used i n thi s manual and tel l s

where to fi nd more i nformati on.

Index

contai ns a comprehensi ve, standard i ndex.

MODEL 1151 ALPHALINE

PRESSURE

TRANSMITTERS

Thi s manual descri bes the fol l owi ng Model 1151 Al phal i ne

Pressure

Transmi tters.

Model 1151DP Di fferenti al Pr essure Transmi tter

measures di fferenti al pressure from 6 i nH

2

O to 1,000 psi

(1.493 to 6895 kPa).

Model 1151HP Di fferenti al Pr essure Transmi tter

for Hi gh Li ne Pressur es measures hi gh l i ne pressures from

25 i nH

2

O to 300 psi (6.22 to 2668 kPa).

Model 1151GP Gage Pressur e Transmi tter

measures gage pressure from 6 i nH

2

O to 6,000 psi (1.493 to

41369 kPa).

Model 1151AP Absol ute Pressure Transmi tter

measures absol ute pressure from 25 i nH

2

O to 1,000 psi (6.22 to

6895 kPa).

Model 1151 Alphaline

Pressure Transmitters

1-2

TRANSMITTER OVERVIEW

The Rosemount Model 1151 Al phal i ne

seri es of pressure transmi tters

has set an i ndustr y standard as the l argest-sel l i ng transmi tter i n the

worl d. I t bri ngs true preci si on to the measurement of fl ow, l evel , gage

and absol ute pressures, vacuum, and speci fi c gravi ty.

Wi th proven performance, qual i ty, and rel i abi l i ty, the Model 1151

provi des accurate measurement usi ng the vari abl e capaci tance

pri nci pl e. I t i s vi rtual l y unaffected by changes i n temperature, stati c

pr essure, vi brati on, and power suppl y vol tage.

I nstal l ati on, cal i brati on, and commi ssi oni ng are si mpl i fi ed by the

transmi tter s compact desi gn, i ntegral juncti on box, and l ocal span and

zero adjustments. I ts modul ar desi gn and hi gh degree of

i nterchangeabi l i ty resul t i n a mi ni mal i nvestment for spar e parts.

Section

2-1

2 Installation

Thi s secti on covers areas to consi der when i nstal l i ng the Model 1151

Anal og Transmi tter:

General Consi derati ons

Mechani cal Consi derati ons

Envi ronmental Requi rements

El ectri cal Consi derati ons

Li qui d Level Measurement

GENERAL

CONSIDERATIONS

The accuracy of a fl ow, pressure, or l evel measurement depends on

proper i nstal l ati on of the transmi tter and i mpul se pi pi ng. The pi pi ng

between the process and transmi tter must accuratel y transmi t process

pr essure to the transmi tter. Mount the transmi tter cl ose to the process

and use a mi ni mum of pi pi ng to achi eve best accuracy. Keep i n mi nd,

however, the need for easy access, safety of personnel , practi cal fi el d

cal i brati on, and a sui tabl e transmi tter envi r onment. I n general , i nstal l

the transmi tter so as to mi ni mi ze vi brati on, shock, and temperature

fl uctuati ons.

I nstal l ati ons i n food, beverage, and pharmaceuti cal processes may

requi re sani tary seal s and fi tti ngs. Regul ati ons may di ctate speci al

i nstal l ati on requi rements needed to mai ntai n sani tati on and

cl eanabi l i ty consi derati ons. See Product Data Sheet 00813-0100-4016

for more i nformati on about sani tary pressure i nstruments from

Rosemount I nc.

MECHANICAL

CONSIDERATIONS

Rosemount Model 1151DP, GP, HP, and AP transmi tters may be

mounted i n several ways. They may be panel -mounted, wal l -mounted,

or attached to a 2-i nch pi pe through an opti onal mounti ng bracket.

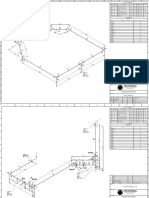

Fi gure 2-1 shows the transmi tter di mensi ons. The fol l owi ng

paragraphs di scuss factors necessary for a successful transmi tter

i nstal l ati on.

Model 1151 Alphaline Pressure Transmitters

2-2

Range

Flange Distance A

Center to Center

inches mm

3, 4, 5 2.125 54

6, 7 2.188 56

8 2.250 57

9 2.281 58

0 2.328 59

14 NPT

Conduit

Connection

(2 Places)

Meter

Housing

Terminal Connections

This Side

18 NPT on

Flanges for Pressure

Connection without

Flange Adapters

14 NPT on

Flange

Adapters

A

(See Table)

4.5 (114)

Max.

7.5 (191) Max.

with Optional Meter

0.75 (19)

Clearance for

Cover Removal

(Typical)

Transmitter

Circuitry

This Side

1.625

(41)

Blank Flange

Used on

AP and GP

Transmitters

Flange

Adapter

4.5 (114)

3.375

(86)

Flanges Can

Be Rotated

3.69

(94)

4.5 (114)

Max.

Permanent

Tag (Optional)

9.0 (229) Max.

Nameplate

Wired-on

Tag

(Standard)

Drain/Vent

Valve

18 NPT for

Side Drain/Vent

(Optional Top

or Bottom)

FIGURE 2-1. Dimensional Drawing

for Model 1151 Transmitter.

NOTE

Dimensions are in inches (millimeters).

1

1

5

1

-

1

1

5

1

A

,

B

0

5

A

2-3

Installation

ENVIRONMENTAL

REQUIREMENTS

Mount the transmi tter to mi ni mi ze ambi ent temperature changes. The

transmi tter el ectr oni cs temperature operati ng l i mi ts are 40 to 200 F

(40 to 85 C) for E output opti ons, 20 to 150 F (29 to 66 C) for J

output opti ons, and 20 to 200 F (29 to 93 C) for G, L, and M output

opti ons. Section 5 Maintenance and Troubleshooting l i sts the

sensi ng el ement operati ng l i mi ts. Mount the transmi tter to avoi d

vi brati on and mechani cal shock, and to avoi d external contact wi th

corrosi ve materi al s.

Access Requirements

When choosi ng an i nstal l ati on l ocati on and posi ti on, take i nto account

the need for access to the transmi tter.

Process Flange Orientation Ori ent the process fl anges to enabl e process connecti ons to be made.

For safety reasons, ori ent the drai n/vent val ves so that process fl ui d i s

di rected down and away from techni ci ans when the val ves are used.

Thi s can be accompl i shed by poi nti ng the hol e i n the outsi de val ve body

downward and away. I n addi ti on, consi der the need for a testi ng or

cal i brati on i nput.

Housing Rotation The el ectroni cs housi ng may be rotated up to 90 degrees to i mprove

fi el d access to the two housi ng compartments. To rotate the housi ng l ess

than 90 degrees, l oosen the housi ng l ock nut and turn the housi ng not

more than 90 degrees from the ori entati on shown i n Fi gure 2-1. To

rotate the housi ng more than 90 degrees, fol l ow the transmi tter

di sassembl y procedures i n Section 5 Maintenance and

Troubleshooting.

Terminal Side of

Electronics Housing

Make wi ri ng connecti ons through the condui t openi ngs on the top si de

of the housi ng. The termi nal si de of the housi ng i s marked on the

namepl ate l ocated on the si de of the transmi tter. Mount the transmi tter

so that the termi nal si de i s accessi bl e. A -i nch cl earance i s requi red

for cover removal wi th no meter. A 3-i nch cl earance i s requi red for cover

removal i f a meter i s i nstal l ed. I f practi cal , provi de approxi matel y 6

i nches cl earance so that a meter may be i nstal l ed l ater.

Circuit Side of

Electronics Housing

The ci rcui t compartment shoul d not routi nel y need to be opened when

the uni t i s i n servi ce; however, provi de 6 i nches cl earance i f possi bl e to

al l ow access for on-si te mai ntenance. The ci rcui t si de of the housi ng i s

marked on the namepl ate l ocated on the si de of the transmi tter.

Exterior of Electronics Housing The anal og Model 1151 uses l ocal span and zero screws, whi ch are

l ocated under the namepl ate on the si de of the transmi tter. Pl ease al l ow

6 i nches cl earance i f possi bl e to al l ow access for on-si te mai ntenance.

Do not rotate the transmitter housing more than 90 degrees

without disconnecting the header board. Exceeding 90

degrees rotation will damage the internal sensor module

wiring. Refer to Removing the Sensor from the Electrical

Housing on page 5-6 for further information.

Model 1151 Alphaline Pressure Transmitters

2-4

Mounting Effects

The anal og Model 1151 wei ghs 12 l b (5.4 kg) for AP, DP, GP, and HP

transmi tters, excl udi ng opti ons. Thi s wei ght must be securel y

supported; see Fi gure 2-2 on page 2-6 for mounti ng bracket

i nformati on. The transmi tter i s cal i brated i n an upri ght posi ti on at the

factory. I f thi s ori entati on i s changed duri ng mounti ng, the zero poi nt

wi l l shi ft by an amount equi val ent to the l i qui d head caused by the

mounti ng posi ti on. Zero and Span Adjustment on page 3-6 descri bes

how to correct thi s shi ft.

Process Connections

Model 1151AP, DP, GP, and HP process connecti ons on the transmi tter

fl anges are 18 NPT. Fl ange adapter uni ons wi th 14 NPT

connecti ons are suppl i ed as standard. These are Cl ass 2 thr eads; use

pl ant-approved l ubri cant or seal ant when maki ng the process

connecti ons. The fl ange adapters al l ow users to di sconnect from the

process by removi ng the fl ange adapter bol ts. Fi gure 2-1 on page 2-2

shows the di stance between pressure connecti ons. Thi s di stance may be

vari ed

1

/8 i nch (3.2 mm) by rotati ng one or both of the fl ange adapters.

To ensure a ti ght seal on the fl ange adapters or three-val ve mani fol d,

fi rst fi nger-ti ghten both bol ts, then wrench-ti ghten the fi rst bol t to

approxi matel y 29 ft-l bs (34 Nm). Wr ench-ti ghten the second bol t to

approxi matel y 29 ft-l bs (34 Nm).

Process leaks can cause death or serious injury. Only use

bolts supplied with the transmitter or sold by Rosemount

Inc. as a spare part. Using unauthorized bolts may reduce

pressure retaining capabilities and render the instrument

dangerous.

Do not plug the low side with a solid plug. Plugging the low

side will cause an output shift.

2-5

Installation

NOTE

I f Tefl on O-ri ngs are used, they shoul d be repl aced i f the fl ange adapter

i s r emoved.

The l ow-si de process fl ange has a 18 NPT connecti on. A fl ange

adapter uni on i s suppl i ed for 14 NPT process connecti ons. The

fl ange adapter al l ows the transmi tter to be easi l y di sconnected from the

process by removi ng the fl ange adapter bol ts. On open vessel s the l ow-

si de process fl ange i s open to atmosphere and shoul d be mounted wi th

the threaded hol e poi nted down. On cl osed vessel s thi s connecti on i s

used for the dry or wet l eg.

Mounting Brackets

An opti onal mounti ng bracket permi ts mounti ng the transmi tter to a

wal l , a panel , or a 2-i nch hori zontal or verti cal pi pe. Fi gure 2-2

i l l ustrates some typi cal confi gurati ons usi ng these mounti ng brackets.

Process leaks can cause death or serious injury. Install and

tighten all four flange bolts before applying pressure, or

process leakage may result. When properly installed, the

flange bolts will protrude through the top of the module

housing. Attempting to remove the flange bolts while the

transmitter is in service may cause process fluid leaks.

Failure to install flange adapter O-rings can cause process

leaks, which can result in death or serious injury.

There are two styles of Rosemount flange adapters, each

requiring a unique O-ring, as shown below. Each flange

adapter is distinguished by its unique groove.

Use only the O-ring designed to seal with the corresponding

flange adapter.

Refer to the Spare Parts List on page 6-13 for the part

numbers of the flange adapters and O-rings designed for

the Model 1151 Pressure Transmitter.

Unique O-ring

Grooves

MODEL 3051/2024/3001/3095

MODEL 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

Model 1151 Alphaline Pressure Transmitters

2-6

2.625 (67)

2.625

(67)

5.625

(143)

5.625

(143)

3

0

5

1

-

3

0

5

1

D

1

9

A

,

1

1

5

1

-

1

1

5

1

D

,

B

0

6

C

PIPE MOUNTING BRACKET OPTION CODES B1, B4, AND B7

2.81 Typ.

(71)

2.625

(67)

PANEL MOUNTING BRACKET OPTION CODES B2 AND B5

1.40

(36)

2.81 Typ.

(71)

1.40 (46)

Mounting Holes

0.375 Diameter

(10)

3

0

5

1

-

3

0

5

1

B

1

9

A

,

1

1

5

1

-

0

2

4

4

A

,

1

1

5

1

-

1

1

5

1

E

0

6

A

1.62 (41)

2.125 (54)

2.81 (71)

8 (203)

FLAT MOUNTING BRACKET OPTION CODES B3, B6, AND B9

3

0

5

1

-

3

0

5

1

H

1

9

B

,

1

1

5

1

-

1

1

5

1

F

0

6

B

NOTE

Dimensions are in inches (millimeters).

FIGURE 2-2. Mounting Bracket

Options.

3.87

(98)

1.65 (42)

2.62

(67)

4.97

(127)

2.81

(71)

3.75

(95)

3.87 (98)

3.75 (95)

2.81 Typ.

(71)

4.5 (114)

1.65 (42)

2-7

Installation

Mounting Requirements

(for Steam, Liquid, Gas)

The fol l owi ng i nformati on appl i es to steam, l i qui d, and gas i nstal l ati ons.

Taps Di fferent measurement condi ti ons cal l for di fferent pi pi ng

confi gurati ons. For l i qui d fl ow measur ement, pl ace taps to the si de of

the l i ne to prevent sedi ment deposi ts, and mount the transmi tter besi de

or bel ow these taps so gases can vent i nto the process l i ne. For gas fl ow

measurement, pl ace taps i n the top or si de of the l i ne and mount the

transmi tter besi de or above the taps so l i qui d wi l l drai n i nto the process

l i ne. For steam fl ow measur ement, pl ace taps to the si de of the l i ne wi th

the transmi tter mounted bel ow them to ensure that the i mpul se pi pi ng

stays fi l l ed wi th condensate. See Fi gure 2-3 for a di agram of these

arrangements.

Drain/Vent Valves For transmi tters wi th si de drai n/vent val ves, pl ace taps to the si de of

the l i ne. For l i qui d servi ce, mount the si de drai n/vent val ve upward to

al l ow the gases to vent. For gas servi ce, mount the drai n/vent val ve

down to al l ow any accumul ated l i qui d to drai n. To change the drai n/vent

val ve ori entati on from top to bottom, rotate the process fl ange 180

degr ees.

I n steam servi ce, l i nes shoul d be fi l l ed wi th water to prevent contact of

the l i ve steam wi th the transmi tter.

NOTE

For steam service do not blow down impulse piping

through transmitter. Flush lines with blocking valves closed

and refill lines with water before resuming measurement.

Plugged Tee

for Steam Service

for Sealing Fluid

STEAM SERVICE

Sufficient

Length for

Cooling

Blocking

Valves

3-valve

Manifold

Flow

Vent/Drain

Valve

3-valve

Manifold

GAS SERVICE

Flow

3-valve

Manifold

Drain/Vent

Valve

Flow

Optional Side-

mounted Drain/

Vent Valve

3-valve

Manifold

Flow

1

1

5

1

-

1

1

5

1

D

,

A

,

B

,

C

0

1

A

FIGURE 2-3. Steam, Liquid, and

Gas Service Installation Diagrams.

H

L

LIQUID SERVICE

H

H

H

L

L

L

Steam or other elevated temperature processes can cause

damage to the sensor. Do not allow the temperature inside

the process flanges to exceed the transmitter limit of 220 F

(104 C).

Model 1151 Alphaline Pressure Transmitters

2-8

Impulse Piping The pi pi ng between the process and the transmi tter must accuratel y

transfer the pressure i n order to obtai n accurate measurements. I n thi s

pressure transfer, there are fi ve possi bl e sources of error: l eaks, fri cti on

l oss (parti cul arl y i f purgi ng i s used), trapped gas i n a l i qui d l i ne, l i qui d

i n a gas l i ne, and temperature-i nduced or other densi ty vari ati on

between the l egs.

The best l ocati on for the transmi tter i n r el ati on to the process pi pe

depends on the process i tsel f. Consi der the fol l owi ng general gui del i nes

i n determi ni ng transmi tter l ocati on and pl acement of i mpul se pi pi ng:

Keep i mpul se pi pi ng as short as possi bl e.

Sl ope the i mpul se pi pi ng at l east 1 i nch per foot (8 centi meters

per meter) upward from the transmi tter towar d the process

connecti on for l i qui d.

Sl ope the i mpul se pi pi ng at l east 1 i nch per foot (8 centi meters

per meter) downward from the transmi tter toward the process

connecti on for gas.

Avoi d hi gh poi nts i n l i qui d l i nes and l ow poi nts i n gas l i nes.

Make sure both i mpul se l egs are the same temperature.

Use i mpul se pi pi ng l arge enough to avoi d fri cti on effects and

prevent bl ockage.

Vent al l gas from l i qui d pi pi ng l egs.

When usi ng a seal i ng fl ui d, fi l l both pi pi ng l egs to the same l evel .

When purgi ng i s necessary, make the purge connecti on cl ose to

the process taps and purge through equal l engths of the same si ze

pi pe. Avoi d purgi ng through the transmi tter.

Keep corrosi ve or hot process materi al out of di rect contact wi th

the sensor modul e and fl anges.

Prevent sedi ment deposi ts i n the i mpul se pi pi ng.

Keep the l i qui d head bal anced on both l egs of the i mpul se pi pi ng.

ELECTRICAL

CONSIDERATIONS

Before maki ng any el ectri cal connecti ons to the Model 1151 anal og,

consi der the fol l owi ng standards and be sure to have proper power

suppl y, condui t, and other accessori es. Make sure al l el ectri cal

i nstal l ati on i s i n accordance wi th nati onal and l ocal code requi rements,

such as the NEC (NFPA 70).

Explosions can cause death or serious injury. Do not

remove the instrument cover in explosive atmospheres

when the circuit is alive.

Do not connect the power signal wiring to the test terminals.

Voltage may burn out the reverse-polarity protection diode

in the test connection. If the test diode is destroyed, then the

transmitter can still be operated without local indication by

jumping the test terminals.

2-9

Installation

Wiring

The si gnal termi nal s and test termi nal s are l ocated i n a compartment

of the el ectroni cs housi ng separate from the transmi tter el ectroni cs.

The namepl ate on the si de of the transmi tter i ndi cates the l ocati ons of

the termi nal and el ectroni cs compartments. The upper pai r of

termi nal s ar e the si gnal termi nal s and the l ower pai r ar e the test

termi nal s. The test termi nal s have the same 420 mA output as the

si gnal termi nal s and are onl y for use wi th the opti onal i ntegral meter

or for testi ng.

To make connecti ons, remove the cover on the si de marked Termi nal

on the namepl ate. Al l power to the transmi tter i s suppl i ed over the

si gnal wi ri ng. Connect the l ead that ori gi nates at the posi ti ve si de of

the power suppl y to the termi nal marked + and the l ead that

ori gi nates at the negati ve si de of the power suppl y to the termi nal

marked as shown i n Fi gure 2-4. No addi ti onal wi ri ng i s requi red.

Shi el ded cabl e shoul d be used for best resul ts i n el ectri cal l y noi sy

envi ronments.

High voltage (greater than 55 Volts for E electronics, 85

Volts for G electronics, 12 Volts for L electronics, and 14

Volts for M electronics.) can cause damage to the

transmitter. Do not apply high voltage to the test terminals.

FIGURE 2-4. Terminal Connections.

POWER

SUPPLY

The signal loop may be grounded at

any point or left ungrounded.

1

1

5

1

-

1

1

5

1

G

0

5

A

Power

Supply

A to D

Converter

Shield

Field Wiring

Label Detail

Common

Terminal

Case

+

Signal

+ Power

1

1

5

1

-

1

1

5

1

H

0

5

A

FIGURE 2-5. Wiring Connections for

Low Power Output Codes L and M.

Model 1151 Alphaline Pressure Transmitters

2-10

NOTE

An al ternate l ocati on to connect an ammeter i s on the set of termi nal s

l abel l ed TEST. Connect the posi ti ve l ead of the ammeter to the

posi ti ve test termi nal , and the negati ve l ead of the ammeter to the

negati ve test termi nal .

NOTE

When condui t l i nes are used, si gnal wi ri ng need not be shi el ded, but

twi sted pai rs shoul d be used for best resul ts. Wi ri ng shoul d be 12-24

AWG.

Conduit Sealing

The 1151 has been rated as Factory Seal ed by Factory Mutual (FM)

and Canadi an Standards Associ ati on (CSA). I t i s therefore not

necessar y to i nstal l condui t seal s near the transmi tter encl osure.

Do not run si gnal wi ri ng i n condui t or open trays wi th power wi ri ng, or

near heavy el ectri cal equi pment. Si gnal wi ri ng may be grounded at any

one poi nt on the si gnal l oop, or i t may be l eft ungrounded. The negati ve

termi nal of the power suppl y i s a recommended groundi ng poi nt. The

transmi tter case must be grounded through the process or condui t

connecti ons.

Power Supply

The dc power suppl y shoul d provi de power wi th l ess than 2 percent

ri ppl e. The total resi stance l oad i s the sum of the resi stance of the

si gnal l eads and the l oad resi stance of the control l er, i ndi cator, and

rel ated pi eces. Note that the resi stance of i ntri nsi c safety barri ers, i f

used, must be i ncl uded.

To power the l oop, connect the l eads at the set of termi nal screws

l abel ed Si gnal . Fi gure 2-6 i l l ustrates power suppl y l oad l i mi tati ons

for the transmi tter:

NOTE

For CSA Approval s (codes E and J), V

max

= 42.4 V dc.

Code V

min

V

max

R

min

R

max

R

L

at Supply Voltage (V

S

)

E, J 12 45 0 1650 R

L

= 50 (V

S

12)

G 30 85 0 1100 R

L

= 20 (V

S

30)

L 5 12

Low Power Minimum Load Impedance:

100 k

M 8 14

R

max

R

L

R

min

V

min

V

S

V

max

Operating

Region

FIGURE 2-6. Power Supply Load

Limitations.

2-11

Installation

FIGURE 2-7. Conduit Installation

Diagrams.

Unused condui t connecti ons on the transmi tter housi ng shoul d be

pl ugged and seal ed to avoi d moi sture accumul ati on i n the termi nal si de

of the housi ng. The recommended connecti ons of condui t are shown i n

Fi gure 2-7.

Grounding

Use the fol l owi ng techni ques to properl y ground the transmi tter si gnal

wi ri ng and case:

Signal Wiring Do not run si gnal wi ri ng i n condui t or open trays wi th power wi ri ng, or

near heavy el ectri cal equi pment. Si gnal wi ri ng may be grounded at any

one poi nt on the si gnal l oop, or i t may be l eft ungrounded. The negati ve

termi nal of the power suppl y i s a recommended groundi ng poi nt.

Transmitter Case The transmi tter case must be grounded i n accordance wi th nati onal

and l ocal el ectri cal codes. The most effecti ve transmi tter case

gr oundi ng method i s a di rect i nternal connecti on to earth ground wi th

mi ni mal i mpedance.

1

1

5

1

-

1

1

5

1

E

2

5

A

1

1

5

1

-

1

1

5

1

F

2

5

A

Sealing

Compound

Conduit

Lines

CORRECT CORRECT INCORRECT

Possible

Conduit Line

Positions

1

1

5

1

-

1

1

5

1

D

2

5

A

Sealing

Compound

Possible

Conduit Line

Positions

All explosion proof, flameproof, and dust-ignition proof

installations require insertion of conduit plugs in all unused

openings with a minimum of 40 ft-lbs (54 N-m) of torque.

This will maintain five full threads of engagement.

If all connections are not sealed, excess moisture

accumulation can damage the transmitter. Make sure to

mount the transmitter with the electrical housing positioned

downward for drainage. To avoid moisture accumulation in

the housing, install wiring with a drip loop, and ensure the

bottom of the drip loop is mounted lower than the conduit

connections or the transmitter housing.

Model 1151 Alphaline Pressure Transmitters

2-12

Internal Ground Connection: I nsi de the FI ELD TERMI NALS si de of

the el ectroni cs housi ng i s the I nternal Ground Connecti on screw. Thi s

screw i s i denti fi ed by a ground symbol : .

NOTE

Gr oundi ng the transmi tter case vi a threaded condui t connecti on may

not provi de suffi ci ent ground conti nui ty.

NOTE

The transi ent protecti on termi nal bl ock (See Fi gure 4-4 on page 4-8)

does not provi de transi ent protecti on unl ess the transmi tter case i s

properl y grounded. Use the precedi ng gui del i nes to ground the

transmi tter case.

Do not run the transi ent protecti on ground wi re wi th si gnal wi ri ng as

the ground wi re may carry excessi ve current i f a l i ghtni ng stri ke occurs.

Grounding Effects The capaci tance sensi ng modul e requi res al ternati ng current to

generate a capaci tance si gnal . Thi s al ternati ng current i s devel oped i n

an osci l l ator ci rcui t wi th a frequency of approxi matel y 32 kHz. Thi s

si gnal i s capaci tor-coupl ed to transmi tter-case ground through the

sensi ng modul e. Because of thi s coupl i ng, a vol tage may be i mposed

across the l oad, dependi ng on the choi ce of groundi ng. See Fi gure 2-8.

Thi s i mpressed vol tage, whi ch i s seen as hi gh frequency noi se, wi l l have

no effect on most i nstruments. Computers wi th short sampl i ng ti mes

wi l l detect a si gni fi cant noi se si gnal , whi ch shoul d be fi l tered out by

usi ng a l arge capaci tor (1 F) or by usi ng a 32 kHz LC fi l ter across the

l oad. Computers are negl i gi bl y affected by thi s noi se and do not need

fi l teri ng

Hazardous Locations

Certifications

The Model 1151 was desi gned wi th an expl osi on-proof housi ng and

ci rcui tr y sui tabl e for i ntri nsi cal l y safe and non-i ncendi ve operati on.

Factory Mutual expl osi on-proof certi fi cati on i s standard for the Model

1151 Transmi tter. I ndi vi dual transmi tters ar e cl earl y marked wi th a

tag i ndi cati ng the approval s they carry. Transmi tters must be i nstal l ed

i n accordance wi th al l appl i cabl e codes and standar ds to mai ntai n these

certi fi ed rati ngs. Refer to Hazardous Locations Certifications on

page 6-2 for i nformati on on the approval s associ ated wi th the anal og

Model 1151.

.

2-13

Installation

NOTE

Typi cal effects caused by the i mpressed vol tage on a computer wi th a

sampl i ng ti me of 100 mi croseconds usi ng a 2 to 10 vol t si gnal .

FIGURE 2-8. Typical Effects of Grounding

on Accuracy for Fast Sample Computers

(4-20 mA loops only).

PT

LOAD

PS

+

Ungrounded System

Impressed Voltage: 12 to 22 mVp-p

32 kHz

Effect: 0.01% of span.

PT

LOAD

PS

+

PT

LOAD

PS

+

PT

LOAD

PS

+

Ground Between Negative Side of Power Supply and Load

Impressed Voltage: 35 to 60 mVp-p

32 kHz

Effect: 0.03% of span.

Ground Between Positive Side of Transmitter and Power Supply

Impressed Voltage: 35 to 60 mVp-p

32 kHz

Effect: 0.03% of span.

Ground Between Negative Terminal of Transmitter and Load

Impressed Voltage: 500 to 600 mVp-p

32 kHz

Effect: 0.27% of span.

Model 1151 Alphaline Pressure Transmitters

2-14

LIQUID LEVEL

MEASUREMENT

Di fferenti al pressure transmi tters used for l i qui d l evel appl i cati ons

measure hydrostati c pressure head. Li qui d l evel and speci fi c gravi ty of

a l i qui d ar e factors i n determi ni ng pressur e head. Thi s pressure i s

equal to the l i qui d hei ght above the tap mul ti pl i ed by the speci fi c

gravi ty of the l i qui d. Pressure head i s i ndependent of vol ume or vessel

shape.

Open Vessels

A pressur e transmi tter mounted near a tank bottom measur es the

pressure of the l i qui d above.

Make a connecti on to the hi gh pressure si de of the transmi tter, and

vent the l ow pr essure si de to the atmosphere. Pr essure head equal s the

l i qui ds speci fi c gravi ty mul ti pl i ed by the l i qui d hei ght above the tap.

Zero range suppressi on i s r equi red i f the transmi tter l i es bel ow the zero

poi nt of the desi red l evel range. Fi gure 2-9 shows a l i qui d l evel

measurement exampl e.

Closed Vessels

Pressure above a l i qui d affects the pressure measured at the bottom of

a cl osed vessel . The l i qui d speci fi c gravi ty mul ti pl i ed by the l i qui d

hei ght pl us the vessel pressur e equal s the pr essure at the bottom of the

vessel .

To measur e tr ue l evel , the vessel pressure must be subtracted from the

vessel bottom pr essure. To do thi s, make a pressure tap at the top of the

vessel and connect thi s to the l ow si de of the transmi tter. Vessel

pressure i s then equal l y appl i ed to both the hi gh and l ow si des of the

transmi tter. The r esul ti ng di fferenti al pressure i s proporti onal to l i qui d

hei ght mul ti pl i ed by the l i qui d speci fi c gravi ty.

Dry Leg Condition Low-si de transmi tter pi pi ng wi l l r emai n empty i f gas above the l i qui d

does not condense. Thi s i s a dry l eg condi ti on. Range determi nati on

cal cul ati ons are the same as those descri bed for bottom-mounted

transmi tters i n open vessel s, as shown i n Fi gure 2-9.

ZERO SUPPRESION

mA dc

20

540 90 0

inH

2

O

4

FIGURE 2-9. Liquid Level

Measurement Example.

Let X equal the vertical distance between the minimum and maximum

measurable levels (500 in.).

Let Y equal the vertical distance between the transmitter datum line and the

minimum measurable level (100 in.).

Let SG equal the specific gravity of the fluid (0.9).

Let h equal the maximum head pressure to be measured in inches of water.

Let e equal head pressure produced by Y expressed in inches of water.

Let Range equal e to e + h.

Then h = (X)(SG)

= 500 x 0.9

= 450 inH

2

O

e = (Y)(SG)

= 100 x 0.9

= 90 inH

2

O

Range = 90 to 540 inH

2

O

2

0

2

4

-

0

1

7

1

A

,

0

1

7

2

A

T

Y

X

2-15

Installation

Wet Leg Condition Condensati on of the gas above the l i qui d sl owl y causes the l ow si de of

the transmi tter pi pi ng to fi l l wi th l i qui d. The pi pe i s purposel y fi l l ed

wi th a conveni ent reference fl ui d to el i mi nate thi s potenti al error. Thi s

i s a wet l eg condi ti on.

The reference fl ui d wi l l exert a head pressure on the l ow si de of the

transmi tter. Zero el evati on of the range must then be made. See Fi gure

2-10.

FIGURE 2-10. Wet Leg Example.

Let X equal the vertical distance between the minimum and maximum

measurable levels (500 in.).

Let Y equal the vertical distance between the transmitter datum line and the

minimum measurable level (50 in.).

Let z equal the vertical distance between the top of the liquid in the wet leg

and the transmitter datum line (600 in.).

Let SG

1

equal the specific gravity of the fluid (1.0).

Let SG

2

equal the specific gravity of the fluid in the wet leg (1.1).

Let h equal the maximum head pressure to be measured in inches of water.

Let e equal the head pressure produced by Y expressed in inches of water.

Let s equal head pressure produced by z expressed in inches of water.

Let Range equal e s to h + e s.

Then h = (X)(SG

1

)

= 500 x 1.0

= 500 in H

2

O

e = (Y)(SG

1

)

= 50 x 1.0

= 50 inH

2

O

s = (z)(SG

2

)

= 600 x 1.1

= 660 inH

2

0

Range = e s to h + e s.

= 50 660 to 500 + 50 660

= 610 to 110 inH

2

0

ZERO ELEVATION

LT

Y

H L

mA dc

20

0

4

-110 -610

inH

2

O 2

0

2

4

-

0

1

6

7

A

2

0

2

4

-

0

1

6

8

A

X

Z

Model 1151 Alphaline Pressure Transmitters

2-16

Bubbler System in Open Vessel A bubbl er system that has a top-mounted pressure transmi tter can be

used i n open vessel s. Thi s system consi sts of an ai r suppl y, pressure

r egul ator, constant fl ow meter, pressur e transmi tter, and a tube that

extends down i nto the vessel .

Bubbl e ai r thr ough the tube at a constant fl ow rate. The pressur e

requi red to mai ntai n fl ow equal s the l i qui ds speci fi c gravi ty mul ti pl i ed

by the verti cal hei ght of the l i qui d above the tube openi ng. Fi gure 2-11

shows a bubbl er l i qui d l evel measurement exampl e.

FIGURE 2-11. Bubbler Liquid Level

Measurement Example.

mA dc

Let X equal the vertical distance between the minimum and maximum

measurable levels (100 in.).

Let SG equal the specific gravity of the fluid (1.1).

Let h equal the maximum head pressure to be measured in inches of water.

Let Range equal zero to h.

Then h = (X)(SG)

= 100 x 1.1

= 110 inH

2

O

Range = 0 to 110 inH

2

O

20

inH

2

O

0

4

110

2

0

2

4

-

0

1

6

6

A

T

AIR

2

0

2

4

-

0

1

6

5

A

X

Section

3-1

3 Calibration

Cal i brati on of the Rosemount Model 1151 Pressur e Transmi tter i s

si mpl i fi ed by i ts compact and expl osi on-proof desi gn, external span and

zero adjustments, separate compartments for el ectroni cs and wi ri ng,

and weatherproof constructi on. Descri pti ons of span, l i neari ty, zero

adjustments, and dampi ng fol l ow.

QUICK CALIBRATION

PROCEDURE (FOR E, G,

AND J ELECTRONICS)

The fol l owi ng Qui ck Cal i brati on Procedures are for those users who are

al ready fami l i ar wi th the anal og Model 1151.

NOTE

The zero and span adjustments are i nteracti ve. For appl i cati ons

requi ri ng l arge el evated or suppressed val ues, refer to Elevated or

Suppressed Zeros on page 3-7.

1. Appl y 4 mA-poi nt pressure and turn zero screw to output 4 mA.

2. Appl y 20 mA-poi nt pressure.

3. Subtract actual output from desi red output.

4. Di vi de di fference by 3.

5. Turn span screw above or bel ow desi red output by val ue i n Step 4.

6. Repeat Steps 1 through 5 unti l cal i brated.

QUICK CALIBRATION

PROCEDURE (FOR L AND

M ELECTRONICS)

1. Apply 1 V dc-point pressure for M electronics (0.8 V dc for L electronics)

and turn zero screw to output 1 V dc (0.8 V dc for L electronics).

2. Apply 5 V dc-point pressure (M electronics) or 3.2 V dc (L electronics).

3. Subtract actual output from desi red output.

4. Di vi de di fference by 3.

5. Turn span screw above or bel ow desi red output by val ue i n Step 4.

6. Repeat Steps 1 through 5 unti l cal i brated.

Explosions can cause death or serious injury. Both

transmitter covers must be fully engaged to meet explosion-

proof requirements.

When replacing housing covers, tighten the covers enough

to make contact with the O-ring seals. If the covers are not

tightened enough, moisture can enter the housing and

cause transmitter failure.

Model 1151 Alphaline

Pressure Transmitters

3-2

Example for a Model 1151DP Range 4: For a desi red cal i brati on of 0

to 100 i nH

2

O, use the fol l owi ng procedure:

1. Adjust the zero. Wi th zero i nput appl i ed to the transmi tter, turn

the zero adjustment screw unti l the transmi tter reads 4 mA.

2. Adjust the span. Appl y 100 i nH

2

O to the transmi tter hi gh si de

connecti on. Turn the span adjustment screw unti l the transmi tter

output reads approxi matel y 20 mA.

3. Rel ease the i nput pressure and readjust the zero output to r ead 4

mA 0.032 mA.

4. Re-appl y 100 i nH

2

O to the transmi tter. I f the output readi ng i s

gr eater than 20 mA, di vi de the di fference by 3, and subtract the

resul t from 20 mA. Adjust the 100% output to thi s val ue.

I f the output readi ng i s l ess than 20 mA, di vi de the di fference by 3 and

add the resul t to 20 mA. Adjust the 100% output to thi s val ue.

Example: The ful l scal e transmi tter output i s 20.100 mA. Di vi di ng

0.100 by 3.0 gi ves the product 0.033. Subtracti ng the product 0.033

from 20.00 mA gi ves the di fference 19.967 mA. Adjust the 100% output

to thi s val ue.

5. Rel ease i nput pressure and readjust the zero.

6. Appl y 100% i nput and repeat Steps 3 through 5 i f the ful l scal e

output i s not 20 0.032 mA.

NOTE

Under operati ng condi ti ons that subject the transmi tter to temperature

extr emes or si gni fi cant vi brati on, mechani cal backl ash may occur i n the

zero and span adjustment screws. To i mprove the stabi l i ty of zero and

span setti ngs i n these ci rcumstances, back off the adjustment screws

sl i ghtl y after fi nal adjustment to break contact between the

potenti ometer bl ades and the adjustment screw sl ot surfaces.

3-3

Calibration

DATA FLOW WITH

CALIBRATION OPTIONS

Fi gure 3-1 i l l ustrates the Model 1151 Transmi tter data fl ow wi th

cal i brati on tasks.

FIGURE 3-1. Model 1151 Transmitter

Data Flow with Calibration Options.

Thi s data fl ow can be summari zed i n four major steps:

1. Pressure i s appl i ed to the sensor.

2. A change i n pressur e i s measur ed by a change i n the sensor

output.

3. The sensor si gnal i s condi ti oned for vari ous parameters.

4. The condi ti oned si gnal i s converted to an appropri ate anal og

output.

Pressure

Output

Sensor

Signal

Conditioning

Sensor

Excitation

Output

Span

Adjustment

Zero

Adjustment

Model 1151 Alphaline

Pressure Transmitters

3-4

SPAN ADJUSTMENT

RANGE

The span on a Model 1151 wi th E, G, and J output opti ons i s

conti nuousl y adjustabl e to al l ow cal i brati on anywhere between

maxi mum span and one-si xth of maxi mum span. For exampl e, the span

on a Range 4 transmi tter can be adjusted between 25 and 150 i nH

2

O

(6.2 and 37.2 kPa).

ZERO ADJUSTMENT

RANGE

The zero on a Model 1151 wi th the E or G output opti ons can be

adjusted for up to 500% suppressi on or 600% el evati on. See Fi gure 3-2.

FIGURE 3-2. Zero Adjustment Range.

The zero may be el evated or suppressed to these extremes wi th the

li mi tati on that no pressure wi thin the cal i brated range exceeds the full -

range pressure li mi t. For example, a Range 4 transmi tter cannot be

cali brated for 100 to 200 inH

2

O (24.8 to 49.7 kPa) (onl y 100% zero

suppressi on) because 200 i nH

2

O exceeds the 150 i nH

2

O full -range

pressure l imit of a Range 4.

To make l arge el evati on or suppressi on adjustments, i t i s necessary to

move the jumper on the component si de of the ampl i fi er board. Fi gure

3-3 on page 3-5 shows el evati on and suppressi on jumper setti ngs. The

jumper has three posi ti ons. The mi ddl e posi ti on al l ows normal l evel s of

el evati on or suppressi on. For l arger adjustments, move the jumper to

the ELEVATE ZERO (EZ) or SUPPRESS ZERO (SZ) as marked.

1

1

5

1

-

0

1

9

3

A

600% Zero Elevation

600% Zero Elevation*

150 125 100 75 50 25 0 25

4

Pressure

(inH

2

O)

Pressure

(inH

2

O)

0 25

4

20

No Zero Elevation or Suppression*

4

20

Output

(mA)

500% Zero Elevation

500% Zero Suppression*

Output

(mA)

*Graphs based on a range 4 (0-25 inH

2

O to 0-150 inH

2

O) 1151

with a calibrated span of 25 inH

2

O.

0 25 50 75 100 125 150

20

Output

(mA)

3-5

Calibration

NOTE

Al ways make sur e that the jumper i s ful l y seated on i ts pi ns. I f the

jumper has not been pl aced i n any of the three posi ti ons, the ampl i fi er

board wi l l provi de normal l evel s of el evati on or suppressi on. A sl i de

swi tch repl aces the jumper pi n on some versi ons of the ampl i fi er board.

FIGURE 3-3. Elevation and

Suppression Jumper Settings.

E Output Option

(420 mA)

Suppress Zero

Elevate Zero

G Output Option

(1050 mA)

Suppress Zero

Elevate Zero

NOTE: The jumper is located on the component side of the

amplifier board. Jumper positions may vary from those shown. The

board must be unplugged from the transmitter to gain access to

the component.

1

1

5

1

-

0

1

9

4

A

Model 1151 Alphaline

Pressure Transmitters

3-6

ZERO AND SPAN

ADJUSTMENT

The zer o and span adjustment scr ews ar e accessi bl e exter nal l y

behi nd the namepl ate on the ter mi nal si de of the el ectr oni cs

housi ng. See Fi gur e 3-4. The output of the tr ansmi tter i ncr eases

wi th cl ockwi se r otati on of the adjustment scr ews. The zer o

adjustment scr ew and ELEVATE ZERO/SUPPRESS ZERO jumper

do not affect the span. Span adjustment, however, does affect zer o.

Thi s effect i s mi ni mi zed wi th zer o-based spans. Ther efor e, when

cal i br ati ons havi ng el evated or suppr essed zer os ar e made, i t i s

easi er to make a zer o-based cal i br ati on and achi eve the r equi r ed

el evati on or suppr essi on by adjusti ng the zer o adjustment scr ew

(and ELEVATE ZERO/SUPPRESS ZERO jumper as r equi r ed).

A degree of mechani cal backl ash i s present i n the zero and span

adjustments, so there wi l l be a dead band when the di recti on of

adjustment i s changed. Because of the backl ash, the si mpl est procedure

i s to purposel y overshoot a l arger amount before reversi ng the di recti on

of the adjustment.

FIGURE 3-4. Zero and Span

Adjustment Screws.

Zero

Screw

Span

Screw

1

1

5

1

-

1

1

5

1

A

2

5

A

3-7

Calibration

ELEVATED OR

SUPPRESSED ZEROS

Non-zero-based cal i brati ons are termed as havi ng el evated or

suppressed zeros. Cal i brati ons that have a l ower cal i brated val ue

bel ow zero are termed el evated. Compound ranges are i ncl uded i n thi s

category. Cal i brati ons that have a l ower cal i brated val ue above zero are

termed suppressed.

The easi est way to cal i brate transmi tters wi th el evated or suppressed

zeros i s to perform a zero-based cal i brati on and then el evate or

suppress the zero by adjusti ng the zero adjustment screw.

Model 1151DP Range 4 Suppression Example: For a desi r ed

cal i brati on of 20 to 120 i nH

2

O (4.9 to 29.8 kPa), proceed as fol l ows:

1. Cal i brate the transmi tter to 0 to 100 i nH

2

O (0 to 24.8 kPa) as

descri bed i n the zero and span adjustment i nformati on.

2. Appl y 20 i nH

2

O (4.9 kPa) to the hi gh si de process connecti on, and

adjust the zero unti l the transmi tter output reads 4 mA.

Do not use the span adjustment.

Model 1151DP Range 4 Elevation Example: For a cal i brati on

of 120 to 20 i nH

2

O (29.8 to 4.9 kPa), proceed as fol l ows:

1. Cal i brate the transmi tter to 0 to 100 i nH

2

O (0 to 24.8 kPa) as

descri bed i n the zero and span adjustment i nformati on.

2. Appl y 120 i nH

2

O (29.8 kPa) to the l ow si de process connecti on,

and adjust the zero unti l the transmi tter output r eads 4 mA.

Do not use the span adjustment.

NOTE

For l ar ge amounts of el evati on or suppressi on, i t may be necessary to

reposi ti on the ELEVATE/SUPPRESS ZERO jumper. To do thi s, remove

the ampl i fi er boar d, and move the jumper to the ELEVATE or

SUPPRESS posi ti on as requi red. See Fi gure 3-3 on page 3-5.

LINEARITY ADJUSTMENT

I n addi ti on to the span and zero adjustments, a l i neari ty adjustment

screw (marked LI N) i s l ocated on the sol der si de of the ampl i fi er boar d.

See Fi gure 3-5. Thi s i s a factory cal i brati on adjusted for opti mum

performance over the cal i brated range of the i nstrument and normal l y

i s not readjusted i n the fi el d. The user may, however, maxi mi ze

l i neari ty over a parti cul ar range usi ng the fol l owi ng procedure:

1. Appl y mi d-range pressure and note the error between the

theoreti cal and actual output si gnal .

2. Appl y ful l -scal e pressure. Mul ti pl y the error noted i n Step 1 by

si x and then that product by the Range Down Factor, whi ch i s

cal cul ated as shown bel ow:

Add thi s resul t to the ful l -scal e output (for negati ve errors), or subtract

the resul t from the ful l -scal e output (for posi ti ve errors) by turni ng the

l i neari ty adjustment screw.

Range Down Factor

Maxi mum Al l owabl e Span

Cal i brated Span

------------------------------------------------------------------------- =

Model 1151 Alphaline

Pressure Transmitters

3-8

Example: At 4 to 1 Range Down Factor, the mi d-scal e poi nt i s l ow by

0.05 mA. Therefore, turn the l i neari ty adjustment screw unti l ful l -scal e

output i ncreases by (0.05 mA 6 4) = 1.2 mA.

3. Readjust the zero and span.

FIGURE 3-5. Damping and Linearity

Adjustment Screws.

DAMPING ADJUSTMENT

The ampl i fi er boards for output opti ons E, G, and J are desi gned to

permi t dampi ng of rapi d pul sati ons i n the pressure source through

adjustment of the dampi ng screw shown i n Fi gure 3-5 on page 3-8. The

adjustment i s marked DAMP on the sol der si de of the ampl i fi er board.

The setti ngs avai l abl e provi de ti me constant val ues between 0.2 and

1.66 seconds. The i nstrument i s cal i brated and shi pped wi th thi s

contr ol set at the countercl ockwi se stop (0.2 second ti me constant). I t i s

recommended that the shortest possi bl e ti me constant setti ng be

sel ected. Si nce the transmi tter cal i brati on i s not i nfl uenced by the ti me

constant setti ng, the dampi ng may be adjusted wi th the transmi tter

connected to the process. Turn the dampi ng control cl ockwi se unti l the

desi red dampi ng i s obtai ned.

Access to linearity and damping adjustments is gained by

removing cover on circuit board side.

Location of linearity adjustment screws may vary slightly between

output codes.

1

1

5

1

-

0

1

9

6

B

Damping

Adjustment

Screw

Linearity

Adjustment

Screw

The adjustment screw has positive stops at both ends.

Forcing it beyond the stops may cause permanent damage.

3-9

Calibration

STATIC PRESSURE SPAN

CORRECTION FACTOR

Hi gh stati c pressur e causes a systemati c span shi ft i n the transmi tter.

I t i s l i near and easi l y correctabl e duri ng cal i brati on. Tabl e 3-1 shows

the amount of span shi ft for range codes 3 through 8.

TABLE 3-1. Model 1151 DP/HP Span

Shift.

:

The fol l owi ng exampl es i l l ustrate a compensati on method of accounti ng

for the span shi ft. For more compl i cated cal i brati on condi ti ons, refer to

Rosemount Report D8500141 or contact Customer Central at 1-800-

999-9307.

Example 1 - Refer to Table 3-1: One method i s to adjust the i nput

and al l ow the transmi tter output to r emai n at 20 mA. Use the fol l owi ng

formul a:

Corrected I nput

= Desi red URV + [(S URV) (P/1000)],

Where S = Val ue from Tabl e 3-1, di vi ded by 100.

To cal i brate a Range 4 transmi tter 0 to 150 i nH

2

O (0 to 37.2 kPa) and

correct for 1,500 psi stati c l i ne pressure, use the fol l owi ng correcti on:

Corrected I nput

= 150 + [(0.0087 150) (1500/1000)]

= 148.04 i nches

Wi th 148.04 i nches appl i ed as i nput at atmospheri c pressure, set the

transmi tter to 20 mA. When the transmi tter i s exposed to 1,500 psi

stati c l i ne pressure, output wi l l be 20 mA at 150 i nches i nput.

Where computers or mi croprocessor recei vers ar e used, the

mathemati cal defi ni ti ons used i n the precedi ng tabl es can be used to

automati cal l y and conti nuousl y make the correcti on.

Al l transmi tters shoul d be r ezeroed under l i ne pressure to remove zero

Range

Code

Span Shift % Input Per 1,000 psi

316L SST Hastelloy Monel

3

4

5

6

7

8

1.75%

0.87%

0.81%

1.45%

1.05%

0.55%

1.00%

0.60%

0.70%

1.45%

1.05%

0.55%

1.00%

0.50%

0.75%

1.45%

1.05%

0.55%

Model 1151 Alphaline

Pressure Transmitters

3-10

error.

Example 2 - Refer to Table 3-2: A Model 1151DP Range 4 wi th a 420

mA output operati ng at 1,200 psi stati c pr essure requi res the output at

100% to be corrected to 20.168 mA. Therefore, the transmi tter shoul d

be adjusted from 420.168 mA duri ng cal i brati on. After i nstal l ati on,

and wi th both process i nputs pressuri zed to 1,200 psi , readjust the zero

to 4.000 mA to remove the smal l zero error.

TABLE 3-2. Model 1151DP Static

Pressure 420 mA Output Code E

Corrected Output Calibration at 100%

Input SST Isolators.

Example 3 - Refer to Table 3-3: The correcti on factor at 100% i nput

shi ft for a Range 5 transmi tter wi th a 420 mA output operati ng at

1,500 psi stati c pressure woul d be:

S = 0.131 1.5 = 0.197 mA

Therefore, the cal i brati on for thi s transmi tter woul d be

fr om 420.197 mA.

TABLE 3-3. Output Correction Factors

SST Isolators.

NOTE

Correcti on factors appl y to E and G outputs at 100% i nput (P = stati c

pressure i n 1,000 psi ).

Static

Pressure (psi)

Static

Pressure (kPa) Range 3 Range 4 Range 5

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

689

1379

2068

2758

3447

4137

4826

5516

6205

6895

7584

8274

8963

9653

10342

11032

11721

12411

13100

13790

20.029

20.057

20.086

20.114

20.143

20.171

20.200

20.228

20.257

20.285

20.314

20.342

20.371

20.399

20.428

20.456

20.485

20.513

20.542

20.570

20.014

20.028

20.042

20.056

20.070

20.084

20.098

20.112

20.126

20.140

20.154

20.168

20.182

20.196

20.210

20.224

20.238

20.252

20.266

20.280

20.013

20.026

20.039

20.052

20.066

20.079

20.092

20.104

20.118

20.131

20.144

20.157

20.170

20.183

20.197

20.210

20.223

20.236

20.250

20.262

Range

Code

E Output

420 mA

G Output

1050 mA

3

4

5

6

7

8

S = 0.285 P

S = 0.140 P

S = 0.131 P

S = 0.235 P

S = 0.170 P

S = 0.088 P

S = 0.712 P

S = 0.350 P

S = 0.327 P

S = 0.588 P

S = 0.425 P

S = 0.220 P

Section

4-1

4 Options

Model 1151 opti ons can si mpl i fy i nstal l ati on and operati on. Thi s secti on

descri bes the fol l owi ng opti ons:

Mounti ng Brackets

Anal og and LCD I ndi cati ng Meters

Termi nal Bl ocks (Transi ent Pr otecti on and Fi l ter)

MOUNTING BRACKETS

(OPTION CODES B1B7 AND B9) Opti onal mounti ng brackets avai l abl e wi th the Model 1151 al l ow

mounti ng to a 2-i nch pi pe or panel . Fi gure 4-1 shows bracket

di mensi ons and mounti ng confi gurati ons for the vari ous bracket

opti ons.

Pipe Mounting Brackets

Opti on Codes B1, B4, and B7 are sturdy, epoxy-pol yester-pai nted

brackets desi gned for 2-i nch pi pe mounti ng. Opti on Code B1 i s

constructed of carbon steel wi th carbon steel bol ts. Opti on Code B4 i s

the same bracket as Opti on Code B1, wi th 316 SST bol ts. Opti on Code

B7 i s al so the same bracket as Opti on Code B1 wi th a 316 SST bracket

and 316 SST bol ts.

Fl at Mounti ng Brackets

Opti on Codes B3, B6, and B9 are fl at brackets desi gned for 2-i nch pi pe

mounti ng. Opti on Code B3 i s constructed of carbon steel wi th a carbon

steel U-bol t. Opti on Codes B6 and B9 ar e the same bracket

confi gurati on as Opti on Code B3. Opti on Code B6 provi des 316 SST

bol ts and Opti on Code B9 provi des a 316 SST bracket and 316 SST

bol ts.

Panel Mounting Brackets

Opti on codes B2 and B5 are panel brackets desi gned for bol ti ng to any

fl at surface.

Model 1151 Alphaline

Pressure Transmitters

4-2

2.625 (67)

2.625

(67)

5.625

(143)

5.625

(143)

3

0

5

1

-

3

0

5

1

D

1

9

A

,

1

1

5

1

-

1

1

5

1

D

,

B

0

6

C

PIPE MOUNTING BRACKET OPTION CODES B1, B4, AND B7

2.81 Typ.

(71)

2.625

(67)

PANEL MOUNTING BRACKET OPTION CODES B2 AND B5

1.40

(36)

2.81 Typ.

(71)

1.40 (46)

Mounting Holes

0.375 Diameter

(10)

3

0

5

1

-

3

0

5

1

B

1

9

A

,

1

1

5

1

-

0

2

4

4

A

,

1

1

5

1

-

1

1

5

1

E

0

6

A

1.62 (41)

2.125 (54)

2.81 (71)

8 (203)

FLAT MOUNTING BRACKET OPTION CODES B3, B6, AND B9

3

0

5

1

-

3

0

5

1

H

1

9

B

,

1

1

5

1

-

1

1

5

1

F

0

6

B

NOTE

Dimensions are in inches (millimeters).

FIGURE 4-1. Mounting Bracket

Options.

3.87

(98)

1.65 (42)

2.62

(67)

4.97

(127)

2.81

(71)

3.75

(95)

3.87 (98)

3.75 (95)

2.81 Typ.

(71)

4.5 (114)

1.65 (42)

4-3

Options

ANALOG METERS

(420 mA ONLY)

Opti on Codes M1M3 and M6 provi de l ocal i ndi cati on of the

transmi tter output i n a vari ety of scal i ng confi gurati ons wi th an

i ndi cator accuracy of 2 percent. The pl ug-i n mounti ng confi gurati on

al l ows for si mpl e i nstal l ati on and removal of the anal og meters. The

meter scal i ng opti ons ar e shown bel ow.

M1 Li near anal og meter, 0-100% scal e

M2 Square-root anal og meter, 0-100% fl ow scal e

M3 Speci al scal i ng anal og meter, (speci fy range)

M6 Square-root anal og meter, 0-10 scal e

LCD METERS

(420 mA ONLY)

The LCD meter opti ons, M4 and M7M9 provi de a hi ghl y accurate l ocal

di spl ay of the process vari abl e. A vari ety of scal i ng confi gurati ons ar e

avai l abl e and l i sted as fol l ows:

M4 Li near LCD Meter, 0 to 100%, User Sel ectabl e

M7 Speci al scal e LCD meter (speci fy range, mode, and

engi neeri ng uni ts)

M8 Square-root LCD meter, 0 to 100%

M9 Square-root LCD meter, 0 to 10

LCD Meter Configuration

The Rosemount LCD meter pl ugs di rectl y i nto the Model 1151 to

pr ovi de a hi ghl y accurate di gi tal di spl ay of the process vari abl e. The

fol l owi ng expl ai ns the confi gurati on and assembl y of the LCD meter

and i ncl udes the appl i cabl e functi onal , performance, and physi cal

speci fi cati ons. Thi s meter adds no vol tage drop i n the 420 mA current

l oop when connected di rectl y across the transmi tter test termi nal s.

The LCD meter may be confi gured to meet speci fi c requi rements by

usi ng the l eft and ri ght cal i brati on buttons l ocated on the meter face as

shown i n Fi gure 4-2. The anal og bar graph i s al so shown i n Fi gure 4-2.

The 20-segment bar graph i s factory cal i brated and represents

420 mA di r ectl y.

Explosions can cause death or serious injury. To meet

hazardous location requirements, any transmitter with a tag

specifying Option Codes I5, I1, N1, I8, I7, or N7 requires an

intrinsically safe analog meter (Part No. 01151-0744-XXXX)

or an LCD Meter (Part No. 01151-1300-XXXX).

Explosions can cause death or serious injury. When adding

a meter option to a Model 1151 with an Option Code R1 or

R2 terminal block, make sure to change to cemented meter

covers with a glass window. Make sure a sticker is located

inside the cover that indicates a cemented cover. This

cover is required to maintain explosion-proof approval.

Model 1151 Alphaline

Pressure Transmitters

4-4

FIGURE 4-2. LCD Meter.

No cal i brati on equi pment i s requi red to confi gure the LCD meter, but

there must be a current (between 4 and 20 mA) fl owi ng through the

l oop. The actual val ue of the current i s not si gni fi cant. I n addi ti on,

meter confi gurati on does not affect the transmi tter/l oop current. Use

the fol l owi ng meter confi gurati on procedure to properl y confi gure the

LCD meter.

Remove the Cover 1. Unscrew the retai ni ng ri ng shown i n Fi gure 4-2 and l i ft the

transparent cover off of the housi ng.

NOTE

The LCD meter ti me-out i s approxi matel y 16 seconds. I f keys ar e not

pr essed wi thi n thi s peri od, the i ndi cator reverts to readi ng the current

si gnal .

Position the Decimal Point and

Select the Meter Function

2. Press the l eft and ri ght confi gurati on buttons si mul taneousl y and

rel ease them i mmedi atel y.

3. To move the deci mal poi nt to the desi red l ocati on, press the l eft

confi gurati on button. Note that the deci mal poi nt wraps around.

4. To scrol l through the mode options, press the ri ght confi gurati on

button repeatedly until the desired mode is di splayed. See Table 4-1.

TABLE 4-1. LCD Meter Modes.

Retaining

Ring

Right Configuration

Button

Left Configuration

Button

Analog

Bar Graph

L

C

D

-

0

0

1

A

B

Options Relationship between Input Signal and Digital Display

L in

L inF

Srt

SrtF

Linear

Linear with five-second filter

Square root

Square root with five-second filter

Square root function only relates to the digital display.

The bar graph output remains linear with the current signal.

Square root response

The digital display will be proportional to the square root of the input current where 4 mA=0

and 20 mA=1.0, scaled per the calibration procedure. The transition point from linear to

square root is at 25% of full scale flow.

Filter response operates upon present input and input received in the previous five second

interval in the following manner:

Display = (0.75 previous input) + (0.25 present input)

This relationship is maintained provided that the previous reading minus the present reading is

less than 25% of full scale.

4-5

Options

Store the Information 5. Press both confi gurati on buttons si mul taneousl y for two seconds.

Note that the meter di spl ays ---- for approxi matel y 7.5 seconds

whi l e the i nformati on i s bei ng stored.

Set the Display Equivalent

to a 4 mA Signal

6. Press the l eft button for two seconds.

7. To decrement the di spl ay numbers, press the l eft confi gurati on

button and to i ncrement the numbers, press the ri ght

confi gurati on button. Set the numbers between 999 and 1000.

8. To store the i nformati on, press both confi gurati on buttons

si mul taneousl y for two seconds.

Set the Display Equivalent

to a 20 mA Signal

9. Press the ri ght button for two seconds.

10. To decrement the di spl ay numbers, press the l eft confi gurati on

button on the di spl ay and to i ncrement the numbers, press the

ri ght confi gurati on button. Set the numbers between 999 and

9999. The sum of the 4 mA poi nt and the span must not exceed

9999.

11. To store the i nformati on, press both confi gurati on buttons

si mul taneousl y for two seconds. The LCD meter i s now

confi gured.

Replace the Cover 12. Make sure the rubber gasket i s seated properl y, repl ace the

transparent cover, and repl ace the retai ni ng ri ng.

LCD Meter Assembly

Fi gure 4-3 shows the mounti ng hardware requi red to properl y i nstal l

the LCD meter on a transmi tter or i n the fi el d si gnal i ndi cator. Thi s

mounti ng hardware may al so be used wi th the Rosemount uni versal

(anal og) meter.

FIGURE 4-3. LCD Meter

Exploded View.

Cover Foam Spacer

Cover Bushing

Mounting Plate

Meter (Meter may be rotated

in 90 degree increments)

Terminal Screws

(Mount into Transmitter

Test Terminal Block)

Mounting Screws into Meter

(6-32 x 5/6 in.)

Retaining Straps

Mounting Screw into Housing

(6-32 x 1/4 in.)

Strap Washer

Mounting Screw

into Mounting

Plate

7

5

1

-

0

2

6

4

B

Model 1151 Alphaline

Pressure Transmitters

4-6

LCD Meter Specifications

Input Signal

420 mA dc.

Meter Indication

4-di gi t LCD showi ng 999 to 9999. A 20-segment bar graph di r ectl y